Used Sine Wave Ruler for sale (469)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Sierakowska Huta

Sierakowska Huta

17,772 km

Multispindle Drill

MAGGIBoring System 23

Call

Condition: new, CATALOG NUMBER M0252

PRODUCT FEATURES

Main features of the machine:

- Single-head drilling machine for drilling at an angle range of 0 - 90°

- Head tilt angle adjustable pneumatically

- Side stops adjustable with an accuracy of up to 0.1 mm

- Securing clamps allow quick panel positioning without adjustment

- Spindles adapted for quick couplings

- Patented pneumatic material clamps

- Work table made of MDF

- Fast and precise adjustments

- Accurate drilling

- Italian-made

Standard machine equipment:

- 2 aluminum rulers, 1.5 m long (right and left), each with four stops

- 5 quick couplings

- Wooden crate for safe transport of the machine

ADVANTAGES

- Drilling vertically/horizontally/at an angle

- Multiple spindles

Ppedpfx Aaox Rqk Isljl

- New machine

- CE certificate

- Robust

- Professional

TECHNICAL DATA

- Number of spindles: 23

- Distance between the first and last drill bit: 704 mm

- Distance between centers of adjacent spindles: 32 mm

- Max. size of workpiece: 950 x 3000 mm

- Max. workpiece thickness: 60 mm

- Max. drilling depth: 65 mm

- Number of pneumatic clamps: 2

- Working pressure: 6-7 bar

- Air consumption: 10 l/cycle

- Motor power: 1.5 kW

- Noise level: 76.1 dB

- Spindle speed: 2800 rpm

- Overall dimensions: 1235/950/1310 mm

- Weight: 310 kg

Net price: 19,500 PLN

Net price: 4,650 EUR

Net price calculated at an exchange rate of 4.15 PLN/EUR

(price may change if the exchange rate fluctuates significantly)

Listing

Germany

Germany

18,260 km

Notching Machine

TumakonTU 300-8

Call

Condition: used, Year of construction: 1990, Technical details:

plate thickness: 8 mm

cutting range: 300 x 300 mm

Ppjdpsu Ictbefx Aalsl

table-size: 1100 x 900 mm

voltage: 380 V / Hz

Weight approx.: 1,7 t

dimension machine xH: 1,3 x 1,2 x 1,5 m

For notching of 90° sheet metal segments, works hydraulically.

On the table are 2x rulers 300mm 90° offset.

T-slot according to DIN 680: a=12mm, h=21mm, b=22mm, c=14mm with length = 1x 330mm and 2x 700mm

Operation via control panel and foot switch

*

Listing

Germany

Germany

18,260 km

Center Lathe

StrunguriSNA 560x2000

Call

Condition: used, Technical details:

turning diameter over bed: 560 mm

turning diameter over support: 300 mm

turning length: 2000 mm

centre height: 250 mm

support travel z-axis: quer: 300 mm

support travel x-axis: längs: 2000 mm

spindle passage: Ø 65 mm

turning dia. in gap: 700 mm

length of gap: 300 mm

range of revolution per miute: 16...1250 / 23 step U/min

range of feed in x - axis: 0,028...5 m/min

tailstock quill taper MT: 5

tailstock quill adjustment:: 260 mm

Pjdpfx Aasu Ix Emolopl

total power requirement: 11,0 kW

weight of the machine ca.: 3,5 t

dimension machine xH: 3,8 x 1,3 x 1,4 m

other features:

-3 jaw lathe chuck Ø 315mm

-Disposes of a cross slide and a top slide (top slide with tool holder for quadruple clamping)

-cooling system

-moving tip MK5 in the tailstock

- chuck protection cover

-ruler for conical turning

- manual route control (via limit switch)

Accessories:

1x steady rest Ø 200mm closed

*

Listing

Siedlce

Siedlce

17,614 km

Fiber Laser cutting machine 3000x1500

CORMAKLF3015GEP 6000W

Call

Condition: new, Year of construction: 2025, Laser fiber cutting machine

GEP Series

A modern, fully enclosed fiber laser for sheet metal cutting. The offer includes a laser with a power from 1000W to 6000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Fiber optics laser cutters constitute modern devices with many advantages. These are not only a perfect and more profitable alternative to the CO2 technology, but they also possess a lot of pros by themselves, such as improving the production by considerable margin and increasing its quality. FIBER technology allows for cutting sheets and other materials of various thickness: from very thin to very thick. The length of a wave in a FIBER laser is 1.064 micrometre long.

The biggest advantages of the laser are

failure-free optical fiber cable

no elements that wear out

the source of the fiber optic laser takes 1/3 less space

high energetic efficiency - 100000 hours of work

universal applicability (specific metal sheets, carbon and stainless steel, copper, brass, aluminium, titanium)

Optical fiber laser

Pjdpfx Aajizi S Islopl

increases the efficiency by 80%

reduces the handling costs by 70%

saves 80% of energy

minimises the consumption of gas

saves space in the workplace by 30%

Technical parameters

WORKING AREA 1500x3000 mm | 2000x4000 mm | 2000x6000 mm

POWER 1000W 2000W 3000W 4000W 6000W

POSITIONING REPEATABILITY ACCURACY ±0.02 mm/m

MAXIMUM SPEED 120 m/min

MAXIMUM ACCELERATION 1,5G

DIMENSIONS 8850x2850x2310 mm

POWER SUPPLY 400V 50Hz

Safety and pollution

Fully built-on laser

Observational window with a laser protective glass compliant with the European CE marking

The smoke produced by cutting can be filtered internally, and not pollute environment

Sliding gate made of annealed aircraft aluminium

The construction of the sliding gate is made of annealed aircraft aluminium, formed with a strength of 4300 tonnes, achieving unprecedented rigidity. Aircraft aluminium has many advantages: high rigidity (higher than cast iron), small mass, resistance to corrosion and oxidation as well as susceptibility to machining.

Replaceable working table

Replaceable working table consists of upper and lower platforms, whose movement and swapping are controlled through the controller. The machine can swap the platform in 15 seconds.

Welded bed made of rectangular profiles

The inner structure of the bed adopts a metal honeycomb structure which is welded by a plurality of rectangular tubes. Inside the tubes, stiffeners are placed to increase the strength and tensile strength of the bed, and also to increase the strength and stability of the guide rail to effectively avoid deformation of the bed.

RayTools head

Automatic focus regulation – Autofocus – The software automatically regulates the focusing lens during cutting metal sheets of various thickness. The speed of automatic focus regulation is 10 times higher than the speed of manual regulation.

Greater range of manual regulation – The range of regulation -10mm - + 10 mm, precision of 0.01 mm is useful in when it comes to materials of different thickness (0–20 mm) – Below 1500W.

Long durability. Collimating lenses and converging lenses possess a heat sink which cools down water, in turn decreasing the temperature of a cutting head, in order to improve the durability of the cutting head.

The laser uses components from world producers

Listing

Siedlce

Siedlce

17,614 km

Universal lathe 500x1500

CORMAK500x1500YB WOLNE OBROTY

Call

Condition: new, Year of construction: 2025, Industrial metal lathe CORMAK 500x1000YB - solid cast iron bed construction, gearbox with min. speed control from 9 rpm and powerful 7.5 kW/ 400V induction motor - maximum torque. Large spindle passage 85 mm.

Machine characteristics

The 500 x 1500YB CORMAK universal lathe is a multi-tasking machine, ideal for machining various surfaces, such as internal and external turning, tapers, polishing, metric, inch, modular and DP threading, drilling and broaching.

The digital readout works on three axes: longitudinal, transverse and upper slide. The processed signal from the optical rulers displays the movement values on the digital screen, which increases precision and comfort of work.

The lathe is equipped with a high-quality spindle bearing system with modern bearing of the main spindle, which improves the stability and durability of work, especially at low rotational speeds.

A large 105 mm spindle passage, a 3-jaw 320 mm lathe chuck and a powerful 7.5 kW engine ensure optimal work results, even with demanding tasks at low rotational speeds.

The longitudinal and transverse rapid feed system significantly increases productivity and shortens machining time, but due to the slow-speed nature of the machine, operations requiring precise finishes take place in stable and controlled conditions.

Hardened and ground gears in the spindle gear ensure the reliability and stability of the machine's operation for many years, which is crucial in operations requiring precise turning at low speeds.

Equipped with a lead screw and a feed shaft, the lathe allows threading in various systems (metric, inch, modular, DP) without the need to change change wheels, which allows for quick adaptation to different tasks.

Easy adjustment of the spindle speed and automatic feed from the ergonomic control panel provides full control over the machining process, which is crucial for precise, low-speed operations.

The ability to turn a wide range of threads, including right-hand and left-hand threads, without the need to change wheels, and a special thread turning clock facilitate precise counting of threads, which saves time on complex tasks.

The interchangeable bed bridge allows for the machining of larger components (e.g. discs) and allows the turning of large diameters up to 710 mm when the bridge is removed, which gives a wide range of possibilities in the field of machining large parts.

All these features, combined with the slow-speed nature of the machine, make the CORMAK 500 x 1500YB lathe ideal for precise, complex machining operations.

Technical data

TURNING DIAMETER OVER BED

500 mm with LCD readout

TURNING DIAMETER OVER BRIDGE

300 mm

TURNING DIAMETER IN BRIDGE RECESS

710 mm

TURNING LENGTH IN BRIDGE RECESS

240 mm

CENTER HEIGHT

250 mm

CENTER DISTANCE

Ppedpfjvwz Irsx Aaljl

1500 mm

BED

induction hardened

SPINDLE SPEED RANGE (24 ADJUSTMENT STAGES)

9-1600 rpm

SPINDLE BORE DIAMETER

105 mm

SPINDLE INTERNAL TAPER

90 mm 1:20

FEED RANGE LONGITUDINAL

0.063-2.52 mm

CROSS FEED RANGE

0.027-1.07 mm

METRIC THREADING RANGE

0.5 - 224 mm

INCH THREAD

72-1/8 T/"

MODULAR THREAD

0.5 - 112 mm

D.P. THREAD

56-1/4

MAX CROSS CARRIAGE DISPLACEMENT

320 mm

MAX UPPER SLIDE DISPLACEMENT

145 mm

MAX LATHE CHUCK SIZE

25 x 25 mm

TAILSTOCK SLEEVE TIP

150 mm

MAIN MOTOR POWER S1/S6

7.5/9 kW

MAIN ENGINE SPEED

1440 rpm

WEIGHT APPROX.

3300 kg

Listing

Siedlce

Siedlce

17,614 km

410x1500 Universal Lathe

CORMAKCORMAK 410X1500

Call

Condition: new, Year of construction: 2025, This lathe can be used for many tasks such as internal and external surfaces turning, tapers turning, buffing, modular and DP threading, drilling and internal broaching.

Machine features

Lathes from this series can be used for many tasks such as turning internal and external surfaces, tapers turning, buffing, modular and DP threading, drilling and internal broaching

By default equipped with a 3 axes digital readout

Modern and precise spindle bearings

52 mm large spindle bore

Heavy bed made of cast iron, ground and inductively hardened

Gear wheels strengthened through hardening and precise grinding

Removable bridge allows for greater machining capabilities

Protection guards compliant with the newest regulations

Machining accuracy: circularity deviation below 0.01 mm, cylindricality deviation no more than 0.02 mm for 200 mm long measurement, perfect surface finish

Equipped with a mechanical foot mechanical brake

Possibility of equipping the lathe with a ruler for turning tapers

Optional VARIO model with a smooth spindle speed adjustment and a digital indicator

Technical data

Swing over bed

410 mm

Swing over cross slide

255 mm

Swing over gap bridge

580 mm

Turning length in gap bridge

190 mm

Centres distance

1500 mm

Centres height

205 mm

Bed

inductively hardened

Bed width

250 mm

Spindle bore diameter

52 mm

Spindle tip

D1-6

Spindle mount

MK6

Spindle speed

(16) 45–1800 rpm

Maximum tool dimensions

20 mm×20 mm

Longitudinal feed range

(17) 0.05–1.7 mm/turn

Transverse feed range

(17) 0.025 – 0.85 mm/turn

Metric thread

(42) 0.2–14 mm

Inch thread

(45) 2–72 T.P.I.

Modular thread

0.3–3.5 M.P (18)

D.P. thread

8–44 D.P. (21)

Tailstock quill diameter

50 mm

Tailstock quill extension

120 mm

Tailstock quill tip

MK 4

Digital readout

in 3 axes

Main motor power

3.0/4.5 kW

Flood coolant pump power

0.1 kW

Dimensions

2440×850×1320 mm

Psdpfsrh E Smsx Aaljpl

Net weight

1830 kg

Listing

Siedlce

Siedlce

17,614 km

460x1500 Universal Lathe

CORMAKTokarka uniwersalna 460x1500

Call

Condition: new, Year of construction: 2025, This lathe can be used for many tasks such as internal and external surfaces turning, tapers turning, buffing, modular and DP threading, drilling and internal broaching.

This series lathes can be used for many tasks such as internal and external surfaces turning, tapers turning, buffing, modular and DP threading, drilling and internal broaching

By default equipped with a 3 axes digital readout

Modern and precise spindle bearings

80 mm large spindle bore

Heavy bed made of cast iron, ground and inductively hardened

Gear wheels strengthened through hardening and precise grinding

Removable bridge allows for greater machining capabilities

Protection guards compliant with the newest regulations

Equipped with a foot mechanical brake

Possibility of equipping the lathe with a ruler for turning tapers

Technical data

Swing over bed

460 mm

Swing over cross slide

270 mm

Swing over gap bridge

690 mm

Turning length in gap bridge

165 mm

Centres distance

1500 mm

Bed

inductively hardened

Bed width

300 mm

Spindle bore diameter

80 mm

Spindle tip

D1-8

Spindle mount

MK7

Spindle speed

Ppjdpfx Aaericzislol

(12) 25–1700 rpm

Maximum tool dimensions

25×25 mm

Longitudinal feed range

(42) 0.031–1.7 mm/turn

Transverse feed range

(42) 0.014 – 0.784 mm/turn

Metric thread

(41) 0.1–14 mm

Inch thread

(60) 2–112 T.P.I.

Modular thread

0.1–7 M.P (34)

D.P. thread

4–112 D.P. (50)

Tailstock quill diameter

60 mm

Tailstock quill extension

130 mm

Tailstock quill tip

MK4

Digital readout

in 3 axes

Main motor power

5.5 kW

Flood coolant pump power

0.1 kW

Dimensions

2750×1080×1370 mm

Net weight

1820 kg

Listing

Siedlce

Siedlce

17,614 km

Laser Fiber cutting LF3015GEP 2kW

CORMAKLF3015GEP 2000W

Call

Condition: new, Year of construction: 2025, Laser fiber cutting machine

GEP Series

A modern, fully enclosed fiber laser for sheet metal cutting. The offer includes a laser with a power from 1000W to 6000W, and the highest quality components ensure long and trouble-free use of the fiber laser.

Fiber optics laser cutters constitute modern devices with many advantages. These are not only a perfect and more profitable alternative to the CO2 technology, but they also possess a lot of pros by themselves, such as improving the production by considerable margin and increasing its quality. FIBER technology allows for cutting sheets and other materials of various thickness: from very thin to very thick. The length of a wave in a FIBER laser is 1.064 micrometre long.

The biggest advantages of the laser are

failure-free optical fiber cable

no elements that wear out

the source of the fiber optic laser takes 1/3 less space

high energetic efficiency - 100000 hours of work

universal applicability (specific metal sheets, carbon and stainless steel, copper, brass, aluminium, titanium)

Optical fiber laser

increases the efficiency by 80%

reduces the handling costs by 70%

saves 80% of energy

minimises the consumption of gas

saves space in the workplace by 30%

Technical parameters

WORKING AREA 1500x3000 mm | 2000x4000 mm | 2000x6000 mm

POWER 1000W 2000W 3000W 4000W 6000W

POSITIONING REPEATABILITY ACCURACY ±0.02 mm/m

MAXIMUM SPEED 120 m/min

MAXIMUM ACCELERATION 1,5G

DIMENSIONS 8850x2850x2310 mm

POWER SUPPLY 400V 50Hz

Safety and pollution

Fully built-on laser

Observational window with a laser protective glass compliant with the European CE marking

The smoke produced by cutting can be filtered internally, and not pollute environment

Sliding gate made of annealed aircraft aluminium

The construction of the sliding gate is made of annealed aircraft aluminium, formed with a strength of 4300 tonnes, achieving unprecedented rigidity. Aircraft aluminium has many advantages: high rigidity (higher than cast iron), small mass, resistance to corrosion and oxidation as well as susceptibility to machining.

Replaceable working table

Replaceable working table consists of upper and lower platforms, whose movement and swapping are controlled through the controller. The machine can swap the platform in 15 seconds.

Welded bed made of rectangular profiles

The inner structure of the bed adopts a metal honeycomb structure which is welded by a plurality of rectangular tubes. Inside the tubes, stiffeners are placed to increase the strength and tensile strength of the bed, and also to increase the strength and stability of the guide rail to effectively avoid deformation of the bed.

Ppodpfx Aasiznlyjlsl

RayTools head

Automatic focus regulation – Autofocus – The software automatically regulates the focusing lens during cutting metal sheets of various thickness. The speed of automatic focus regulation is 10 times higher than the speed of manual regulation.

Greater range of manual regulation – The range of regulation -10mm - + 10 mm, precision of 0.01 mm is useful in when it comes to materials of different thickness (0–20 mm) – Below 1500W.

Long durability. Collimating lenses and converging lenses possess a heat sink which cools down water, in turn decreasing the temperature of a cutting head, in order to improve the durability of the cutting head.

The laser uses components from world producers

Listing

Siedlce

Siedlce

17,614 km

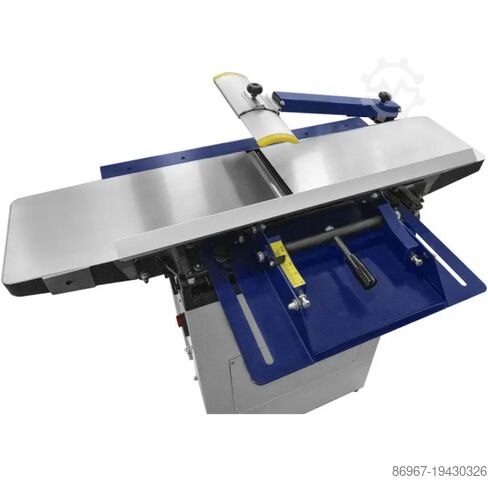

Planer and Thicknesser

CORMAKPT265 400V

Call

Condition: new, Year of construction: 2025, The Cormak PT265 planer-thicknesser is a solid and well-thought-out design that offers great possibilities for adjustment and mechanical processing of both hard and soft wood. The adjustment itself is simple and changing the planer to a thicknesser takes a few seconds.

The latest version of the machine with an innovative tabletop opening system:

❌ Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

✔️ The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

✔️ This solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Stable construction resistant to vibrations

The weight of the machine up to 170 kg combined with wide cast iron grinded tops 265 mm guarantees great stability, which ensures safe work.

The additional rubber feet used allow work without the slightest vibrations.

VERSION with the most powerful engine with a total power of S6: 2.6kW

The PT265 planer-thicknesser is distinguished by an exceptionally powerful engine with a total power of S6 2.6 kW (S1 2.2 kW). This is much more than competitive devices offer, which translates into greater efficiency and stability of work.

A more powerful engine means stable work and ease of processing hard materials: Hardwood requires more force for processing. A strong engine will handle this without a problem.

Trouble-free change of the planer to the thicknesser.

Switching from the planer to the thicknesser function is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

- Smooth height adjustment of the tops with a scale.

- The thicknessing table mounted centrally on the column has a knob for adjusting the setting up and down

- Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical data:

Knife shaft diameter [mm] 75

Knife shaft revolutions [rpm] 4000

Suction nozzle diameter [mm] 100

Swing ruler tilt angle [°] 0 - 45

Number of knives 3

Shaft length [mm] 262

Knife dimensions [mm] 2500x300x30

Maximum planer width [mm] 265

Maximum thicknesser width [mm] 265

Maximum planing height [mm] 180

Podpfx Aasvxhznsljpl

Maximum thicknesser cutting depth [mm] 3

Maximum planer cutting depth [mm] 2.5

Thicknesser feed speed [m/min] 6

Fence size [mm] 700 x 150

Machine dimensions (length x width) [mm] 1080 x 269

Weight [kg] 170

Total engine power S6: 2.6 kW

Power supply 400V

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 250mm

CORMAKS-200R manual

Call

Condition: new, Year of construction: 2025, Cormak S200R Manual band saw for cutting in large industrial facilities.

Features high accuracy metal cutting, even at 45º/60º.

Machine features

CORMAK S-200R MANUAL band saw with EC declaration, provides cutting metal at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Appropriate arm lowering speed is ensured by a valve controlling oil flow between the chambers.

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. Material is fed manually. This model is used in both low and high quantity production, and due to its solid construction allows for cutting various materials, including stainless steel, tool steel and profiles. The machine provides cutting at an angle due to rotary arm. The band saw arm is made of uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of various materials. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. The arm is equipped with an automatic blade tension sensor, at a 25° angle, thus increasing blade's durability.

There is a blade cleaning brush attached to the bottom of the arm. Machine drive is transmitted through a worm drive filled with gear oil. The machine is equipped with a three-phase motor with double winding and two cutting speeds. The motor is thermally protected.

Two cutting band speeds: 35 and 70 m/min. The construction: the arm, the vice and the rotating table are iron castings. Closed cooling system. The machine is equipped with a bumper with a ruler for setting the length of material cut. The base of the machine is a rigid cuboid made of steel sheets in which a fluid container with a flood coolant pump is located. Safety during cutting ensures an electrical system that meets all EC requirements. The machine is equipped with a limit switch which stops the machine after a cutting process is finished, an emergency button, and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened

Technical data

Type gravitational

Arm raising and lowering gravitational with stepless arm lowering adjustment

Band speed 36/70 m/min

Cutting at an angle from 45° left up to 60° right

Vice manual

Minimum cutting diameter Ø 5 mm

Minimum material length in vice 30 mm

Vice base height 890 mm

Pedpfxsfy Ttij Aalspl

Cutting band dimensions 27×0.9×2910 mm

Total power 2.1 kW

Dimensions (LxWxH) 1600×800×1400 mm

Weight 500 kg

Max. cutting range [mm]

Angle

0º ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

For more information please visit our web page or contact us

Listing

Siedlce

Siedlce

17,614 km

Universal lathe 660x4000

CORMAKGOLIAT 660X4000

Call

Condition: new, Year of construction: 2025, Main advantages:

- The CORMAK GOLIAT 660 x 4000 universal lathe can be used for many tasks, such as turning internal and external surfaces, cones, polishing, metric, inch modular and DP threading, drilling and broaching.

- The solid cast iron bed construction ensures maximum vibration reduction. Additionally, the bed is hardened and precisely ground. The device bed is extremely resistant to twisting and does not vibrate, which is the basic condition for precise turning.

- Central feed switching system, lead screw and feed shaft for threading

- The digital readout works in (3) three axes of movement: longitudinal, transverse, upper slide. The processed electronic signal from the optical rulers visualizes the obtained values from movements along the axes on the digital screen.

- The lathe is equipped with a high-quality, reinforced spindle bearing system. Modern main spindle bearing with ball bearings

- Optimal work results are ensured by a large spindle passage of 105 mm, a 4000 mm center spacing, a 3-jaw lathe chuck of 320 mm, and a powerful 7.5 kW engine.

- The rapid longitudinal and transverse feed system significantly shortens the machining time and increases productivity.

- Hardened and ground gears in the spindle gear - ensures long-term stability of work.

- Equipped with a lead screw and a feed shaft for threading, automatic longitudinal and transverse feed.

- Easy adjustment of the spindle speed and automatic feed from the ergonomic control panel on the gear.

- Possibility of machining a wide range of threads without the need to replace the change wheels in the guitar. Wide range of threads: metric (22) 1 - 14 mm, inch (25) 2-28 T.P.I, modular (18) 0.5-7 M.P., D.P. thread (24) 4-56 D.P. Turning right and left threads.

- Thread turning clock designed for accurate counting of turns. The function is to save time so that in several passes you can unscrew the lead screw nut to manually quickly return the support to its original position.

- The bed has a replaceable bridge for turning larger elements, e.g. a disc. This lathe model allows for machining with a maximum diameter of 870 mm with the bridge removed.

Ppedpfsvw Abgsx Aalol

Technical data

Max. turning diameter over bed Ø660 mm

Max. turning diameter over support Ø420 mm

Max. turning diameter in bridge slot Ø870 mm

Slot length 240 mm

Centre spacing 4000 mm

Max. turning length 3950 mm

Spindle bore Ø105 mm

Spindle taper diameter and angle Ø113 mm 1:20

Spindle nose D1-8 CAMLOCK

Spindle speeds 12 speeds (36-1600 rpm)

Number and range of longitudinal feeds 65 (0.063-2.52 mm/rev.)

Number and range of cross feeds 65 (0.027-1.07 mm/rev.)

Metric thread 22 (1-14mm)

Inch thread 25 (28-2 TPI-pitches per inch)

Modular thread 18 (0.5-7mm)

DP thread 24 (56-4 DP)

Rapid longitudinal feed 4.5 m/min.

Rapid cross feed 1.9 m/min.

Lead screw pitch 12 mm

Spindle axis distance from tool surface 28 mm

Tool dimension 25x25 mm

Max. top slide travel 145 mm

Max. cross slide travel 380 mm

Tailstock quill diameter 75 mm

Tailstock taper MT5

Max. tailstock quill travel 150 mm

Tailstock cross travel ±15 mm

Main motor S1/S6 7.5/9 kW / 400V

Rapid feed motor 250W

Coolant pump 60W, 25 L/min.

Dimensions L/W/H 5500 x 1100 x 1450 mm

Weight 5 200 kg

Listing

Siedlce

Siedlce

17,614 km

Planer and Thicknesser

CORMAKPT265 230V

Call

Condition: new, Year of construction: 2025, The Cormak PT265 planer-thicknesser is a solid and well-thought-out design that offers great possibilities for adjustment and mechanical processing of both hard and soft wood. The adjustment itself is simple and changing the planer to a thicknesser takes a few seconds.

The latest version of the machine with an innovative tabletop opening system:

Pedpswu T S Aofx Aalepl

❌ Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

✔️ The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

✔️ This solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Stable construction resistant to vibrations

The weight of the machine up to 170 kg combined with wide cast iron grinded tops 265 mm guarantees great stability, which ensures safe work.

The additional rubber feet used allow work without the slightest vibrations.

VERSION with the most powerful engine with a total power of S6: 2.6kW

The PT265 planer-thicknesser is distinguished by an exceptionally powerful engine with a total power of S6 2.6 kW (S1 2.2 kW). This is much more than competitive devices offer, which translates into greater efficiency and stability of work.

A more powerful engine means stable work and ease of processing hard materials: Hardwood requires more force for processing. A strong engine will handle this without a problem.

Trouble-free change of the planer to the thicknesser.

Switching from the planer to the thicknesser function is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

- Smooth height adjustment of the tops with a scale.

- The thicknessing table mounted centrally on the column has a knob for adjusting the setting up and down

- Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical data:

Knife shaft diameter [mm] 75

Knife shaft speed [rpm] 4000

Suction nozzle diameter [mm] 100

Swing ruler tilt angle [°] 90 - 45

Number of knives 3

Shaft length [mm] 262

Knife dimensions [mm] 250x30x3

Maximum planer width [mm] 265

Maximum thicknesser width [mm] 265

Maximum planing height [mm] 180

Maximum thicknesser cutting depth [mm] 3

Maximum planer cutting depth [mm] 2.5

Thicknesser feed speed [m/min] 6

Fence size [mm] 700 x 150

Machine dimensions (length x width) [mm] 1080 x 269

Weight [kg] 170

Total engine power S6: 2.6 kW

Power supply 230V

Listing

Siedlce

Siedlce

17,614 km

Universal lathe 325x915

CORMAKTytan 330L

Call

Condition: new, Year of construction: 2025, Semi-professional CORMAK 330x915 universal lathe for metal is equipped with a 12-speed gearbox with an induction motor (constant speed) 1.1 kW/400V - maximum torque. Recommended for turning hard steels, mechanical turning. It can be used for many tasks such as internal and external surface turning, tapers, polishing, metric and inch threading, drilling and broaching.

Podjm Nb Srspfx Aalopl

Technical data:

Max. turning diameter over bed: 325mm

Max. installed part length (in tusks): 915 mm

Max. length of installed part (turning chuck/center): 830mm

Turning diameter over carriage: 208mm

Bed width: 160mm

spindle bore: 38mm

Spindle taper: MK5

Turning post dimensions: 78 x 78 x 20mm

Max. tool dimension: 16x16mm

Top slide range: 100mm

Longitudinal feed range: 153mm

Longitudinal shift range: 800mm

Spindle speeds: 12 spans (L/H)

Spindle speed range: L: 65, 90, 120, 120, 160, 300 / H: 380, 500, 640, 850, 1100, 1650 rpm.

Longitudinal feed range: 0.087-2.218 mm/rev

Traversing range: 0.019-0.477mm/rev

Spindle nose: MK5

Metric thread: (16) 0.25-6mm

Inch thread: (24) 4-120 T.P.I.

Tailstock liner diameter: 32mm

Tailstock sleeve tip: MK3

Tailstock liner travel distance: 75mm

Engine power: 1.1kW / 400V

Pump size: 0.1kW

Weight: 390 kg

Dimensions: 1770x740x1600mm

Equipment:

Lathe base

2-axis digital readout (optical ruler)

160mm 3-jaw lathe chuck

Jaws left

Fixed Tooth: MK3

Change wheels

Spindle reducer

Cooling system

Lubricator

Handle and holder wrench

A set of maintenance tools

CE safety guards

Manual in Polish

CE Declaration of Conformity

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Universal lathe 410x1000

CORMAK410x1000

Call

Condition: new, Year of construction: 2025, One of our best-selling conventional lathes, this lathe can be used for many tasks such as turning internal and external surfaces as well as tapers, polishing, modular and DP threading, drilling and internal broaching.

Machine features

Lathes from this series can be used for many tasks such as turning internal and external surfaces, tapers turning, buffing, modular and DP threading, drilling and internal broaching

By default equipped with a 3 axes digital readout

Modern and precise spindle bearings

52 mm large spindle bore

Heavy bed made of cast iron, ground and inductively hardened

Gear wheels strengthened through hardening and precise grinding

Removable bridge allows for greater machining capabilities

Protection guards compliant with the newest regulations

Machining accuracy: circularity deviation below 0.01 mm, cylindricality deviation no more than 0.02 mm for 200 mm long measurement, perfect surface finish

Equipped with a mechanical foot mechanical brake

Possibility of equipping the lathe with a ruler for turning tapers

Optional VARIO model with a smooth spindle speed adjustment and a digital indicator

Technical data

Swing over bed 410 mm

Swing over cross slide 255 mm

Swing over gap bridge 580 mm

Turning length in gap bridge 190 mm

Centres distance 1000 mm

Centres height 205 mm

Bed inductively hardened

Bed width 250 mm

Spindle bore diameter 52 mm

Spindle tip D1-6

Spindle mount MK6

Spindle speed (16) 45–1800 rpm

Maximum tool dimensions 20 mm×20 mm

Longitudinal feed range (17) 0.05–1.7 mm/turn

Transverse feed range (17) 0.025 – 0.85 mm/turn

Metric thread (42) 0.2–14 mm

Inch thread (45) 2–72 T.P.I.

Modular thread 0.3–3.5 M.P (18)

D.P. thread 8–44 D.P. (21)

Tailstock quill diameter 50 mm

Tailstock quill extension 120 mm

Tailstock quill tip MK 4

Digital readout in 3 axes

Main motor power (S1/S6) 2.2/3.3 kW

Flood coolant pump power 0.1 kW

Dimensions 1940×850×1320 mm

Weight 1590 kg

Default equipment

200 mm 3-jaw lathe chuck

250 mm 4-jaw lathe chuck

3 axes digital readout

Face plate

Steady rest

Follow rest

Spindle reducing sleeve

Dead centre

Change gears for the swing-frame of the gear train

Cooling system

Lighting installation

Thread indicator (gauge)

Lathe equipped with an electromechanical foot brake compliant with EC regulations

Chips container

Set of handling tools

Protective guards compliant with the newest EC regulation

User manual

EC declaration of conformity

Factory new machine under full warranty

Pedpeiz Tf Sofx Aalepl

Factory new machine, under warranty

For more information you can visit our web page.

Listing

Siedlce

Siedlce

17,614 km

Planer-thicknesser

CORMAKPT260Q

Call

Condition: new, Year of construction: 2025, VERSION with the most powerful engine with a total power of S6: 2.6kW. A more powerful engine means stable operation and easy processing of hard materials: Hardwood requires more force for processing. A powerful engine will handle this without a problem.

The latest version of the machine with an innovative tabletop opening system:

Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

Such a solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Trouble-free change from a planer to a thicknesser.

The transition from planer to thicknesser is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

Smooth height adjustment of the tops with a scale.

The thicknesser table mounted centrally on the column has a knob for adjusting the setting up and down

Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical parameters

Knife shaft diameter 75 mm

Knife shaft speed 4000 rpm

Suction nozzle diameter 100 mm

Swing ruler tilt angle 90–45°

Number of knives 3

Shaft length 250 mm

Knife dimensions 250x30x3 mm

Maximum planer width 250 mm

Maximum thicknesser width 250 mm

Maximum planing height 180 mm

Maximum thicknesser cutting depth 3 mm

Maximum planer cutting depth 2.5 mm

Thicknesser feed speed 6 m/min

Fence size 700 x 150 mm

Ppjdpfx Ajvxh A Ssalol

Machine dimensions (length x width) 1080 x 269 mm

Weight 175 kg

Total engine power S1: 2.2 kW S6: 2.6 kW

Power supply 400V

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

18,650 km

Surface grinding machine

JUNGFlat Grinding Machine

Condition: not inspected (used), functionality: unexamined, overall weight: 700 kg, grinding wheel diameter: 150 mm, jaw width: 70 mm, No minimum price – guaranteed sale to the highest bidder!

The machine is being auctioned due to company closure. Submitting a bid commits you to timely collection between 26.01.2026 and 29.01.2026!

TECHNICAL DETAILS

Magnet dimensions: 500 x 200 mm

Grinding wheel diameter: 150 mm

Ppsdexqb D Aopfx Aalel

Jaw width: 70 mm

MACHINE DETAILS

Dimensions & Weight

Dimensions (L x W x H): 3,000 x 1,500 x 1,600 mm

Weight: 700 kg

EQUIPMENT

Matching workbench with sine magnetic chuck

Various grinding wheels

Precision vise

Listing

Nattheim

Nattheim

18,550 km

Table router including feed

FelderProfil 45 M

Call

Condition: used, Year of construction: 2019, incl. 4-roller feed unit Felder Variofeed 4 (3-18 m/min.) electronically controlled height and angle adjustment milling spindle D=30 mm Centrex access protection for milling milling fence max. cutter diameter 250 mm infinitely variable fine adjustment of the take-off side +35/-10 mm with digital display complete fence position-controlled adjustable milling fence can be folded up and down milling fence rails 550 mm ALU anodized with safety rulers quick clamping of the milling fence extension frame 1270 mm with emergency stop EURO run-in protection 5.5 kW motor with variable speed control speed range: 1500 - 10000 rpm speed range: 8000 - 15000 rpm HG spindle control panel at eye level with x-motion control table size: 1160 x 770 mm table opening: 320 mm swing-away device for feed unit on F 900 incl. extension for feed unit

Location: Supplier

Ppedsxta Dyopfx Aalsl

Listing

Aurach

Aurach

18,508 km

Electromagnetic chuck

Call

Condition: good (used), Electromagnetic clamping plate 400 x 170 mm

Manufacturer SAV type 112-17.5/45 watts

with sine swivel

24 volts with 4-pin plug. Was last on a JUNG grinding machine.

But with the appropriate plug it also fits other models e.g. ELB, ABA, ZIERSCH; G+H etc.

The magnetic plate can be swiveled with end dimensions using the sine function.

Ppsdpfevr Stnsx Aalsl

Very good condition.

Price net ex warehouse

Listing

Vilnius

Vilnius

17,338 km

Reefer semitrailer

SCHMITZ CARGOBULLSKO FP 60 ThermoKing SLXi 300

Call

Condition: used, functionality: fully functional, maximum load weight: 27,000 kg, overall weight: 8,809 kg, axle configuration: 3 axles, first registration: 11/2020, total length: 14,040 mm, total width: 2,600 mm, suspension: air, color: white, Year of construction: 2020, Equipment: cooling unit, full service history, power assisted steering, Technical specifications

Cooling unit - THERMO KING SLXi 300, diesel and electrical

Axles producer - SCB

Full air suspension

Insulated double rear doors with 4 steel lockrods

FP insulated sidewall, 60 mm

Plastic toolbox with cover holder

Fuel tank, 245 l

Electronic brake system EBS

Anti-lock braking system ABS

Pjdpex N Ntlefx Aaljpl

ROTOS SCB (disc brakes)

Thermometer

Insulated ventilation flap in the left hand rear door

Contact switch for rear door

Aluminium barley seed floor

Basket type spare wheel carrier for 2 wheels

Spare wheel

(6+1) tyres - 385/65R22.5 (11.75x22.5)

Loading capacity 33 euro paletts

Length/width/heigth - 1341cm/246cm/265cm

Gross vehicle weight - 39 000 kg

Approximate own weight - 8 410 kg

3 axles

Pallet rack for 36 Euro pallets

TrailerConnect S.KO COOL country package wave 3

Listing

Ebikon

Ebikon

18,761 km

Moulder

WEINIGPowermat 500

Call

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, machine/vehicle number: 114550, working width: 230 mm, planing height: 120 mm, number of spindles: 6, Weinig Powermat 500 Four-Sided Planer and Moulder for planing and profiling solid wood on four sides. The machine features CNC control and the proven PowerLock quick-change system. Additionally, it is equipped with an automated return mechanism for the planed workpieces, ensuring optimum suitability for efficient production processes.

Machine Configuration

- 6 spindles

1st spindle: 7.5 kW, 8,000 rpm

2nd spindle: 7.5 kW, 8,000 rpm, PowerLock

3rd spindle: 7.5 kW, 8,000 rpm, PowerLock

4th spindle: 7.5 kW, 8,000 rpm, PowerLock

5th spindle: 7.5 kW, 8,000 rpm, PowerLock

6th spindle: 7.5 kW, 8,000 rpm, PowerLock

Ppjdpfx Aasx Sxfveljl

Working width: 20 – 230 mm

Working height: 8 – 120 mm

Worktable length: 2.5 m (including straightening ruler)

Top pressure rollers, spring-loaded

Side pressure, pneumatically actuated

Frequency-controlled feed with brake, feed speed: 5 – 30 m/min

Reduced feed roller spacing between feed elements (400 mm)

Additional feed rollers and shortened roller spacing

Durofer steel feed roller, self-cleaning

Infeed roller before the first bottom tool, pneumatically actuated

Siemens/Powercom control system

The machine is in very good and well-maintained condition, has been professionally operated and serviced regularly, and will remain in operation until 17.12.2026. Viewing of the machine in operation is possible by appointment at any time.

The technical description as well as the layout drawing of the machine can be found in the documents.

Listing

Delmenhorst

Delmenhorst

18,336 km

Rolling container stainless steel container boiler

10345

Call

Condition: good (used), Used insulated stainless steel container with electric heating

Last use: Food

Item number: 10345

Volume: 90 L

Type: Standing on four rolls

Material (media-touched): 1,4301/AISI 304

Execution: Waved with insulation

Subsoil: Flat floor

Top floor: Folding lid

Operating pressure according to type plate: ATM

Dimensions containers:

Exterior diameter: 500mm

Interior diameter: 450mm

Manhole: 450x305mm

Total height: 1340mm

Height of feet: 440mm

Total width: 970mm

Total length: 1030mm

Materials:

Inside: 1,4301/AISI 304

Exterior: 1,4301/AISI 304

Facilities:

Lids folding

Various connections

Insulation

Electric radiator in the container

Panel

Grid sheet welded

Podpfed Ngdaox Aalspl

Trust Seal

Dealers certified through Machineseeker

Listing

Bitburg

Bitburg

18,682 km

Band saw

PanhansBSB 600

Call

Condition: new, Year of construction: 2025, machine/vehicle number: C890, PANHANS band saw

Type BSB 600

Stand in modern steel construction, table top thick-walled,

high ribbed cast iron massive grey cast iron band saw frames

technology:

- upper and lower PANHANS band saw blade guide APA II

- finely planed cast iron table

- swivelling table top up to 20

- dynamically balanced band saw blades with vulcanized rubber bandages

- fence ruler can be used to the left of the saw blade

- Fence profile can be folded down

- blade tension indicator

- mechanical height adjustment by hand wheel with locking pinion

- automatic motor brake with main switch and motor protection switch

technical data:

- max. cutting height 380 mm

- max. cutting width 570 mm

- table size (BT) 590 x 810 mm

- table height 905 mm

- wheel-Ø 600 mm

- engine power 2,2 kW

- wheel speed 820 rpm

- max. saw band length 4710 mm

- suction nozzle-Ø 2 x 100 mm

- machine weight 272 kg

- machine size (LBH) 1120 x 750 x 2125 mm

Location: ex stock Bitburg

Podpfsbzmb Hex Aaljpl

Top exhibition price

Freely loaded

Listing

Bitburg

Bitburg

18,682 km

Multiple Combination

Holzkraft SCMCU 410 Elite S 32 Tersa

Call

Condition: new, Year of construction: 2026, Maximum equipment for the professional. Multiple combination with TERSA cutterhead, miter cutting device and swiveling milling spindle.

Ø 350 mm main saw blade with 118 mm max. cutting height, which is also achieved with the scoring saw blade installed

Scoring device with separate motor and Ø 120 mm saw blade, easily and conveniently adjustable from the outside

High-precision sliding carriage made of anodized aluminum on hardened and drilled steel guide rails

Large boom (1200 x 650 mm) with roller and extendable aluminum telescopic fence up to max. 3300 mm

Sawing unit swivels from 90° to -45

Pivoting milling spindle from 90° to -45° backwards into the milling fence

Four milling speeds

Right-left rotation of the milling spindle

Quick change to thickness planer thanks to parallel opening jointer tables

2-stage feed in the thicknessing table

Sharp toothed steel infeed roller for uniform wood infeed

Three independent industrial motors

With separate saw-parallel fence and separate feeder fence

With lockable main switch

Equipment details:

Format fence

Immediate control

Boom

Boom with angle-adjustable telescopic lay-off stop

with graduation

Sliding carriage with ball contact system

made of anodized aluminum

guides in hardened and ground steel F550S, 15% harder than conventional steel

Psdocnxa Sspfx Aalspl

guides riveted and not glued

light running, low noise and reliable

10 years HOLZKRAFT warranty on wear of hardened guideways

cast iron double cradle saw unit

height adjustment via dovetail guide

extremely robust and torsionally stiff for precise cuts

close to the saw blade, mounted on both sides

height and inclination adjustable up to 45

standard scoring unit with separate scoring motor 0,55 kW

double cradle scoring unit

large-dimensioned swiveling double cradle milling unit made of cast iron

milling stop

heavy professional design

the high quality cast iron fence is supplied with fine adjustment as standard

3-fold positionable for fast readjustment of the setting

with fine adjustment via toothed rack, numerical display and aluminum fraise stop jaws

Planer

steel infeed rollers with helical teeth for a constant and uniform wood infeed

solid backstops prevent the backstroke of workpieces

4-knife torsion shaft ensures an optimal planing pattern

table lips for a quieter running

Tersa planing cutterhead

No more adjusting and screwing

Change of planing knives in seconds

Self-locking

Especially low noise

Thicknessing table

The thicknessing table is mounted on four large-dimensioned spindles, which ensure high stability under all working conditions.

Due to the special lifting device, the table position is perfectly maintained even without locking.

Rip fence

with fine adjustment and quick clamping

stable round bar guide made of ground steel

reversible aluminum ruler

no measuring gap, guide rods are overlapping

Separate dressing fence

large professional design (1800 x 150 mm)

0-45° swiveling

with quick adjustment

stable round bar guide made of ground steel

simultaneous opening

Art: No. 5500557

Listing

Bitburg

Bitburg

18,682 km

Edge sanding machine

HolzkraftKSO 150 F Basic

Call

Condition: new, Year of construction: 2026, Heavy machine base guarantees high torsional rigidity and vibration-free operation

Better sanding results due to sanding belt oscillation via separate gear motor

Oscillation optionally switchable

Veneer edge sanding device with fine adjustment as standard

Grooved infeed ruler for sanding veneer overhangs

Quick changeover from veneer to solid wood sanding

Height-adjustable sanding table for utilization of the entire sanding belt width

Height adjustment of the sanding table and sanding unit swivelling via hand wheels

Height-adjustable additional table with suction device for grinding radii

Optimum chip removal through extraction at the unit and at the cross table

Automatic compensation of strip length differences due to spring-loaded strip tension

Dimensions and weights

Length approx. 1900 mm

width/depth approx. 810 mm

Height approx. 1230 mm

Weight approx. 290 kg

Dust extraction connection

Suction socket diameter 120 mm

Drive power

Oscillating motor 0,25 kW

Work table(s)

Working table length 960 mm

Working table width 352 mm

Working table height adjustment 210 mm

Cross table height min. 730 mm

Electrical data

Input power 3 kW

Psdjff Ed Topfx Aalopl

Supply voltage 400 V

Phase(s) 3 Ph

Current type AC

Mains frequency 50 Hz

Sanding unit

Sanding belt length 3000 mm

Sanding belt width 150 mm

Belt speed(s) 20 m/s

grinding surface length 1050 mm

Grinding surface width 220 mm

Swivel 0 - 45 °

Oscillation stroke 20 mm

Availability: Short term

Listing

Bitburg

Bitburg

18,682 km

Band saw

Panhans - sofort verfügbar -BSB 800

Call

Condition: new, Year of construction: 2025, Panhans BSB 800 band sawing machine

TECHNICAL DESCRIPTION

Solid German machine construction

Machine stand in shapely modern design

torsion-free

double-chamber welded steel construction

Upper and lower door secured by limit switches

Upper and lower precision band saw blade guide APA

2, size 2

Finely planed gray cast iron table

Swivel table top up to 45

Ppjdpfxjr Igzcj Aalel

Dyn. balanced band saw wheels with

vulcanized rubber bandages

Stop ruler can be used to the left of the saw blade,

Fence profile can be reversed

Blade tension indicator

1 piece saw blade5775 x 30 x 0.8 mm, tooth width9 mm,

No. 3780.301

Mechanical height adjustment of the saw blade guard

by hand wheel with locking pinion

Rotary cam switch with star-delta start and

emergency stop button

Mechanical motor brake with main switch and

motor protection relay

CE-compliant

GS tested

Left-hand machine stand

Rotary cam switch with star-delta start

and emergency stop switch

Wheel diameter 800 mm

Belt speed 1800 m/min

Cutting height 520 mm

Cutting width 780 mm

Blade length max. 5775 mm

Saw blade width min. /max. 15 mm /4 0m m

Optional with special coating Saw blade width min.

max. 10 mm / 35 mm

Table size 1145 x 760 mm

Table height 930m m

Suction nozzle 2 x 0 120 mm,

Motor power 4 kW / 5.5P S

Voltage 400 V / 50 Hz

Color RAL 7035 light grey

and RAL 5000 violet blue

Net weight approx. 525 kg

Location: From stock 54634 Bitburg

- immediately available -

We make it easier for you to find: "sine wave ruler"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sine Wave Ruler (469)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you