Used Nitrogen for sale (330)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Erlangen

Erlangen

18,454 km

Nitrogen generator 65 Nm³/h

OxysystemsOS-225-NX

Call

Year of construction: 2025, condition: new, New OS-225-NX Nitrogen PSA Generator

with the delivery for 505.2 Nm³/h at 5 bar (g) and a purity of 98.0 %

(Other interpretations on request)

Requirements for the compressed air supplied on site:

Volume flow 20.21 m³/min

Pressure 7 bar (g)

Temperature: + 10°C to +50°C

Compressed air quality according to ISO 8573: 1.4.1

Blsdpfx Aewa I Ebeafsc

Specification of Nitrogen Obtained:

Volume: 505.2 Nm³/h

Nitrogen pressure: 5 bar (g)

Purity: 98.0%

Equipment:

Nitrogen Generator OS-225-NX

Compressed Air - Pressure Dew Point Sensor

Air-Purity-Control

Siemens S7 Touch Control Panel

Flow Meter

-Inlet and outbound filtration

Purity Sensor & Analysis

-Stainless steel piping

-Input and output controls

-Output needle valve (flow regulator)

-Output pressure sensor

-Multi-language touch control panel

-Working hours display

Visit our business premises in Erlangen.

On over 450 square meters of exhibition space you will find a large number of used and new compressors.

Listing

Milano

Milano

18,772 km

Krones 32,000 Bph water filling line

KronesComplete Filling line 32.000 BPH

Call

Condition: excellent (used), Year of construction: 2006, functionality: fully functional, Technical data:

- Capacity: 32,000 bph on 1.5L

- Formats: 1500 ml

- Filling product: Water and Non-carbonated drinks

- Blowing/Filling/Capping: COMBI

- Closure system: 26.7 mm plastic screw caps

Equipment includes:

Preform hopper – M. Tanner AG / Prologic

Cap hopper – Gassner

Preform orientator – M. Tanner AG

Blow moulder – Krones Contiform S20

Filler – Krones Volumetric

Bjdpsxxbl Nefx Aafjlc

Nitrogen doser – Cryotech International

Capper – Krones

Bottle inspector – Krones Checkmat

Bottle conveyors – Krones SynCo

Labeller – Krones Etima

Coder – Markem SmartLase C350

Shrink-wrapper – Ocme Vega N70/2

Handle applicator – Comag/Decimo HM 100/2

Pack conveyors – Europool

Palletiser – Ocme Pegasus M400

Pallet wrapper – Bema Silkworm Turbo

Pallet label printer/applicator – Bancale Eidos 7P6ERL

Listing

Braak

Braak

18,215 km

Selective soldering system

SEHOGo Selective 2

Call

Year of construction: 2005, condition: used, Description:

Selective soldering system with two pots.

PB and PB Free

Inline

Miscellaneous:

Pneumatic connection: 6 bar

Nitrogen connection: min. 2 bar

Bsdpeygwf Asfx Aafelc

Mask size: 350 x 350 mm

Max. PCB size (in mask): 320 x 300 mm

Max. PCB size (without mask): 350 x 350 mm

Max. component height top: 50 mm

Max. component height bottom: 35 mm

Listing

Turkey

Turkey

17,172 km

AZOT JENERATÖRÜ

AZOT JENERATÖRÜ NOVA GAS INDUSTRYNGS-1550

Call

Condition: new, functionality: fully functional, Year of construction: 2025, actuation type: electric, Nitrogen Gas Production Capacity 30 Nm3/H

Nitrogen Outlet Pressure 200 BARG

Nitrogen Gas Purity % 99.999

Hourly Energy Consumption 42 kWh

Nitrogen Manifold Set 2 Pieces

Blodpfoxrcauox Aafec

Listing

Striegistal

Striegistal

18,238 km

Tempering furnace

AichelinKES-4

Call

Year of construction: 1973, condition: good (used), rust size: 700 x 650 x 1.100 mm

batch weight: 1.000 kg

Temperature: Max. 750 °C

Bedsydld Iepfx Aafolc

connected load: 78 kW

Equipment: Incl. Control system (should be renewed) + Charging machine

others: Furnace can be moved under nitrogen

Listing

Poljčane

Poljčane

18,270 km

Laser cutting machine

BODORC4 CE 12kW MAX

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2024, control type: CNC control, degree of automation: automatic, actuation type: electric, controller model: Bodor Thinker 3.0 software, laser type: fiber laser, laser source manufacturer: MAX, laser power: 12,000 W, sheet thickness (max.): 40 mm, table length: 4,000 mm, table width: 2,000 mm, power: 12 kW (16.32 HP), Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Working area

4000mm*2000mm

Max. positioning speed

110 m/min

Bodor Lightning perforation - function

●

Exchange time of exchangeable tables

16 s

Basic parameters

Automatic adjustment of cutting

O2, N2, air

gas pressure

Automatic focusing of laser head

●

Ergonomic remote control (Bodor

●

Mango®)

Automatic collision avoidance

●

Anti-vibration function of sheet metal

●

Cutting quality

Cutting parameter database

●

Slag protection

●

Management software

●

Cost savings

4

Nozzle for uniform gas flow

●

Maintenance reminder

●

Services

BodorCloud services

●

WIFI wireless connection

●

Max. acceleration

1.5G

Table load capacity

1886 kg

Dimensions of the device - gross floor plan without

11388*3235*2311 mm

peripherals

Version

Machine weight

7400 kg

Z-axis travel

370 mm (max.)

Positioning accuracy

±0.05 mm

Repeatability

±0.03 mm

Laser source

MAX Photonics

Optical system

Laser head

Bodor Genius

Welded table structure

Welded segments

Linear guides and racks

Bodor

Mechanical system

X-axis, Y-axis, Z-axis - Servo

Quality manufacturer

Protective housing

●

Control system

Bodor Thinker 3.0

Display

21.5 inches

Circuit breaker

Schneider

Relay

Schneider/ABB

Electrical system

Proportional gas valve

SMC/AVENTICS

Cutting valve oxygen

SMC

Nitrogen cutting valve

SMC

Alarm

●

Water cooling

●

Peripheral system

Emission removal

Filter extraction

Bljdpfox Ag Udsx Aafsc

Available in first quarter of 2026

Listing

Menslage

Menslage

18,398 km

Tecnoimpianti W. T. MINI STAB 300 SINGLE Ion Exchange Unit (2017)

Tecnoimpianti W. T.Ionenaustausch-Einheit

Call

Condition: used, Year of construction: 2017, Overview The Tecnoimpianti MINI STAB 300 SINGLE is a compact system for the acid stabilization of must and wine using the ion exchange process. It was built in 2017 by the Italian manufacturer Tecnoimpianti Water Treatment S.r.l. and was rarely used by the original owner and is now being sold due to a change of ownership. The machine is therefore in very good condition and available immediately. It is ideal for wineries, breweries or the production of carbonated beverages. Technical details Capacity: approx. 300 l/h Area of application: Acidification / stabilization of must and wine Process: Ion exchange with strongly acidic cation exchange resin Compressed air requirement: min. 6 bar Power supply: 400 V / 3 Ph + N / 50-60 Hz Installed power: 3.2 kW Operation: Touchscreen HMI Protection class: IP65 Compressor tank: 400 L, 3 bar operating pressure Certification: EU-compliant / CE Special features Fully automated process control Precise pressure and temperature control Stainless steel construction (hygienic & durable) Plug-and-play system with touchscreen Built-in nitrogen feed Effectively reduces potassium bitartrate formation

Bjdpfx Ajwm Rfksafslc

Listing

Menslage

Menslage

18,398 km

Ishida (CCW-RV-228-S/05-SS) Pouch Packer

Volpak (SI-280 F1)Beutel-Verpacker

Call

Condition: used, Year of construction: 2016, Overview This weighing and packaging line was built in 2016 by the Spanish manufacturer Volpak. The system is fully equipped, in very good technical condition and shows only minor wear. The system is still installed and connected and can therefore be viewed in person at any time. Technical details Output: 60 bags/minute Doypack/flat bag formats: 20/25g, 50g, 300g, 500g, 750g Possibility of micro-dosing powders Modern wide zipper/belt Scope of delivery Doypack packaging machine | Volpak | SI-280 F1 Multi-head weigher | Ishida | CCW-RV-228-S/05-SS 4 raw material unloading stations Lindor mixer Cox & Plant feeder between the unloading stations and the mixer and multihead weigher Ishida X-ray unit with recoil, IX-GA-4075 Ishida dynamic check weigher with DACS-G-S0 recoil Installation for the injection of nitrogen or another inert gas, together with a measuring system Dust extraction system Euro slot Smooth welding system

Bljdpotz H T Defx Aafec

Listing

Menslage

Menslage

18,398 km

KHS Blomax 16C, Innofill, etc. Aseptic PET filling line (2005)

KHSAseptische PET-Abfülllinie

Call

Condition: used, Year of construction: 2005, Overview This aseptic PET filling line for fruit juices, beverages containing fruit juice and spritzers was built between 2005 and 2006 by the German manufacturer KHS. It is suitable for still and carbonated products (up to 5 g/l CO₂) - also with or without fruit fibers. The line covers all process steps from blowing to filling, labeling, packaging and palletizing and is designed for bottle sizes from 0.5 l to 1.5 l with various closure types. The nominal output is approx. 27,000 bottles per hour at 1.0 l still. The line will be in operation until approx. February/March 2026 and can be inspected by appointment. Technical details Output: up to 27,000 bph at 1.0 l still Bottle sizes: 0.5 l - 1.5 l PET Products: Still beverages, carbonated up to 5 g/l, with or without fruit fibres Caps / neck finish: 26/22, 38 mm flat cap, sports cap possible Years of manufacture of the main machines: 2005-2006, individual units more recent (e.g. servo capper 2023, labeller 2013, winder 2017) Scope of delivery Stretch blow molder KHS Blomax 16C (2005-2006), incl. chiller from Riedel Rinser KHS Bottle rinser FR-DR (ACF) 140 28/38 Filler KHS Innofill DNVF-PET ACF 100/15 SV, 100 filling stations, 15 capping stations, servo capper (2023) Nitrogen dropper from VBS, sterile tank, filling management from Eckel & Sohn, cap disinfection KHS Innoclean KR9 (flat cap) and SC4 Twin 28 S 04 (sports cap), cap disinfection KHS Innoclean KR9 (flat cap) and SC4 Twin 28 S 04 (sports cap). VBS, sterile tank, filler management KHS Metec Cap feeder Eckel & Sohn, cap disinfection KHS Innoclean KR9 (Flatcap) and SC4 Twin 28 S 04 (Sportscap) Cleanroom Cleanroom incl. ventilation system Fa. M&W, Zander/Smardt OPK Transport technology Container and air transport KHS, Lanfranchi Inspection Full bottle inspection Heuft Squeezer Labeling Krones Starmodul (YOM 2013) with Contiroll + 2x AutoCol units + dryer Krones Linadry Label inspection unit Heuft FinalView Packaging Tray/Shrink packer KHS Kisters Innopack TSP 050 V TPFO Wrap Around Packer KHS Kisters Innopack 320/70 (BJ 1999) Carry handle applicator KHS Carry Strip Master CSM 050- 2 Palletizing & wrapping Palletizer KHS Innopal Markant 1BSH2-PL + Innopal Markant 1BSH2/1-PL (both year 1999) Wrapper Haloila Octopus 1845S (year 2017, currently at a different location)

Blsdjwzlb Nspfx Aafsc

Listing

Babenhausen

Babenhausen

18,550 km

Standard tractor unit

SCANIAR 460*SPITZER SILO*WENIG KM*ACC*KOMPRESSOR*TOP

Call

Condition: used, mileage: 186,000 km, power: 338 kW (459.55 HP), first registration: 07/2023, fuel type: diesel, overall weight: 18,000 kg, axle configuration: 2 axles, next inspection (TÜV): 09/2025, brakes: retarder, color: green, gearing type: automatic, Year of construction: 2023, Equipment: ABS, air conditioning, compressor, electronic stability program (ESP), navigation system, parking heater, soot filter, SCANIA R 460 | SPITZER SILO | LOW KM | ACC | PTO | EXCELLENT CONDITION

----VEHICLE HISTORY

* 1 OWNER

* GERMAN VEHICLE

* MAINTENANCE CONTRACT WITH SCANIA

* VIDEO AVAILABLE ON REQUEST

----VEHICLE EQUIPMENT

----GENERAL DATA

* EXCELLENT CONDITION

* OPERATING HOURS: 4,300 H

----AXLES

AXLE 1:

* TIRES: 385/65R22.5

* SCANIA AXLES

* ALCOA DURA BRIGHT EVO

* LEAF SUSPENSION

AXLE 2:

* TIRES: 315/70R22.5

* AIR SUSPENSION

* ALCOA ULTRA ONE DURA BRIGHT EVO

----DRIVELINE & TECHNOLOGY

* RETARDER

* COMPRESSOR

* PTO (POWER TAKE-OFF)

* AUTOMATIC TRANSMISSION

* DIFFERENTIAL LOCK

* TRACTION CONTROL (TC)

* HILL START ASSIST

* HILL DESCENT CONTROL

----TANK & BRAKES

* 1X DIESEL TANK 440 LITERS

----ASSISTANCE SYSTEMS

* ACC (ADAPTIVE CRUISE CONTROL)

* LANE KEEP ASSIST

----COMFORT & INTERIOR

* SCANIA ENTERTAINMENT PREMIUM

* STATIONARY AIR CONDITIONING

* PARKING HEATER

* AUTOMATIC CLIMATE CONTROL

* 1 BED

* 1 FRIDGE

----DRIVER'S SEAT

* SEAT HEATING

* SEAT VENTILATION

----SPECIAL FEATURES

* NAVIGATION SYSTEM

* ELECTRIC WINDOWS

* HEATED SIDE MIRRORS

----TRAILER

SPITZER | CEMENT SILO

* 1 OWNER

* GERMAN VEHICLE

----GENERAL DATA

* MANUFACTURER: SPITZER

* MODEL: S11037

* FIRST REGISTRATION: 11/2023

* YEAR OF MANUFACTURE: 2023

* UNLADEN WEIGHT: 4,475 KG

* GROSS WEIGHT: 37,000 KG

* COMPARTMENT 1: 34,000 LITERS

* PERMISSIBLE TEMPERATURE: -40°C TO +80°C

----AXLES & CHASSIS

* 3-AXLE

* TIRES: 385/65 R22.5

* FULL AIR SUSPENSION

* BPW AXLES

* LIFT AXLE

* ALCOA DURA BRIGHT EVO

----TECHNOLOGY & EQUIPMENT

Bjdpfx Aajxpbn Sofelc

* TOP LOADING

* NITROGEN INLET REAR

---- EXPORT SALES ONLY WITH DEPOSIT MIN. €500 - €2,000

----CUSTOMS EXPORT DECLARATION EXW IN 10 MIN. (APPROVED EXPORTER) 5 DAY, 30 DAY TEMPORARY GERMAN PLATE AND 17 - 21 DAY AUSTRIAN PLATE EURO 1

RESERVATIONS ONLY VIA EMAIL FUNCTION

VERBAL RESERVATIONS ARE NOT VALID!

A deposit of at least €500.00 / €1,000.00 will be charged for sales to EU & third countries.

Subject to change, errors, and prior sale.

Find more vehicles on our homepage:

Sale is strictly according to our General Terms and Conditions – see homepage.

Important note – Important information: Despite carefully checking all details in our offer, errors may occur. These may be caused by transmission errors in the systems of various platform providers. Therefore, all information is given without guarantee and does not constitute a legal claim.

Legal: This sales advertisement does not constitute an offer in the sense of §145 BGB. It serves solely as information to initiate a contract. The details provided are without obligation and do not represent guaranteed characteristics.

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg820S 4000-2100/400

Call

Condition: excellent (used), Year of construction: 2012, Arburg 820S 4000-2100/400 / Production line with the robot Sepro Industrial Robot SR S5-35 S3 Trans / Operating hours: 42,014 h in automatic mode

Year of manufacture: 09.2012

Injection unit:

Screw diameter: 60 mm

Injection weight: 723 g

Bledpfxjyctzfs Aafsc

Injection pressure: 2500 bar

Dosing volume: 792 cc

Clamping unit:

Clamping force: 400 t

Bar spacing: 820x820 mm

Size of the clamping plates: 1171x1171 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control: SELOGICA - touchscreen

Additional equipment:

2K injection molding machine with rotary table and robot

Very good technical condition

Operating hours: 42,014 h in Automatic operation

Euromap 67

Robot interface

Air valve x 6

Hydraulic, needle core pull, controlled by a proportional valve x 4 pairs

Control with hot runners x 24

Reinforced injection units - bimetal

Proportional valve on the vertical injection unit - precise injection

Machine with six cylinders / batteries with compressed nitrogen (additional charge for fast work)

Parallel movements

Automatic tool height adjustment

Screw diameter in the vertical injection unit: ⌀40 mm - 184 g/PS

The built-in system for controlling the print quality from the Sensor Kistler brand - measuring the tool pressure

Original Weber rotary table: very precise, electrically driven by a servo motor controlled by an inverter

Rotary table diameter: 1200 mm

Purchase of the rotary table at an additional cost

Robot Sepro Industrial Robot SR S5-35 S3 Trans

Year of manufacture: 2012

3-axis robot: 3 axes are driven by servo motors (electric): X, Y, Z (telescopic)

Travel paths in axes approx.: X-5000, Y-1400, Z-2000

Automatic axis lubrication

Touch control panel

The robot safety package

Robot with adapter and protective housing

Purchase of the robot for an additional charge

Dimensions:

Weight: 21000 kg

Length/width/height: 8.00x2.32x4.21 m

All machines offered are started by our service technicians before sale.

It is possible to receive a video of the technical tests of the selected machine or to take part in live technical tests in our company in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg630S 2500-1300 ECO

Call

Condition: excellent (used), Year of construction: 2008, Arburg 630S 2500-1300 ECO / Production Line with Sepro Industrial Robot SDR 22S

Year of manufacture: 2008

Injection Unit:

Screw diameter: 55 mm

Shot weight: 521 g

Injection pressure: 2380 bar

Dosage volume: 570 ccm

Clamping Unit:

Clamping force: 250 t

Tie bar distance: 630x630 mm

Platen size: 900x900 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control: SELOGICA - touchscreen

Blodpfeyctyhex Aafjc

Additional equipment:

Euromap 67

Robot interface

Air valves x 4

Hydraulic core pulls x 2

Controller with 15 hot runner zones

Injection assembly hardened - bimetallic

Machine with cylinder / battery with compressed nitrogen (additional charge for fast operation)

ECO – machine equipped with a system to adjust the minimal mould height

Robot - Sepro Industrial Robot SDR 22S

Year of manufacture: 2016

4-axis robot: 3 axes driven by servomotors (electric); C-axis - pneumatic

Axis strokes: X-1500, Y-2200, Z-800

Vacuum x 2

Gripper x 2

Touch control panel

Robot with adapter, conveyor belt and protective housing

Acquisition of the robot and the conveyor belt available at extra cost

Dimensions:

Weight: 12,510 kg

Length/Width/Height: 6.57x1.76x2.46 m

All offered machines are commissioned by our service technicians before sale.

It is possible to receive a video of the technical tests for the selected machine or to participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg570S 2200-290/100/100

Call

Condition: excellent (used), Year of construction: 2016, Arburg 570S 2200-290/100/100 / Production line with the Wittmann W823 robot / Operating hours: 20,499 h in automatic mode

Year of construction: 2016

Injection unit:

Screw diameter: 35 mm

Injection weight: 132 g

Injection pressure: 2000 bar

Metering volume: 144 ccm

Clamping unit:

Clamping force: 220 t

Distance between tie bars: 570x570 mm

Size of the clamping platens: 795x795 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: SELOGICA touchscreen

Additional equipment:

3-component injection molding machine, high speed

Very good technical condition

Operating hours: 20,499 h in automatic mode

Euromap 67

Robot interface

Air valve x 6

Hydraulic, needle core pull, controlled by a proportional valve x 4

Control unit with hot runners

Hardened injection unit - bimetal

Proportional valve on the injection unit - precise injection

Machine with two cylinders / battery with compressed nitrogen (additional charge for fast work)

The machine is designed for operation with an electric turntable. The machine has an inverter to control the servomotor in the rotary table and an interface for connecting the rotary table

Parallel movements

Screw diameter in the vertical injection unit: ⌀25 mm - 45 g/hp

Screw diameter in the lateral injection unit: ⌀25 mm - 45 g/hp

Wittmann W823 robot

Year of construction: 2015

5-axis robot: 3 axes are driven by servomotors (electric); axis C and movement A

Travel in axes: X-550, Y-1400 (telescopic), Z-3500

Touch control panel

The safety package for robots

Robot with adapter, conveyor belt and protective housing

Purchase of the robot and conveyor belt for an additional charge

Dimensions

Weight: 10830 kg

Bledsyctx Ropfx Aafsc

Length/width/height: 5.53x1.77x3.29 m

All offered machines are started by our service technicians before sale.

It is possible to obtain a video of the technical tests of the selected machine or participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg570H 2000-800 e²

Call

Condition: excellent (used), Year of construction: 2011, Arburg 570H 2000-800 e² / Hybrid Machine / Production Line with Arburg Multilift Select Robot

Year of Manufacture: 2011

Injection Unit:

Screw diameter: 50 mm

Shot weight: 359 g

Injection pressure: 2000 bar

Dosing volume: 392 cc

Clamping Unit:

Clamping force: 200 t

Tie bar spacing: 570x570 mm

Platen size: 795x795 mm

Ejector: electric

Clamping unit: toggle lever

Control System: SELOGICA - Touchscreen

Additional Equipment:

Hybrid machine: high-speed, energy-saving, and very quiet

Euromap 67

Robot interface

Air valves x 4

Hydraulic core pull x 2

Controller with 12 hot runner zones

Injection unit hardened - bimetallic

Main motor of the machine: servo motor driven by inverter – energy saving

Injection unit driven by a servo motor, controlled by an inverter

Machine with cylinder / battery with compressed nitrogen (additional charge for fast operation)

Central lubrication system

Parallel motions

Arburg Multilift Select robot, 6 kg transverse

Year of manufacture: 03.2011

4-axis robot: 3 axes driven electrically by servo motors; C-axis pneumatic

Travel distance in axes: X-400, Y-800, Z-1400

Robot with adapter, conveyor belt, and safety enclosure

The purchase of the robot and conveyor belt is available for an additional charge

Dimensions:

Weight: 8700 kg

Length/Width/Height: 5.58x1.71x2.21 m

Blsdpfjyctw Tjx Aafsc

All machines offered are started up and tested by our service technicians before sale.

It is possible to receive a video of the technical tests of the selected machine or to participate in live technical tests at our facility in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg520S 1600-400/170 e²

Call

Condition: excellent (used), Year of construction: 2012, Arburg 520S 1600-400/170 e² / Production Line with Geiger Robot

Year of manufacture: 10.2012

Injection Unit:

Screw diameter: 35 mm

Shot weight: 141 g

Injection pressure: 2500 bar

Bsdpfxoyctwge Aafolc

Dosage volume: 154 cc

Clamping Unit:

Clamping force: 160 t

Tie bar spacing: 520x520 mm

Platen size: 695x695 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: SELOGICA – Touchscreen

Additional equipment:

2K injection molding machine with rotary table and Geiger robot

Very good technical condition

Hybrid machine: energy-efficient and very quiet

Euromap 67

Robot interface

Air valve x 4

Hydraulic core pull x 5

Hot runner control x 12

Reinforced injection units – bimetallic

Machine with two cylinders / compressed nitrogen accumulators (additional charge for fast operation)

Parallel movements

Screw diameter in vertical injection unit: ⌀30 mm - 77 g/PS

Integrated Arburg conveyor belt and sorting flap

Original Weber rotary table, highly precise – electrically driven

Purchase of the rotary table and robot for a surcharge

Dimensions:

Weight: 8140 kg

Length/Width/Height: 4.81x1.84x3.45 m

All machines offered are started up by our service technicians prior to sale.

It is possible to receive a video of the technical tests of the selected machine or to participate in live technical tests at our facility in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg520S 1600-290/100

Call

Condition: excellent (used), Year of construction: 2011, Arburg 520S 1600-290/100 / Production line with Wittmann W823 robot / Operating hours: 20,181 h in automatic mode

Year of construction: 09.2011

Injection unit:

Screw diameter: 35 mm

Injection weight: 132 g

Injection pressure: 2000 bar

Metering volume: 144 ccm

Clamping unit:

Clamping force: 160 t

Distance between tie bars: 520x520 mm

Size of the clamping plates: 695x695 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: SELOGICA touchscreen

Additional equipment:

2K injection molding machine with rotary table and robot

Very good technical condition

Operating hours: 20,181 h in automatic mode

Total number of operating hours: 28,473 h

Euromap 67

Robot interface

Air valve x 3

Hydraulic, needle core pull, controlled by a proportional valve x 2

Reinforced injection units - bimetal

Proportional valves on injection units - precise spraying

Machine with two cylinders / batteries with compressed nitrogen (additional charge for fast work)

Parallel movements

Screw diameter in the vertical spraying unit: ⌀25 mm - 45 g/hp

Original turntable

Purchase of the turntable for an additional charge

Robot Wittmann W823

Year of construction: 2015

5-axis robot: 3 axes are driven by servo motors (electric); axis C and movement A

Travel in axes: X-550, Y-1400 (telescopic), Z-3500

Touch control panel

The safety package for robots

Robot with adapter, protective housing

Purchase of the robot for an additional charge

Dimensions

Weight: 6720 kg

Length/width/height: 4.41x1.84x3.20 m

All offered machines are started by our service technicians before sale.

Blsdpfxoyctwao Aafoc

It is possible to obtain a video of the technical tests of the selected machine or participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg470H 1000-400 e²

Call

Condition: excellent (used), Year of construction: 2010, Arburg 470H 1000-400 e² / Hybrid Machine / Production Line with Arburg Multilift Select Robot

Year of manufacture: 2010

Injection Unit:

Screw diameter: 40 mm

Shot weight: 184 g

Injection pressure: 2000 bar

Dose volume: 201 ccm

Clamping Unit:

Clamping force: 100 t

Tie bar spacing: 470x470 mm

Platen size: 637x637 mm

Ejector: electric

Clamping system: toggle lever

Control: SELOGICA - Touchscreen

Additional Equipment:

Hybrid machine: energy-efficient and extremely quiet

Euromap 67

Robot interface

Air valve x 4

Hydraulic core pull x 1

Control for hot runner systems x 12

Hardened injection unit - bimetallic

Main drive motor - servo motor powered by inverter – energy saving

Injection unit driven by servo motor controlled by inverter

Machine equipped with a cylinder / accumulator with compressed nitrogen (additional charge for fast cycling)

Central lubrication

Integrated sorting flap

Arburg Multilift Select robot, 6kg transverse

Year: 09.2010

4-axis robot: 3 axes electrically driven by servo motors; C axis - pneumatic

Travel range (axes): X-400, Y-600, Z-1800

Robot with adapter, conveyor belt and safety enclosure

Purchase of robot and conveyor belt available at extra cost

Dimensions:

Weight: 5180 kg

Bsdpoyctrdsfx Aafjlc

Length/Width/Height: 4.40x1.56x2.02 m

All machines offered are commissioned by our service technicians before sale.

It is possible to receive a video of the technical tests of the selected machine or to participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

KraussMaffeiKM 110-700 C2

Call

Condition: excellent (used), Year of construction: 1998, Krauss Maffei KM 110-700 C2

Year of manufacture: 1998

Injection unit:

Screw diameter: 45 mm

Injection weight: 278 g

injection pressure: 2336 bar

Metering volume: 305 ccm

Clamping unit:

clamping force: 110 t

tie bar distance: 470x470 mm

size of clamping platens: 745x770 mm

ejector: hydraulic

clamping unit: hydraulic

Control system: MC IV

Additional equipment:

Machine in very good technical condition

Euromap 12

Robot interface

Air valve x 1

Hydraulic core pull x 1

Control with hot runners x 12

Injection unit hardened - bimetal

Parallel movements

Proportional valve on the injection unit - precise injection

Bljdpjyctghofx Aafjc

Machine with cylinder / battery with compressed nitrogen (additional charge for fast work)

The machine has been regularly serviced by the authorized service Krauss Maffei in Switzerland

Dimensions:

Weight: 6200 kg

Length/width/height: 4.66x1.51x2.19 m

Propulsion:

Pumps/motor: 18.5 kW

Heating power: 16 kW

Total power: 34,5 kW

All offered machines are started by our service technicians before sale.

It is possible to get a video of technical tests of the selected machine or participate in live technical tests in our company in Łódź.

Price: Upon request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Ferromatik MilacronK-TEC 350-2650

Call

Condition: excellent (used), Year of construction: 2017, Ferromatik Milacron K-TEC 350-2650 / Production line with Sepro robot

Year of manufacture: 2017

Injection unit:

Screw diameter: 70 mm

Shot weight: 1,104 g

Injection pressure: 2,175 bar

Dosage volume: 1,213 cm³

Clamping unit:

Clamping force: 350 t

Tie bar distance: 750 x 750 mm

Platen size: 1,110 x 1,165 mm

Bjdpfjyctb Eex Aafolc

Ejector: hydraulic

Clamping unit: hydraulic

Control system: MOSAIC - touchscreen

Additional equipment:

Very good technical condition

High-speed machine

Operating hours: approx. 10,000 h (automatic mode)

Euromap 67

Robot interface

Air valve x 5

Hydraulic core pull x 3

Hot runner control

Hardened injection unit - bimetallic

Proportional valve on injection unit – precise injection

Parallel movements

Machine equipped with cylinder / nitrogen accumulator (additional charge for high-speed operation)

Energy-efficient machine – features a system with three variable output hydraulic pumps

Machine has been regularly serviced by authorized service in Germany

Dimensions:

Weight: 22,000 kg

Length/Width/Height: 8.62 x 2.21 x 2.80 m

All machines offered are started up by our service technicians before sale.

It is possible to receive a video of the selected machine’s technical tests or participate in live technical demonstrations at our premises in Łódź.

Price: On request

Listing

Łódź

Łódź

17,814 km

Injection molding machine

Arburg370S 700-100/100

Call

Condition: excellent (used), Year of construction: 2009, Arburg 370S 700-100/100 / 2K machine / operating hours: 33.544 in automatic mode / very good technical condition

Year of manufacture: 2009

injection unit:

Screw diameter: 30 mm

injection weight: 65 g

Injection pressure: 1390 bar

Metering volume: 71 ccm

Clamping unit:

clamping force: 70 t

tie bar distance: 370x370 mm

Bledpfxoycr Rro Aafec

size of clamping platens: 510x510 mm

ejector: hydraulic

clamping unit: hydraulic

Control system: SELOGICA - touch screen

Additional equipment:

2K machine

Operating hours: 33.544 in automatic mode

Euromap 67

Robot interface

Air valve x 5

Hydraulic core pull x 2

Control with hot runners

Reinforced injection units - bimetal

Proportional valves on injection units - precise spraying

Parallel movements

The vertical injection unit - screw diameter fi 20 mm (29 g/hp)

Machine with cylinder / battery with compressed nitrogen (additional charge for fast work)

Machine with the built-in conveyor belt Arburg and original sorting flap

There is a possibility to buy an original Weber turntable

It is possible to change screw diameters in both injection units for the screw diameters recommended by the manufacturer

Dimensions:

Weight: 4440 kg

Length/width/height: 3.48x1.58x2.97 m

Drive:

Pumps/motor: 15 kW

Heating power: 4,9 kW

Total power: 19,9 kW

All offered machines are started by our service technicians before sale.

It is possible to get a video of technical tests of the selected machine or participate in live technical tests in our company in Łódź.

Price: Upon request

Listing

Plauen

Plauen

18,330 km

Laser cutting machine

PFEIFER technology & innovation Plauen DskyCUBE XL class 1500 x 3000

Call

Condition: new, functionality: fully functional, Year of construction: 2026, laser power: 12,000 W, laser wavelength: 1,064 nm, table length: 1,500 mm, table width: 3,000 mm, travel distance X-axis: 1,550 mm, travel distance Y-axis: 3,050 mm, input voltage: 400 V, type of input current: three-phase, overall weight: 8,500 kg, warranty duration: 24 months, space requirement height: 2,400 mm, space requirement length: 8,550 mm, working range: 1,500 mm, Equipment: cooling unit, safety light barrier, XL class = processing area X 1550 mm x Y 3050 mm x Z 150 mm

Blodpfx Asr D Nfksafjc

High-precision linear axis system with 6 - 12 KW laser power

Double change table system, laser processing at one working height!

(* Prices depending on equipment and laser power, this is a brand new laser machine from our production)

Maximum dimensions (L × W × H (with table 8504) × 2310 × 2400 mm / laser machine 6.5 T + external loading table 2T = 8.5 tons

Power supply depends on the laser source (6kW) 400V/50Hz 3 phases / 27kW

Process gas control for: oxygen / nitrogen / compressed air depending on the material and process

Simple and highly precise laser processing - laser cutting at high speed and quality

Trust Seal

Dealers certified through Machineseeker

Listing

Plauen

Plauen

18,330 km

Laser cutting machine

PFEIFER technology & innovation Plauen DskyCUBE XL class 1500 x 3000

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser power: 6,000 W, laser wavelength: 1,064 nm, table length: 3,050 mm, table width: 1,550 mm, type of input current: three-phase, overall weight: 6,500 kg, Equipment: CE marking, cooling unit, documentation/manual, emergency stop, safety light barrier, skyCUBE XL class – Large Format – Shuttle Table Laser Cutting

The multifunctional flatbed laser center skyCUBE XL class, manufactured by PFEIFER technology in Saxony, Germany, has been designed for your professional cutting applications. It combines a new level of productivity with cost-effectiveness and precision.

skyCUBE laser systems meet all requirements of Class 1 according to DIN EN 60825-1, offering you the highest level of safety. The ergonomic design with a pull-out worktable makes machine loading easier. Drawers in the lower section of the machine collect cutting waste.

Optimize quality and cutting speed even with thick materials thanks to 6kW laser power—even when cutting with compressed air. Switch between materials while maintaining consistently high cutting quality without compromise.

Naturally, you’re always on the safe side when operating the skyCUBE laser!

The skyTUBE Pro is a Class 1 laser system. There is no risk of exposure to laser beam emissions or reflections during operation.

For all our laser systems, nothing is more important than complete safety and compliance with the highest standards and regulations.

Blodpfxot A N A Rs Aafsc

Special safety glass and a perfectly shielded cutting area reliably protect you from the hazards of laser radiation, while an independent safety system allows loading without interrupting production.

Select the laser power best suited to your needs; 6 kW is our current standard!

(* Pricing depends on configuration and laser power; this is a brand-new laser machine manufactured by us)

Maximum dimensions (L×W×H): 2310×8505×2505 mm / Laser machine 4.0 T

Power supply depending on laser source (6kW) 400V/50Hz 3 phase / 27kW

Process gas control for: oxygen / nitrogen / compressed air depending on material and process

Laser processing made easy and highly precise – high-speed, high-quality laser cutting

Listing

Borken

Borken

18,513 km

Thermogravimetric analyzer (TGA)

NETZSCHTG 209 F3 Tarsus Analysegerät TGA

Call

Condition: excellent (used), Netzsch

Model: Netzsch TG 209 F3 Tarsus

NETZSCH Proteus® Software for Thermal Analysis included.

Bedeyamzajpfx Aafolc

Description:

For sale is a NETZSCH TG 209 F3 Tarsus thermogravimetric analyzer (TGA) manufactured in Germany. This device is used in laboratories, research, development, and quality control for thermogravimetric analysis.

Thermogravimetry measures the change in mass of a sample as a function of temperature and time. This method serves, among other purposes, for assessing thermal stability, decomposition processes, moisture and solvent content, as well as filler and ash fractions.

The TG 209 F3 Tarsus is a robust, high-precision instrument designed for industrial and research applications—not a hobby or DIY device.

Typical fields of application:

- Plastics and polymer analysis

- Chemical & pharmaceutical industry

- Materials research

- Quality control

- Research & development

Software / Data Analysis:

The scope of delivery includes NETZSCH Proteus® software for thermal analysis. The Proteus® software is used for device control, data acquisition, and evaluation of thermogravimetric measurements (TGA). Key features include:

- Control of measurement programs (temperature profiles, heating rates, dwell times)

- Recording of mass changes as a function of temperature and time

- Graphical representation of measurement curves (TG, DTG)

- Evaluation of decomposition stages, mass losses, and residual masses

- Data export for documentation and further processing

The software package includes (see photos):

- Original NETZSCH Proteus® installation media

- Printed software and device documentation

- NETZSCH USB dongle (hardware license key)

System requirements (according to documentation):

- Microsoft Windows 7 / 8.1 / 10 (Professional or Enterprise)

Technical specifications (approximate values):

Manufacturer: NETZSCH (Made in Germany)

Model: TG 209 F3 Tarsus

Measurement principle: Thermogravimetric Analysis (TGA)

Temperature range: Ambient to approx. 1000 °C

Heating rate: approx. 0.1 – 50 K/min

Max. sample weight: approx. 1 g

Balance resolution: up to approx. 0.1 μg

Gas operation: Air / Inert gas (e.g., nitrogen)

Mains voltage: 230 V AC / 50–60 Hz (switchable to 115 V)

Power consumption: approx. 1.0 – 1.2 kW

Dimensions (W×D×H): approx. 45 × 55 × 35 cm

Weight: approx. 40 kg

Important note:

"The table shown in the photos is not included in the sale."

Condition: used

Scope of delivery: (See photo)

(Specifications are subject to change and errors excepted!)

For further questions, feel free to contact us by phone.

Listing

Germany

Germany

18,384 km

Semitrailer LNG

LNG tank filling station Methan Gas

Call

Condition: excellent (used), Year of construction: 2011, Schwingenschlögel LNG tank filling station Methan Gas Cryogenic tank gas tank trailer German

Bljdstzcdrjpfx Aafjc

Cryogenic gas semi-trailer for LNG (liquid methane).

Tank filling station

Manufacturer: Schwingenschlögel

EU approval.

Year: 2011

Full working condition with valid certificates.

We also have other tankers for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, Hydrogen, Methane

We would also be happy to provide you with a quotation or give you more information about other pressure vessels.

To discuss the possibilities, please contact us by phone or e-mail.

Listing

Haarle

Haarle

18,492 km

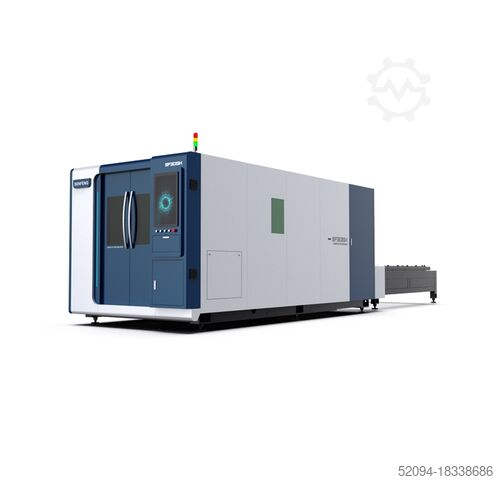

Fiber laser: Senfeng SF3015HC 6.0 KW MAX

SenfengSF3015HC

Call

Condition: new, Year of construction: 2025, The Senfeng H1 is Senfeng's best-selling model!

This is our entry-level fiber laser with interchangeable table, suitable for a power of 1 to 6 kilowatts, this can process up to 25 mm of steel

Ideal for the entrepreneur with a medium to large production requirement.

Besten Machines has been a dealer for metalworking machines for more than 25 years.

We already have more than 50 Senfeng lasers operational in the Benelux and support and install them with our own Dutch employees.

In addition, we have a large stock of spare parts to be able to offer a high level of service.

Bljdpovty N Tofx Aafec

- Laser Power: 6,000 W

- Laser Wave length: 1020 nm - 1080 nm

- X-axis range: 3000 mm

- Y-axis range: 1500 mm

- Max. Acceleration plate cutting: 1.2 G

- Maximum simultaneous axes speed: 130 m/min

- Positioning accuracy: ± 0.03 mm/m

- Repeat accuracy: ± 0.02 mm/m

- Operating voltage: 400V / 50Hz ± 5%

- Cutting gases: Oxygen, Nitrogen

- Cutting table: 3000×1500 mm

- Machine weight: ± 6,000Kg

- Equipped with shuttle table

– Max. weight of plate per changing table: 700 Kg

=====

In addition, the machine is equipped with the following options:

- Control: Cypcut

- Pull-out drawers for collecting small parts

- Aviation aluminum beam

- 6,000 watt Max Photonics EU Laser source

- Cutting head: Precitec Thunder

- Closed top and full machine housing

- Proportional pressure control for Oxygen (low pressure), Nitrogen (high pressure)

- Water cooler

- Power stabilizer

- Automatic lubrication unit

- Matching extraction

- Installation by our own technicians (Additional price based on location)

We make it easier for you to find: "nitrogen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nitrogen (330)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you