Used machining centers with flat or grid table for sale (337)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Woodworking machinery CNC-processing machines Machining centers with flat or grid table

Listing

Zaleszany

Zaleszany

17,694 km

CNC ROUTER 1020 SPECIAL

PGCNC1020 SPECIAL

Call

Condition: new, Year of construction: 2026, 1020 SPECIAL milling ploter is a precise machine constructed in Poland. It can be used to process many different materials such as wood, wood-based materials (chipboard, MDF, OSB, etc.), plastics (plexiglass, PVC, HPL, etc.), composites (dibond, carbon, alucobond), soft metals, etc.

Construction of the machine is made out of steel which gives it high rigidity as well as resistance to congestions associated with the machining process. The plotter is equipped with a user-friendly interface that is easy to use, but also has advanced functions.

CONSTRUCTION: The plotter is made entirely of high quality steel. During the production process, all elements undergo a special heat treatment.

WORK AREA: The usable area of our machine tool is 1000 x 2000 [mm].

AXIS RANGE AND GATE CLEARANCE: The standard range of the Z axis is 200 mm. However, it is possible to increase it to 400 mm.

DRIVES: Our machine tools were powered by digital motors with high resolution and high power, which ensures appropriate acceleration and speed in particular directions. Classic and proven helical blades work in the X and Y axes, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw. All axes run on rail guides.

SPINDLE: The cutting tool is driven by a strong, liquid-cooled and durable high-class brushless spindle. The spindle bearing is high-quality machine bearings, very quiet and guaranteeing above-average durability. The rotational speed of the spindle ranges from 6 to 24 thousand. RPM An inverter is used for power supply, which has more power than the spindle, which protects against speed drops when working under heavy load.

SOFTWARE: The machine is equipped with appropriate CAD / CAM software in the latest version. The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

Rsdpfxjin Ezde Ahzobt

CONTROL: The machine is operated by the controller, which has its own processor and operating memory, which ensures stable and reliable operation. The machine controller has the function of active vector analysis, thanks to which the operation of the device is smooth and the error in processing is small. The controller has the function of returning to further work after the loss of power, so there is no need to initialize the program from a scratch. The memory built into the controller allows the machine to work without having to load the program each time.

Additional options:

- vacuum table with Busch or Becker pump

- chip extraction system

- oil mist

- any size of the working table

Listing

Zaleszany

Zaleszany

17,694 km

CNC Router 2030 ATC 5X

PGCNC2030 ATC 5X

Call

Condition: new, Year of construction: 2026, The ATC series was created for professional use in large industrial plants and factories. Like the plotters of the SPECIAL series, it can be designed for machining various materials. To meet the demands of heavier machining, ATC machines use an additional reinforced structure and stronger AC servo drives on each axis. The presence of five axes provides support in the machining process of even the most demanding elements.

The standard in these devices is a vacuum work table. It is also possible to install a hybrid table.

The plotters in this series come standard with automatic tool change, a six-position linear magazine and a tool height sensor. The applied solutions significantly accelerate the machining process requiring the use of several milling cutters.

Processed materials:

-wood

Rbedpfx Ahsin Etzozot

- wood-based materials (chipboard, MDF, OSB, etc.)

-plastics

-Composites

-PVC

- non-ferrous metals (aluminum, brass, copper, etc.)

CONSTRUCTION: The plotter is made entirely of high quality steel. During the production process, all elements undergo a special heat treatment.

WORK AREA: The usable area of our machine tool is 2100 x 3100 [mm].

MATERIAL FASTENING:

The machine is equipped with a vacuum table.

AXIS RANGE AND GATE CLEARANCE: The standard range of the Z axis is 300 mm

DRIVES: Our machine tools were powered by digital motors with high resolution and high power, which ensures appropriate acceleration and speed in particular directions. Classic and proven helical blades work in the X and Y axes, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw. All axes run on rail guides.

SPINDLE: The cutting tool is driven by a strong, liquid-cooled and durable high-class brushless spindle. The spindle bearing is high-quality machine bearings, very quiet and guaranteeing above-average durability. The rotational speed of the spindle ranges from 6 to 24 thousand. RPM An inverter is used for power supply, which has more power than the spindle, which protects against speed drops when working under heavy load.

TOOL MAGAZINE:

The standard equipment of the machine is a linear tool magazine equipped with 6 ISO30 cones.

SOFTWARE: The machine is equipped with appropriate CAD / CAM software in the latest version. The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

CONTROL: The machine is operated by the controller, which has its own processor and operating memory, which ensures stable and reliable operation. The machine controller has the function of active vector analysis, thanks to which the operation of the device is smooth and the error in processing is small. The controller has the function of returning to further work after the loss of power, so there is no need to initialize the program from a scratch. The memory built into the controller allows the machine to work without having to load the program each time.

Listing

Zaleszany

Zaleszany

17,694 km

CNC ROUTER 1012 SPECIAL

PGCNC1012 SPECIAL

Call

Condition: new, Year of construction: 2026, 1012 SPECIAL milling ploter is a precise machine constructed in Poland. It can be used to process many different materials such as wood, wood-based materials (chipboard, MDF, OSB, etc.), plastics (plexiglass, PVC, HPL, etc.), composites (dibond, carbon, alucobond), soft metals, etc.

Construction of the machine is made out of steel which gives it high rigidity as well as resistance to congestions associated with the machining process. The plotter is equipped with a user-friendly interface that is easy to use, but also has advanced functions.

Redein Ewzopfx Ahzebt

CONSTRUCTION: The plotter is made entirely of high quality steel. During the production process, all elements undergo a special heat treatment.

WORK AREA: The usable area of our machine tool is 1000 x 1200 [mm].

AXIS RANGE AND GATE CLEARANCE: The standard range of the Z axis is 200 mm. However, it is possible to increase it to 400 mm.

DRIVES: Our machine tools were powered by digital motors with high resolution and high power, which ensures appropriate acceleration and speed in particular directions. Classic and proven helical blades work in the X and Y axes, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw. All axes run on rail guides.

SPINDLE: The cutting tool is driven by a strong, liquid-cooled and durable high-class brushless spindle. The spindle bearing is high-quality machine bearings, very quiet and guaranteeing above-average durability. The rotational speed of the spindle ranges from 6 to 24 thousand. RPM An inverter is used for power supply, which has more power than the spindle, which protects against speed drops when working under heavy load.

SOFTWARE: The machine is equipped with appropriate CAD / CAM software in the latest version. The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

CONTROL: The machine is operated by the controller, which has its own processor and operating memory, which ensures stable and reliable operation. The machine controller has the function of active vector analysis, thanks to which the operation of the device is smooth and the error in processing is small. The controller has the function of returning to further work after the loss of power, so there is no need to initialize the program from a scratch. The memory built into the controller allows the machine to work without having to load the program each time.

Additional options:

- vacuum table with Busch or Becker pump

- chip extraction system

- oil mist

- any size of the working table

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Zaleszany

Zaleszany

17,694 km

CNC Router 2030 SPECIAL

PGCNC2030 SPECIAL

Call

Condition: new, Year of construction: 2026, 2030 SPECIAL milling ploter is a precise machine constructed in Poland. It can be used to process many different materials such as wood, wood-based materials (chipboard, MDF, OSB, etc.), plastics (plexiglass, PVC, HPL, etc.), composites (dibond, carbon, alucobond), soft metals, etc.

Construction of the machine is made out of steel which gives it high rigidity as well as resistance to congestions associated with the machining process. The plotter is equipped with a user-friendly interface that is easy to use, but also has advanced functions.

CONSTRUCTION: The plotter is made entirely of high quality steel. During the production process, all elements undergo a special heat treatment.

WORK AREA: The usable area of our machine tool is 2100 x 3100 [mm].

AXIS RANGE AND GATE CLEARANCE: The standard range of the Z axis is 200 mm. However, it is possible to increase it to 400 mm.

DRIVES: Our machine tools were powered by digital motors with high resolution and high power, which ensures appropriate acceleration and speed in particular directions. Classic and proven helical blades work in the X and Y axes, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw. All axes run on rail guides.

SPINDLE: The cutting tool is driven by a strong, liquid-cooled and durable high-class brushless spindle. The spindle bearing is high-quality machine bearings, very quiet and guaranteeing above-average durability. The rotational speed of the spindle ranges from 6 to 24 thousand. RPM An inverter is used for power supply, which has more power than the spindle, which protects against speed drops when working under heavy load.

SOFTWARE: The machine is equipped with appropriate CAD / CAM software in the latest version. The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

Rjdpfxein Eqfs Ahzebt

CONTROL: The machine is operated by the controller, which has its own processor and operating memory, which ensures stable and reliable operation. The machine controller has the function of active vector analysis, thanks to which the operation of the device is smooth and the error in processing is small. The controller has the function of returning to further work after the loss of power, so there is no need to initialize the program from a scratch. The memory built into the controller allows the machine to work without having to load the program each time.

Additional options:

- vacuum table with Busch or Becker pump

- chip extraction system

- oil mist

Listing

Zaleszany

Zaleszany

17,694 km

CNC Router

PGCNC2030 ATC

Call

Condition: new, Year of construction: 2026, THE MACHINE HAS A TOOL STORAGE EQUIPPED WITH 6 ISO30 CONES !!!

CNC 2030 ATC CNC Router is a precise machine constructed in Poland, it is used to process many engineering materials, i.e. wood, wood-based materials (chipboard, MDF, OSB etc.), plastics (plexiglass, PVC, HPL etc.), composites (dibond, carbon, alucobond), soft metals, etc.

The ATC series machines have an additionally reinforced structure and the applied AC servo drives on each axis, coupled with an affordable price, leave the competition far behind.

CONSTRUCTION: The plotter is made entirely of high quality steel. During the production process, all elements undergo a special heat treatment.

WORK AREA: The usable area of our machine tool is 2100 x 3100 [mm].

AXIS RANGE AND GATE CLEARANCE: The standard range of the Z axis is 300 mm

DRIVES: Our machine tools were powered by digital motors with high resolution and high power, which ensures appropriate acceleration and speed in particular directions. Classic and proven helical blades work in the X and Y axes, which ensure high durability and precision, and the Z axis is driven by a high-quality ball screw. All axes run on rail guides.

SPINDLE: The cutting tool is driven by a strong, liquid-cooled and durable high-class brushless spindle. The spindle bearing is high-quality machine bearings, very quiet and guaranteeing above-average durability. The rotational speed of the spindle ranges from 6 to 24 thousand. RPM An inverter is used for power supply, which has more power than the spindle, which protects against speed drops when working under heavy load.

SOFTWARE: The machine is equipped with appropriate CAD / CAM software in the latest version. The software enables quick and easy design of elements, which the program then converts into the so-called G-code. It is also possible to import finished files from other programs.

CONTROL: The machine is operated by the controller, which has its own processor and operating memory, which ensures stable and reliable operation. The machine controller has the function of active vector analysis, thanks to which the operation of the device is smooth and the error in processing is small. The controller has the function of returning to further work after the loss of power, so there is no need to initialize the program from a scratch. The memory built into the controller allows the machine to work without having to load the program each time.

Additional options:

- vacuum table with Busch or Becker pump

- chip extraction system

- oil mist

Rbodpfx Ahein Ek Dszjt

- any size of the working table

Auction

Auction ended

Kranj

Kranj

18,351 km

5-axis machining center

SCMRECORD 132 Prisma

Condition: ready for operation (used), Year of construction: 2006, operating hours: 19,857 h, functionality: fully functional, travel distance X-axis: 4,400 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 180 mm, number of slots in tool magazine: 72, TECHNICAL DETAILS

X-axis travel: 4,400 mm

Y-axis travel: 1,300 mm

Z-axis travel: 180 mm

Milling unit power: 15 HP

Tool change: automatic

Number of tool positions: 3 x 24 slots

Rodpfx Ahox Sri Iezsbt

EQUIPMENT

Worktable with traverse

Auxiliary unit for heavy parts

Pneumatic clamps for door and window production

Vacuum pump 250 m3/h

Automatic lubrication

Waste conveyor

Listing

Cebrosa

Cebrosa

18,890 km

Vertical machining center

BULLERIFPM 2913

Call

Condition: used, Year of construction: 2004, functionality: limited functionality, travel distance X-axis: 2,500 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 250 mm, rotational speed (max.): 24,000 rpm, input voltage: 400 V, We offer this used vertical machining centre BULLERI FPM 2913, year of manufacture 2004.

If you have any questions or require further information, please do not hesitate to send us a message or call us.

Rbedpfsx Sq Uiox Ahzet

Listing

San Giovanni Al Natisone

San Giovanni Al Natisone

18,442 km

2005 BIESSE ROVER B 4.40 FT

BIESSEROVER B 4.40 FT

Call

Condition: used, Year of construction: 2005, 2005 BIESSE ROVER B 4.40 FT 3-axis CNC machining center

Technical features in the last photo

Engine hours on: 45,343

Rodpfx Ajwmdynjhzebt

Machine hours in automatic operation (work): 27,267

Listing

Lukovica

Lukovica

18,342 km

Machining center

MorbidelliAuthor 444S

Call

Condition: good (used), Year of construction: 2007, functionality: fully functional, travel distance X-axis: 5,000 mm, travel distance Y-axis: 1,700 mm, travel distance Z-axis: 180 mm, rapid traverse X-axis: 45 m/min, rapid traverse Y-axis: 45 m/min, rapid traverse Z-axis: 30 m/min, feed length X-axis: 4,500 mm, feed length Y-axis: 1,300 mm, feed length Z-axis: 180 mm, feed rate X-axis: 45 m/min, feed rate Y-axis: 45 m/min, feed rate Z-axis: 30 m/min, controller manufacturer: esa, controller model: kvara 6, workpiece length (max.): 4,500 mm, workpiece width (max.): 1,300 mm, workpiece height (max.): 180 mm, total height: 2,750 mm, total length: 7,000 mm, total width: 3,000 mm, table width: 1,200 mm, table height: 950 mm, table length: 4,500 mm, rotational speed (min.): 24,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 5,000 kg, spindle speed (min.): 24,000 rpm, spindle speed (max.): 24,000 rpm, spindle motor power: 7,500 W, number of spindles: 2, number of slots in tool magazine: 10, mount diameter: 200 mm, tool length: 200 mm, tool diameter: 150 mm, tool weight: 5,000 g, input voltage: 400 V, Equipment: documentation/manual, rotational speed infinitely variable, Electronic control with PC Office

Software Xilog Plus

Remote control device to manage the main functions of the machine

Working area: 4.400 x 1.300 x 180 mm.

Working table “Nesting” aluminum

Reverse flow system

Nr. 6 Back stops

Nr. 6 Drowned intermediate stops at 620 mm. from backside

Nr. 1 Electrospindle 7,5 KW – HSK 63

Tool changer RAPID at nr. 10 positions

Motor 2 manual tool change HSK63F

Disc unit 0-90 4 hp

Boring unit:

Nr. 18 independent vertical spindles

Nr. 3 Independent horizontal spindles with double outlet, nr. 2 in “X” direction and nr. 1 in “Y” direction

Nr. 2 Vacuum pump of 250 m3/h

Automatic lubrication

Aspiration system optimized

Safety nets and bumper

CE Marks

Rbodpeufgg Refx Ahzjt

Listing

Almelo

Almelo

18,480 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

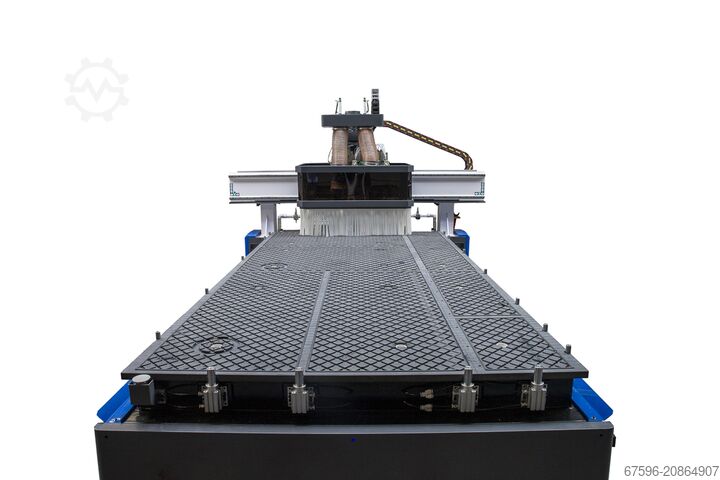

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Rjdpfx Ahox R D Rnezobt

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Listing

Almelo

Almelo

18,480 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

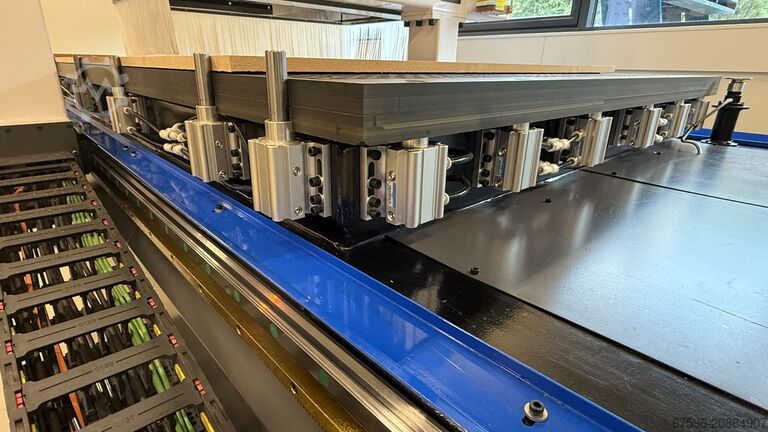

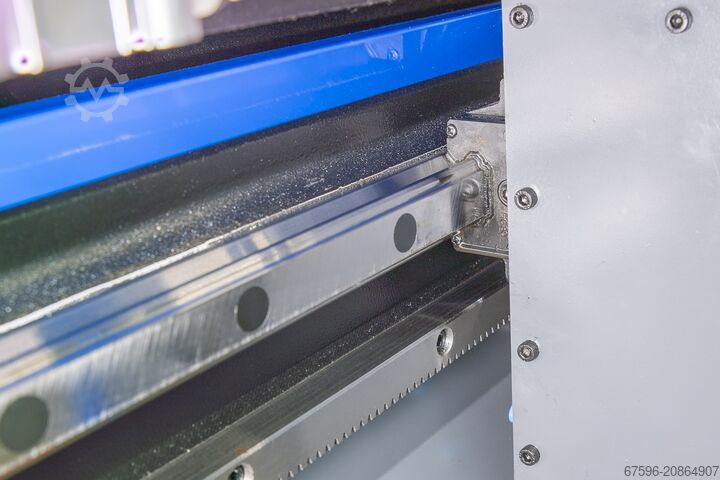

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Rbodpfxsx Rz Aus Ahzjt

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

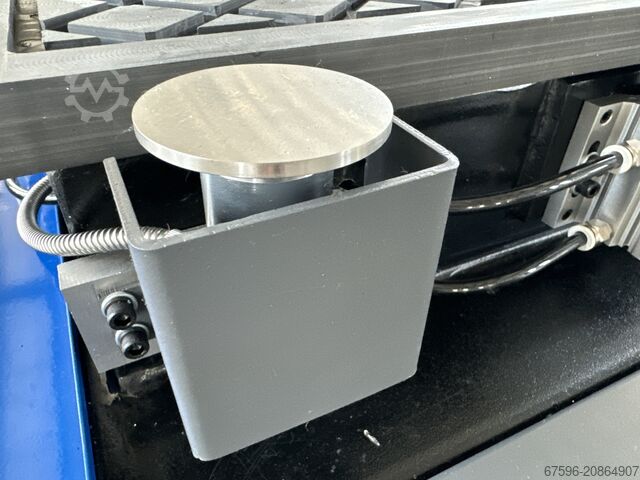

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Listing

Almelo

Almelo

18,480 km

Machining center

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at bottom prices by eliminating expensive service contracts and on-site installation visits. Ideal for professionals who prefer to remain in control themselves.

The purchase price includes:

- CNC control “SYNTEC”

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools for sheet metal machining CNC machining centers.

Rjdpfx Ahjxx Uc Ujzsbt

• Parts supply: In the event of a defect within 12 months, components will be shipped free of charge after diagnosis (photo/video).

• Excluding labor costs: Replacement of the part is done by you or outsourced at your discretion.

• Designed with minimal maintenance requirements

• Digital preparation: via app or TeamViewer for direct online service. This makes technician visits unnecessary, resulting in significant cost and time savings.

• Online service: 24/7

Digital Support as an Alternative

• Video manuals: Clips covering calibration or part replacement

• Exploded view diagrams: Instantly identify the necessary component

Focus on functionality: Your machine, your management, our lowest price.

You can call or WhatsApp us for more information and/or to make an appointment.

WhatsApp:

Listing

Lukovica

Lukovica

18,342 km

Machining centre

SCMRECORD 110ALXLTWNPR

Call

Condition: good (used), Year of construction: 2010, operating hours: 25,000 h, functionality: fully functional, machine/vehicle number: AA2/001307, travel distance X-axis: 6,500 mm, travel distance Y-axis: 1,700 mm, travel distance Z-axis: 250 mm, rapid traverse X-axis: 60,000 m/min, rapid traverse Y-axis: 45,000 m/min, rapid traverse Z-axis: 30,000 m/min, feed length X-axis: 6,500 mm, feed length Y-axis: 1,300 mm, feed length Z-axis: 1 mm, feed rate X-axis: 6,000 m/min, feed rate Y-axis: 45,000 m/min, feed rate Z-axis: 30,000 m/min, nominal power (apparent): 15 kVA, controller manufacturer: NUM, controller model: 1040, workpiece length (max.): 6,500 mm, workpiece width (max.): 1,350 mm, workpiece height (max.): 180 mm, total height: 2,750 mm, total length: 8,000 mm, total width: 4,000 mm, table width: 1,350 mm, table height: 950 mm, table length: 6,500 mm, spindle speed (min.): 24,000 rpm, spindle motor power: 11 W, Working travel of axes X-Y-Z: 6500 x 1350 x 250 mm

Working area: 6500 x 1250 mm

C-Axis = 640, B-Axis = 270

PRISMA milling unit with 5 interpolating axes X, Y, Z, C, B

Electric spindle 11 kW, 600–20,000 rpm

Tool holder HSK63

Working table with TVN pads and vacuum cups

Cross laser projector on working table

TVN vacuum cup

Pneumatic clamps

Tool magazine for 24 tools

Drilling unit

Vacuum pump 5.5 kW, 250 m³/h

CNC control NUM

Operating system: Windows XP

Xilog Plus

Maestro

Weight approx. 5,450 kg

Redpfxsw Au N Se Ahzebt

Listing

Bad Honnef

Bad Honnef

18,588 km

Machining center HOLZ-HER 7405 EVOLUTION CONNECT -exhibition machine-

Holz-Her7405 EVOLUTION CONNECT

Call

Condition: new, HOLZ-HER 7405 EVOLUTION CONNECT machining center

-Exhibition machine-

This offer is an equipment package.

The following items and options are already included in the price:

- Material support

- Height-adjustable infeed roller conveyor

- EVOLUTION diamond formatting cutter set

Rbjdpeu Tid Hofx Ahzet

- CAMPUS V8 EVOLUTION CAD/CAM software

- Flat screen 21.5", 16:9

- Workpiece length measurement LASER

- Milling unit 7830

- 7887 tool changer 6-position magazine pick-up

- ECO vacuum system

- Air conditioning unit for switch cabinet cooling

- Tool changer 7874

- Angular gear 7869

- Adapter for Clamex milling cutters

- Tool set - 4-axis CLAMEX

- Tool holder HSK-F 63

- Drilling unit XL 7885, 19 spindles

- Manual control unit

- Tool set - EVOLUTION for XL drilling head 7885

- new exhibition machine -

Listing

Bad Honnef

Bad Honnef

18,588 km

MASTERWOOD machining center project TF 100 2.0

MasterwoodProjekt TF 100 2.0

Call

Condition: new, - Edition Partnership -

With our TF 100 2.0 "Partnership Edition" we offer

CNC technology for the highest demands.

And at a sensational price.

Drilling, grooving, milling

Unique in operation and in the

"Partnership Edition" even more so in terms of features:

The TF 100 2.0, specially developed for furniture and interior

TF 100 2.0, specially developed for furniture and interior

than 5 m² production area, it can perform drilling

5 levels of the workpiece, groove sawing work

and also milling work.

The machine impresses with its extremely high

processing speed with maximum precision

Rbodpju Tiwvofx Ahzst

and ease of operation. The

standard pre-equipment for angular gears, the optional

the optional CLAMEX and lock case milling cutters can be

can be retrofitted easily and at any time.

The TF 100 2.0 "Partnership Edition" is completely manufactured in

in our large factory in Rimini, the headquarters of

Masterwood, and is 100% "Made in Italy".

----- Technical data -----

Max. workpiece length X: unlimited,

max. workpiece length Y: 1,000 mm,

max. tool thickness Z: 60 mm,

Vertical spindles X - direction: 5 pieces,

Vertical spindles Y - direction: 5 pieces,

Horizontal double drilling spindles X - direction: 2 + 2 pieces,

Horizontal double drilling spindles Y - direction: 1 + 1 piece,

Units: 16 drill head,

Drilling spindle speed: 4,000 rpm,

Distance between drilling spindles: 32 mm,

Motor power: 1.7 kW,

Grooving saw: X - direction,

Saw blade Ø: 125 mm,

Extraction connection Ø: 150 mm,

Dimensions (LxWxH): 1,920 x 2,818 x 1,620 mm,

Weight: 1,500 kg

Listing

Stalowa Wola

Stalowa Wola

17,688 km

CNC milling plotter

SeronNóż cnc, ploter bigująco-tnący

Call

Condition: new, Year of construction: 2026, CNC knife, creasing and cutting plotter, cutting plotter, creasing plotter

Machine configuration:

Drives: Helical hardened ground X, Y

ball screw Z axis

Linear bearing: Trapezoidal rails

Travel speed: 80 m/min

Program resolution: 0.005 mm (0.0025 servo motors)

Positioning accuracy: 0.01 mm

Double-sided gate drive: yes

Electrospindle power: 7.5Kw S6

Maximum electrospindle speed: 24000 rpm

Electrospindle inverter: yes

Brushless electrospindle: yes

Cutter shank diameters: from 1 to 20 mm

Construction: Steel welded

Power supply: 400 V

Possible additional options:

- tool cooling

- positioning bases with control

Rbedpfxst N Stxs Ahzot

- central lubrication system

- Pneumatic extraction foot

- Manual manipulator

- 10-position linear magazine

- 1.50 mm pneumatic oscillating knife

- Creasing head

- Circular knife

- Material height sensor

- Tool length and diameter sensor

- 24-inch touchscreen monitor

- Remote service access

- 244 m3 vacuum pump with control system

- Gate angle auto-calibration

- Intelligent energy recovery

- Safety fence

Material fixing: Vacuum, pneumatically controlled sections with expansion valve

Control Real-time industrial control system

steel and soft metals: aluminum, brass, copper, bronze etc.

composites: dibond, alucobond, etc.

plastics: polycarbonate, PVC, plexiglass, teflon, polyamides, gambit, rubber, etc.

solid wood and wood-based panels: plywood, chipboards, MDF, OSB, etc.

paper, cardboard, foil, etc.

foams, extruded materials, etc.

leather, textiles etc.

#plotter #CNC #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Pywood #plytawiorowa #Chipboard #steel #aluminum #aluminum

#brass #stainless steel #cast iron #polypropylene #polycarbonate #acrylic #fermacell

Listing

Stalowa Wola

Stalowa Wola

17,688 km

Beam Machining Center 1363

SERONBeamCenter

Call

Condition: as good as new (ex-display), Year of construction: 2026, travel distance X-axis: 1,300 mm, travel distance Y-axis: 6,300 mm, travel distance Z-axis: 300 mm, Technical Data:

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN communication, EtherCat, sampling time below 2ms, correction map, RTCP tool tip tracking, remote service access.

Working Area: 1300×6300 mm

Z-Axis Clearance: 300 mm

Drive System: Servo drives with EtherCat protocol, X and Y axes with helical, hardened and ground racks (accuracy class 6), Z axis with precision class 6 ball screw, planetary gearboxes with backlash less than 1’.

Linear Bearings: Linear guides with preloaded tension.

Traverse Speed: Up to 30 m/min

Software Resolution: Up to 0.0001 mm

Positioning Accuracy: 0.01 mm

Electrospindles: 15 kW inverter-driven, liquid-cooled.

Tool Taper: HSKF63

Redpfsn Nv Rcjx Ahzebt

Maximum Electrospindle Speed: Up to 24,000 rpm

Construction: Welded steel, ribbed, stress-relieved, precision machined from a single setup.

Table Type: Beam table

Equipment Options:

- Schmalz dual-circuit beam system

- Schmalz pneumatic and mechanical workpiece clamps

- Positioning stops

- Dual-zone operation capability

- Chip extraction readiness

- Chip conveyor

- Turret tool magazine and 2 linear magazines (26 tools)

- Drilling aggregate: 12 vertical tools, 4 horizontal tools, 2x saw blades

- Functions: correction map and intelligent energy recovery

- Advanced safety system

- Compatibility with CAD/CAM programming software (for furniture, fronts, stairs, windows, doors, and other components)

- Automatic central lubrication

- Control cabinet air conditioning

- Remote service access, remote diagnostics

- Tool diameter and length measuring probe with diameter compensation via control system

- Laser projection for workpiece positioning

- Machine designed in the Industry 4.0 concept

- Tool life option

#ploter #CNC #router #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #chipboard #steel #aluminium #aluminum #BLUM

Listing

Stalowa Wola

Stalowa Wola

17,688 km

5 Axis Pro+ 4.0 Machining Center

SERON5 Axis Pro+ 4.0

Call

Condition: new, Year of construction: 2026, Technical data

Control system multi-axis real-time interpolator, with active

trajectory prediction, LAN communication, EtherCat, sampling time below 1ms,

correction map, RTCP, remote service access

Rbedpfx Ahjvyrgqezet

Working area 2100x4100mm

Z-axis clearance 400mm

Drive system servo drives with EtherCat protocol, X, Y hardened helical strips ground in accuracy class 6, Z axis ball screw in accuracy class 5

Linear bearings trapezoidal rails

Speed of travel up to 60 m/min

Program resolution up to 0.0001 mm

Positioning accuracy 0.01mm

Gate drive double-sided master/slave with gate angle correction

Electric spindle 17kw s6 tilt/rotate head kit axis range a= +- 185°, c= +- 320°, orbital k plus px-2 15/12 63f nc hsk63 for 5 axis machines

Tool cone HSK63F

Maximum speed of the electrospindle up to 24,000 rpm

Design welded steel, ribbed, stress-relieved, precisely machined

Milling cutter shank diameters from 2 to 20 mm (optional up to 26 mm)

Brushless electrospindle

Table type vacuum, pneumatic sections

Equipment options

3-position linear magazine

16-position revolver magazine with tool presence sensor

positioning bases and vacuum blocks

automatic central lubrication with solid grease

pressure booster

security fence

intelligent vacuum sections

wireless manipulator

sensor for measuring the length and diameter of the tool

positioning laser

Listing

Stalowa Wola

Stalowa Wola

17,688 km

5-axis Machining Center

SERONPRO+ 5Axis

Call

Condition: new, Year of construction: 2026, Working area: 1500 – 3000 x 2100 – 12000 mm

Z axis range: 500 – 1500 mm

Linear bearing: Bosch Rexroth 35

Redpfx Asn Nv H Sjhzobt

Speed: X, Y up to 45 m/min; C, A up to6000 degrees/min

Program resolution: 0,0005 mm

Positioning accuracy: 0,01 mm

Gate drive: double-sided master / slave with gate angle correction

Electrospindles: 8 kW up to 36 kW

Electrospindle inverter: yes

Maximum revolutions of the electro-spindle: 24 000 rpm (option 6000, 40 000 50 000)

Construction: Steel welded, ribbed, stress relieved, precision machined

Table type vacuum, hybrid, steel, aluminum with M16 or M18 holes

Listing

Stalowa Wola

Stalowa Wola

17,688 km

CNC milling plotter

SeronPRO+ Specialist Maszyna do obróbki zlewo

Call

Condition: new, Year of construction: 2026, Machine for processing sinks made of materials such as sintered quartz, granite, granite composites and ceramic models, etc.

Technical data:

MILLING PLOTTER 1325 PRO+ WORKING AREA 1300X2500MM

Z AXIS RANGE 700MM - PRO

OMRON SERVO AC HIGH SPEED DRIVES (SET WITH PLANETARY GEARS) 1.5KW ETHERCAT

INTELLIGENT ENERGY RECOVERY

OSAI OPENSMART REAL-TIME INDUSTRIAL CONTROL SYSTEM, CYCLE TIME BELOW 2MS, SUPPORT UP TO 16 AXES, ETHERCAT COMMUNICATION WITH THE CONTROL CABINET

AUTO CALIBRATION OF THE GATE ANGLE

EUCHNER HBA-103037 HAND MANIPULATOR

Rbsdpfx Aheualqqjzst

CONTROL CABINET AIR CONDITIONING

TOOL LENGTH SENSOR (60MM)

AUTOMATIC CENTRAL LUBRICATION WITH SKF SOLID GREASE

BEAM SYSTEM PNEUMATIC CLAMPS

SINK FIXING SYSTEM

DUST REMOVAL CHANNELS

BALL SCREW COVER ON THE Z AXIS

BLOWING SYSTEM FOR RIDING ELEMENTS

VACUUM SENSOR SYSTEM

DOUBLE SCRAPER SET

Listing

Stalowa Wola

Stalowa Wola

17,688 km

Machining center

SERONProNEST+

Call

Condition: new, Year of construction: 2026, Technical Specifications

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN and EtherCat communication, sampling time below 1 ms, correction map, RTCP, remote service access.

Working Area: 2100 x 3100 mm (option: 2100 x 4100 mm)

Z-axis Clearance: 100 – 300 mm

Drive System: Servo drives with EtherCat protocol, X and Y axes with hardened, precision-ground helical racks (accuracy class 6), Z-axis with ball screw (accuracy class 5), intelligent energy recovery.

Linear Bearings: Trapezoidal rails with protective strip.

Traverse Speed: Up to 80 m/min

Programmable Resolution: 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave system with gantry angle correction.

Electrospindles: 8 kW to 36 kW powered by inverter.

Tool Taper: HSK63F

Max Electrospindle Speed: 24,000 rpm

Frame Design: Welded steel, rib-reinforced, stress-relieved, precision-machined.

Table Type: Vacuum table

Optional Equipment:

- Linear drives

- Material positioning and correction via camera, laser, or touch probe

- 12-position turret tool changer

- Air-cooled tool system

- 3D laser or touch scanner

- Positioning stops

- 12-spindle drilling aggregate, angular aggregates

Redpfx Aerlkxmjhzsbt

- Pneumatic sections

- Panel storage

- Label printer, code reader

- Workpiece identification system

- CAD/CAM software for furniture, carcass, and front design

- Automatic labeling

- Pressure rollers for material feed

- Chip extraction system

#ploter #CNC #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #Particleboard #Chipboard #steel #aluminium #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell

Trust Seal

Dealers certified through Machineseeker

Listing

Stalowa Wola

Stalowa Wola

17,688 km

Machining center

SERON5 Axis ProG+

Call

Condition: new, Year of construction: 2026, Technical Data

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN and EtherCat communication, sampling time below 1 ms, RTCP, remote service access.

Rbjdpewhxcgefx Ahzot

Working Area: X: 2000-4700 mm; Y: 3000-30000 mm

Z-Axis Clearance: up to 3000 mm

Drive System: Servo drives with EtherCat protocol; X, Y, Z axes equipped with hardened, ground, helical racks accuracy class 6

Linear Bearings: Trapezoidal rails; quadruple guideway size 35 for Y axis, triple guideway size 35 for X and Z axes

Traverse Speed: X, Y up to 25 m/min; C, A up to 6000 degrees/min

Program Resolution: 0.0005 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Electrospindles: up to 50 kW

Electrospindle Inverter: Yes

Maximum Electrospindle Speed: 24,000 rpm (optionally 6,000 – 40,000)

Construction: Welded steel, stress-relieved, precision-machined gantry design

Table Type: Modular T-slot (steel or aluminum), separated from the main construction

Available Additional Options:

3D printing head

Tool cooling

Tool changer: linear, mobile linear, turret, or chain type

Cutting saws

Laser scanner

Wireless measurement probe

Machining area separators

Compensation map

Roll-up roof

Vacuum table

Suction foot for 5-axis heads

Dedicated CAD/CAM software

3D granulate printers can process a variety of plastics such as PLA, ABS, PETG, polyamides, or polypropylene.

#router #CNC #millingmachine #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #chipboard #steel #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell

Listing

Stalowa Wola

Stalowa Wola

17,688 km

Machining center

SERONPRO+

Call

Condition: new, Year of construction: 2026, Technical Data

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN communication, EtherCat, sampling time below 2 ms, correction map, RTCP, remote service access.

Working Area: X: 2500–4000 mm, Y: 6000–12000 mm

Z-Axis Clearance: 300–700 mm

Drive System: Servo drives with EtherCat protocol, X and Y axes with hardened and ground helical racks (accuracy class 6), Z axis with ball screw (accuracy class 5)

Linear Bearings: Trapezoidal guide rails

Traverse Speed: up to 80 m/min

Software Resolution: up to 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Electrospindles: 12 kW up to 50 kW powered by inverter

Tool Taper: ISO30 or HSK63 ER32

Maximum Electrospindle Speed: 24,000 rpm (optionally 6,000; 40,000; 50,000)

Construction: Welded, ribbed, stress-relieved steel frame, precision machined

Table Type: T-slot aluminum grid, solid aluminum, or solid steel

Equipment Options:

- Material positioning and correction via camera, laser, or measuring probe

- Linear or turret tool magazine

- Tool cooling with oil mist or chilled air

- 3D scanner (laser or contact)

- Positioning bases

Rbodpjn Sk Huofx Ahzot

- Additional angular/rotary axes

- Drilling and angular heads

- Pneumatic workpiece clamps

- Part marking

- Integration with industrial robot

- 3D CAD/CAM software

- Automatic central lubrication

- Automated liquid cooling system

#ploter #CNC #router #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #chipboard #steel #aluminium #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell #BLUM

Listing

Stalowa Wola

Stalowa Wola

17,688 km

CNC for capacitor welding

SERONCNC do zgrzewania kondensatorowego 1510

Call

Condition: new, Year of construction: 2026, travel distance X-axis: 1,500 mm, travel distance Y-axis: 1,000 mm, Technical Data:

X, Y axis travel range: from 600 x 900 mm up to 2100 x 2100 mm

Z axis range: up to 500 mm

Control system: Multi-axis real-time interpolator with active trajectory prediction, LAN communication, EtherCat, 2 ms sampling time, optional: RTCP tool tip tracking, correction map

Drive system: Servo drives with EtherCat protocol, X, Y axes with precision-ground helical racks (accuracy class 6), Z axis with precision-ground ball screw (accuracy class 5)

Linear guides: Trapezoidal rails

Rodpfjv T Uy Tex Ahzjbt

Traverse speed: Up to 90 m/min

Software resolution: up to 0.0001 mm

Positioning accuracy: 0.01 mm

Gantry drive: Dual-sided master/slave with gantry angle correction

Automatic head: SK type

Material: Steel, Stainless Steel, Aluminum, Brass

Welding range: Ø 3 - M 8

Stud welding range: M 3 x 6 - M 8 x 40, 50 to 100 Volt, fully adjustable, accuracy ± 1 Volt

Ball bearing

Min. tolerance / 490 Ws at 99 V

Stroke: Pneumatic 50 mm

Weight: 1.5 kg (without cable)

Option: CNC capacitor discharge stud welding MULTI-HEAD

Listing

Stalowa Wola

Stalowa Wola

17,688 km

CNC milling plotter

SERONExpert+

Call

Condition: new, Year of construction: 2026, Technical data

Control system Multi-axis real-time interpolator, with active trajectory forecasting, LAN communication, EtherCat, 2ms sampling time, optional RTCP tool end tracking, correction map

Working area X 600 – 2500mm Y 900 – 6100 mm

Redpfxon Nwifj Ahzjbt

Gate clearance and Z axis range 100 – 700 mm

Drive system Omron servo drives with EtherCat protocol,

X, Y helical slats hardened ground in accuracy class 6,

Z axis ball screw with accuracy class 5

Linear bearing Trapezoidal rails, Bosch Rexroth 25

Speed Up to 90 m/min

Acceleration Up to 1G

Program resolution Up to 0,0001mm

Positioning accuracy 0,01 mm

Gate drive double-sided master / slave with gate angle correction

Electrospindles 2 kW to 18 kW powered by an inverter

Tool taper ISO30 or HSK63 ER32

Maximum speed of the electro-spindle 24000 rpm (option 6 000, 40 000, 50 000)

Construction Steel welded, ribbed, stress relieved, precision machined

Equipment options

positioning and correction of the material by means of a camera, laser, measuring probe

linear, revolver tool magazine

cooling the tool with mist, chilled air

3D laser or touch scanner

positioning databases

additional angular / rotary axes

drilling units, angular

active oscillating knife, roller knife, drag knife, creaser, marker pen

pneumatic clamping clamps

chip extraction installation

Table type T-slot: aluminum profiles, solid aluminum, solid steel; vacuum; hybrid, pneumatic clamping clamps

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used machining centers with flat or grid table (337)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Bed Type Milling

- Bed Type Milling Machine

- Center Lathe

- Cnc Turning And Milling Center

- Flat Bed Cnc Lathe

- Flat Bed Grinding Machine

- Gear Griding Machine

- Machine Table

- Machining Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month