Used Homogenizer for sale (224)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Sankt Leon-Rot

Sankt Leon-Rot

18,615 km

Block heat and power plant

Bosch KWK Systeme GmbHCHP CE 140 N

Call

Condition: excellent (used), Year of construction: 2016, operating hours: 30,000 h, functionality: fully functional, Bosch CHP Complete System (1 Set) – CHP CE 140 N (Year 2016) including Cabero Heat Exchanger/Dry Cooler (Year 2017)

For sale is 1 complete, homogenous CHP unit consisting of 1× Bosch CHP Module CE 140 N (gas-powered CHP) including the corresponding peripherals as well as 1× Cabero heat exchanger/dry cooler.

The unit is operational and in very good condition. Sale only as a complete package.

1) CHP / CHP Module

Manufacturer: Bosch KWK Systeme GmbH

Model: CHP CE 140 N

Year of manufacture: 2016

Engine: MAN 2867 E 218 (gas-powered Otto engine)

Performance data (CE 140 NA / typical as per datasheet series):

Electrical output (nominal, 90/70°C): 70 – 140 kWel

Thermal output (nominal, 90/70°C): 106 – 212 kWth

Gas input: 192 – 384 kW

Modulation range: 50 – 100 %

Net efficiency: electrical 36.5 %, thermal 55.2 %, total 91.7 %

Power supply: 400 V / 50 Hz, 3-phase

Own energy consumption (electrical): 2,500 W

Max. operating pressure (heating circuit): 6 bar

Acoustics / emissions (CE series):

Module noise level: 71 dB(A)

NOx (dry, 5% O₂): ≤ 0.250 g/Nm³

CO (dry, 5% O₂): ≤ 0.300 g/Nm³

Dimensions (CE 140 NA – indicative values):

Width W ≈ 1,160 mm

Length L ≈ 3,850 mm

Required room height min. ≈ 2,900 mm

Wall clearance A > 900 mm

2) Cabero Heat Exchanger / Dry Cooler (1 unit)

Manufacturer: Cabero

Designation / Item No.: GCDD099MB-2X7-64-S D (EB) EC AXI A

Version / Standard: PED / DIN EN 14276-2:2011

Year of manufacture: 2017

Cgodpfxjycl Abe Abben

Heating surface: 2,742.65 m²

Medium: Ethylene glycol 34% / Water 66%

Fluid Group: 2

Max. allowable pressure (PS): 12 bar

Test pressure (PT): 17.16 bar

Permitted temperature range (TS): −40 / +60 °C

Volume: 439.5 L

Pressure test date: 03./04.07.2017

Listing

Mouvaux

Mouvaux

18,773 km

Meat processing machine

LutetiaBaratte T40

Call

Condition: ready for operation (used), functionality: fully functional, The Lutetia T40 tumbler is designed for processing plants seeking to secure their mixing operations with proven equipment. It ensures consistent and controlled blending of mixtures, contributing to uniform quality across all productions. As a result, recipes remain consistent and batch-to-batch variations are minimized. Additionally, the design of the drum promotes continuous movement of the materials, which improves final product homogeneity.

This tumbler integrates easily into existing production lines due to its layout, which meets the demands of daily industrial use. The front discharge configuration simplifies end-of-cycle unloading and enhances process throughput. Furthermore, the overall ergonomics make it easy to load the machine, reducing unnecessary handling. This results in more efficient and consistent operator workflows.

When Europ’Équipement refurbishes a Lutetia T40 tumbler, all mechanical and functional components are thoroughly checked. This ensures the user gets a reliable machine, ready for immediate integration into their facility. Refurbishment also represents a cost-effective alternative to new equipment, providing an industrial performance level while controlling budgets. Therefore, this solution fits within a sustainable and rational investment logic.

The Lutetia T40 is suitable for meat processing and value-added food applications that require continuous and repeatable operation. Its capacity meets the needs of medium-sized productions, making it a logical choice for industrial operators aiming to strengthen their production tools and secure their processes.

Technical specifications:

- Meat and brine capacity: 2,000 – 2,200 kg

Cgedsyfn Hbopfx Abben

- Usable volume: 3,675 L

- Operating mode: rotating drum

- Discharge: large-capacity front mouth

- Dimensions (L × W × H): 3,250 × 1,550 × 1,990 mm

- Drum diameter: 1,440 mm

- Loading height: 1,110 mm

- Machine weight: 1,500 kg

Listing

Mouvaux

Mouvaux

18,773 km

Meat processing machine

LutetiaBaratte T40

Call

Condition: ready for operation (used), functionality: fully functional, The Lutetia T40 tumbler meets the needs of processing workshops seeking a reliable solution for the consistent mixing of batches. It ensures homogeneous blending throughout the cycle, maintaining consistent product quality during production. This way, recipes remain stable and batch variations are kept to a minimum. Additionally, the Lutetia design promotes smooth material flow, further improving uniformity in the final product.

This tumbler integrates easily into existing production setups, as its architecture is designed for intensive use. Its robust structure ensures excellent stability during operation, even under heavy loads. Furthermore, its ergonomic design facilitates daily operations, including cleaning and maintenance, thus minimizing downtime and enhancing production continuity.

When Europ’Équipement refurbishes a Lutetia T40 tumbler, their teams inspect all mechanical components and control systems. This allows users to operate a reliable, immediately ready machine that is fully adapted to industrial requirements. Refurbishment also helps control investment costs while maintaining performance levels that align with production demands. As a result, this solution is both sustainable and economically sound.

The Lutetia T40 is suitable for meat processing and the manufacturing of processed products that require constant and repeatable mixing. In addition, it offers enough operational flexibility to handle various recipes and production speeds. Therefore, this tumbler is a smart choice for manufacturers aiming to improve process reliability while controlling operating costs.

Cgedjyfnvpjpfx Abbon

Technical specifications:

Meat + brine capacity: 2,000 – 2,200 kg

Usable volume: 3,675 L

Mixing mode: rotating drum

Discharge: high-capacity front discharge mouth

Dimensions (L × W × H): 3,250 × 1,550 × 1,990 mm

Drum diameter: 1,440 mm

Loading height: 1,110 mm

Machine weight: 1,500 kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Borken

Borken

18,513 km

Transformer Kernprüfanlage isolation tra

Betschart SwissKPA 15 Prüfanlage

Call

Condition: good (used), Betschart Swiss transformer core testing system KPA 15

function

The output voltage, which can be infinitely adjusted by hand using a rotary knob, is fed directly to the excitation coils of the test core.

As a result, in the air gap of the test core a homogeneous electromagnetic field is to be built up, with which core material inserted into the air gap can be characterized.

The basic operation of the core testing system is carried out via the switching and display elements on the front panel on the front of the test car.

Technical specifications

Input voltage: 2 x 400 V - 50/60 Hz

Input current: 38.3 A maximum

Output voltage: 0 ... 230V

Output current: 65 A maximum

Measurements: Moving iron voltmeter 0 ... 500V for input voltage

Moving iron Voltmeter 0 ... 250V for output voltage

Moving iron ammeter 0 ... 40 / 80A for input current

Moving iron ammeter 0 ... 75 / 150A for output current

Laboratory sockets for external voltage measurement direct, 1: 1

Miniature circuit breaker 2-pole, 63A characteristic B

Voltage measurement output voltage

Current measurement output current

Voltage measurement input voltage

Current measurement input current

Laboratory sockets for external current measurement Current transformer 50A / 5A

Current measurement current transformer 75A / 5A output side

Main and emergency stop switch

Cgedpfx Aed Nxhkjbben

Manufacturer price: 27,000, - € gross

Matching variable transformers can be found in our shop

More articles - new and used - can be found in our shop!

International shipping costs on request!

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

16,878 km

Asphalt mixing plant

Polygonmach240 tph asphalt plant hot mix batch type

Call

Condition: used, color: orange, Warranty: 24 months

Productivity: 100 tph

Polygon can produce mobile or fixed asphalt plants with capacities of 60-240 tons/ h quality asphalt plant are produced with experienced staff.

Polygon batch Mix Asphalt Plants Advantages

Optimum price, high performance

Precision weighing and high quality blend

High efficiency rotary dryer and burner

Easy Maintenance

7-24 after sale support

Possibility of asphalt mixing plant spare parts at reasonable prices

Operator friendly asphalt plant automation system

Easy assembly and disassembly possibility

Products suitable for different asphalt production (mastic asphalt, colored asphalt, recycling

Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader.

Cold feed bins are used to dosage the different aggregates used in the mix to the drying drum.

Our Advantages;

Thanks to its functional design, it facilitates transportation and installation. Attachments have bolted design.

Thanks to its high strength silo casing and twisted body undergoes no change in shape under load.

Thanks to the frequency-controlled dosing bands, each material can be supplied in any desired rate.

The flame size of the dryer burner can be controlled automatically with the measurement sensor (optional)

Polygon asphalt plant mixer provides long wear parts life and homogeneous blend.

Features;

Heavy duty group high quality reducer.

Heat and abrasion resistant inner liners

Long life arms and paddles

Double-valved discharge system

Discharge valve with external resistance heating

Polygon-asphalt plant filter system separates the gas and dust generated during asphalt production. The decomposed filler dust can be used in mixture if desired.

Features;

Input and output temperature measurement

Clean air valve to protect bags from burns

Nomex filter bags with vertical casette

Dust-proof design

Easy bag changing

Reverse air flow bag cleaning system

Insulation suitable for climate conditions and heat transfer

The dust collection system includes supporting feet for easy installation and implementation. The filter dust collection system is perfectly tailored to the mixing plant capacity. The vertical layout-of the filter bags guarantees maximum utilisation of the surface area with efficient filter function.

Polygon dryer creates a maximum heat transfer surface thanks to its special wing design. With minimum fuel consumption, it allows the removal of humidity of aggregate and heat it up to the desired temperature.

Our Advantages;

Dryer rollers and rings are manufactured from long-life forged steel.

Easily interchangeable bolt-type compensation springs that distributes body load evenly

Suitable for stainless steel insulation coating and heat transfer, rockwool covered body

Cedpfsx D A N Tsx Abbsgn

With soft starter support, operation without problem under load

Automatically adjustable burner according to humidity and amount of aggregate (optional

The drum tube, which is made of a thick-walled, solid steel construc- tion, achieves maximum efficiency, very low exhaust gas temperatures and prevents temperature losses during the...

Listing

Mouvaux

Mouvaux

18,773 km

Meat processing machine

LutetiaBaratte T5

Call

Condition: ready for operation (used), functionality: fully functional, The Lutetia T5 tumbler is designed for processing facilities seeking homogeneous and repeatable mixing on large volumes. It ensures even distribution of ingredients while preserving the product structure. As a result, quality remains consistent from batch to batch, securing the manufacturing process. Additionally, the tank design promotes controlled product flow to minimize poorly processed areas.

This tumbler integrates easily into existing production environments, as its architecture is engineered for intensive use. Its robust construction ensures excellent stability during operation, even under heavy loads. Furthermore, the accessibility of key areas simplifies cleaning and maintenance operations, reducing downtime and improving daily machine availability.

Refurbished by Europ'Equipement, the Lutetia T5 tumbler undergoes a rigorous check of all mechanical and functional elements. Users benefit from a reliable piece of equipment, ready for operation without major modifications. Refurbishment also allows for controlled investment while maintaining a high performance level. Consequently, this solution reflects a sustainable approach focused on reliability and long-term cost reduction.

Codpfx Ajydaftsbbsgn

The Lutetia T5 is particularly suitable for applications involving meat processing and value-added products that require consistent and regular mixing. It also offers excellent operational flexibility to accommodate various recipes and production requirements. Therefore, this tumbler is an optimal choice for industrial users aiming to enhance their processes while ensuring quality, consistency, and safety.

Technical specifications:

Meat + brine capacity: 3,800 to 4,000 kg

Drive: two motors

Control: programmer with variable speed drive

Dimensions (L × W × H): 3,500 × 2,050 × 2,450 mm

Weight: 3,000 kg

Tank volume: 6,750 L

Listing

Turkey

Turkey

17,178 km

POWDER COATING EQUIPMENT

VOGAMAKINAVG1E-VN

Call

Condition: new, Year of construction: 2025, VG1E-VN MANUAL FAST COLOR CHANGE TYPE POWDER COATING SYSTEM

The powder coating system is designed for powder coating applications with frequent color changes during the day. The equipment is on a wheeled stand for ease of operation.

Powder coating is sucked directly from the powder box, which allows rapid color changes. The powder box is placed on the vibrating table, suction pipe fluidizes the powder coating in the box, ensuring effective mixing, and the powder coating is homogeneously sent to the gun through an injector placed on the suction pipe.

TECHNICAL SPECIFICATIONS

Input voltage : 220V 50Hz

Air need : 350 lt/min

Input pressure : 6 bar

Vibration motor : 220V 25W

Gross weight : 55 Kg

VG4 CONTROLLER AND MANUAL POWDER COATING GUN

The VM manual powder coating gun is completely dismountable. The ergonomic gun handle design ensures ergonomic handling and does not tire the operator during coating application. The high voltage cascade has a long service life, its tightness prevents contact with dust and minimizes the risks in this area. The well-designed head assembly and nozzle ensure excellent polarization and homogeneous coating on surfaces during application.

The electronic touch panel on the back of the gun provides ease of use during operation. The control unit is digital and allows precise adjustment of settings via the touch panel.

TECHNICAL SPECIFICATIONS

Gun Type : Corona System

Polarization : Negative

Cgodovv N Tyopfx Abbsn

Cascade input voltage: 0-10,5V DC

Output voltage : 100 kV

Output current : 0 -150 μA

Powder output (3,5 bar) 500 g/min

Protection class : IP 54

Voltage cable length : 5 m

Powder hose length : 5 m

Gun weight (gross) : 450 g

Operating temperature :-20-50 ° C

Nozzle :Flat jet or Ø16-20-24mm deflectör

Listing

Krotoszyn

Krotoszyn

17,941 km

Emulsifier

Karl SchnellF150

Call

Condition: excellent (used), Year of construction: 2015, functionality: fully functional, Karl Schnell F150 Emulsifier

Manufacturer: Karl Schnell GmbH & Co. KG

Model: F150

Type: 049

Machine number: 38717

Cgsdpoycl Rrsfx Abbon

Year of manufacture: 2015

Power supply: 400 V, 3 phase, 50 Hz, 32 A

Power: 7.5 kW

Weight: 152 kg

Dimensions: 950 × 700 × 1100 mm

The Karl Schnell F150 emulsifier is a professional machine designed for industrial emulsification and homogenisation of food products, used e.g. in the production of sausages, pâtés, fillings, and other mixtures requiring homogeneous consistency. The F series emulsifiers from Karl Schnell ensure a consistent and repeatable emulsion effect, shortening processing time and minimising temperature increase of the product during operation. These solutions are characterised by robust stainless steel construction, ensuring hygiene and equipment durability.

Listing

Enschede

Enschede

18,476 km

Agitator

EkatoUnimix 100

Call

Condition: new, Year of construction: 2024, machine/vehicle number: 30065973-10, Unused 100-liter Ekato Twin Motion Vacuum Mixer, model UniMix, type SRC 100, with 316L stainless steel product contact surfaces. It has a 100-liter maximum working capacity and a 5-liter minimum working capacity, rated for -1/+2 bar (29 psi and full vacuum) at 133°C, and jacketed for -1/+4 bar (58 psi and full vacuum) at 151°C. Features include a top-mounted Ekato Paravisc axial Z-type mixer with bottom and sidewall scrapers, driven by a 3 kW motor. It also has a bottom-mounted Ekato S-Jet 500 high-performance rotor/stator homogenizer powered by a kW motor, 480 volts, and a control panel with PLC and VFD controllers, as well as an operator HMI. The vessel is ASME-rated, with Ekato project# 30065973-10, built in 2024. The system is unused, still on its original shipping skids from Ekato, with FAT performed.

Cgsdpfx Aboyba Szsbjn

Listing

Turkey

Turkey

17,249 km

Concrete mixing plant, concrete plant

FABO Concrete Mixing Plant60 m3 Concrete Mixing Plant

Call

Condition: new, functionality: fully functional, fuel type: electric, color: yellow, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

COMPACT series Stationary Concrete Batching Plants provide satisfaction of all levels need with practical and effective solutions. Stationary concrete batching plants can easily and efficiently reach high capacity production of homogeneous concrete mixture.

COMPACT series have easy operating system and lowest investment costs. In addition, the plant provides the use of enterprise resources accurately, so that gaining time-saving will transform to more earnings.

TECHNICAL SPECIFICATIONS:

Model: COMPACT 60

Production capacity: 60 m3

Mixer type: Twinshaft mixer 1 m3

Cement weighing: 600 kg

Cgodpfx Aeyaptrjbbjn

Additives weighing: 30 kg

Water weighing: 250 kg

Cement silo is optional.

COMPACT-60 consists of:

• Aggregate Storage Bunker

• Aggregate Weighing Hopper

• Aggregate Weighing Conveyor

• Aggregate Transfer Conveyor or Bucket System

• Twinshaft Mixer

• Mixer Chassis, Walking Platforms, Ladder

• Water Weighing Hopper

• Cement Weighing Hopper

• Admixture Weighing Hopper

• Air Compressor

• Cement Screw Conveyor

• Bolted Cement Silo

• Top Filter, Safety Valve and Accessories

• Control Cabinnet with Air Conditioner

• PC and Automation System

• Control and Power Panel

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Krotoszyn

Krotoszyn

17,941 km

Paddle mixer

Alco

Call

Condition: excellent (used), functionality: fully functional, Alco Twin-Shaft Paddle Mixer

Manufacturer: Alco

Power supply: 400 V

Overall dimensions: 3500 × 1550 × 3000 mm

Bowl dimensions: 1700 × 1050 × 900 mm

Top inlet with pneumatic valve

Bottom outlet with pneumatic discharge valves

Digital parameter readout

The Alco twin-shaft paddle mixer is a professional machine designed for intensive and uniform mixing of various food masses, especially in the meat industry. Its twin-shaft, paddle-based construction ensures high process efficiency and a homogeneous final product structure.

Codoyahw Aopfx Abbegn

The mixer is equipped with a pneumatically controlled top feed and a bottom discharge system, allowing for efficient operation and easy integration into production lines. Key advantages include a robust build and a large bowl capacity.

Listing

Krotoszyn

Krotoszyn

17,941 km

Twin-shaft paddle mixer

AlcoEqual Mix

Call

Condition: excellent (used), functionality: fully functional, Alco Equal Mix Double Shaft Paddle Mixer

Codpfxsyahwce Abbogn

Manufacturer: Alco

Model: Equal Mix

Power supply: 400 V

Overall dimensions: 3500 × 1550 × 3000 mm

Mixing chamber capacity: 1700 × 1050 × 900 mm

Top inlet with pneumatically actuated valve

Bottom outlet with pneumatically operated discharge valves

Digital display of operating parameters

Standard bin lifting system with integrated weighing unit

The Alco Equal Mix double shaft mixing machine is designed for intensive and uniform mixing of various food products, especially meat masses. The dual mixing shafts ensure excellent product homogeneity and short cycle times. The machine is equipped with pneumatic systems for easy loading and unloading, as well as an integrated weighing unit for precise process control.

Listing

Janville

Janville

19,054 km

Vacuum mixer

Fryma KorumaDinex Lab

Call

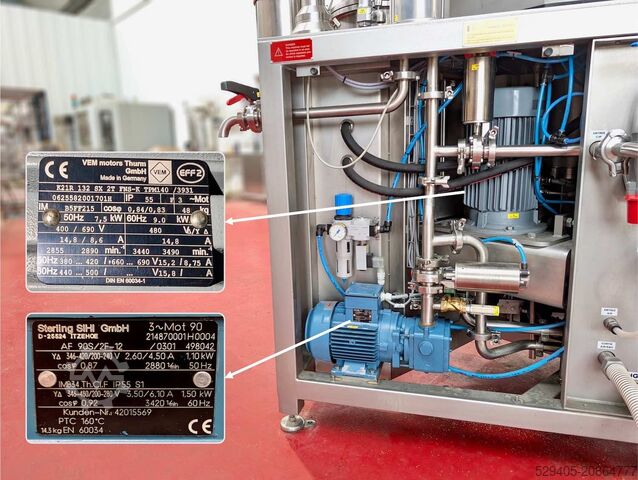

Condition: used, Year of construction: 2009, Manufacturer: Romaco - Frymakoruma

Model: Dinex Lab

Year: 2009

Type: Vacuum mixer for R&D or small-scale production

Application: liquid and/or viscous (semi-liquid) products = dispersion, homogenization, emulsion, grinding, and pumping of the product

Tank:

Pressure: -1 / 0 bar

Volume: 18 L

Temperature: 130°C

Jacket:

Pressure: 6 bar

Volume: 2 L

Temperature: 180°C

Homogenizer: high-speed agitation

2 modes = Pumping with discharge / Dispersion with high shear force

Tool size: 100 mm

Rotor: 20 x 4 mm

Stator: 30 x 4 mm

VEM motor 7.5 kW / 2890 RPM

Scraper mixer: slow agitation

SEW 0.37 KW motor

Sterling SIHI LEMA 25 liquid ring vacuum pump

Power 1.1 KW - Max. 16 m³/h.

CIP (clean in place)

2 x feed hoppers, 1 of which is connected to the jacket with its piping

Air pressure: 6 bar

Water pressure: 6 bar

Temperature control regulator

Cjdpfx Aox R D Elobbsgn

Single-acting seal: reconditioned by Burgmann

Paper documentation

Weight: 750 kg

Listing

Janville

Janville

19,054 km

Vacuum mixer

OlsaSpeedycream 750

Call

Condition: used, Year of construction: 1986, Manufacturer : OLSA

Model : Speedycream 750

Year : 1986

Type: vacuum mixer

Capacity: 750 Liters

Total capacity: 880 Liters

Minimum working capacity: 280 Liters

Jacketed : 3 bars

Inside tank pressure: 1 bar

Slow stirring: 5.5 KW

Planetary: 15-78 rpm

Blade with Teflon scrapers: 5-26 rpm

Satellite rapid mixer (located on the lid): 7.5 KW

Homogenizing disperser: 1400 - 2800 rpm

Movement speed: 5-26 rpm

Temperature controller

Planetary mixer speed indicator

Internal vacuum indicator

Planetary mixer power consumption indicator

Fast stirrer power consumption indicator

Planetary speed indicator

Satellite speed selector

Tilting axis

Vacuum pump : 1,45 KW

Drain valve Ø 65 mm

Exterior dimensions: 2658 mm x 1420 mm x 2510 mm (3870 mm - lid open)

Spare parts available (see photos)

Original paper documentation available

Video available in running condition

Cgedpfx Abex R Dmijbjn

Listing

Janville

Janville

19,054 km

Vacuum mixer

Dumek-

Call

Condition: used, Year of construction: 1985, Manufacturer : Dumek

Model: –

Year : 1985

Type: Vacuum mixer / Homogenizer

Codpfxex R Awas Abbsgn

Total volume: 80 L

Useful volume: approx. 50 L

Slow agitation : Stirring / counter-stirring

Rapid agitation : rotor / stator 3.3 KW

Up/down: mechanical

Tilting: manual

Jacketed with integrated heating unit

Immersion heaters (new): 2 x 3000 W

Regulation: mechanical

Tank bottom sample

Vacuum pump

New scrapers are required; these items can be quoted separately.

Listing

Turkey

Turkey

17,249 km

Mobile concrete mixing plant

FABO Mobile Concrete Batching Plant120 m3/h Mobile Concrete Batching Plant

Call

Condition: new, functionality: fully functional, fuel type: electric, color: yellow, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

FABO TURBOMIX FULL AUTOMATIC MOBILE CONCRETE BATCHING PLANTS are ideal solutions for the projects that require short term and a compacted settlement on a dedicated job site. Since all the equipment of a concrete plant is assembled on a single mobile chassis, the plant can be moved easily by only one truck. Productivity of TURBOMIX mobile concrete plants vary from 30 m3/h to 150 m3/h.

FABO TURBOMIX series of mobile concrete batching plants have automatic control, static/dynamic Load Cell Weighing of aggregate materials and additives. Concrete plants have qualitative and strong concrete mixer, which provides high capacity homogeneous mixture.

TECHNICAL SPECIFICATIONS:

Model: TURBOMIX 120

Production capacity: 120 m3

Dimensions (length x width x height): 17500 x 3200 x 4600 mm

Mixer type: Twinshaft – 3 m3

Aggregate bunker: 4 x 25 m3

Transfer conveyor: 6600 kg

Cement weighing: 1750 kg

Additives weighing: 40 kg

Water weighing: 1000 lt

Total weight: 31460 kg

Total motor power: 145 kW

Cement silo is optional.

Turbomix 120 consists of:

• Aggregate Storage Hopper

• Aggregate Weighing Hopper

Cgsdex Uqtwepfx Abbon

• Aggregate Transfer Conveyor

• Twinshaft Mixer

• Mixer Chassis, Walking Platforms, Ladder

• Water Weighing Hopper

• Cement Weighing Hopper

• Admixture Weighing Hopper

• Air Compressor

• Cement Screw Conveyor

• Bolted Cement Silo

• Top Filter, Safety Valve and Accessories

• Control Cabinnet

• PC and Automation System

• Control and Power Panel

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Lorquí

Lorquí

19,581 km

S/S KRAMER+GREBE 200 L Cutter

KRAMER GREBE

Call

Condition: like new (used), The Kramer + Grebe SM 200 cutter (also known as a bowl cutter) is an industrial machine mainly used in the meat industry for cutting, mixing, and emulsifying meat and other ingredients.

Main function:

- It features a bowl with an approximate capacity of 200 litres.

- The blades rotate at high speeds to cut meat, fat, ice, spices, etc.

- Cutting while the bowl rotates produces a fine emulsion, resulting in a homogeneous texture in products such as sausages, pâtés, frankfurters, and more.

Cgsdpfxsx S Ih Tj Abben

Listing

Bitburg

Bitburg

18,682 km

Glue spreader

OsamaS4R/P-1400 sofort verfügbar

Call

Condition: new, Year of construction: 2024, Osama Automatic 4-Roller Glue Application Machine

Model: S4R/P-1400

Automatic gluing machine with 2 motors

Working width: 1,400 mm

Max. pass-through height: 0 - 100 mm

Speed: 22 m/min

Working height: 900 mm

Diameter of application rollers: 250 mm

Motor power: 3 kW

Codpju I R Utefx Abbogn

Electrical: 400 V / 50 Hz / 3 phase

Automatic gluing machine with 4 rollers for polyvinyl acetate (PVAC), urea-formaldehyde (UF), and polyurethane adhesives, suitable for various materials such as MDF, multi-layer boards, particle boards, composites, and gypsum plasterboard.

This type of gluing machine allows for precise and homogeneous dosing of adhesive, taking into account the corrugation of the rollers, which must be suitable for the respective production requirements. The heavy-duty structure and the roller cores, manufactured with greater thickness compared to earlier models, enable a high production rate without issues and bonding of materials up to 2200 mm in width. Roller removal for maintenance is straightforward, as the supports can be split in two via a simple bayonet coupling.

The gluing machine can also be equipped with different accessories, such as an electronic speed controller, automatic roller washing device, and an automatic upper roller lifting mechanism with position display on the control panel.

The S4R/P gluing machine is used in various production sectors, including construction and the manufacturing of foam panels and mattresses.

Equipment:

- Automatic roller cleaning

- Infeed roller

- Outfeed roller

- Working height: 900 mm

- Infeed table TRF 1400x3000 mm with PVC rollers, 60 mm diameter, 200 mm spacing

- Outfeed table TDF 1400x3000 mm with disc rollers, D: 122 mm, stainless steel

Location: in stock at 54634 Bitburg

- Available immediately -

Listing

Lopik

Lopik

18,584 km

Direct UHT Unit

GEATDS-6600-160INJ

Call

Condition: excellent (used), Year of construction: 2023, operating hours: 400 h, Skid-mounted UHT system, direct steam injection, 16,000 L/h, 2023.

A complete UHT line, suitable for milk, cream and ice cream mixes.

The system is delivered turnkey and is ready for both pilot and production operations.

GEA TDS-6600-160INJ – 16,000 liters per hour

Process Configuration

Direct steam injection into the product with culinary steam filter

Holding tube/flash tank

Plate heat exchangers:

PHE1: regeneration + steam heating

PHE2: regeneration + chilled water cooling

Heater: 137–142 °C / 6 seconds

Final product temperature fully controllable via plate cooler

Skid Layouts

The UHT line is constructed on multiple skids, including the UHT section, homogenizer, and aseptic systems:

SKID A: Balance tank for product, Fristam product pumps, Grundfos water pumps, process and steam valves, piping, ROI-box with recorder

SKID B: Steam injector, holding heater, flash tank, pumps, valves, and auxiliary systems:

PHE1: Plate heat exchanger for regeneration + steam heating

PHE2: Plate heat exchanger for regeneration + chilled water cooling

Aseptic Homogenizer: Soavi Ariete 5200, 250 bar, 5 pistons, 2-stage, installed downstream

Sterile Water Skid: Auxiliary system for homogenizer

Control Panels & MCC: including PLC and frequency converters

SKID A: Aseptic valve manifolds (inlet and outlet cluster for tank)

SKID B: Sterile air system for aseptic tank

SKID C: Jacketed water circulation

Excluding: 60 m³ aseptic tank

Control System

Siemens PLC

Danfoss variable frequency drives (VFDs)

SCADA-controlled (SCADA system needs adaptation; not included in this offer)

Central control panel and MCC included

Condition

Year of Manufacture: 2023

Less than 400 operating hours

Cedpjx R Uk Sofx Abbegn

Excellent condition

Documentation and P&ID drawings available

Listing

Grünkraut

Grünkraut

18,639 km

Drum Chipper type ATH 220x530/3

S&F GmbHATH 220x530/3

Call

Condition: as good as new (ex-display), Year of construction: 2026, S&F drum chipper type ATH 220x530/3

Demonstration machine / trade fair machine / new machine

Solid design with long service life

Feed height: 200 mm

Feed width: 500 mm

Number of chipper knives: 2 pieces

Number of counter knives: 1 piece

Rotor diameter: 520 mm (solid steel rotor)

Number of feed rollers: 3 pieces

Throughput rate: up to approx. 20 rm/h *

Chipping length: approx. 30 mm

Chipper drive power: 45 kW or on request

Feed roller drive power: 2 x 2.2 kW

Operating/control voltage:400/220 V, 50 Hz

Weight: 2,600 kg

*depending on chipper length, kW main motor, number of knives, feed

S&F chippers and drum chippers with horizontal infeed are used in many areas of the wood processing industry (sawmills, timber mills). Chippers from the ‘ATH’ series produce high-quality and homogeneous wood chips with a low proportion of fines from residual wood, for example as quality chips for the cellulose industry or as fuel chips for energy generation

Advantages:

- Maximum throughput

- Low fines content

- Low maintenance

- Flexible use

Cgjdpfxow I R Rns Abbon

- Customised production

Listing

Grünkraut

Grünkraut

18,639 km

Drum Chipper ATH 220 series

S&F GmbHATH-220/530/3 | ATH-220/730/3

Call

Condition: new, Year of construction: 2026, Drum chipper series

ATH-220/530/3 | ATH-220/730/3 | ATH-220/1060/3

S&F chippers and drum chippers with horizontal infeed are used in many areas of the wood processing industry (sawmills, timber mills). Chippers from the ‘ATH’ series produce high-quality and homogeneous wood chips with a low proportion of fines from residual wood, for example as quality chips for the cellulose industry or as fuel chips for energy generation

Series ATH-220/530/3 | ATH-220/730/3 | ATH-220/1060/3

- Feed height: 200 mm

- Feed width: 500 | 700 | 1000 mm

- Number of chipper knives: 2 - 4 pieces

- Number of counter knives: 2 pieces

- Rotor diameter:520 mm

- Number of feed rollers: 3 pieces

Cgjdpjwbv Erjfx Abben

- Throughput: up to approx. 40 rm/h *

- Chipping length: 5 - 50 mm

- Chipper drive power: 22 - 110 kW

- Drive power feed rollers: 2 x 2.2 kW

- Operating/control voltage: 400/220 V, 50 Hz

- Weight: 2,800 - 4,000 kg

*depending on chipper length, kW main motor, number of knives, feed

Advantages:

- Maximum throughput

- Low fines content

- Low maintenance

- Flexible use

- Customised production

Trust Seal

Dealers certified through Machineseeker

Listing

Grünkraut

Grünkraut

18,639 km

Drum Chipper ATH series

S&F GmbHATH 300

Call

Condition: new, Year of construction: 2026, Drum chipper series ATH

S&F chippers and drum chippers with horizontal infeed are used in many areas of the wood processing industry (sawmills, timber mills). Chippers from the ‘ATH’ series produce high-quality and homogeneous wood chips with a low proportion of fines from residual wood, for example as quality chips for the cellulose industry or as fuel chips for energy generation

ATH 220 series

- Feed height: 200 mm

- Feed width: 500 | 700 | 1000 mm

- Number of chipper knives: 2 - 4 pieces

- Number of counter knives: 2 pieces

- Rotor diameter:520 mm

- Number of feed rollers: 3 pieces

- Throughput: up to approx. 40 rm/h *

- Chipping length: 5 - 50 mm

- Chipper drive power: 22 - 110 kW

- Drive power feed rollers: 2 x 2.2 kW

- Operating/control voltage: 400/220 V, 50 Hz

- Weight: 2,800 - 4,000 kg

ATH 330 series

- Feed height: 300 mm

- Feed width: 500 | 700 | 1000 mm

- Number of chipper knives: 2 - 6 pieces

- Number of counter knives: 2 pieces

- Rotor diameter: 700 mm

- Number of feed rollers: 3 pieces

- Throughput capacity: up to approx. 70 rm/h *

- Chipping length: 5 - 80 mm

- Chipper drive power: 37 - 250 kW

- Drive power feed rollers: 2 x 3.0 kW

- Operating/control voltage: 400/220 V, 50 Hz

Cgjdpfsuz Hmxox Abbon

- Weight: 3,500 - 5,000 kg

*depending on chipper length, kW main motor, number of knives, feed

Advantages:

- Maximum throughput

- Low fines content

- Low maintenance

- Flexible use

- Customised production

Listing

Borken

Borken

18,513 km

Climate cabinet 138 liters

CLIMATSEXCAL 1413-HA -40 bis 180°C

Call

Condition: excellent (used), Climats

Type: EXCAL 1413-HA

Air-cooled climate control cabinet

EXCAL is equipped with a 15-inch capacitive multi-touch panel PC, SSD

memory, Windows 7 and 2 USB ports.

This means it is state-of-the-art.

Technical data:

Test room dimensions: width 550 mm x depth 500 mm x height 500 mm

Housing dimensions: width 820 mm x depth 1375 mm x height 1730 mm

Window 350 x 380

Volume: 138 liters

Flow-through installed in basic equipment

R1: 80 mm ∅

L1: 80 mm ∅

Data for temperature tests:

Temperature range: -40°C to +180°C

Temperature deviation over time ± 0.1 to ± 0.3 K

Temperature homogeneity in space ± 0.5 to ± 1.8 K

Csdpov Dt T Tsfx Abbsgn

Temperature change rate

Heating 15 K/min

Cooling 10 K/min

Data for climate tests:

Temperature range + 10 to +90 °C

Humidity range 10 to 98 %r.h.

Data for operation:

3/N/Ph+T 400V±10% 50 Hz

Rated power 9.8 KVA

Refrigerant R-404A / R-23

Weight: 430 kg

For your safety as a buyer, the following information!

The following points are carried out in advance on the chambers we offer:

1. Functional check and replacement of necessary components

2. If necessary, new filling with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (See image)

(Changes and errors in the technical data, information is subject to change!)

We are happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

18,513 km

Xenon Weather-Ometer/ Fade-Ometer

AtlasCI3000+ Bewitterungsprüfung

Call

Condition: excellent (used), Atlas

Type: CI3000+

Ci3000+ Weather-Ometer/ Fade-Ometer

Model: CI3000W

Year of manufacture: 06/2022

Operating time: Device 816.5 hrs.

Light duration device 647.4 hrs.

Total lamp operation 88.9 hrs.

Atlas CI3000+ Xenon Weather-Ometer with calibration case

The Ci3000+ Weather-Ometer and the Fade-Ometer with its advanced digital control systems,

represent monumental achievements in the application of digital and optical technologies in easy-to-use laboratory weathering instruments.

The 3000 series is recognized by many OEMs in the textile, paint, coatings and plastics industries as the exclusive platform for precise, reproducible and repeatable results,

reproducible and repeatable life prediction results. The 3000 series is CE, UL, CSA, ISO and EN certified.

Key features of this device include: a rotating sample basket to maximize the homogeneity of all samples;

customized nozzles for uniform sample front and back spraying;

ASTM black plate thermometer or ISO/DIN black standard thermometer for control and monitoring,

temperature at sample level to ensure test repeatability.

4500 W water-cooled xenon lamp

Total exposure area 2188 cm2 (339 in2)

12-inch TFT full-color touchscreen control panel - display of all test parameters

Direct setting and control of black panel (BPT, non-insulated) or black standard (BST, insulated) temperature

Direct setting and control of relative humidity

Direct setting and control of the air temperature of the sample chamber

Display of diagnostic messages

14 factory pre-programmed test methods (Weather-Ometer); 6 factory pre-programmed test methods (Fade-Ometer)

Features:

Climate type

Test type Sunlight simulation

Light source with xenon arc lamp

Applications:

Additives and colorants

Adhesives and sealants

Architecture and construction

Automotive industry

Food and beverages

Graphics

Packaging

Paints and coatings

Photovoltaics

Plastics

Textiles

Wind and solar

Consumer electronics

Voltage: 340-415V 43A 50/60Hz

〜3/N/PE 8kW

410 kg

Condition: gebraucht / used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

Codstq Em Eepfx Abbegn

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

18,513 km

Temperature cabinet -72°C to +180°C

WeissTempEvent T/800/70/10 800 Liter

Call

Year of construction: 2022, condition: excellent (used), White

Type: T/800/70/10

Water-cooled

External dimensions (HxWxD): 2085 x 1415 x 2810mm

Test room dimensions (HxWxD): 950 x 1100x 800 mm

Volume: 800 liters

Minimum temperature: -72 °C

Maximum temperature: +180 °C

Temperature change rate, cooling: 12.0 K/min

Temperature change rate, heating: 12.0 K/min

Temperature deviation over time: ±0.1 to ±0.5 K

Temperature homogeneity spatially: ±0.5 to ±2.0 K

Temperature gradient: ≤2.0 K

Heat compensation, at +20 °C: 8000 W

Power connection 3/N/PE AC 400 V ±10% 50 Hz or 3/N/PE AC 440 V ±10% 60 Hz

Rated power: 30 KW

Csdpfx Ajvxrwgebbegn

Rated current: 57 A

Operating hours: approx. 10 (never used)

Condition: used

Weight 1600 kg

Scope of delivery: (See picture)

Sold ex location!

(Changes and errors in the technical data, information are reserved!)

We will be happy to answer any further questions you may have over the phone.

We make it easier for you to find: "homogenizer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Homogenizer (224)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month