Used Stage for sale (2,499)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Hilden

Hilden

18,565 km

Lathe - cycle-controlled

MAS KOVOSVITMASTURN 70/4500 CNC

Call

Condition: used, Year of construction: 2009, dist. between centers 4.500 mm

greates pass round over bed 820 mm

Maximum cutting diameter 530 mm

control Heidenhain Manual Plus 4110

workpiece weight max. 2.500 kg

Cpsdpjyhq Tvsfx Ac Nou

spindle bore 128 mm

spindle nose DIN 55027 B11

turning speed range - spindle 0 - 1800 U/min

phase 1 0 - 450 U/min

phase 2 20 - 1.800 U/min

Max. torque stage 1 3.000 Nm

Max. torque stage 2 540 Nm

travel -x axis 360 mm

travel -z axis 4.500 mm

feed capacity - x 10 kN

rapid traverse 10.000 mm/min

dia. of quill 115 mm

total connected load 55 kVA

machine weight ab. 7000 kg

dimensions of the machine ca. 6.500 x 1.840 x 1.860 mmxmmxmm

Equipment/accessories:

-1 x faceplate

-5 x jaw chucks

-1 x closed steady rest

-Clamping jaws

-Multifix holder

-Turning tools

-Various tips

-Technical documentation

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

NC high-pressure clamp, high-pressure vise, NC precision machine vise, NC machine vise

RÖHMRKD-125

Call

Condition: used, NC High-Pressure Vice, High-Pressure Machine Vice RÖHM

NC Precision Machine Vice

Type: RKD-125

ID No.: 180467 / D2950

Year of manufacture: approx. 2010

Jaw width, step jaws: 125 mm

Jaw height, step jaws: 40 mm

Jaw width, attachment jaws: 135 mm

Jaw height, attachment jaws: 49 mm

Machine vice base width: 126 mm

Opening width, max.: 141 mm per side (only with step jaws, without attachment jaws)

Clamping force: 4 tons

Guideway height: 105 mm

- High-pressure vice with mechanical force amplifier

- Clamping force adjustable in 4 stages from 1 to 4 tons

- 2 clamping functions: single clamping with dummy and double clamping

Cjdpfxexxmf Uj Ac Njpu

- Various clamping ranges via 3 guide grooves in each base jaw

- Step jaws (reversible)

- Stable base body, ground on all sides

- Can be mounted horizontally, vertically and laterally

- Center jaw dimensions (L x W x H): 125 x 40 x 40 mm

- Attachment jaw dimensions (L x W x H): 135 x 20 x 49 mm

Dimensions (L x W x H): 680 x 135 x 155 mm

Weight: 56 kg

Good condition

Listing

Haan

Haan

18,559 km

PET Preform Injection Molding Machine

ENGEL4550 / 320 MacPET

Call

Condition: ready for operation (used), Year of construction: 2004, PET preform injection molding machine clamping force 320t injection weight 6935gr. screw 130mm preform removal system SERVO IV, TPS robot TRT-M4-72-E, 72-fold, 4-stage, incl. removal set, conveyor belt LT/h 1825

Output approx. 17,000 preforms/hour

Option1: MHT mold 72-cavity for 30.8 gr. PCO 1810 or 1881 (shorty, 28mm neck ring, 1.5 liter bottles)

Cpjdsnxkxwepfx Ac Nou

Option2: 72 core sets for 27.8 gr. PCO 1810 or 1881 (shorty, 28mm neck ring, 1.0 liter bottles)

Line comes from our own preform production and was in production until our new line was replaced.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wiefelstede

Wiefelstede

18,341 km

Pump control

Grundfos**Control 2000

Call

Condition: good (used), Year of construction: 1999, Pump control for centrifugal pump, high-pressure pump, water pump, multi-stage vertical centrifugal pump

-Manufacturer: Grundfos

-Type: Control 2000

-Control box with display

-Max. drive: 3.3 kW

Cpedpfx Aecwdmtjc Nju

-Dimensions: 380/210/H600 mm

-Weight: 20 kg

Listing

김해시

김해시

9,692 km

Mechanical multi-station press

AsahiseikiTP-65D

Call

Condition: ready for operation (used), Year of construction: 1990, Asahiseiki TP-65D

High-speed Transfer Press

Ram Stroke : 177.8mm

Shutheight: 508.0mm

Stroke Length: 25~100

Standard Specifications

Zigzag feeder is attached

Codpfxoyf R Hqs Ac Nopu

Stage Number: 14

MFD: 1990

Discover more used machines

Listing

Eilenburg

Eilenburg

18,239 km

Minibus

FORDTransit Custom 320L2 Limited Kombi AT AHK 2xSTür

Call

Condition: used, mileage: 32 km, power: 125 kW (169.95 HP), fuel type: diesel, gearing type: automatic, overall weight: 3,225 kg, first registration: 01/2026, color: grey, number of seats: 9, total length: 5,450 mm, total width: 2,275 mm, total height: 1,984 mm, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), navigation system, soot filter, Internal Number: 34557

Errors and prior sale excepted! ----

SPECIAL EQUIPMENT

* 3 USB ports for the 2nd row of seats

* Electrically swiveling tow bar

* 2nd row windows: pop-out windows in the side walls

* Rear air conditioning

* 70 l fuel tank

Cpodpfx Aeyhkh Hec Neu

* Inductive charging station for mobile devices - Qi standard

* Wheels: 6.5 J x 17 alloy wheels in premium Carbonised Gray finish

* Electric sliding doors on both right and left - hands-free operation - Ford Key Free system including Ford Power start function - LED headlights

* Technology Package 5: electrically adjustable, heated, and foldable exterior mirrors - audio system with 13-inch multifunction display, Ford SYNC 4 including navigation - Blind Spot Assist incl. CTA rear cross-traffic emergency braking - Pre-Collision Assist, camera and radar-based - Driver fatigue alert - Lane departure, lane keeping, lane change assist, Lane Pilot - Traffic sign recognition - Wrong-way alert - Front and rear parking pilot system - Adaptive cruise control incl. Stop&Go function - Intelligent speed limiter with speed limit display - Reversing camera - Sensico leather-look steering wheel

* Front carpet floor mats

FURTHER EQUIPMENT

* 2 grab handles on driver and passenger sides

* Two-stage unlocking for passenger compartment and cargo area

* ABS

* Body-colored exterior mirror housings

* Flat roof

* Roof console

* Split rear door

* Rev counter

* Third brake light (LED)

* ESP - Hill Start Assist - Safety brake assist - Traction control

* Front electric windows with quick up/down function for driver and passenger

* Electronic parking brake

* FordPass Connect - WiFi hotspot, 5G modem (up to 5G/LTE, for up to 10 mobile devices)

* Heated windscreen

* Lockable glove compartment with lid

* Rear window, heated - fixed

* Rear window wiper

* Interior lighting in the passenger compartment

* Front interior lighting

* LED cargo area lighting

* Small center console

* Driver fatigue alert

* eCall emergency call system

* Front and rear parking pilot system

* Diesel particulate filter (DPF) with SCR catalyst

* Radio: 10 speakers

* Tire repair kit

* Tire pressure monitoring system

* Steering column gearshift

* Wipers with rain sensor

* Front and rear mud flaps

* Fixed side windows, third row, right and left

* Fixed side windows, second row, right and left

* Power steering

* Front seat belts

* Seats: Rear seat package 3 – 2nd row with 3 individual seats – 3rd row with 3-seater bench

* Seat package 47: Driver's seat manually adjustable in 4 directions with adjustable inner armrest – Fixed twin passenger seat – Headrests for driver and passenger – Heated seats for driver and outer passenger seat – Fold-out tray on passenger's seat – Lumbar support for driver – Side airbags, right and left – Passenger airbag – Front head/shoulder airbags, right and left – Barlo Style fabric upholstery in Black Onyx, seat back and side bolsters in Euro New Onyx fabric

* Start-stop system

* Socket: 12V outlet in the cargo/passenger area

* Front and rear bumpers painted in body color

* Carpet flooring throughout the vehicle

* USB port for the 2nd row

* Recirculation heating

* 4 lashing eyes

* Immobilizer

* Heat-insulating glazing, medium-tinted side windows from B-pillar

* Central locking with remote control – additional second remote key

… and much more ---- One owner. German vehicle.

Listing

Crailsheim

Crailsheim

18,536 km

Articulated telescopic work platform

Manitou180 ATJ

Call

Condition: used, Year of construction: 2024, total length: 7,790 mm, · Arbeitshöhe 18.19 m

· Plattformhöhe 16.19 m

· Maximale seitliche Reichweite 10.51 m

· Ãoeberhang / Knickpunkt Gelenk 7.55 m

· Korbarm-Drehwinkel (Boden) +-59.50 °

· Tragfähigkeit des Arbeitskorbs 230 kg

· Drehung des Oberwagens 350 °

· Drehung des Arbeitskorbs (rechts / links) 90 ° / 90 °

· Anzahl Personen (innen / außen) 2 / 2

· Gegengewicht Versatz (Oberwagen bei 90°) 0.22 m

· Innerer Wenderadius 1.38 m

· äußerer Wenderadius 3.75 m

· Fahrgeschwindigkeit - Transportmodus 5 km/h

· Fahrgeschwindigkeit - Arbeitsmodus 1 km/h

· Steigfähigkeit 45 %

· Zulässige Neigung im Arbeitsmodus 5 °

· Bereifung Schaumgefüllt

· Antriebsräder (vorne / hinten) 2 / 2

· Lenkräder (vorne / hinten) 2 / 2

· Gebremste Räder / Räder 0 / 2

· Hersteller / Motor Modell: Kubota - D1105-E4B

· Motornorm: Vorläufige Stufe 4, Stage IIIA, Stage V

· Nennleistung Verbrennungsmotor / Leistung (kW): 24.80 p / 18.50 kW

· Bodendruck 10 dan/cm2

· Hydraulikdruck 340 bar

· Fassungsvermögen des Hydrauliktanks 54 l

· Fassungsvermögen des Kraftstofftanks 52 l

· Schwingungsbelastung Hand/Arm < 0 m/s²

· Täglicher Verbrauch 4.26 l

· Diese Maschine entspricht: Europäische Richtlinien: 2006/42/EG - Maschinen(Neufassung EN 280:2013) - 2004/108/EG (EMV) -2006/95/EG (Niederspannung)

Cpsdpfxox Avu Ts Ac Nsu

Listing

Écouflant

Écouflant

19,216 km

Copy milling machine

ElumatecAS 170

Call

Condition: good (used), Year of construction: 2004, Large milling area despite compact construction

Copy milling machines with lateral stops or a template in 1:1 ratio

Two-stage pneumatic copying finger for two different cutter diameters

The patented suspension of the copying lever ensures precise milling with minimal effort

Table height adjustment for extremely high profiles up to 400 mm

Cpedsx Rixkjpfx Ac Neu

Simple tool change with "Spindle lock"

Pneumatic material clamping device

Spray device with dosing

Listing

Malakoff

Malakoff

18,980 km

Wire eroding machine

MitsubishiEA12VM ADVANCE

Call

Condition: excellent (used), FOR SALE

Cpodjyhgc Hepfx Ac Nju

Mitsubishi EA12VM ADVANCE Die-Sinking EDM:

General Information

- Manufacturer: Mitsubishi Electric

- Model: EA12VM ADVANCE

- Type: Die-Sinking EDM

- Year: approx. 2013

- Control: Mitsubishi M700 Series CNC with touchscreen interface

Machining Capacities

- Axis travels: X: ~400 mm / Y: ~300 mm / Z: ~300 mm

- Table dimensions: ~700 × 500 mm

- Max. workpiece dimensions: approx. 800 × 550 × 250 mm

- Max. workpiece weight: ~700 kg

- Max. electrode weight: ~50 kg

- C-Axis: Equipped with 3R/MACRO chuck for rotation and indexing

Generator and Features

- Power supply: FP80V (80 A) – FP120V (120 A) option available

- Technologies: GM2/SC/PS circuits for optimized speed and surface finish, Fuzzy Pro system

- Connectivity: USB and Ethernet

- Filtration: Dual-stage system with integrated chiller for dielectric thermal management

Dimensions and Weight

- Footprint: approx. 1750 × 2050 × 2335 mm

- Total weight: approx. 3700 – 3800 kg

Listing

Romania

Romania

18,654 km

BAZHOU Wanxin

BAZHOUWanxin

Call

Year of construction: 2021, condition: ready for operation (used), total height: 1,300 mm, product length (max.): 4,500 mm, Pipe Production Line manufactured in 2021. This Bazhou Wanxin machine features a dual-station decoiler, hydraulic shear and butt-welding machine, and a cold saw for precise cutting of pipes. It accommodates round pipes with diameters from Ø16-63.5 mm and offers a feeding speed of up to 120 m/min. Consider the opportunity to buy this Bazhou Wanxin Pipe Production Line. Contact us for further details.

• Dual-station decoiler

• Function: Passively unwinds the coil

• Construction: Dual-station with 180° rotation; manual expansion

• Advantage: Fast loading, simple operation

• Hydraulic shear and butt-welding machine

• Function: Cuts front/rear strip ends, centers, and re-welds

• Construction: Manual hydraulic shear with boom; front/rear pressure rollers; front/rear centering rollers; welding device

• Cutting method: Hydraulic shear

• Pressing method: Double-cylinder press

• Welding method: Manual welding

• Coil accumulator

• Function: Ensures continuous production during strip changeover

• Construction: Frame type with movable and fixed frames (incl. feeding device)

• Feeding speed: max 120 m/min

• Storage speed: max 200 m/min

• Stored strip length: 200–400 m

• Pinching roller motor: AC 11 kW

• Forming and calibration machine

• Working height: +850 mm

• Main drive power: AC/DC motor 160 kW, 1000–2000 rpm; reducer: gear-hardened; gearbox: spiral bevel gear

• Entry/formation: Passive 5-roll straightener; vertical rolls for strip feeding; forming via 7 horizontal + 8 vertical roll stands

• Guiding/pressing/deburring/cooling/calibration: 6 horizontal + 5 vertical roll stands; 1 round calibration stand

• Round calibration stand: 1 smoothing device; 2 sides with 8 rolls (4 per side); Ø30 mm rolls, 40Cr, quenched/tempered/hardened

• Horizontal roller shaft: Ø60 mm, bearing position 55, material 40Cr; surface hardening HRC 50–55

• Vertical roller shaft: Ø40 mm, material 40Cr, quenched/tempered/hardened

• Bearing slider: Forged steel 45#

• Stand style: Gantry type; opening width 120 mm; horizontal stand clamping adjustable via worm gear

• Stands material: Welded, aging annealed

• Pinching roller shaft: Ø50 mm, 2 rollers, manual screw adjustment

• Guide shaft: Ø40 mm

• Deburring knife: 2 pcs (1 in use, 1 spare)

• Cooling tank: Included

• Cold saw (Type KK-5-50)

• Function: Cuts pipes to preset length at line speed

• Pipe diameter: Round Ø16–63.5 mm (and corresponding square/rectangular)

• Cutting length: 1–6 m

• Material thickness: 0.6–2.5 mm

• Saw motor: 11 kW AC with frequency inverter

• Feeding motor: 2.9 kW servo (Yaskawa)

• Drive motor: 11 kW servo (Yaskawa)

• Feeding mode: Servo multi-stage speed

• Speed following: max 110 m/min

• Clamping: Pneumatic

• Saw blade: Ø400 mm

• Saw reducer: Model KK-80

• Sawing stroke (rack length): 3 mNote

• The technical data and descriptions are transcribed from the original order confirmation and are for informational purposes only; they are not binding.

Cpjdpfx Acoyhfvlo Nsu

Additional equipment

• Conveyor track, table, and packing machine

• Function: Automatic pipe transfer from mill to table; packages into hexagonal bundles

• Roller track length: 16 m

• Drive: 1 motor YCT200-4A, 5.5 kW

Listing

Obertraubling

Obertraubling

18,411 km

Box wagon high + long

Mercedes-BenzSprinter317CDI L2H2.AHK-3,5t.Klima.Kamer

Call

Condition: good (used), functionality: fully functional, mileage: 83,688 km, power: 125 kW (169.95 HP), fuel type: diesel, gearing type: mechanical, wheelbase: 3,665 mm, overall weight: 3,500 kg, empty load weight: 2,130 kg, maximum load weight: 1,370 kg, first registration: 10/2021, next inspection (TÜV): 10/2027, loading space length: 3,272 mm, loading space width: 1,780 mm, loading space height: 1,940 mm, emission class: euro6, color: white, number of seats: 3, number of previous owners: 1, Year of construction: 2021, Equipment: ABS, air conditioning, airbag, all-season tires, central locking, electronic stability program (ESP), fog lights, immobilizer system, navigation system, onboard computer, power assisted steering, sliding door, soot filter, trailer coupling, truck registration, 9147 Paint color Arctic White MB 9147

AR5 Axle ratio I = 4.727

C6L Multifunction steering wheel

CB7 Stabilization Stage I

CL1 Steering wheel adjustable in tilt and height

D03 High roof

D50 Full partition wall

E07 Hill start assist

E1D Digital radio (DAB)

E3M MBUX multimedia system with 7-inch touchscreen

E43 13-pin trailer socket

F68 Heated and electrically adjustable exterior mirrors

FF5 Over-windscreen storage shelf

FJ4 Storage compartment under dashboard

FKA Panel van

FR8 Reversing camera

FY7 Multi-button remote control

GD8 6-speed manual transmission ECO Gear

H20 All-around thermal insulation glass

HH9 Semi-automatic climate control Tempmatic

IH6 Headunit ECE/ROW

IK0 Complete vehicle

IR4 Wheelbase 3665 mm (BM code)

IT4 3.5-ton vehicle

J52 Engine oil level display at cold start

J65 Outside temperature display

JA8 Crosswind assist

JI7 Maintenance interval 60,000 km

K13 Main tank 71 liters

KP7 SCR Generation 4 emission control

L94 Omission of parking lights

LA2 Light assistant

LB1 Side marker lights

LB5 3rd brake light

LE1 Adaptive brake light

MD3 Speed limitation 120 km/h

MJ8 ECO start-stop function

MT2 Emission standard Euro 6D-TEMP N1 Gr.III/N2

MU5 Engine OM654 DE 20 LA 125 kW (170 hp)

Q11 Longitudinal member reinforcement

QA7 Towbar for increased towing capacity 3.5 t

QA9 Step at rear wall door for towbar

RH2 Tires 235/65 R16 C

S02 Driver's seat

S22 Armrest for driver's seat, ISOFIX (child seat anchorage system)

S23 Dual passenger seat

SA5 Driver's airbag

SK2 Driver's seat occupancy detection

T16 Sliding door right

T77 Grab handle at load compartment sliding door on partition wall

T86 Entry handle at rear right corner pillar

Cpsdpfx Acoyhfh Ue Nsu

V43 Wooden floor

V94 Conduit on side wall

V95 Conduit on rear portal

VA2 Interior panelling load compartment up to roof height (wood)

VF7 Maturin black fabric

W54 Twin rear doors 270 degrees

X99 Manufacturer Mercedes-Benz AG

XC9 COC documents

XG7 Without uprating/derating 3500 kg

XM1 Noise reduction measure

Listing

Newton Aycliffe

Newton Aycliffe

18,490 km

PET Bottle Recycling Line 2,000 kg/h

SKM2,000 kg/hour

Call

Condition: used, Used PET Bottle Recycling Line. Approximately 2,000 kg/hour (4,400 lbs/hour) input, producing about 1,700–2,000 kg/hour (3,750–4,400 lbs/hour) of clean PET flakes depending on feedstock quality and operating conditions. The line was built in 2011-2012. Originally designed for processing post-consumer PET bottles into clean PET flakes. Includes bale breaking, bottle sorting, size reduction, hot and cold washing, polymer separation, flake sorting, and bagging.

Main Equipment Includes:

Infeed conveyor

Bale breaker

Metering screw conveyors

Star screen classifier

Vibrating chute

(2) Sesotec optical bottle sorters

(4) Collecting conveyors

Cutting mill (Model KSM 800-1530)

Friction washers

Hot washers with recirculation systems

Sink-float separation stage

Post washer and recirculation system

Cpsdpfxjyhc S Ro Ac Nsu

(2) Double-stage air separators

Sesotec optical flake sorter

(9) Filling stations

Electrical control system

Steel structures and piping

More information is available on request.

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Pieralisi Used Complete Line Jumbo 3 2000 for oil production - 3 tons per hour

PieralisiJUMBO 3

Call

Condition: used, Year of construction: 2000, machine/vehicle number: LC590, Technical Specifications & Performance Data

This second hand complete oil production line is engineered for continuous olive oil extraction with industrial reliability and efficiency. Designed and manufactured by Pieralisi, the JUMBO 3 configuration delivers consistent throughput for food-grade processing and can be integrated downstream with bottling equipment for industrial packaging operations.

Codoyhb Auopfx Ac Nepu

Manufacturer: Pieralisi

Model: JUMBO 3

Production capacity: 3 tons per hour

Application: Edible oil extraction and clarification

Line composition: Leaf remover, washer, crusher, malaxers (7 units total), decanter, separator, conveyors

Year of manufacture: 2000

Configuration: Complete process line, suitable for integration with a used bottling line for final packaging

Advanced Automation & Control Systems

The Pieralisi JUMBO 3 platform is known for robust process control across extraction stages. The line supports synchronized operation from fruit preparation through separation, ensuring stable throughput and repeatable quality. Quick adjustments on the malaxers and decanter support optimization for different olive batches and temperatures.

Process-stage synchronization for steady 3 t/h throughput

Adjustable malaxing parameters for yield and quality optimization

Consistent separation and clarification via decanter and final separator

Operator-friendly controls supporting safe and reliable operation

Production Line Integration Capabilities

Engineered as a complete process solution, this second hand line interfaces easily with upstream fruit intake and downstream industrial packaging or bottling equipment. Conveyors enable smooth material handling between stages, while modular elements facilitate format and process adjustments.

Inline integration with depitting, storage, and bottling/packaging lines

Conveyor-based transfers between preparation, malaxing, and separation

Flexible setup for edible oil production workflows

Machine Condition & Maintenance History

The complete line has been dismantled and stored. Components are complete as listed, ready for inspection and recommissioning at the new site.

Operational status: dismantled and in storage

Complete core components included as listed

Operational Performance & Versatility

With a 3 tons per hour capacity, the line delivers stable performance across critical stages of oil extraction. The seven malaxers provide thermal and residence-time flexibility to balance yield and flavor profile. The decanter and final separator ensure efficient solids-liquid separation and product clarity suitable for edible oil standards.

High-throughput crusher feeding multiple malaxers

Seven malaxers: 2 double and 3 single units (7 malaxing sections total)

Decanter centrifuge for primary separation

Final separator for polishing and clarity

Installation Requirements & Site Preparation

Recommissioning requires appropriate floor space for the process modules and conveyors, utility hookups, and material flow planning from fruit reception to clarified oil storage an...

Listing

Nicaragua

Nicaragua

18,643 km

Used UHT Milk Preparation Room Tetra Pak 4000 L-h

Call

Condition: used, Year of construction: 2006, machine/vehicle number: LC562, Used UHT Milk Preparation Room Tetra Pak 4000 L-h

Operating Capacity and Product Versatility

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers optimized aseptic thermal processing for dairy and beverage applications. Specifically, the unit operates at variable flow rates from 2000 to 4000 liters per hour, making it suitable for plain milk, flavored milk, drinking yoghurt, and condensed milk. Furthermore, with program adjustments, the same line also processes fruit juices, nectars, and soft drinks. As a result, this flexibility makes it ideal for multi-product operations. The plant currently remains in storage, and as such, is ready for relocation and installation in a new production facility.

In-Line Aseptic Homogenization

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h includes an aseptic homogenizer manufactured by Tetra Pak, model Tetra Alex, year 2006. In particular, this unit, positioned downstream of preheating, operates in sterile conditions to ensure the breakdown of fat globules and uniform dispersion of solid and liquid phases. Consequently, it helps preserve the emulsion stability of flavored milk and yoghurt drinks. Moreover, the inline aseptic design reduces contamination risk after thermal processing. Therefore, it maintains the product’s physical and chemical consistency throughout downstream stages. In addition, the robust construction simplifies cleaning and routine maintenance.

Clean-in-Place (CIP) System

The line integrates a CIP (Clean-in-Place) system supplied by Gemak in 2009, which consists of four dedicated tanks: nitric acid, caustic soda, hot water, and rinse water. Notably, the system automatically sanitizes all product-contact surfaces under controlled parameters. In doing so, it ensures compliance with hygiene standards across multiple cleaning phases. Additionally, it manages solution recovery and water usage optimization across all cleaning circuits. As such, the CIP system in the Used UHT Milk Preparation Room Tetra Pak 4000 L-h minimizes downtime and supports continuous production. Above all, it protects product integrity between production cycles.

Thermal Treatment and Holding Time Control

The sterilization process relies on a holding coil supplied by Tetra Pak in 2006, designed to maintain the product at the target temperature for the required time. When paired with a tubular UHT heat exchanger, this coil enables indirect and uniform thermal processing. Thus, the system ensures accurate residence times and optimal microbial reduction. Likewise, the unit maintains organoleptic properties through consistent thermal transfer. Therefore, the Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers reliable processing for both dairy and plant-based applications.

Deaeration and Sterile Storage

Cedjyhbudepfx Ac Nspu

The system includes a Tetra Pak deaerator from 2006, which removes dissolved oxygen and unwanted gases before the UHT process. Accordingly, it improves product shelf-life and minimizes oxidative degradation. Furthermore, the deaerator connects directly to a 3500-liter sterile tank, model Alsafe, also by Tetra Pak (2006). Because of this connection, the product transfers in a closed, sterile environment. In turn, this configuration preserves product sterility after treatment and maintains aseptic conditions up to the filling stage.

Technical Conclusion

In summary, the Used UHT Milk Preparation Roo...

Listing

Schwanberg

Schwanberg

18,287 km

Rotary screw compressor

AGRE ALUPSonetto 7,5+ 10

Call

Condition: new, Screw compressor

AGRE

Model Sonetteo 7,5+ 10

Csdpfx Ajhun Tzjc Nepu

Screw compressor compact unit incl. refrigerant dryer and DL tank 270 lt.

Belt driven. Space saving. Inexpensive.

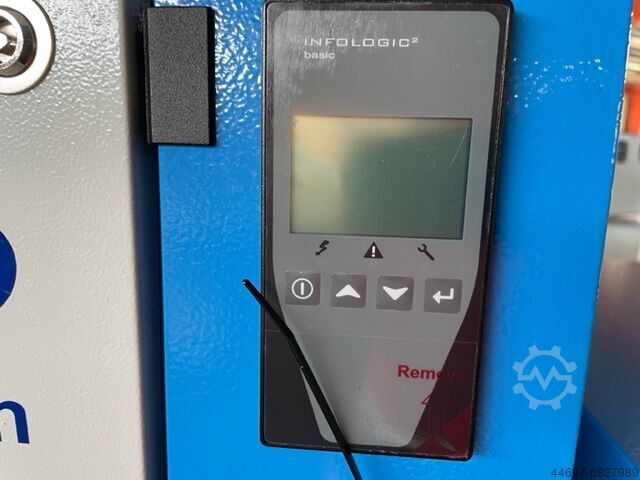

Easy operation thanks to Infologic² Basic control.

Efficient compressor stage. Perfect solution for industrial and craft businesses.

Convincing compressed air quality.

Mounted refrigeration dryer.

Equipment in detail:

Compression concept: oil-lubricated screw compressor

Cooling: air-cooled, efficient cooling system

Drive: Efficient IE3 motor, belt drive

Control: fixed speed

Control: Infologic² Basic control unit

Refrigerant dryer: Mounted, refrigerant R513A

Tank: 270 lt. horizontal painted 11 bar

Motor power: 5,5 kW

Pressure: 10 bar

Delivery rate: 780 lt./min

incl. time controlled condensate drain

Dimensions L x W x H = 1500 x 1350 x 600 mm

Listing

Schwanberg

Schwanberg

18,287 km

Veneer press

OTTJU 2513

Call

Condition: excellent (used), Year of construction: 1993, OTT Model JU 2513

Hydraulic veneer press with electric heating plates

Under-piston design

BUSSE electric heating plates

Central control panel with all operating elements

Analog temperature display for both heating plates

Pressing pressure infinitely adjustable via pressure switch device

Main switch

Two-stage hydraulic pump with automatic switching valve from low to high pressure

Emergency safety pull cord

Rack compensation

Stroke limitation

CE compliant

Press area: 2500 x 1300 mm

Number of press cylinders: 4

Total pressing force: 70 t

Csdpfx Acoxgpaqe Nopu

Operating voltage: 3 x 400 V + N, 50 Hz

Total connected load: approx. 20.3 kW

Required space (L x W x H): approx. 2900 x 1250 x 1900 mm

Weight: approx. 3200 kg

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Used Nissei blow molding machine ASB 50MB 2010

NISSEIASB-50MB

Call

Condition: used, Year of construction: 2010, operating hours: 39,000 h, machine/vehicle number: SO134, Technical Specifications & Performance Data

This Nissei ASB ASB-50MB is a one-stage biaxial orientation stretch blow molding machine designed for precision PET bottle production. As a compact rotary indexing platform, it integrates injection and blow molding in a single cycle, ensuring excellent neck finish accuracy and consistent wall distribution. This second hand machine offers reliable output for beverage production and industrial packaging projects seeking a proven, cost-effective solution.

Manufacturer: Nissei ASB engineering

Model: ASB-50MB

Manufacturing year: 2010

Process: One-stage ISBM (injection-stretch-blow)

Production speed: approx. 1000 bph with 4 cavities

Cavities: current setup 4 (machine supports 1–6 cavities depending on article)

Bottle formats: 40 ml to 750 ml

Cpjdpsyhbf Ajfx Ac Neu

Container type: PET bottles

Electrical data (plate): 400 V AC heater, 6.1 kW; motor 380 V AC 18.5 kW and 200 V AC 0.75 kW; 50 Hz

Installed power (approx.): 25.35 kW

Advanced Automation & Control Systems

The ASB-50MB platform offers stable, repeatable operation with synchronized control of injection, conditioning, stretching, and blowing stations. Its rotary indexing table ensures precise timing between stages, supporting high-quality bottle formation in a compact footprint. Operator interfaces facilitate routine adjustments and process monitoring, while integrated heating controls deliver accurate temperature profiles for consistent preform conditioning.

Rotary indexing one-stage machine with coordinated station control

Dedicated heater power section for precise thermal management

Structured electrical supply at 50 Hz for stable operation

Designed for quick mold and format changeovers within the compatible size range

Integrated protections and interlocks for safe machine access

Production Line Integration Capabilities

This blow molding machine integrates seamlessly within a used bottling line or as a standalone PET container production unit. Its output can feed conveyors to downstream rinsing, filling, capping, and labeling equipment in beverage production and other industrial packaging applications.

Standalone or inline configuration with downstream bottling equipment

Compatible with standard conveyor interfaces

Format flexibility for 0.04L to 0.75L PET bottles

Suitable for water, juice, CSD, and other PET applications when paired with appropriate downstream systems

Machine Condition & Maintenance History

This second hand ASB-50MB is in good working condition and ready for operation. The machine shows approximately 39,000 operating hours, consistent with typical industrial usage while retaining solid performance potential for new production environments.

Operational status: ready for operation

Operating hours: approx. 39,000

Well-maintained example from a proven ISBM series

Operational Performance & Versatility

Known for robust build quality, the ASB-50MB delivers precise neck geometry and excellent clarity through controlled stretch ratios. The one-stage pr...

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Used Nissei blow molding machine ASB 50MB 2006

NISSEIASB-50 MB

Call

Condition: used, Year of construction: 2006, operating hours: 33,000 h, machine/vehicle number: SO135, Technical Specifications & Performance Data

This one-stage biaxial orientation stretch blow molding machine delivers consistent PET bottle production with reliable throughput and compact footprint. Manufactured by ASB INTERNATIONAL PVT. LTD. (Nissei ASB engineering), the ASB-50 MB combines injection, conditioning, and blow molding in a single machine, reducing handling and improving quality control for a second hand or used bottling line seeking dependable PET bottle supply.

Manufacturer: ASB INTERNATIONAL PVT. LTD. (Nissei ASB)

Model: ASB-50 MB

Machine type: One-stage biaxial orientation stretch blow molding machine

Year: 2006

Production speed: ~1,000 bottles/hour with 4-cavity mold

Cavities: Configurable 1–6; supplied in 4-cavity configuration

Formats: 40 ml to 750 ml (typical PET bottle sizes within this range)

Containers: PET bottles

Electrical supply: 400 VAC, 50 Hz

Installed power (observed): approx. 20.1 kW

Motor circuits: 380 VAC — 13.5 kW; 200 VAC — 0.5 kW

Heater circuits: 400 VAC — 6.1 kW

Advanced Automation & Control Systems

The ASB-50 MB architecture enables precise control of heating and stretch-blow parameters for stable bottle quality across different formats. Typical one-stage controls coordinate injection, conditioning, and blowing stations for repeatable results, with safety interlocks and guarding to protect operators. Quick-change mold capability supports efficient format changes, minimizing downtime during product transitions common in industrial packaging and beverage production environments.

Production Line Integration Capabilities

Designed for PET bottle manufacturing upstream of filling, capping, and labeling systems, this machine integrates effectively with conveyors, accumulation tables, and downstream bottling equipment. Its one-stage process eliminates the need for separate preform handling equipment (such as preform unscramblers, tippers, and elevators), simplifying line layouts in a used bottling line. Bottle format flexibility from 40 ml to 750 ml supports water, juice, CSD, and other beverage applications when equipped with appropriate molds.

Cedpjyhbfiofx Ac Njpu

Machine Condition & Maintenance History

This second hand machine is presented in ready-for-operation condition, suitable for immediate integration into an existing beverage production or industrial packaging setup. As with any pre-owned blow molding machine, commissioning checks and routine maintenance are recommended to align the installation with site utilities and product specifications.

Operational Performance & Versatility

The ASB-50 MB delivers stable output around 1,000 bph in a 4-cavity configuration, with potential to reconfigure up to 6 cavities depending on molds and process settings. Its one-stage design promotes excellent neck dimensional control and clarity, supporting a wide range of bottle shapes within the 40–750 ml range. When paired with suitable molds and process recipes, it can produce PET containers for still water, flavored beverages, and similar products, providing consistent quality for high-uptime pac...

Listing

Germany

Germany

18,260 km

Rapid Radial Drilling Machine

DONAUDanuflex 135

Call

Condition: used, Year of construction: 1997, Technical details:

bore capacity in steel (diameter): 35 mm

arm length: - mm

workpiece height max.: 660 mm

threading: GG 25 M36

threading: ST 60 M30

drill capacity in cast iron: 42 mm

tool taper: MK4

quill stroke: 165 mm

Table dimensions: 1200 x 600 mm

Codpfxoxu Dwgs Ac Nepu

column diameter: 170 mm

work height max.: 900 mm

current type: Drehstrom

total power requirement: 25 A

frequency: 50 Hz

connection voltage: 400 V

connected load: 6,5 kVA

dimension machine xH: 2,3 x 1,7 x 2,4 m

weight of the machine ca.: 2,5 t

Accessories and Equipment – DONAU DANUFLEX 135

Accessories:

·1 × Drill chuck

·2 × Angle plates

·1 × Machine vice

·1 × Clamping cube

Features / Equipment:

·Side drilling table, height-adjustable

·Drilling possible at up to 3 stations (front, left, rear)

·Two-stage spindle gearbox, automatic switching via push button

·Continously variable spindle speed control in each gear stage: 20 – 3,100 rpm

·Continuously adjustable feed rate

·Thread cutting device integrated

·Adjustable depth limit stop

*

Listing

Schwanberg

Schwanberg

18,287 km

Screw air compressor

AGRE / ALUPSONETTO 9

Call

Condition: new, Screw compressor with refrigeration dryer

Belt-driven. Space-saving. Affordable.

Easy operation thanks to Infologic² Basic control.

Efficient compressor stage. Perfect solution for industrial and trade businesses.

Impressive compressed air quality

Features in detail:

Compression concept: Oil-lubricated screw compressor

Cooling: Air-cooled, efficient cooling system

Drive: Efficient IE3 motor, belt drive

Control: Fixed speed

Control: Infologic² Basic control unit

Refrigeration dryer: Attached, refrigerant R513A

Receiver: Horizontal, painted, manufactured according to AD2000

Performance data:

Flow rate at operating pressure 9.5 bar: 0.98 m³/min

Operating pressure min. / max. 5.5 / 10.0 bar

Total power consumption at 9.5 bar / full load: 9.6 kW

Rated motor power; IP55 7.5 kW

Oil volume 3.2 lt

Pressure dew point of refrigeration dryer (20°C 100% RH) approx. +3 °C

Installation data:

Ambient conditions min. / max. 1 / 46 °C

ΔT above cooling medium temperature 2 °C

Cooling air requirement 756 m³/h

Free fan pressure 30 Pa

Noise level 68 dB(A)

Voltage / PH / Frequency 400 / 3 / 50 V / Ph / Hz

Refrigeration dryer power (230V/50Hz) 0.27 kW

Dimensions and weight:

Cjdpfxowm Ih As Ac Nepu

Length x width x height 1540 x 665 x 1350 mm

Weight 240 kg

Compressed air outlet G 1/2" female

Compressed air tank capacity 270 lt

INCLUDES OPTION:

Aftercooler C43 MINI (so that the Condensate accumulation is reduced to a minimum)

Listing

Hohenems

Hohenems

18,655 km

Screw Compressor DSDX243SFC

KaeserDSDX243SFC

Call

Condition: excellent (used), Year of construction: 2008, operating hours: 126,772 h, functionality: fully functional, Kaeser DSDX243SFC screw compressor, 132 kW with 8.5 bar and 26.90 m³/min. Integrated frequency converter. New compressor stage installed at around 45,000 operating hours.

Cpjdpfx Asyhakkec Nju

Trust Seal

Dealers certified through Machineseeker

Listing

Eilenburg

Eilenburg

18,239 km

Fire truck

FORDTransit Custom 320L2 Limited Stndhzg LED MTW 112

Call

Condition: used, mileage: 32 km, power: 100 kW (135.96 HP), first registration: 08/2025, fuel type: diesel, overall weight: 3,225 kg, color: red, gearing type: mechanical, emission class: euro6, number of seats: 9, total width: 2,275 mm, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), navigation system, parking heater, soot filter, Internal number: 74852----

Subject to errors and prior sale!

SPECIAL EQUIPMENT

* Windows: Side windows, 2nd row, fixed, right and left including sliding door right and left

* Heated rear window, fixed - Interior mirror - Partition with window

* Radio: Ford audio system with 13 inch multifunction display and Ford SYNC 4 including navigation - DAB/DAB+ - 13 inch TFT multifunction display - Integrated control panel and audio remote control on the steering wheel - Ford SYNC 4 with AppLink and touchscreen - AppLink - Amazon Alexa Built-in voice assistant

* Limited-slip differential, mechanical

* Auxiliary heating (fuel-water heating) with remote control including H7 AGM double battery

* MTW conversion: RAUWERS PHOENIX SOLARIS special signal bar - electronic siren city/country - Control unit for the special signal system on the center console - Antenna for digital radio - Third beacon at the rear - Schnierle individual seats

OTHER EQUIPMENT

* 2-stage unlocking for passenger compartment and cargo area (rear door flaps or rear swing door)

* Airbag (passenger side)

* Airbag driver side

* Anti-lock braking system with electronic brake force distribution

* Outside mirror housing in vehicle color

* Battery: H7 AGM single battery

* On-board computer with consumption and mileage information (e.g. B. remaining range) and outside temperature display

* Roof console

* Double-wing rear door with 180° opening angle (without window)

* ESP - hill start assist - safety brake assist - traction control

* Electric front windows - with quick-up/down switch for driver and front passenger

* Electronic parking brake

* Ford Key Free system - including Ford Power start function

* FordPass Connect - including live traffic information and WiFi hotspot 5G modem (up to 5G/LTE, for up to 10 mobile devices)

* Heated windshield

* Floor mats: rubber floor mats at the front

* Grab handle, driver and front passenger side

* Lockable glove compartment with lid

* Interior lighting at the front with delay switch

* Automatic air conditioning at the front - with recirculation heating - with R-1234yf coolant

* Front headrests

Cpjdpfxeyg Trxs Ac Nsu

* 55 l fuel tank

* LED headlights - LED high beam - LED low beam - LED daytime running lights including integrated LED indicators at the front - cornering light, static - high beam assistant

* Cargo area lighting (LED) - extra bright

* Cargo area floor: vinyl floor covering "Easy Clean"

* Steering wheel, Sensico in leather look

* Center console, small

* Emergency call assistant eCall

* Package: Technology package 2 (Limited) - Exterior mirrors with integrated indicators, electrically adjustable, heated and automatically foldable - Audio system 13?? Multifunction display and Ford SYNC - Pre-Collision Assist, camera-based - Fatigue warning - Traffic sign recognition system - Wrong-way driver warning function - Lane assist including lane keeping assist - Parking pilot system front/rear - Cruise control - Intelligent speed limiter with speed limit display - Rear view camera

* Particle filter: Diesel particle filter

* Radio accessories: 4 speakers

* Tire repair kit

* Tire pressure monitoring system

* Wheels: Light alloy wheels 6.5 J x 16, 10-spoke design - with 215/65 R 16 tires

* Windscreen wiper with rain sensor

* Sliding door right

* Mud flap rear

* Mud flap front

* High side paneling

* Power steering

* Seat belts - Seat belt tensioner and belt force limiter front - Warning system for driver's seat belt not fastened

* Seats: Seat package 46 - driver's seat,

Listing

Sonnenbühl

Sonnenbühl

18,638 km

Tool milling machine

DECKELFP1 Aktivdigital

Call

Condition: excellent (used), Year of construction: 2002, Control: 3-axis active path control, Heidenhain TNC 123

Spindle speed: 40 - 2000 rpm, geometrically stepped direct drive with 16 gear stages for maximum torque / milling performance

Feed rate: 5 to 500 mm/min, infinitely variable

Rapid traverse: 1.2 m/min

Cpjdpfx Asyg I Nfsc Neu

Quill: Extendable vertical quill, 60 mm, SK40 M16 draw thread

Axes X/Y/Z: 300/160/340 mm

Swivel table: 600 x 210 mm, max. load 200 kg

Listing

Germany

Germany

18,654 km

Arburg 520S-1500-400

Arburg520S-1500-400

Call

Condition: ready for operation (used), Year of construction: 2016, operating hours: 9,171 h, clamping force: 1,600 kN, screw diameter: 45 mm, controller manufacturer: ARBURG, This 3s Arburg 520S-1500-400 was manufactured in 2016. It features a clamping force of 1600 kN and a screw diameter of 45 mm, making it suitable for high-temperature thermoplastics. The SELOGICA direct control system with a 15-inch touchscreen enhances usability. Consider the opportunity to buy this Arburg 520S-1500-400 hydraulic injection moulding machine. Contact us for further details.

• Programmable and controlled build-up of clamping force

• Extended clamping program with 2 stages

• Hydraulic, servo-controlled ejector on moving platen

• Injection/plasticizing unit:

• Screw diameter: 45 mm (without nozzle)

• High wear-resistant version

• Sinter-metal check ring

• CrN coating on screw and check ring

• Suitable for abrasive, corrosive, and high-temperature thermoplastics

• Technology level 2 – servo-controlled, dual-circuit pump system:

• Two regulated hydraulic pumps for precise, parallel movements

• Programmable nozzle contact force and holding pressure

Codpfx Acoyg I Ihs Nspu

• Continuous oil circulation with additional cooling and filtration

• SELOGICA direct control system:

• Touchscreen operation with process editor

• 15-inch (38.1 cm) display

• Multilingual interface (German, English, local language)

• Heating capacity zones 1–6: 3.6 kW each (230 V / 16 A)

• Cylinder heating temperature up to 450 °C

• Connectivity/interfaces:

• OPC UA interface (MES/host computer connection)

• USB and CompactFlash interfaces for data storage

• EUROMAP 67 robot interface

• Prepared for ARBURG MULTILIFT robot system

• Utilities:

• Pneumatic supply with pressure regulator

• Cooling water distribution with adjustable circuits and flow indicators

• 400 V / 50 Hz, with neutral conductor

• Hours: 9,171

Additional equipment

• None included in the listing

• Note: Machine is prepared for robot integration (EUROMAP 67 interface; prepared for ARBURG MULTILIFT), but no robot/automation is included.

Listing

Germany

Germany

18,654 km

Arburg 520S-1500-400

Arburg520S-1500-400

Call

Condition: ready for operation (used), Year of construction: 2016, operating hours: 13,361 h, clamping force: 1,600 kN, screw diameter: 45 mm, controller manufacturer: ARBURG, This 3s Arburg 520S-1500-400 was manufactured in 2016. It features a clamping force of 1600 kN, a screw diameter of 45 mm, and a servo-controlled dual-circuit pump system for precise movements. The SELOGICA direct control system with a 15-inch touchscreen enhances usability. Consider the opportunity to buy this Arburg 520S-1500-400 hydraulic injection moulding machine. Contact us for further details.

• Programmable and controlled build-up of clamping force; extended clamping program with 2 stages

• Hydraulic, servo-controlled ejector on moving platen

• Screw diameter: 45 mm (without nozzle)

• High wear-resistant version; sinter-metal check ring; CrN coating on screw and check ring

• Suitable for abrasive, corrosive and high-temperature thermoplastics

Codpfsyg I Egsx Ac Njpu

• Technology level 2: servo-controlled, dual-circuit pump system with two regulated hydraulic pumps for precise, parallel movements

• Programmable nozzle contact force and holding pressure

• Continuous oil circulation with additional cooling and filtration

• SELOGICA direct control system with touchscreen process editor

• 15-inch (38.1 cm) display; multilingual interface (German, English, local language)

• Heating capacity zones 1–6: 3.6 kW each (230 V / 16 A)

• Cylinder heating temperature up to 450 °C

• OPC UA interface (MES/host computer connection)

• USB and CompactFlash interfaces for data storage

• Pneumatic supply with pressure regulator

• Cooling water distribution with adjustable circuits and flow indicators

• Electrical: 400 V / 50 Hz, with neutral conductor

• Hours: 13,361

Additional equipment

• None included as listed

• Robot/automation readiness: EUROMAP 67 robot interface; prepared for ARBURG MULTILIFT robot system

We make it easier for you to find: "stage"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Stage (2,499)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month