Used Emulsion for sale (261)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

18,514 km

Filter Device

HOFFMANNUBF 200/K

Call

Year of construction: 2009, condition: used, KSS/filter/cooling systems

Emulsion

Rsdpfx Ahjw Tbnuszebt

*

Listing

Germany

Germany

18,514 km

Machining Center - Horizontal

HELLERMCT160

Call

Condition: used, Year of construction: 2003, Technical details:

x-travel: 450 mm

y-travel: 450 mm

Rbedpfx Aew Ng D Hjhzot

z-travel: 450 mm

weight of the machine ca.: 14 t

size of pallet: 320 x 320 mm

number of spindles: 2

Double spindle 4-axis machining center Horizontal

4 machine plates

Renishaw probe

Control Siemens Sinumerik 840D

Working space (X / Y / Z): 450x450x450 mm

Load pallet / table max .: 300 kg

Acceleration: 10 m / s²

Rapid traverse: 60 m / min

Pallet size: 320 x 320 mm

Chip-to-chip time: 2.6 s

Workpiece height max .: 700 mm

Tool holder: HSK 63

Tool places: 2x 60

Tool spindle: 10,000 rpm, 95 Nm

Speed ??increase to 18,000 rpm

Infrared receiver for probe,

Make Renishaw Vaf72a0p

Tool magazine with 60 places

Control panel on the workstation

Control panel on the tool installation site

Workpiece positioning stations can be rotated manually

with hydraulic workpiece clamping 60 bar

Pneumatic support control on the workstation

Automatic swing gate

Extended coolant layer 70 bar / 1500I /

VF 250 Coolant Cooler

Working space flushing Emulsion mist suction

Roto - Clear

Automatic setup process

Automatic disarming process

Runtime and quantity recording

Status lamp 3-color modem for remote diagnosis control cabinet lighting

*

Listing

Kirchheim unter Teck

Kirchheim unter Teck

18,605 km

Air filter

AIRTECH

Call

Condition: new, Year of construction: 2025, Mechanical air filter with 3-stage filter system for extracting oil mist / emulsion mist / grinding mist on machine tools

Rodpfx Ahoin Dbrozjbt

Can be operated flexibly or on a single column frame behind the machine

Extraction capacities from 1.000 - 4.000 cbm / hr

(sufficient also for encapsulated turning / milling / grinding machines / BAZ etc. up to approx. 30 cbm encapsulated working area)

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Lithuania

Lithuania

17,327 km

Meat processing machine

HyShprizHySpriz RK50U 3-in-1 Forming System for

Call

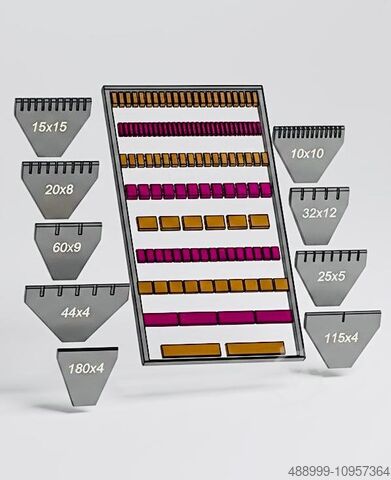

Condition: new, Year of construction: 2025, total length: 600 mm, total width: 600 mm, total height: 1,400 mm, warranty duration: 12 months, overall weight: 300 kg, input voltage: 400 V, power: 1.5 kW (2.04 HP), pressure: 9.8 bar, tank capacity: 50 l, HySpriz RK50U 3-in-1 Forming System for Meat Snacks, Pet Sticks & Mini Salami | Up to 1500kg/shift

Made in Ukraine. 18 month full warranty. RK50U — universal casing-free forming system for meat sticks, jerky & sausage production

HydroShpriz RK50U is a powerful piston-driven filling and forming machine engineered for small and mid-size manufacturers starting production of meat sticks, salami snacks, pet food, kibbeh, fruit bars, and more. Ideal for dry-cured snacks without alginate casing. Strong, compact, and easy to operate — it’s the perfect choice to start your line and grow with Trade-In options.

⸻

Technical specifications

• Drive: hydraulic piston

• Piston force: 94 kN

• Power: 1.5 kW, 380 V, 50 Hz

• External dimensions: 1050×550×950 mm

• Weight: approx. 300 kg

• Material: full stainless steel, food-grade

• Certification: CE certified, built for continuous 8-hour production cycles

⸻

Configuration & possibilities

• Gearbox-driven filler for thick and sticky emulsions down to –2 °C

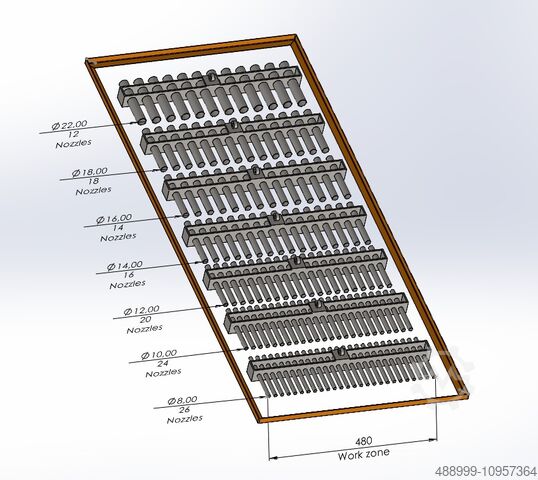

• Multi-nozzle head: up to 25 lanes simultaneously

• Round nozzle set: 8 mm to 22 mm for meat or fish sticks

• Flat nozzle set: 25 mm to 200 mm width, 3–5 mm height — ideal for jerky/strips

• Sausage stuffing set: for traditional casing sausages

• Overhead tray holder: for direct forming onto drying racks

• Trolley integration: fits perfectly with our 30-row drying racks (60 trays)

• Integrated time-based portioning unit with ±8% accuracy

• 24V remote signal: compatible with automatic clippers (PolyClip, Compa, etc.)

• Optional vacuum connection: for better product density and shelf-life

⸻

Production capacity

• From 20 kg to 1,600 kg per 8 hours depending on product shape, tray format and nozzle type

⸻

Availability

✔️ In stock at official distributors in:

• Austria

• Poland

• United Kingdom

• Lithuania

• Australia

• South Africa

• United States

Delivery worldwide. Training, test batch, and spare parts included.

⸻

Made in Ukraine. CE sertified industrial forming system

• meat snack production

• pet food production

Rsdsmrpvyopfx Ahzjbt

• jerky, salami, kebab machine

• food processing equipment

Listing

Germany

Germany

18,654 km

CHIRON Mill 6000 SK

CHIRONMill 6000 SK

Call

Condition: ready for operation (used), Year of construction: 2004, travel distance X-axis: 6,000 mm, travel distance Y-axis: 630 mm, travel distance Z-axis: 550 mm, controller manufacturer: SIEMENS, controller model: n/a, number of axes: 4, This 3-axis CHIRON Mill 6000 SK was manufactured in 2004, featuring a high-speed motor spindle at 12,000 rpm and a travel range of X 6,000 mm, Y 630 mm, Z 550 mm. It includes a 5-axis milling package, 92 tool positions, and a Marposs collision monitoring system. Ideal for long part machining up to 6,000 mm and pendulum machining. If you are looking to get high-quality milling capabilities consider the CHIRON Mill 6000 SK machine we have for sale. Contact us for more information.

Machine Benefits

Technical Machine Benefits

• 92 tool positions hsk-a63 (background magazine)

• Long part machining up to a maximum of 6000 mm

• Machining of the end face (5th side) horizontally with swivel head (right/left)

• Pendulum machining via center partition, max. Workpiece length 1773 mm with sk machining on both end faces (tool length 120 mm)

• 4 hydraulic double vices (fixed center jaw) per pendulum section, positioning, and clamping via linear system (hydraulic release, mechanical clamping)

Extra Information

Additional Equipment

High-speed package with Motor Spindle: 12000 rpm, 140 Nm

Production Package:

Scraper belt conveyor, discharge height 1050 mm

Internal coolant preparation

KNOLL VRF250 vacuum rotary filter (suitable for steel, cast iron, aluminum, plastic, brass)

High pressure 70 bar with HP pump and variable valve

Flushing gun per pendulum field

Emulsion mist extraction, 2 fans each 800 m²/h

Rotating viewing window left and right (1400 mm from machine center)

Automatic loading doors

Rjdpfex Nr Irex Ahzebt

Center partition for pendulum machining

5-Axis Milling Package

Air Blast

Tool Life Monitoring

Additional V24 RS232 in the control cabinet

BDE/MDE interface (statuses: machine on, machine running, part counter)

Marposs (Brankamp) CMS100 Collision Monitoring System

3D machine model for kinematic simulation in the CAM programming system

210 bar hydraulic power unit, 2 clamping circuits, separate system clamping pressure for each pendulum field, clamping pressure control

KOHN linear clamping system

8 KOHN Multi 2000 MFS 125/680 HD hydraulic vices

Two-part operator step across the entire operating width of 6000 mm

With the 3 axes x, y, z and the swivel head, the software package 5-axis milling can be used to mill shapes, e.g. a curve. The software then synchronizes the axes.

Discover more used machines

Listing

Wiefelstede

Wiefelstede

18,341 km

Exhaust air purification system

KMASR2200

Call

Condition: good (used), Exhaust gas filter system, exhaust gas filter system, exhaust gas filter, hot filter, industrial exhaust gas filter, exhaust air purification system, filter cleaning system, electrostatic precipitator, filter system, oil mist separator, oil mist separator, air filter, mist separator, oil and emulsion mist separator, HEPA filter

-Manufacturer: KMA, Exhaust air purification system filter cleaning system type SR2200

-Rated power: 0.65 kW

-Individual components: see photos

-Dimensions: 1220/645/H1335 mm

Rbjdpelb Iv Eefx Ahzot

-Total weight: 196 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Oil mist separator

W+WME-FI 600

Call

Condition: good (used), Year of construction: 2006, Filter system, oil mist separator, oil mist separator, air filter, mist separator, oil and emulsion mist separator, suspended matter filter

Rsdpoiz Udwsfx Ahzobt

-Manufacturer: WW, oil mist separator filter system type ME-FI 600

-Voltage: 230V / 0.15 kW

-Filter: without filter

-Quantity: 1 piece available

-Dimensions: 710/390/H445 mm

-Weight: 38 kg

Listing

Blumberg

Blumberg

18,708 km

Coolant equipment

DeltathermE 4

Call

Condition: excellent (used), Year of construction: 2023, Immersion cooler Deltatherm E 4

Redpfxox Rrn Ij Ahzsbt

Suitable for cooling: oil – emulsion – water

Temperature range: 10–40 °C

Several units available

Listing

Kirchheim unter Teck

Kirchheim unter Teck

18,603 km

Cylindrical Grinding Machine - Universal

KELLENBERGERVaria UR 175-1000 1-2-6-7

Call

Condition: used, Year of construction: 2021, grinding diameter 350 mm

grinding length 1000 mm

centre height 175 mm

Control Fanuc 31i

Maschine aus 1998 jedoch 2021 überholt von Kellenberger inklusive

neue Steuerung FANUC31 mit Blue solution

Nur 790 Stunden Schleifzeit

1 UR-175 / 1000 Standardausführung (T1, T2, T6, T7)

1 Schleifscheibenausrüstung T1 500x80x127mm

1 Schleifscheibenausrüstung T2 400x63x127mm

1 HF-Innenschleifeinrichtung T6 MFM 1224/42 42.000 U/min

1 HF-Innenschleifeinrichtung T7 MFM 1242/60 60.000 U/min

1 Spitzenhöhe 175mm

Rjdpex Rn Uwsfx Ahzsbt

1 CNC Steuerung FANUC 31i mit Blue solution

1 Unrundschleifen

1 Remote Diagnostic

1 B-ACHSE CNC-gsteuert

1 Reitstock mit pneumatisch betätigten Pinolenrückzug

1 MIKROVERSTELLUNG: Reitstock Unterteil mit Mikroverstellung

1 Werkstückspindelstock mit C-Achse

1 Werkstückspindelstock mit schwenkbarem Unzerteil

1 KELPOS: Aktive Längspositionierung

1 Vorbereitung für Messsteuerungen Movomatic ESZ 400 oder Marposs P7 ME

1 KELSET : Werkzeugvermessungssystem

1 Grundmodul für Anschnittsensoren und Auswuchteinrichtungen

Fluid-Anschnittsensor mit Magnetfuss

1 Vollverschalung Emulsion

1 Kühlmittel-Reinigungspistole am Tisch angeschlossen

1 Vorbereitung für Schleifnebel-Absauganlage Emulsion

Listing

Duxford

Duxford

18,728 km

IKA Eurostar PWR CV Overhead Stirrer

IKAEurostar PWR CV

Call

Condition: used, This listing is for a IKA Eurostar PWR CV Overhead Stirrer.

The unit is in full working condition and is ready for immediate release.

The IKA Eurostar PWR CV Overhead Stirrer is an efficient laboratory device specifically designed for various stirring tasks, excelling in mixing both high and low viscosity substances. This stirrer is part of the comprehensive IKA Eurostar series, which offers diverse models tailored to different laboratory needs.

Key Features:

Speed Range:

Features a versatile speed range of rpm, with automatic adjustments made possible through advanced microprocessor-controlled technology.

Safety Circuits:

Equipped with built-in safety circuits that provide automatic cut-off in cases of anti-stall or overload conditions, ensuring user safety and equipment protection.

Constant Speed:

Maintains a steady speed regardless of viscosity changes in the sample, as it continuously compares the actual shaft speed with the set speed for optimal performance.

Stirring Quantity:

The EuroStar 20 model can handle a maximum stirring quantity of 15 litres (H2O), making it suitable for larger volumes.

Torque:

Delivers a maximum torque of 20 Ncm at the stirring shaft, providing sufficient power for effective mixing.

Stirring Element Fastening:

The stirring element is securely fastened using a chuck, ensuring stability during operation.

Applications:

Rbjdoxxz S Aopfx Ahzot

Laboratory Use: Designed specifically for laboratory environments, making it ideal for routine stirring tasks.

Mixing Substances: Capable of efficiently mixing a wide range of substances, whether they are of high or low viscosity, catering to diverse experimental needs.

Intensive Mixing: Suitable for applications that demand intensive mixing, such as preparing emulsions or suspensions.

Listing

Duxford

Duxford

18,728 km

APV Gaulin T Series Homogenizer

APV GaulinT Series

Call

Condition: used, This listing is for the APV Gaulin T Series Homogenizer

The unit is in full working condition and is ready for immediate use

The Gaulin T Series homogenizers, developed by SPX FLOW under the APV brand, are high-pressure, positive displacement reciprocating plunger pumps designed for demanding applications in industries such as dairy, food and beverage, pharmaceuticals, chemicals, and cosmetics.

Key Features

High Pressure Capability: Models like the Gaulin 132T and 125T can handle pressures up to 600 bar (approximately 8,700 psi), making them suitable for applications requiring intense homogenization.

Flow Rate: These homogenizers can process flow rates ranging from 1,000 to 25,000 liters per hour (LPH), accommodating various production scales.

Design Options: The Gaulin T Series offers both mono-block and three-piece valve housing designs, allowing for flexibility in maintenance and customization.

Rbjdpsxhf Tvefx Ahzet

Hygienic Construction: Constructed with stainless steel or duplex materials, these homogenizers feature 3-A sanitary design, making them suitable for hygienic applications.

Maintenance-Friendly: The design includes features like hydraulic valve actuators, easy access to key components, and modular electrical controls, simplifying maintenance and reducing downtime.

Applications

Gaulin T Series homogenizers are ideal for applications such as:

Dairy Processing: Homogenization of milk, cream, and other dairy products.

Food and Beverage: Processing of sauces, dressings, and beverages.

Pharmaceuticals and Cosmetics: Manufacturing of emulsions, creams, and lotions.

Chemical Processing: Production of paints, coatings, and other chemical products

Listing

Zdziechowice

Zdziechowice

17,909 km

Oil mist extractor, Donaldson separator

Donaldson ToritDRYFLO DMC-D2

Call

Condition: used, volume flow: 7,500 m³/h, Oil mist extractor for CNC machines, Donaldson Torit brand filter separator.

Redpfxjxd Ry Ho Ahzsbt

The unit is designed for filtration of oil mist (emulsions as well as pure oil),

vapors and fumes generated by various

metal cutting processes.

Filtration efficiency reaches 99.97%

Model: DMC-D2

Fan power: 7.5 kW

Capacity: 7,500 m3/h

Filtration area: 40.8 m2

Filter cartridges in very good condition.

Stock no.: 1043

Listing

Wiefelstede

Wiefelstede

18,341 km

Oil-water separation system

KaeserÖl-Wasser-Trenner

Call

Condition: good (used), Emulsion splitting plant, oil-water separation system

The cost-effective and permanently reliable

The solution to the problem is usually the oil/water-

Rbsdpfx Asb A Ib Hehzst

Separation for dispersed condensates.

Purified water meets legal requirements

Regulations for sewer discharge

Listing

Wiefelstede

Wiefelstede

18,341 km

Oil-water separation system

BEKOOEWAMAT

Call

Condition: good (used), Emulsion splitting plant, oil-water separation system

The cost-effective and permanently reliable

The solution to the problem is usually the oil/water-

Separation for dispersed condensates.

Rbjdpfx Aheb A Iy Hezot

Purified water meets legal requirements

Regulations for sewer discharge

-Weight: 70 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Oil-water separation system

KaeserÖl-Wasser-Trenner

Call

Condition: good (used), Emulsion splitting plant, oil-water separation system

The cost-effective and permanently reliable

The solution to the problem is usually the oil/water-

Separation for dispersed condensates.

Purified water meets legal requirements

Rodpfx Aheb A I Dvjzebt

Regulations for sewer discharge

-Dimensions: 500 x 1000 mm

-Weight: 50 kg

Listing

Borken

Borken

18,513 km

Microwave drying balance

CEMTURBO SMART 5

Call

Condition: used, CEM

CEM Smart 5 Turbo Model 907990

Professional Microwave Moisture Analyzer for Moisture and Solids Analysis

Reliable Laboratory Analytics in Record Time

The CEM Smart 5 Turbo is a state-of-the-art microwave drying system for rapid and precise determination of moisture and solids content in a wide range of samples.

Ideally suited for applications in the food, chemical, pharmaceutical, and environmental industries, this device saves significant time while maintaining consistently high measurement accuracy.

Product features:

Turbo technology with Intellitemp™ – Optimal temperature control prevents burning or crust formation on the sample.

Fast analysis times – results within 60–180 seconds

High precision – measurement range from 0.1% to 99.9% moisture or solids

Versatile – suitable for solids, pastes, sludges, and liquids

User-friendly touchscreen operation

Interfaces – RS-232, USB, LIMS-compatible

Typical applications:

Cheese, dairy products, meat

Paints, coatings, plastics, polymers

Sludges, wastewater, organic residues

Creams, pastes, emulsions

Technical Data – CEM Smart 5 Turbo

Feature

Device type: Microwave moisture analyzer / moisture analyzer

Technology: Microwave drying with Intellitemp™ temperature control

Moisture range: 0.1% – 99.9%

Sample types: solids, liquids, pastes, sludges, emulsions

Rjdpewv Ryyjfx Ahzjbt

Analysis time: typically 1–3 minutes

Drying method: direct microwave radiation (non-rotating)

Temperature control: automatic (microwave-controlled, no fixed °C value)

Weighing unit: Optionally connectable external scale (resolution up to 0.001 g possible)

Display / Operation: color touchscreen, intuitive menu navigation

Data interfaces: RS-232, USB, network (LIMS-compatible)

Documentation: Barcode scanner & thermal printer (optional)

Power supply: 230 V / 50–60 Hz

Dimensions (W × D × H): approx. 41 × 44 × 37 cm

Weight: approx. 18 kg

Condition: used

Scope of delivery: (see picture)

(Subject to changes and errors in technical data and information!)

If you have further questions, we will gladly answer them by phone.

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL5 mLT

Call

Condition: repair required (used), Year of construction: 2007, functionality: not functional, machine/vehicle number: P-30010521, Technical specifications:

Work Area

Rodpfx Ahoxxt D Rozjbt

- Maximum diameter of clamping plate: 260 mm

- Maximum turning diameter: 260 mm

- Maximum machining diameter: 220 mm

- Maximum workpiece length: 110 mm

- X-axis travel: 570 mm / Rapid traverse in X: 60 m/min

- Z-axis travel: 200 mm / Rapid traverse in Z: 30 m/min

- Y-axis travel: 40 mm / Rapid traverse in Y: 30 m/min

- Standard closed automation (number of loading magazines by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle according to DIN 55026: Size 6

- Maximum spindle speed: 4500 rpm

- Power at 100% / 40% duty cycle: 18 / 27 kW

- Torque at 100% / 40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Tool holder for cylindrical shank DIN 69880: 12 - VDI40

- Number of turret stations: 12

- Max. tool length including holder: 190 mm

- Maximum speed: 6000 rpm

- Maximum torque at 10% duty cycle: 37 Nm, 25% duty cycle: 26 Nm, 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400 - 480 V

- Connected load: 42 kW

Dimensions

- Total machine dimensions: Length = 2680 mm (3820 mm with chip conveyor), Width = 2040 mm, Height = 2400 mm

- Weight: 6500 kg

Main Features and Capabilities

- Vertical design: Enables optimal chip removal and easy loading/unloading

- Control system: GE Fanuc Series 18i TB

- High precision: Positioning accuracy on X/Z axes is ±0.001 mm thanks to Heidenhain linear scales

- Main spindle: High power and wide speed range

- Automated loading/unloading: Parts are loaded and unloaded via integrated automation

- Driven tools: Enables drilling and milling operations

- Chip conveyor

- Documentation: Electronic version not available, printed manual incomplete

Machine status: NOT WORKING

- Spindle drive

- X-axis linear scale

- Safety access door (Euchner)

- Emulsion solenoid valves x2

Listing

Iași

Iași

17,349 km

Vertical machining center

FANUCA04B-0102-B133#BBH

Call

Condition: repair required (used), Year of construction: 2017, functionality: not functional, machine/vehicle number: P177ZG753, Technical characteristics:

# Machining Workspace: X 500 mm; Y 400 mm; Z 330 mm

# Axis Description: 3 LINEAR AXES (X, Y, Z) + 1 rotary table axis (A-axis) with index dividing head, direct angular measurement system, number of revolutions 50 min⁻¹, accuracy +/- 5"

# A-axis Swivel Range: +/-170˚

# Maximum Clamping/Workpiece Dimensions: 650 x 400 mm; max. weight 300 kg

# Rapid Traverse: X/Y/Z 54 m/min

# Spindle Speed: 100–10,000 rpm, spindle motor power 11 kW

# Spindle Taper: BBT30 (with internal cooling)

# Automatic Tool Changer: 1x21 tools, chip-to-chip average time 1.5 sec

# Maximum Tool Size: Ø40 mm / length max. 200 mm / 2 kg

Electrical connection:

# Voltage: 3x400V/50Hz

# Installed Power: approx. 20 kVA / 22A

Dimensions:

# Installation space: approx. 1.65 x 3.2 m (with chip conveyor) x 2.8 m

# Weight: approx. 8,500 kg

Equipment includes:

# This 4-axis FANUC Robodrill α-D21LiB5 was manufactured in 2016. Ideal for precision machining, this vertical machining centre offers robust performance and reliability.

# CNC Control: Model 31i model b5

# 4th axis and tailstock: Fanuc DDR-TiB 178DU039 2017/08 and TSUDAKOMA tailstock

# Chip extractor & coolant filtration unit max. 40 bar: Mosnic model 1641/2010

# Spindle, Guideways, and Electrical Cabinet Cooling Systems

# Oil Vapor Absorption/Recovery System: Bristol model B 1000 EF

# Fire suppression: Kraft & Bauer

# Part presence detection: with low pressure air sensors

# Automation: Lateral door automatic and interface ready for automation

# In-process inspection: Renishaw TRS2

# Documentation: incomplete

Machine condition:

NOT WORKING

# Hydraulic unit defective

# Two emulsion pumps

# Guideway lubrication pump

Rodoxxt Ehepfx Ahzobt

# Safety switch Euchner

Listing

Iași

Iași

17,349 km

Horizontal machining center

SWBA321

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 2460039, Technical specifications:

# Working area: X 300 mm; Y 500 (725) mm; Z 375 mm

# Axis configuration: 3 LINEAR AXES (X, Y, Z) + 1 rotary axis (A – rotary table with indexing head)

- Direct angular measuring system with up to 50 rpm, accuracy +/- 5”

# Maximum workpiece clamping dimension/weight: Ø575 x 830 mm / max. 360 kg

# Rapid traverse: X/Y/Z 65/75/75 m/min; Positioning accuracy Tp: 0.008 mm

# Spindle center distance: 300 mm

# Spindle speed: 1 – 17,500 rpm

# Spindle interface: DIN 69893-HSK-A63 (with internal coolant supply)

# Automatic tool changer: 2 x 32 tools; chip-to-chip average time: 2.5 sec

# Maximum tool dimensions: Ø75 mm / length: max. 275 mm / up to 7.5 kg

Electrical data:

# Mains voltage: 3x400V / 50Hz

# Connected load: approx. 85 kVA / 125A

Dimensions:

Redpfx Ahjxxrnbszjbt

# Installation area: approx. 3.6 x 6 x 3.7 m

# Weight: approx. 10,500 kg

Equipment includes:

# CNC control: Siemens 840D SL

# Linear measuring systems: Heidenhain linear scales

# Chip extractor: Knoll Type 550 K-1

# Oil cooling system

# Cooling system for shaft, guides, and control cabinet

# 2 oil lubrication systems

# Oil filtration system (up to 80 bar): Knoll VRF450-2450 (can supply 2 machines simultaneously)

# Oil vapor extraction/recovery system: IFS Vario E2000 (2,000 m³/h)

# Fire suppression system: Kraft & Bauer

# Part detection P/Y: with low-pressure air monitors

# In-process measurement: Marposs T25

# Tool breakage detection and length measurement: inductive sensor

# Tool presence monitoring in spindle

Machine status: NOT OPERATIONAL

- Spindle tool and part presence sensors

- Tool breakage sensors

- Tool magazine piston and slide system door open/close (2 units)

- Tool magazine pistons and tool retainer slide system (2 units)

- A-axis position encoder

- Inductive and magnetic sensors (4 units each)

- Chip extraction conveyor requires repair

- Chiller for spindle cooling/heat exchanger

- Communication module Murr

- X axis linear scale

- Emulsion chip conveyor level sensor

- Hydraulic pump

- Motor for hydraulic pump (repairable)

- Heat exchanger unit

- Electric Siemens contactors for electrical cabinet (3 units)

- Safety door lock Euchner

- Emulsion filtration unit is shared with another machine (SW BA321 2460038)

Note: Machine is NOT WORKING and offered as described.

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVT2-4

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 106374, Technical characteristics:

Work Area

- Chuck diameter: 160 mm

- Maximum weight of chuck + workpiece: 45 kg

- Maximum workpiece diameter/height: 100/400 mm

- Distance spindle nose to origin of tailstock: 795.5 mm

- X1/X2 working stroke: 340 mm / Rapid traverse in X: 30 m/min

- Z1/Z2 stroke: 625 mm / Rapid traverse in Z: 30 m/min / Feed force: 18.7 kN

- Loading time: 5–6 sec

- Standard closed automation (number of loading nests by workpiece diameter): 14/(80–200 mm), 18/(30–160 mm), 30/(30–85 mm)

Main Spindle

- Spindle according to DIN 55026: Size KK5

- Maximum speed: 8,500 rpm

- Power at 100% / 40% duty cycle: 34 / 26.5 kW

- Torque at 100% / 40% duty cycle: 75 / 48 Nm

Tailstock

- Interface: MK3

- Clamping force: 120 N/bar

- Clamping stroke: 5 mm

Tool Holder with Motorized Tools

- Tool holders with cylindrical shank according to DIN 69880: 12 – BMT65

- Number of positions: 2 x 12 (1 gripper per turret)

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400–480 V, 120 A

- Connected load: 45 kVA

Dimensions

- Total dimensions: Length = 5,300 mm with chip conveyor, Width = 1,760 mm, Height = 3,650 mm

- Weight: 7,500 kg

Main Features and Capabilities

- Vertical design: Optimized chip evacuation and automatic loading/unloading

- Control: GE Fanuc FS 32i

- High precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High power and wide speed range

- Automation: EMAG O-type – Parts are loaded and unloaded automatically via integrated automation

Rsdsxxtkwepfx Ahzjbt

- Live tools: Allows drilling and milling operations

- Tool life monitoring with sister tool management

- Chip conveyor, coolant unit, switchable dual cartridge filter, high pressure pump (15 bar)

- Fully enclosed working area, LED light in working area

- Documentation: Available both electronically and as hardcopy book

Machine Status: NOT WORKING

- X-axis drive

- Five electrical switches (Siemens)

- Hydraulic pump

- Operator panel (in stock, needs installation)

- Valve chiller

- Pressure switch for oiling unit

- Emulsion tank pump

- Four emulsion circuit switches (electrovalves)

- Pressure switch for hydraulic circuit

- Complete hydraulic block

Listing

Iași

Iași

17,349 km

Horizontal machining center

SW Schwäbische WerkzeugmaschinenBA321

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 2460038, Technical specifications:

Machining workspace: X 300 mm; Y 500 (725) mm; Z 375 mm

Axis configuration: 3 linear axes (X, Y, Z) + 1 rotary table axis (A), index dividing head

- Direct measuring system, angular, rotation speed: max. 50 min⁻¹, accuracy: +/- 5''

Maximum clamping/part dimensions: Ø 575 x 830 mm; maximum weight: 360 kg

Rapid traverse rates: X/Y/Z = 65/75/75 m/min; positioning accuracy Tp: 0.008 mm

Spindle spacing: 300 mm

Spindle speed range: 1–17,500 rpm

Spindle taper: DIN 69893-HSK-A63 (internal coolant supply)

Automatic tool changer: 2 x 32 positions; average chip-to-chip: 2.5 s

Maximum tool diameter: Ø 75 mm; maximum tool length: 275 mm; maximum tool weight: 7.5 kg

Electrical data:

- Supply voltage: 3x400 V / 50 Hz

- Installed power: approx. 85 kVA / 125 A

Machine dimensions:

- Installation area: approx. 3.6 x 6 x 3.7 m

- Weight: approx. 10,500 kg

Equipment includes:

- CNC control: Siemens 840D SL

Rjdjxxrc Sepfx Ahzebt

- Linear axis measuring systems: Heidenhain linear scales

- Chip conveyor: Knoll Typ 550 K-1

- Oil cooling system

- Shaft, guideway, and switch cabinet cooling system

- 2 oil lubrication systems

- Oil mist extraction/recovery system: IFS Vario E2000 (2,000 m³/h)

- Fire protection: Kraft & Bauer

- Workpiece presence detection (P/Y): Low pressure air sensors

- In-process measurement: Marposs T25

- Tool breakage control and length measurement system: Inductive sensor (BRK)

- Tool support detection in working spindle

Machine status: NOT OPERATIONAL / NON-FUNCTIONAL

Installed components:

- Sensors for tool presence in spindle & part presence

- Hydraulic pump

- Hydraulic unit level & temperature sensors (Parker)

- Tool magazine piston & sliding door system (2 units)

- Communication module: Murr

- A-axis position encoder

- Hydraulic switches (Parker, 4 units)

- Emulsion filtration unit is shared with another machine (SW BA321 2460038)

- High-pressure pump from emulsion filtration system

Trust Seal

Dealers certified through Machineseeker

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL 5 mLT

Call

Condition: repair required (used), Year of construction: 2007, functionality: not functional, machine/vehicle number: P-30010522, Technical characteristics:

Work Area

- Maximum clamping plate diameter: 260 mm

- Maximum turning diameter: 260 mm

- Maximum machining diameter: 220 mm

- Maximum workpiece length: 110 mm

- X-axis travel: 570 mm / Rapid traverse X: 60 m/min

- Z-axis travel: 200 mm / Rapid traverse Z: 30 m/min

- Standard closed automation (number of loading nests by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle according to DIN 55026, Size 6 !!! Brand new, replaced in 2024 !!!

- Maximum speed: 4,500 rpm

- Power, 100% / 40% duty cycle: 18 / 27 kW

- Torque, 100% / 40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Tool holders with cylindrical shank to DIN 69880: 12 - VDI40

- Number of turret stations: 12

- Maximum tool length (including holder): 190 mm

- Maximum speed: 6,000 rpm

- Maximum torque: 37 Nm (10% duty cycle), 26 Nm (25% duty cycle), 14 Nm (100% duty cycle)

Electrical Equipment

Redpfx Aoxxkh Tehzobt

- Operating voltage: 400 – 480 V

- Connected load: 42 kW

Dimensions

- Overall dimensions: Length = 2,680 mm (3,820 mm with chip conveyor), Width = 2,040 mm, Height = 2,400 mm

- Weight: 6,500 kg

Main Features and Capabilities:

- Vertical design: Optimal chip evacuation and easy loading/unloading

- CNC control: GE Fanuc Series 18i TB

- High precision: Positioning accuracy in X and Z axes ±0.001 mm (Heidenhain linear scales)

- Main spindle: High power and broad speed range

- Automated loading/unloading: Integrated automation system for part feeding and removal

- Driven tools: Capability for drilling and milling operations

- Chip conveyor

- Documentation: Electronic unavailable, partial hard copy/manual available

Machine status: NOT WORKING

- Hydraulic solenoid valves: 4 units

- Coolant (emulsion) pump defective

Listing

Iași

Iași

17,349 km

Strung vertical

WEISSER SOHNEVertor C-1 HOT

Call

Condition: repair required (used), Year of construction: 2017, functionality: not functional, machine/vehicle number: 179057653, Technical characteristics:

Work Area

- Chuck diameter: 600 mm

- Max. workpiece diameter/height: 450 / 400 mm

- Distance from spindle nose to tailstock reference point: 639 mm

- X1/X2 axes travel (working stroke): 335/289 mm / Rapid traverse in X: 30 m/min

- Z1/Z2 axes travel: 560/494 mm / Rapid traverse in Z: 30 m/min

- Fully enclosed with automatic door opening, supporting manual or automatic loading

Main Spindle

- Spindle according to DIN 55026: Size A6

- Max. speed: 4,500 rpm

- Power at 100% / 40% duty cycle: 23 / 18 kW

- Torque at 100% / 40% duty cycle: 146 / 115 Nm

Tailstock

- Interface: MK4

- Clamping force: 850 daN

- Clamping stroke: 200 mm

Turret Configuration X1/Z1: Toolholder with Powered Tools

- Cylindrical shank holders per DIN 69880: 8 - VDI40

- Max. tool length: 130 mm

- Number of positions: 1 x 8

- Max. speed: 4,500 rpm

- Max. torque at 10% / 100% duty cycle: 27 Nm / 14 Nm

Turret Configuration X2/Z2: Toolholder with Powered Tools

- X-HOT unit for polygonal turning, max. eccentricity (stroke): 8 mm

- X-HOT tool clamping system: HSK 32S

Electrical Equipment

- Operating voltage: 400 V, 100 A

- Connected load: 37 kVA

Dimensions

- Overall dimensions: Length = 3,000 mm (6,477 mm with chip conveyor), Width = 3,000 mm, Height = 3,650 mm

- Weight: 11,000 kg

Main Features and Capabilities:

- Vertical design for optimum chip removal, suitable for manual or automated loading/unloading

Rbodpfx Aexxinfohzst

- Siemens 840D control, NC1 and NC2 axes

- High precision: Positioning accuracy in X, Z axes ±0.002 mm (Heidenhain linear scales)

- Powerful main spindle with a wide speed range

- Live tooling extends machining capabilities to drilling and milling

- Tool life monitoring

- Chip conveyor: Knoll

- Coolant system filtration up to 40 bar: Knoll FKA/1400

- Workpiece presence detection with low pressure sensor

- ROBOT AUTOMATION INFRASTRUCTURE INSTALLED

- Fully enclosed work area; integrated lighting

- Documentation: available both electronically and as hard copy

Machine status:

Not operational

- Missing: valve for emulsion circuit and inductive sensors

Listing

Iași

Iași

17,349 km

Cnc lathe

OkumaL300-MW

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: MW137, Technical characteristics:

Work Area

- Maximum turning diameter: 300 mm

- Maximum workpiece length: 276 mm

- X-axis travel: 250 mm / Rapid traverse in X: 24 m/min

- Z-axis travel: 460 mm / Rapid traverse in Z: 24 m/min

- W-axis travel: 520 mm / Rapid traverse in Z: 24 m/min

Main Spindle

- Spindle nose: A2-8

- Maximum speed: Left 3,000 rpm

- Continuous power (100% duty cycle): Left - 15 kW / Right - 7.5 kW

- Maximum swing over bed: 520 mm

Rjdpfxoxxh Udo Ahzjbt

- C-axis indexing accuracy: 0.001°

- Bar capacity: Left spindle - 80 mm / Right spindle - 53 mm

Counter-Spindle

- Spindle speed: 6,000 rpm

- Maximum bar diameter: 53 mm

- C-axis indexing accuracy: 0.001°

- Travel: 520 mm

Tool Turret with Driven Tools

- Tool interface: Okuma interface

- Number of positions: 12 lower turret stations, all driven

- Maximum speed: 4,500 rpm; Milling spindle power: 4.5 kW

Electrical Equipment

- Operating voltage: 400V (3-phase), fuse protection: 151A

- Connected load: 22.5 kVA

Dimensions

- Machine dimensions (L×W×H): 3,200 × 2,200 × 1,900 mm; Weight: 5,500 kg

Main Features and Capabilities:

- Horizontal design: Optimal chip evacuation, parts catcher + custom-made conveyor belt

- Additional emulsion tank with 10 bar pressure for cutting tool cooling

- CNC control: OSP-P300L-R

- Swarf (chip) extraction conveyor

- Fire suppression system

- Tool measuring system (Q SETTER)

- Broken tool detection: Load monitoring with auto-learning analyzer via OSP-P300L-R

- Workpiece detection on counter-spindle: Low-pressure compressed air gauges

- Spindle cooling system

- Documentation: Electronic and print manual available

Optional:

- Bar feeder: FMB Model: Turbo 10-72XT/3200/A

- Bar feeder dimensions (L×W×H): 3,500 × 800 × 1,200 mm; Weight: 1,500 kg

Machine status:

NOT OPERATIONAL

- X-axis encoder: faulty

Listing

Iași

Iași

17,349 km

Cnc lathe

OKUMAGENOS L300-MW-e

Call

Condition: used, Year of construction: 2017, functionality: limited functionality, machine/vehicle number: MW149, Technical specifications:

Work Area

- Maximum turning diameter: 300 mm

- Maximum workpiece length: 276 mm

- X-axis travel: 250 mm / Rapid traverse in X: 24 m/min

- Z-axis travel: 460 mm / Rapid traverse in Z: 24 m/min

- W-axis travel: 520 mm / Rapid traverse in Z: 24 m/min

Main Spindle

- Spindle nose: A2-8

- Maximum speed: Left spindle 3000 rpm

- Continuous power (100% duty cycle): Left spindle – 15 kW / Right spindle – 7.5 kW

- Maximum swing over bed: 520 mm

- C-axis indexing accuracy: 0.001°

- Bar capacity: Left spindle – 80 mm / Right spindle – 53 mm

Sub-Spindle (Counter Spindle)

- Spindle speed: 6000 rpm

- Maximum bar diameter: 53 mm

- C-axis indexing accuracy: 0.001°

- Travel: 520 mm

Turret with Driven Tools

- Tool interface: Okuma interface

- Number of stations: 12-position lower turret, all driven stations

- Maximum speed: 4500 rpm, Milling motor power: 4.5 kW

Electrical System

- Operating voltage: 400V 3-phase, fuse protection 151A

- Connected load: 22.5 kVA

Dimensions

- Machine dimensions (L×W×H): 3200 × 2200 × 1900 mm

- Weight: 5500 kg

Main Features and Capabilities:

- Horizontal design for optimal chip evacuation

- Parts catcher and custom-made parts conveyor strip

- Additional emulsion tank with 10 bar pressure for cutting tool cooling

- CNC control: OSP-P300L-R

- Chip conveyor

- Fire protection system

- Tool measurement system (Q SETTER)

- Broken tool detection: Load force auto learning analyzer, controlled by OSP-P300L-R

- Part detection at sub spindle with low-pressure compressed air gauges

- Spindle cooling system

- Documentation: available electronically and as manual

Option:

Rbedjxxiiiepfx Ahzst

Bar feeder: TopAutomazione FU352SX

- Bar feeder dimensions (L×W×H): 3500 × 800 × 1200 mm

- Weight: 1500 kg

Machine status:

Machine operational only with main spindle – sub spindle requires repair.

We make it easier for you to find: "emulsion"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Emulsion (261)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month