Used Emulsion for sale (261)

Warstein

Warstein Vertical machining center

StarragCWK 400D

Warstein

Warstein Horizontal machining center

UNISIGNUnivers4

Soltau

Soltau 5 axis vertical machining centre

YCM5-Achsen UV650

+44 20 806 810 84

Soltau

Soltau Vertical machining center

RödersRXP600DSH

Germany

Germany Machining Center - Vertical

YCMTV2110B

Discover more used machines

Rzeszów

Rzeszów Bitumen Sprayer/Crack Sealing Machine

TICABBM Combo

Janville

Janville Vacuum mixer

Fryma KorumaDinex Lab

Janville

Janville Vacuum mixer

VMI>RayneriTrimix (TXR) 10 litres

Rzeszów

Rzeszów Bitum sprayer/crack sealer

TICABBM-Combo

Wiefelstede

Wiefelstede Filter for oil mist separator

Amano440/330/H345 mm

Wiefelstede

Wiefelstede Oil-water separation system for compressors

Domnick HunterES2150

Wiefelstede

Wiefelstede Louvre ventilation flap

unbekannt445/100/H330 mm

Wiefelstede

Wiefelstede Exhaust air purification system 0.75 kW

ifsIF-Vario M 1600

Wiefelstede

Wiefelstede Paint pump

Stöber HEWR27-0000-110-4

Wiefelstede

Wiefelstede Oil-water separation system for compressors

Atlas CopcoOSW30

Wiefelstede

Wiefelstede Oil-water separation system for compressors

KaeserÖl-Wasser-Trenner

Rzeszów

Rzeszów Asphalt recycler

TICABAsphalt recycler RA-800

Oberham

Oberham Band saw

METALLKRAFTHMBS 540 CNC X DG 2000 HORIZONT

Germany

Germany Tool preheating equipment

BilzISG 3200-WK

Germany

Germany Filter Device

IFSIF-Vario M 1600

Germany

Germany Suction

RevenUC Compact 1

Kaufungen

Kaufungen Machining center

DMGMilltap 700

Lorquí

Lorquí S/S KRAMER+GREBE 200 L Cutter

KRAMER GREBE

Lorquí

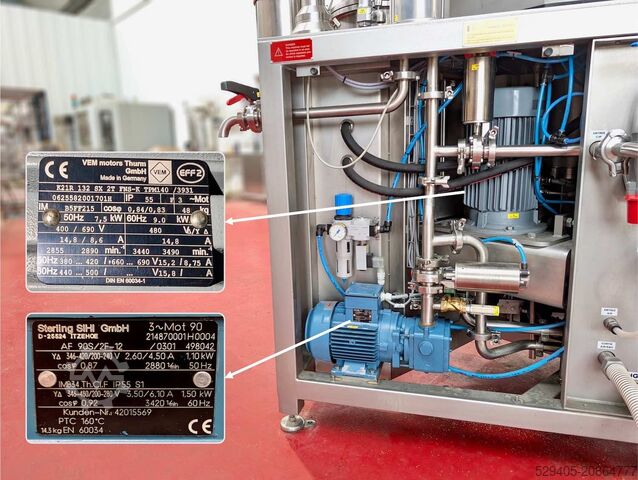

Lorquí Mixer line for juices with homogenizer

Coesfeld

Coesfeld Vacuum tank truck

MERCEDES-BENZAROCS 3545 L 8x4 B13 - Kroll ADR Sauger, 1,0 - 1

Used Emulsion (261)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84