Used Juice Production Plant for sale (18,031)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Stone crushing production lineStone crushing screening plant

Call

Condition: new, Year of construction: 2025, A stone crushing plant for sand and aggregate making is a facility where stones and rocks are crushed into smaller pieces or gravel. It typically includes several stages of crushing and screening to produce various sizes and grades of sand and aggregate materials, which are essential in construction, landscaping, and other applications. Here's an introduction to the components and processes involved in a typical stone crushing plant:

### Components of a Stone Crushing Plant

1. Primary Crusher:

- Purpose: The primary crusher, often a jaw crusher or gyratory crusher, initially breaks down large rocks into smaller pieces.

- Function: It handles raw materials from the quarry or mine and prepares them for further processing.

2. Secondary Crusher:

- Purpose: A secondary crusher, such as a cone crusher or impact crusher, further reduces the size of the crushed stones.

- Function: It refines the material after primary crushing, producing smaller and more uniform-sized aggregates.

3. Tertiary Crusher (Optional):

- Purpose: In some configurations, a tertiary crusher like a vertical shaft impactor (VSI) may be used for shaping and fine crushing.

- Function: It produces finely crushed materials for specific applications, such as concrete production or road base.

4. Screening Equipment:

- Purpose: Screening equipment like vibrating screens or trommel screens separates the crushed materials into different sizes.

- Function: It classifies the aggregates into various grades according to size, ensuring uniformity and meeting specifications.

5. Conveyor Systems:

- Purpose: Conveyor belts transport materials between different stages of crushing and screening.

- Function: They ensure efficient material handling and continuous operation within the plant.

6. Washing Equipment (Optional):

- Purpose: Washing equipment, such as sand washers or scrubbers, may be used to remove impurities from sand and aggregate products.

- Function: It improves the quality of the final products by cleaning them and removing fines or contaminants.

### Processes Involved

Blodpsq N U Duefx Aafec

- Primary Crushing: Large rocks are fed into the primary crusher and reduced to a manageable size.

- Secondary Crushing: The crushed materials from the primary crusher are further processed by secondary crushers to achieve the desired aggregate sizes.

- Screening: The crushed and sized materials are screened to separate them into different sizes and grades.

- Material Handling: Conveyor systems transport materials between different stages of the crushing and screening process.

Final Product Handling:Finished products, such as sand and various sizes of aggregates, are stored or loaded for transport to customers or construction sites.

Applications

- Construction: Used in the production of concrete, asphalt, and road base materials.

- Landscaping: Provides decorative and functional aggregates for gardens, pathways, and driveways.

infrastructure: Essential for building foundations, drainage systems, and structural fill.

As for the capacity we have 30 t/h, 30-50 t/h, 50-100 t/h, 100-150 t/h, 150-200 t/h, 200-300 t/h, 300-500 t/h, and both stationary crushing plant and mobile crushing plant are available for option.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Construction waste recycling plantSand aggregate/gravel production plant

Call

Condition: new, functionality: fully functional, Year of construction: 2025, A sand aggregate or gravel production plant is a facility where raw materials like sand, gravel, and other aggregates are processed to create various products used in construction and other industries. These facilities typically involve a series of processes to transform raw materials into the final products.

Here is a general overview of the key components and processes involved in a sand aggregate or gravel production plant:

1. Mining and Extraction:

- The process starts with the extraction of raw materials from quarries or mines. Heavy machinery such as excavators, loaders, and bulldozers are used to remove the raw materials from the earth.

2. Crushing and Screening:

- The extracted raw materials often need to go through crushing and screening processes to reduce their size and separate them into different grades.

- Crushers break down large rocks into smaller pieces, and screens sort the particles based on size.

3. Washing:

- Washing is a common process to remove impurities such as clay, silt, and dust from the raw materials. This is particularly important for sand and gravel used in construction.

Bjdpfeq Nia Iox Aafjlc

4. Grading and Sorting:

- After washing, the materials may go through grading and sorting processes to separate them into different sizes and qualities.

5. Storage and Stockpiling:

- Processed materials are often stored in stockpiles for further use. Adequate storage facilities are necessary to manage different grades of materials.

6. Conveying and Transportation:

- Conveyor systems are used to transport materials between different stages of the production process. Transportation methods, such as trucks or conveyor belts, are used to move the final products to distribution points.

7. Quality Control:

- Quality control measures are implemented to ensure that the final products meet the required specifications and standards. This may involve regular testing and analysis of the materials.

8. Environmental Considerations:

- Sustainable practices and environmental considerations are crucial in the operation of a production plant. Measures such as dust control, water recycling, and rehabilitation of mined areas are often implemented to minimize the environmental impact.

9. Maintenance and Safety:

- Regular maintenance of equipment is essential for the smooth operation of the plant. Safety measures are also critical to protect workers and ensure compliance with regulations.

10. Final Product:

- The final products from a sand aggregate or gravel production plant may include various grades of sand, gravel, crushed stone, or other types of aggregates used in construction, concrete production, asphalt production, and other applications.

It's important to note that the specific processes and equipment used in a production plant may vary based on the type of raw materials, the intended final products, and local regulations. Additionally, advancements in technology and sustainability practices may influence the design and operation of such facilities.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Mobile / Stationary stone crusher plantSand & aggregate production plant

Call

Condition: new, Year of construction: 2025, A sand aggregate production plant is a facility where various types of aggregates (such as sand, gravel, crushed stone, or recycled concrete) are produced for use in construction and other applications. These plants typically include various stages of processing, from raw material extraction to the final product.

Here are the key components and processes typically involved in a sand aggregate production plant:

1. Raw Material Extraction:

- Quarrying or Mining: Aggregates are often extracted from quarries, mines, or riverbeds. Depending on the type of aggregate, the extraction process may involve drilling, blasting, or dredging.

2. Primary Crushing:

- Jaw Crusher or Gyratory Crusher: The extracted raw material is usually transported to the plant and fed into a primary crusher, where large rocks are broken down into smaller pieces.

3. Secondary Crushing:

- Cone Crusher or Impact Crusher: The crushed material from the primary crusher may undergo further reduction in size through secondary crushing.

4. Screening:

- Vibrating Screens: After crushing, the material is often screened to separate different sizes of aggregates. This process ensures that the final product meets the required specifications.

5. Washing:

- Sand Washers: In some cases, especially for sand production, washing is done to remove impurities, clay, and fines from the aggregates, ensuring a cleaner and higher-quality product.

6. Grading and Sorting:

- Classifiers or Graders: After washing and screening, the aggregates may go through additional processes to separate them based on size or quality.

7. Stockpiling:

- Stockpiles: The final aggregates are usually stockpiled for storage before being transported to construction sites or other end-users.

Bodpjq Ngb Defx Aafjlc

8. Aggregate Storage and Handling:

- Storage Bins or Silos: Larger production plants may have storage facilities, such as bins or silos, to store different types and sizes of aggregates before distribution.

9. Quality Control:

- Laboratory Testing: Regular quality control testing is performed on aggregates to ensure they meet specifications for strength, size, gradation, and other properties.

10. Environmental Considerations:

- Water Management: Some plants incorporate water management systems to recycle and reuse water used in the washing process, minimizing environmental impact.

11. Transportation:

- Conveyors or Trucks: Aggregates are typically transported from the production plant to construction sites by conveyors, trucks, or other means.

Listing

Nattheim

Nattheim

18,550 km

Window production plant

WeinigUnicontrol 10

Call

Condition: used, Year of construction: 2000, Storage location: Nattheim

Blodpfjvwdmwox Aafec

Listing

Burgdorf

Burgdorf

18,811 km

Pellet production plant 10 t/h

Friedli AG

Call

Condition: used, Year of construction: 2007, functionality: fully functional, Wood Pellet Production Plant 10 t/h

On behalf of AEK Pellets AG, Switzerland, we are selling a currently operational, fully functional production plant for the manufacture of wood pellets with a throughput of 10 t/h, expandable up to a maximum of 12 t/h.

Overview

- 3-press system including machines by CPM, Salmatec, Knoblinger, Friedli

- Scope of supply: from dry wood shavings silo (incl. discharge screws) to pellet screen

- Including control system and wiring

Condition

- Years of construction: 2003 / 2006 / 2007

- Plant in ongoing operation; inspections possible by prior arrangement

- Annual maintenance by manufacturer

- Various essential spare parts available

- Manufacturer’s drawings available

Main Components (excerpt)

- Silo discharge screws (IPM, Gottwald)

- Conveyor technology incl. belt bucket elevators, chain and connecting conveyors

- Intermediate bunker for dry shavings (48 m³)

- 2 pcs. starch silos with micro dosing (26 m³)

- Dry chip mill Champion CHAMP 30X54, 250 kW, with magnetic separator, foreign body extractor, and Scheuch filter

- Salmatec 1900LS conditioner with moisture measurement and steam/water regulation

- Maturation silos and dosing systems

- Pellet presses 2× Salmatec Maxima 840 and 1× CPM 7930-4

- Belt cooler, AVITEC pellet screen (3 fractions) with pellet cracker

- Central dust extraction with cyclone, bag filter (181 m²), and fan (45 kW)

- Associated steel structures and access platforms

Bledpfx Aajydr Akjfoc

Availability

- Dismantling available from July 20, 2026, with later dates upon request

- Commercial Terms

- Sale ex site, as is, with all warranties and guarantees excluded

- Buyer must ensure CE compliance of the entire plant at the new location

- Dismantling and transport to be carried out by the buyer; risk and liability transfer upon start of dismantling

- Lifting equipment and export documents provided by the seller

- Registration of personnel and proof of insurance to be arranged by the buyer

- Components not explicitly mentioned as well as external media (power, steam, water, compressed air) not included

- Pellets have so far been produced according to ENplus A1; no guaranteed property

- Liability for consequential damages excluded; technical details without guarantee

Contact

Commercial / Inspection: Marcel Moser, AEK Pellets AG

Technical: Dieter Friedli, Friedli AG Engineering und Anlagenbau

Friedli AG Engineering und Anlagenbau has over 25 years of industry experience and has been operating its own wood pellet production plant for more than 10 years. We are pleased to support you with consultancy, feasibility studies, and technical and commercial evaluations.

Discover more used machines

Listing

Germany

Germany

18,260 km

Sandwich Panel Production Plant

SANDWICH ANLAGEXBJ-II A Laminator

Call

Condition: used, Year of construction: 2002, Technical details:

thickness: 0,6 mm

width: 1200 mm

Length: 100 mm

work speed: 1,5 - 3 m/min

motor power: 45 kw

compressed air: 7 bar

Total weight, approx.: 4500 kg

dimension machine xH: gesamt: 20 m / 2,6 m / 3 m m

2 pcs Sandwich Panel Production Plant

The plant is especially suitable for producing light laminated panels. The plant consists of a feeding system (conveyor belt) for the material, cutting system, profile system and an electronically control system. The plant has a length of 20m, width of 2,6m, height of 3m. The total weight of the plant is approximately 4,5 tons. The power consumption including the thermal output is 36 KW.

The recommended material of the internal layers are flame retardant Polystyrol or other light heat insulation materials. The sheet will be stable connected under pressure and heat with the Polystyrol through double sided application from portions of glue on the Polystyrol.

The panels have good physical characteristics such as thermal insulation, sound insulation, wet consistency, bending strength, compressive strength and mechanical attributes. Any length of the laminated panels is possible and adjustable on customer demand. The color of the panel is variable and is depending from the color of the used sheets.

Data Sheet

Power Consumption of the plant (with heating system): 36KW

Measurements:

- Length = 20m

- Width = 2,6m

- Height = 3 m

- Operating Temperatures: The optimal temperature for producing the panels is approximately 25 °C.

- Material: galvanized metal sheet on rolls, sheet thickness 0,3 – 0,6mm and a width of 1200mm

- Power Supply: 380 V 50Hz

- Maximum engine power: 45 KW

- Compressed Air: 7 bar

Measurements of the laminated panels:

Model 1

- Width 800 – 1200 mm

- Thickness 20 - 30mm

Model 2

- Width 1150 mm

- Thickness 50 – 150mm( adjustable)

production plant consists of:

- unwinding device

- feed system

Blodpfx Asu Nxa Hjafjc

- lamination

- cutting device

- glueing

- fume extractor device

- stacking device

- electronic control system (Mitsubishi)

*

Listing

Germany

Germany

18,384 km

Stone Production Plant

OmagTronic S22 140-90

Call

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Bsdpfx Aaow R Uziefjlc

Listing

Tauberbischofsheim

Tauberbischofsheim

18,531 km

Window production plant Weinig Unicontrol 10

WeinigUnicontrol 10

Call

Condition: used, Angular system Weinig Unicontrol 10 (UC 10) for the production of windows, elements and doors. Frame by frame, in series or individual part production with 2 tapping and slotted spindles incl. Oertli tool set * Aggregates: 1. Crosscut saw, NC axis, 3 kW, ø 40 mm, 2,800 rpm 2. First tapping and slotting spindle, NC axis, ø 50 mm, 15 kW, Clamping length: 640 mm (8 x 80) mm 3. Second tapping and slotting spindle, NC axis, ø 50 mm, 11 kW, clamping length: 400 mm 4. Profiling spindle 1, NC axis, ø 50 mm, 11 kW, clamping length: 4 x 80 mm 5. Profiling unit, horizontal from above, 3 kW 6. Profiling spindle 2, NC axis, ø 50 mm, 11 kW, clamping length: 4 x 80 mm 7. Profiling spindle 3, NC axis, ø 50 mm, 11 kW, clamping length: 400 mm 8. Profiling unit, vertical right, 3 kW 9. Profiling unit, vertical right from above, 3 kW 10. Profile milling unit, horizontal from below, NC axis 3 kW * Double part package * Milling package with milling carriage * Automatic turning system * PC control NEXUS * CNC controlled length stop * Studio window facility * Aggregate for edge rounding from below with a crosscut saw * Rung support bar * Incl. suction pipe system * Incl. tool set Oertli * Further technical data and tool drawings on request.

Blodpfsv Ag Tdsx Aafjc

Listing

Austria

Austria

18,332 km

Mobile Juice Production

KreuzmayrKML 750

Call

Year of construction: 2020, operating hours: 20 h, condition: as good as new (ex-display), The mobile Kreuzmayr units are used for the processing of fruit juices on site. The fruit is loaded into the washing container with the bin tipper, transported to the grinder, crushed and then conducted to the sieve belt press. The generated juice is automatically pumped into tanks, heated to about 80° C in the pasteurizer, and then filled into Bag in Box.

The following machines are built on the trailer:

• Bin Tipper Kreuzmayr GKE

• Wasching and Crushing Unit KWEM 2000

Blsdpfxoc Rghys Aafoc

• Single Belt Press KEB 750 with cleaning brush

• Bigger juice pan for the KEB 750

• Pomance conveyor • Stainless steel tank 530 Liter with hanging sieve

• Pasteurizer Kreuzmayr PAS 1500 Liter oil

• Bag in Box filler Kreuzmayr KBF 2000 special construction for mobile trailer

• Accessories: like pumps, air compressor, high pressure cleaner, hoses and fittings • Trailer with canvas cover, pneumatic brake system and antilocking system

The trailer has only a few operating days and is thus in a new condition.

Listing

Orle

Orle

17,739 km

Concrete block production plant

HENKEVARIANT 140/100

Call

Condition: good (used), Year of construction: 1993, HENKE VARIANT 140/120, dual-feed machine, year of manufacture 1993, 2 moulds, new control system

Bodpjxl S Uhefx Aafelc

Listing

Privalj

Privalj

18,155 km

Complete pellet production plant

Call

Condition: like new (used), Complete plant with all machines

Blsdpfxoxmtgbe Aafsc

Capacity 1000 kg per hour

Listing

Orle

Orle

17,739 km

Concrete block production plant

WASAblaty produkcyjne 1200x850x45

Call

Condition: excellent (used), Year of construction: 2017, Plastic pallets 1200x850x40, €17 each, available quantity: 1800 pcs. The quoted price is per piece.

Bsdpsxl Rpqjfx Aafjlc

Listing

Orle

Orle

17,739 km

Concrete block production plant

SCHLOSSERBH40

Call

Condition: good (used), functionality: fully functional, Year of construction: 1982, SHLOSER BH40 complete line, production pallet size 1400-1100, dual-feed machine, year of manufacture 1982, 16-level lifts, racking trolley with rotation, repackaging, armored conveyor, 3 moulds, control panel, photos available on request.

Bedexl N Tnjpfx Aafslc

Listing

Rennes

Rennes

19,189 km

Complete plant for animal feed production

Call

Condition: good (used), 2 complete manufacturing plants for animal feed products

Blodpfx Aaoncbnaofsc

Listing

Freising

Freising

18,468 km

Concentration plant for juice

Unipektin

Call

Condition: used, Year of construction: 1995, Concentrating plant for the juice industry. The plant dates back to 1977 and was rebuilt in 1992. It was extended and equipped with a new cooling tower circuit. The plant is designed for 6600 kg/h of cloudy apple juice. With a single-stage concentration, the juice is thickened from 12° to 25°Brix. Up to 71°Brix can be achieved in the second pass.

Additional title: with aroma recovery

Bedpswu N T Ajfx Aafolc

Input quantity apple juice: 6600 kg/h

Water evaporation: 4840 kg/h

Discharge quantity concentrated juice: 1760 kg/h

Steam consumption: 1685 kg/h

Length: 7,70 m

Width: 6,70 m

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Bodpfx Aasflpnyjfjlc

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

Bjdoflppljpfx Aafslc

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Gargždai

Gargždai

17,502 km

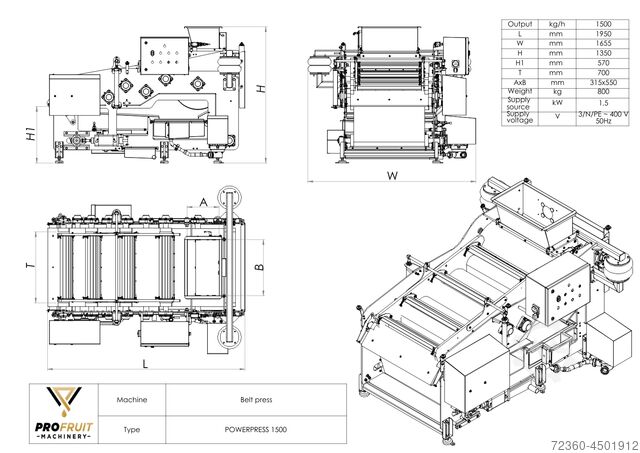

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

Bjdpfx Aaeflpp Esfolc

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Szczecin

Szczecin

18,007 km

Line for juice production

Flottweg

Call

Year of construction: 2008, condition: good (used), A complete line for the production and packaging of fruit and vegetable juices. The line consists of machines: fruit-vegetable pulp milling and production line (MEGA bunker hopper, MEGA 2012 rotary sieve, MEGA 2008 batching rung elevator, MEGA 2008 brush dripper, roller inspection conveyor- MEGA 2008, 2017 screw conveyor, pulp impeller pump, pulp tank, belt press-FLOTTWEG 2008, rinse water tank-FLOTTWEG 2008, juice cooling system- STM 2018), packaging line (triblock arrow-STM 2014, buffer tank STM 2014, bottle orientator STM 2013, capping machine STM 2013, HITACHI printer 2016, labelling machine 2018).

We also have a second smaller bottling and packaging line for sale.

Blodpfx Ajpqxvxoafec

Listing

Odžak

Odžak

18,081 km

Dairy plant for cheese production

Different10T

Call

Year of construction: 2005, condition: like new (used), DAIRY FOR THE PRODUCTION OF HARD AND SEMI-HARD CHEESE, as well as fresh cheese for the bakery industry

We offer a complete dairy for processing milk into hard and semi-hard milk

cheeses with high quality cheese production technology (such as

Grana Padano–Italy), and the production of fresh cheese for the bakery industry.

It was built in 2005 and equipped with the most modern stainless steel equipment for cheese production. It has its own heating, has a laboratory for product control, and within the factory there are offices, as well as a spare warehouse.

Capacity: 1 batch of 5,000 L of milk can be processed within 3-4 hours

1 shift of 8 hours can process 10,000 L of milk with 4 workers

Finished products based on monthly capacity:

Semi-hard and hard cheeses...up to 30 tons/month.

Curd……………up to 10 tons/month.

Fresh cheese……………up to 10 tons/month.

Plant description……….see attached FLOOR PLAN:

Reception, production, drying, packaging, brine, ripening...

Maturation room with wooden shelves equipped with regulation

humidity and temperature. There is also a bio-purifier of waste water.

The equipment requires an area of 500 m2, height approx. 5 m.

Boiler room 130 m2, 2 boilers, one gas and the other oil burner.

Refrigerator approx. 50 m2, height 6 m, regime 2-8 °C

Required electrical power: 50-60 kW

List of technological equipment:

1. Milk flow meter with vent

2. Storage tank for fresh milk

3. Plant for thermalization of milk/plate pasteurizer

4. Separator-centrifugal purification and standardization of milk

5. Cylindrical container for receiving cream

6. Fermenters for the production of pure cheese culture

7. Cheese maker

8. Storage tank for thermally processed milk

9. Storage tank for whey

10. Prepress for cheese

11. Work table for filling cheese mass into moulds

12. Pneumatic presses for cheese

13. CIP-plant for circular machine washing

14. Brine

15. Wooden racks for ripening cheese

16. Moving platform for sorting and caring for cheese

17. Three-part washing basin/mould for cheese and cheese

18.SC-self-priming pump

19. CC-centrifugal pump

20. Tub for the production of fresh cheese

21. Packaging machine

Milk intake: 2 tanks per 10,000 L

Whey tank: 1 pc of 20,000 L

CIP: 3 tanks of 1,000 L each

Duplicators: 2 x 1,000 L

Bledpfxeix N R No Aafsc

Main boiler 5,000 L manual adjustment of parameters, Alfa Metal – HR

Pasteurizer: Jedinstvo - HR - 5,000 L/h - approx. 20 years old.

Separator: Alfa Laval - Sweden - 5,000 L/h - approx. 20 years old.

Schulenburg tub 2,500 L

Start of operation of the dairy: 2007-2008…….stopped production in 2016.

Minor service required: inspection of equipment and lubrication

There is technical documentation of the equipment

Note: For sale only complete equipment. Transport approx. 5-6 x 40ft.

More photos upon request !!

Listing

Isola Vicentina

Isola Vicentina

18,598 km

Pellet production plant

EHW ITALIA SRLIMPIANTO PRODUZIONE PELLET

Call

Condition: refurbished (used), Year of construction: 2021, functionality: fully functional, control type: PLC-controlled, degree of automation: automatic, actuation type: electric, PELLET PRODUCTION PLANT 2 TON/H COMPLETE WITH BELT DRYER

Blodow Ebx Sepfx Aafsc

Trust Seal

Dealers certified through Machineseeker

Listing

Austria

Austria

18,290 km

Wood pellet production plant

Salmatec, Bruks, Rudnik&EnnersSalmatec Pelletswerk 4 To pro Std

Call

Condition: used, Year of construction: 2009, operating hours: 1 h, machine/vehicle number: -----, Business Relocation – High-Quality Pellet Production Plants for Sale!

For years, we have been recognized as one of the leading manufacturers of premium pellets. Due to the relocation of our production site to our main plant premises, attractive opportunities now arise for companies in the wood and pellet industry:

We are offering you the chance to acquire our currently operational production plants for manufacturing A1plus grade pellets.

Your Benefits

• High-quality machines and equipment currently in operation

• Ideal for producing premium-grade A1plus pellets

• Facility visits possible during ongoing production until mid-October 2025

• Attractive conditions for prompt purchase

• On-site inspection & consultation

Bjdpow Tdk Sefx Aafelc

Interested parties have the opportunity to see the equipment in operation on site and gain a comprehensive impression of the condition and performance of the machinery.

For initial orientation, we provide you with informative photos of the machines. Upon request, we are happy to send you detailed technical specifications and provide individual consultation.

For further information or to arrange a viewing appointment, please do not hesitate to contact us:

Listing

Undoolya

Undoolya

4,256 km

Mobile concrete mixing plant

PROMAX Mobile Concrete Batching PlantMobile Concrete Batching Plant

Call

Condition: new, MOBILE CONCRETE BATCHING PLANT M100-TWN

GENERAL

Plant Type : MOBILE Concrete Plant with TWIN SHAFT MIXER

Plant Capacity : 100m³/hour freshly compressed concrete

Mixer Capacity : 3000/2000 lt (2m³ Compressed Concrete)

Total Motor Power : 143kw Standard Value can be changed depending on Equipment..

Voltage/Frequency : 380V/50Hz Standard Value.

Bodpfewhybdsx Aafelc

The installation and startup of the plant is under our responsibility.

We provide excellent after-sales service.

24/7 SERVICES. REMOTE CONTROL SERVICE.

Exporting more than 1000 Concrete Batching Plants to more than 90 Countries all over the world.

* HIGHLY EFFICIENT AND DUPLICATE PRODUCTION

* EASY TRANSPORTATION

* MINUMUM INVESTEMENT FOR FIELD GROUNDWORK

* QUICK INSTALLATION

DETAILS:

Crjbtuhm Njflz Hlo Aeb

Compacted concrete capacity: 100 m³/h

Air Compressor Capacity : 950 lt/min

Aggregate Hopper : 4 Bins : 4×11.25 = 45 m³

Mixer Type : TWIN Shaft (2 m³). 3000/2000 lt capacity

Mixer Converyor Band : 1000 mm * 13000 mm

Weighbridges: Aggregate/ Cement /Water/ Additives

Listing

Gottmadingen

Gottmadingen

18,696 km

Machining center

DUKART engineering & productionKUKA Bearbeitungszentrum 500

Call

Condition: new, Year of construction: 2020, operating hours: 10 h, functionality: fully functional, SPECIAL OFFER / 6-Axis Robot Machining Center

🔥 Universal 6-Axis Robot Center – Milling, Welding, Grinding, 3D Printing & More | Modular configuration available from €49,000 to €99,000 (net)

Product Details

• Year of manufacture: 2020

• Condition: NEW – The system was exclusively used for demonstration and promotional purposes. No heavy-duty or machining work was performed.

• Original price: €199,000 (net)

• Warranty: 1-year warranty on the system

Highlights and Features

1. OCTOPUZ Software

o Value: €25,000

o Serves as the interface between the KUKA controller and SolidCAM. This powerful software makes programming easy and efficient, especially for complex machining tasks.

2. Precision KUKA Robot

o Value: €85,000

o Exceptional precision and reliability, perfectly suited for demanding applications such as milling, cutting, welding, grinding, polishing, including material handling.

o Handheld control panel.

o Up to 5,000 mm working range.

o Up to 120 kg load capacity.

3. High-quality KEB Controller

o Value: €15,000

o Supports automatic tool changing, spindle control, and specific add-on modules such as:

Chip, vapor and fume extraction

Welding torches

Tool heads for a range of applications

4. High-Speed Spindle

o Value: €5,000

o Perfect for precise machining of steel, aluminum, wood, plastic, and other materials.

5. Robust Frame with Large Machining Table

o Value: €20,000

o Aluminum table for horizontal and vertical machining, ideal for both small and large workpieces.

Note: The stated values refer to the pure component costs without fasteners, adapters and brackets, as well as assembly and machining costs.

Applications and Advantages

This robot machining center is extremely flexible and can be used for a variety of tasks:

• Milling: Complex, three-dimensional geometries with the highest precision.

• Welding: Integration of a welding head for versatile metal processing.

• Material Handling: Automatic workpiece feeding for increased efficiency.

• Surface Processing: Polishing, grinding or deburring.

The machining center is ideally suited for integration into a fully automated production line.

Sale Price and Options

• Special offer: €113,000 (net) for the existing system in its current configuration.

• Modified version: €149,000 (net) for customer-specific adaptations, such as the integration of tool changers, welding or laser cutting heads. (Welding and laser units not included in the price and must be provided separately.)

Bsdpfx Aju T Rx Teafolc

Inspection and Delivery

• Connection: The system is ready for operation and can be inspected at any time.

• Delivery time: Immediately available. Lead time for modifications upon agreement.

• Disassembly and transport: Not included in the price.

Additional Advantages

• Future-proof: Expandable and adaptable for new applications.

• Mobility: Usable at different locations.

• Cost-effectiveness: Saves time and costs due to multifunctional capabilities.

Do you have any further questions or would you like individual consultation? We are happy to assist you!

Listing

Turkey

Turkey

17,249 km

Crushing equipment / jaw crusher

FABO Mobile Crushing PlantMobile Crushing and Screening Plant

Call

Condition: new, functionality: fully functional, fuel type: hybrid, color: yellow, overall weight: 55,000 kg, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

Fabo tracked jaw crusher FTJ 11-75 is a complete mobile system which moves on hydraulically driven tracked system with 1 km/h speeds and combination of a vibrated grizzly feeder, 1070x760 mm jaw crusher, foldable stockpile conveyors, control unit and electric generator.

In today's conditions and technological processes, businesses are beginning to think about how to make their field of activity more efficient. As they make it more efficient, they always take into consideration factors such as the operationally of the machines they use, their low cost and staffing needs. Our Tracked Crushers can crush with high performance even on the most demanding mine sites with its specially designed body and compact structure. Customization can be done to our tracked systems by Jaw Crusher, Primary and Secondary Impact or Cone Crusher.

All necessary equipment for the process is combined only single chassis and processing equipment is driven by electrical motors. Overall production capacity is 150-300 tph

Advantages of Tracked Crushers;

-Heavy-duty walking tracks can reach places where ordinary machines cannot reach.

-It has the appropriate dimensions and sound level to crush construction waste in the city.

-The fuel consumption of the generator and the travel track units is highly economical.

Bedpfx Aasygqw Ejfslc

-System maintenance and management is very easy with latest technology control software.

TECHNICAL SPECIFICATIONS:

-Model: FTJ 11-75

-Production Capacity: 150 – 300 tons per hour

-Maximum Feeding: 700 mm

-Crusher Type: Jaw Crusher

-SIZE: 1070x760 mm

-Generator: 300 kva

-CSS Setting: 45 – 160 mm

-Weight: 55000 tons

-Dimensions: 2900x3500x14.500mm

– Low investment and operation cost

– Zero substructure preparation

– Easiness at usage and maintenance

– Easy assembly and disassembly advantages.

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

We make it easier for you to find: "juice production plant"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Juice Production Plant (18,031)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you