Used Soap Production for sale (15,838)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Ireland

Ireland

18,646 km

Beverage production machine

Brewery Production Equipment

Call

Condition: good (used), Beer / Brewery Production Equipment

9 qty insulated tanks, approx 1000 lts capacity each

2 qty large tanks, approx 1500 lts capacity each

All associated pumps, chiller pump units, wash station.

2 qty tanks with lids, approx 1000 lts each

2 qty large tanks with lids, approx 1500 lts each

Gsdeyg R Azopfx Ahzsin

All associated pumps, water filteration system

2 qty timber clad tanks, approx 1000 lts and 1500 ltd capacity each

2 qty insulated tanks, approx 1000 lts capacity each

All associated equipment, heat exchanger, pumps,

Listing

Gottmadingen

Gottmadingen

18,696 km

Machining center

DUKART engineering & productionKUKA Bearbeitungszentrum 500

Call

Condition: new, Year of construction: 2020, functionality: fully functional, operating hours: 10 h, SPECIAL OFFER / 6-Axis Robot Machining Center

🔥 Universal 6-Axis Robot Center – Milling, Welding, Grinding, 3D Printing & More | Modular configuration available from €49,000 to €99,000 (net)

Product Details

• Year of manufacture: 2020

• Condition: NEW – The system was exclusively used for demonstration and promotional purposes. No heavy-duty or machining work was performed.

• Original price: €199,000 (net)

• Warranty: 1-year warranty on the system

Highlights and Features

1. OCTOPUZ Software

o Value: €25,000

o Serves as the interface between the KUKA controller and SolidCAM. This powerful software makes programming easy and efficient, especially for complex machining tasks.

2. Precision KUKA Robot

o Value: €85,000

o Exceptional precision and reliability, perfectly suited for demanding applications such as milling, cutting, welding, grinding, polishing, including material handling.

o Handheld control panel.

o Up to 5,000 mm working range.

o Up to 120 kg load capacity.

3. High-quality KEB Controller

o Value: €15,000

o Supports automatic tool changing, spindle control, and specific add-on modules such as:

Chip, vapor and fume extraction

Welding torches

Tool heads for a range of applications

4. High-Speed Spindle

o Value: €5,000

o Perfect for precise machining of steel, aluminum, wood, plastic, and other materials.

5. Robust Frame with Large Machining Table

o Value: €20,000

o Aluminum table for horizontal and vertical machining, ideal for both small and large workpieces.

Note: The stated values refer to the pure component costs without fasteners, adapters and brackets, as well as assembly and machining costs.

Applications and Advantages

This robot machining center is extremely flexible and can be used for a variety of tasks:

• Milling: Complex, three-dimensional geometries with the highest precision.

• Welding: Integration of a welding head for versatile metal processing.

Gedpfx Asu T Rx Tohzein

• Material Handling: Automatic workpiece feeding for increased efficiency.

• Surface Processing: Polishing, grinding or deburring.

The machining center is ideally suited for integration into a fully automated production line.

Sale Price and Options

• Special offer: €113,000 (net) for the existing system in its current configuration.

• Modified version: €149,000 (net) for customer-specific adaptations, such as the integration of tool changers, welding or laser cutting heads. (Welding and laser units not included in the price and must be provided separately.)

Inspection and Delivery

• Connection: The system is ready for operation and can be inspected at any time.

• Delivery time: Immediately available. Lead time for modifications upon agreement.

• Disassembly and transport: Not included in the price.

Additional Advantages

• Future-proof: Expandable and adaptable for new applications.

• Mobility: Usable at different locations.

• Cost-effectiveness: Saves time and costs due to multifunctional capabilities.

Do you have any further questions or would you like individual consultation? We are happy to assist you!

Listing

Ignalina

Ignalina

17,249 km

Pellet Line

Pellet Production Line

Call

Condition: new, Year of construction: 2025, We produce pellet-briquette line

We are the only manufacturers in Lithuania, the only ones with our own service.

We will deliver, install, set up and train the lines.

We select a package according to your budget.

We not only produce the equipment ourselves, but we also produce pellets ourselves, you can come and see the working equipment.

Pellet production lines from 100 kg/h to 30 t/h

We produce:

Drum dryer

Belt dryer

pipe dryer

Pellet plant Mills

crushers

Conveyor

Coolers

Cyclones

Bunker

Gijdpfx Aohgbarshzsn

Packing machines

TSF-Justinas

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Poland

Poland

17,824 km

Construction machine

Production boards Mywood

Call

Condition: excellent (used), 4000 pcs production boards Mywood 1400x1150x50

Gisdpfxoyftzdj Ahzjn

- out of production March 2026

- price: 15 euro pcs

Listing

Krustpils pagasts

Krustpils pagasts

17,214 km

Production of Birch dimensional parts

Production of Birch dimensional parts

Call

Condition: ready for operation (used), functionality: fully functional, Machines for full production of birch dimensional parts:

1) Leadermac LMC-523SP

2) WoodEye 5, W5-CC-4444

3) Paul 11KE

4) SCM Group Celaschi Progress

Gsdpfx Ahottmm Rozoin

5) Weinig AG Unimat 23 EL

All conveyors and extraction pipes are included.

Discover more used machines

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Production line for rock & concrete processing

Henan Mingyuan sand production line50-600 t/h sand gravel production line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, 🚧 50-600 T/H Sand & Gravel Production Line – Transforming Raw Materials into High-Quality Aggregates! 🚧

🌟 General Introduction

Looking for a reliable and efficient solution for your sand and gravel production needs? Our 50-600 T/H Sand & Gravel Production Line is a high-performance system designed to meet the diverse requirements of construction, infrastructure, and industrial projects. Whether you need coarse aggregates or fine sand, this production line ensures precision, efficiency, and scalability.

---

🏗️ Wide Range of Applications

Giodpfoq Nywxex Ahzjn

Our sand and gravel production line is perfect for:

- Construction Projects: Producing aggregates for concrete, asphalt, and roadbeds.

- Mining Operations: Processing various ores and minerals.

- Infrastructure Development: Creating high-quality materials for bridges, dams, and highways.

- Commercial Sand Supply: Meeting market demand for sand and gravel in bulk.

---

💎 Key Advantages

### 1. High Capacity & Versatility

- Produces 50-600 tons per hour, easily scaling to match project demands.

- Handles a wide range of raw materials, including limestone, granite, basalt, and river stones.

### 2. Advanced Technology

- Incorporates cutting-edge crushing, screening, and washing equipment for consistent quality.

- Optimized for energy efficiency, reducing operational costs.

### 3. Customizable Solutions

- Configurable to meet your specific requirements, from particle size to layout design.

- Offers flexibility in combining different crushers (jaw, cone, impact) and vibrating screens.

### 4. Durable & Low Maintenance

- Built with robust materials to withstand heavy-duty operations.

- Easy-to-maintain design minimizes downtime and extends equipment lifespan.

### 5. Environmentally Friendly

- Features dust suppression systems and water recycling units to reduce environmental impact.

- Promotes sustainable practices in aggregate production.

---

🚜 Your Complete Solution

Our production line includes:

- Primary Crushing: Breaks down large rocks into manageable sizes.

- Secondary Crushing: Refines materials to desired specifications.

- Screening Equipment: Ensures uniform sizing and quality control.

- Washing System: Removes impurities for cleaner, higher-grade aggregates.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Stone crushing production lineStone crushing screening plant

Call

Condition: new, Year of construction: 2025, A stone crushing plant for sand and aggregate making is a facility where stones and rocks are crushed into smaller pieces or gravel. It typically includes several stages of crushing and screening to produce various sizes and grades of sand and aggregate materials, which are essential in construction, landscaping, and other applications. Here's an introduction to the components and processes involved in a typical stone crushing plant:

### Components of a Stone Crushing Plant

1. Primary Crusher:

- Purpose: The primary crusher, often a jaw crusher or gyratory crusher, initially breaks down large rocks into smaller pieces.

- Function: It handles raw materials from the quarry or mine and prepares them for further processing.

2. Secondary Crusher:

- Purpose: A secondary crusher, such as a cone crusher or impact crusher, further reduces the size of the crushed stones.

- Function: It refines the material after primary crushing, producing smaller and more uniform-sized aggregates.

3. Tertiary Crusher (Optional):

- Purpose: In some configurations, a tertiary crusher like a vertical shaft impactor (VSI) may be used for shaping and fine crushing.

- Function: It produces finely crushed materials for specific applications, such as concrete production or road base.

4. Screening Equipment:

- Purpose: Screening equipment like vibrating screens or trommel screens separates the crushed materials into different sizes.

- Function: It classifies the aggregates into various grades according to size, ensuring uniformity and meeting specifications.

5. Conveyor Systems:

- Purpose: Conveyor belts transport materials between different stages of crushing and screening.

- Function: They ensure efficient material handling and continuous operation within the plant.

6. Washing Equipment (Optional):

- Purpose: Washing equipment, such as sand washers or scrubbers, may be used to remove impurities from sand and aggregate products.

- Function: It improves the quality of the final products by cleaning them and removing fines or contaminants.

### Processes Involved

Gisdpfx Asq N U Dushzsn

- Primary Crushing: Large rocks are fed into the primary crusher and reduced to a manageable size.

- Secondary Crushing: The crushed materials from the primary crusher are further processed by secondary crushers to achieve the desired aggregate sizes.

- Screening: The crushed and sized materials are screened to separate them into different sizes and grades.

- Material Handling: Conveyor systems transport materials between different stages of the crushing and screening process.

Final Product Handling:Finished products, such as sand and various sizes of aggregates, are stored or loaded for transport to customers or construction sites.

Applications

- Construction: Used in the production of concrete, asphalt, and road base materials.

- Landscaping: Provides decorative and functional aggregates for gardens, pathways, and driveways.

infrastructure: Essential for building foundations, drainage systems, and structural fill.

As for the capacity we have 30 t/h, 30-50 t/h, 50-100 t/h, 100-150 t/h, 150-200 t/h, 200-300 t/h, 300-500 t/h, and both stationary crushing plant and mobile crushing plant are available for option.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Sand Aggregate crushing production lineAggregate & Ballast Crusher Equipment

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Aggregate and ballast crusher equipment are used in the crushing and processing of various materials for construction and infrastructure projects. These crushers are designed to break down large rocks, gravel, or stones into smaller pieces, producing aggregates and ballast that are essential components in the construction industry. Here are some key aspects related to aggregate and ballast crusher equipment:

1. Jaw Crusher:

- Jaw crushers are commonly used for primary crushing in aggregate and ballast production. They operate by compressing the material between a stationary and a movable jaw.

2. Impact Crusher:

- Impact crushers are suitable for shaping and producing fine aggregates. They use impact force to crush the material, making them suitable for various types of rock and ore.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They are efficient for producing well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They use the "rock-on-rock" crushing principle, where rocks are fed into the rotor to be accelerated and crushed against the stationary anvils.

5. Gyratory Crusher:

Godpfx Aheq Nxrxszein

- Gyratory crushers are primarily used in mining, but they may also be used in the production of aggregates. They have a conical head and a concave surface, which crushes the material between the head and concave.

6. Mobile Crushers:

- Mobile crushers, including mobile jaw crushers and mobile impact crushers, provide flexibility and mobility for on-site crushing of aggregates and ballast. They are often used in construction projects where materials need to be processed directly at the job site.

7. Screens and Scalpers:

- Screens and scalpers are used to separate different sizes of aggregates after the initial crushing stage. Vibrating screens are commonly employed to classify and separate materials based on size.

8. Conveyors:

- Conveyors are crucial for transporting materials between various stages of the crushing process and for stockpiling the final products. They enhance efficiency in material handling.

9. Dust Suppression Systems:

- Crushing operations can generate dust, and dust suppression systems are used to minimize environmental and health impacts. These systems may include water sprays or chemical suppressants.

10. Quality Control:

- Quality control measures, such as particle size analysis and gradation testing, are essential to ensure that the produced aggregates and ballast meet the required specifications and standards.

11. Environmental Considerations:

- Crusher equipment should adhere to environmental regulations, and measures like dust control, noise reduction, and proper waste disposal should be implemented.

When selecting aggregate and ballast crusher equipment, factors such as the type of material, required product size, production capacity, and mobility requirements should be taken into consideration. Additionally, adherence to safety and environmental standards is crucial in the operation of crushing equipment.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Powder equipment for sand & micro powder

Mingyuan Powder production equipment1.83X11m Micro Powder Ball Grinding Mill

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Ball Mill with Air Classifier: The Ultimate Powder Processing Equipment

In the world of industrial powder production, precision, efficiency, and flexibility are paramount. Whether producing ultra-fine powders for high-tech applications or coarser materials for everyday products, the combination of a Ball Mill with Air Classifier offers unparalleled performance. This dynamic duo provides a comprehensive solution for industries ranging from chemicals and ceramics to paints, plastics, and pharmaceuticals.

This article introduces the ball mill with an air classifier, explores its applications, and highlights the key advantages of this essential powder equipment.

General Introduction to Ball Mill with Air Classifier

ball mill with air classifier is an advanced grinding and classification system designed for efficient, high-quality powder production. The system consists of two main components:

1. Ball Mill: A cylindrical grinding device filled with grinding media (such as steel balls) that operates by rotating around its axis. The raw material is reduced to smaller particle sizes through impact and friction within the mill.

2. Air Classifier: A sophisticated device that separates particles based on size using airflow. Fine particles are carried away, while coarser particles are returned to the ball mill for further grinding.

The combination of these two components creates a closed-loop system that ensures consistent particle size distribution, high efficiency, and minimal waste.

Applications of Ball Mill with Air Classifier

The ball mill with air classifier is a versatile solution used in a wide range of industries to process various materials. Key applications include:

1. Mineral Processing

The system is widely used in the production of minerals such as calcium carbonate, quartz, feldspar, and talc. These finely ground minerals are essential for industries like ceramics, paints, plastics, and rubber.

2. Cement and Construction Materials

Cement and other construction materials require precise particle size control for optimal performance. The ball mill with air classifier ensures uniformity and enhances the quality of construction materials.

3. Chemicals and Pharmaceuticals

Fine powders play a critical role in the chemical and pharmaceutical industries. From active pharmaceutical ingredients (APIs) to industrial chemicals, this system delivers the consistent quality required for these applications.

4. Paints, Coatings, and Pigments

The production of paints and coatings demands ultra-fine powders to achieve smooth finishes and vibrant colors. The ball mill with air classifier produces high-quality powders for superior results.

#### 5. Food and Agriculture

Food-grade powders such as additives, preservatives, and agricultural products like fertilizers can be efficiently processed using this system, meeting stringent regulatory requirements.

Industries That Benefit from Ball Mill with Air Classifier

Several industries rely on the capabilities of this system to produce fine powders with specific characteristics:

- Ceramics: Produces high-purity powders for tiles, insulators, and advanced ceramics.

Gisdpfxovlwkxj Ahzjn

- Rubber and Plastics: Creates fillers and additives for improved durability and performance.

- Pharmaceuticals: Ensures consistent particle size for APIs and excipients.

-Construction: Delivers materials for concrete, plaster, and other applications.

Listing

Turkey

Turkey

17,151 km

Damper Assembly Production Line

Damper Production Line

Call

Condition: like new (used), Year of construction: 2023, functionality: fully functional, Line was implemented & wasnt used for serial production yet except FOT production. Quite new.

It contains below processes :

Robotics ArcWelding Cell With 3 Axis Turn Table x 2 Qty

2S-1100 Robotics ArcWelding Cell X 1 Qty

Godew Upppjpfx Ahzsin

Knuckle Bracket and Spring Seat Fixture x 4 Qty

Stab Bracket Fixture X 2 Qty

Knuckle Bracket Projection Welding System X 1 Qty

Automatic Base Cap and Knuckle Bracket Assembly System X 1 Qty

Drilling And Press Machine with Industrial Robot X 1 Qty

Leakage Test System X 1 Qty

Marking System X 1 Qty

Listing

Latvia

Latvia

17,265 km

Metal rainwater system production line

metal rain water system production line

Call

Condition: used, Rain gutter, downpipe and elbow forming machines, complete line. Three machines.

1. Rain gutter forming machine, strip cutting with band saw.

Produced gutter diameter: 80 x 100 mm

Used sheet metal dimensions:

Width: 350 mm.

Thickness: 0.43 – 0.55 mm.

2. Downpipe forming machine, can form 127 mm and 152 mm (standard) sizes. Cutting with guillotine.

Used sheet metal dimensions:

Width: 300 mm.

Thickness: 0.43 – 0.55 mm.

3. Elbow forming machine: 400V/3

If you have any further questions, we will be happy to answer them.

Gijdpjv Evctefx Ahzjn

Clickout

嘉兴市

嘉兴市

9,726 km

Minced Meat Production Line

Condition: used, Minced Meat Production Line, Including:

2ea Mixing Elevator, Maker AMFEC, Model 15-C & 2-3K;

Gedpeyhm Najfx Ahzjin

1ea Mixer, Maker AMFEC, Model 510;

1ea Screw Feeder, Maker AMFEC, Model 610;

1ea Vacuum Filling Machine, Maker VEMAG, Model HP25E, Year 2020;

Portioning Machine, Maker VEMAG, Model MMP223, Year 2020;

Plating Machine, Maker VEMAG, Model MLR380, Year 2020;

Conveyor and Inkjet Printer

Listing

Sierakowska Huta

Sierakowska Huta

17,772 km

Parquet production line

FOD BYDGOSZCZ*DDCA DDGA

Call

Condition: excellent (used), CATALOG NUMBER 7816

TECHNICAL DATA

DDCA

- Maximum batten length: 85 mm

- Minimum batten width: 180 mm

- Maximum batten width: 845 mm

- Minimum batten height: 10 mm

- Maximum batten height: 45 mm

- Spindle diameter: 30 mm

- Maximum blade diameter: 250 mm

- 5 spindles:

- Left side:

1) Vertical top spindle 2.2 kW

2) Horizontal bottom spindle 2.2 kW

- Right side:

1) Vertical bottom spindle 2.2 kW

2) Vertical top spindle 2.2 kW

3) Horizontal bottom spindle 2.2 kW

- Spindles adjustable up/down, right/left

- Material hold-down: 2 pcs

- Stepless feed speed adjustment: 0–10 m/min

- Spindle diameter: 5x100 mm

- Dimensions (L/W/H): 1870/2230/1320 mm

DDGA

- Maximum batten width: 130 mm

- Maximum batten height: 100 mm

- Spindle arrangement:

1) Bottom spindle 5.5 kW

Gijdpfxsyi Tqgo Ahzsn

2) Right spindle 5.5 kW

3) Left spindle 5.5 kW

4) Top spindle 5.5 kW

- Spindles adjustable up/down

- 6-knife cutterheads mounted on top and bottom spindles

- Spindle diameter: 40 mm

- Shaper cutters mounted on right and left spindles, max diameter 50 mm

- Spindle diameter: 30 mm

- 2 feed speeds: 4.9 kW

- Central chain lubrication by oil pump

- Spindle diameter: 4x125 mm

- Dimensions (L/W/H): 3100/1300/1700 mm

ADVANTAGES

- Manufactured in Poland

- 5 spindles

- Unpainted

- Very good condition

- Used production line

- High quality, low price

Net price: 52,900 PLN

Net price: 12,600 EUR

Net price calculated at an exchange rate of 4.2 PLN/EUR

(In the event of significant exchange rate fluctuations, the price may change)

Listing

Ożarów Mazowiecki

Ożarów Mazowiecki

17,705 km

Line For Packaging Liquid Products Into Plastic Bottles With Dose Up To 750 ml

Tang OG Weiss ASASK 450

Call

Condition: used, Second hand line by TANG OG WEISS AS (DK) for packaging liquids into plastic bottles. Volume range from 50 ml to 750 ml.

Working output of line:

- for bottles volume 750 ml - up to 600 pcs/h

Giedpoyi Ezkofx Ahzon

- for bottles volume in range from 200 up to 400 ml - in range from 800 - 900 pcs/h,

- for smaller volume bottles it is possible to assume a capacity in the range of 1000 to 1200 pcs/h.

The line consists of:

- Container of bottles produced by PACKFEEDER S.L. (Spain) model MN 100-4,

- Filling-closing unit manufactured by TANG OG WEISS AS (DK) model TWKS. It includes filling module by TANG OG WEISS AS model TWRF, with two filling nozzles, stainless steel buffer tank with total volume 15 l, rotary table, caps feeder, arm for capping/cap tapping and plate conveyor,

- Stainless steel lobe pump manufactured by SSP PUMPS (England) model L2-0017, for feeding the product to the buffer tank,

- Labelling unit, by EME Etiketteringsmaskiner ApS. (Denmark) model 4-120 (4000 series) without printer, equipped with a plate conveyor, two pieces of self-adhesive label applicators (front and back of the packaging). Label feed height range: from 20 mm to 120 mm, label feed width range: from 10 mm to 250 mm, operating speed: 0-40 m/min,

- Automatic packaging machine in heat-shrinkable film by SKINETTA PAC-SYSTEME GMBH & CO. (Germany) model ASK 450. The device wraps packages of 6 bottles with film and thermoform it. The entrance opening to the foil shrinking section has the following dimensions: width 440 mm, height 320 mm (year of manufacture 1994, no documentation),

- Plate conveyors and control panels.

The equipment includes a cabinet with formats for oval bottles with volumes: 50 ml, 200 ml, 400 ml, 750 ml, as well as manufacturer's documentation in Danish and a user manual in Polish. The line was produced in 2007.

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

18,569 km

Colour production machine

Xerox Versant 180 Press incl.Fiery, Bookletfinisher, Paperdeck

Call

Condition: ready for operation (used), functionality: fully functional, In this offer you purchase a used colour production system ‘Xerox Versant 180 Press’

Object of sale:

1 x Xerox Versant 180 with the following equipment:

incl. Fiery Server EX180

incl. Paperdeck A-CF03

incl. Booklet Finisher A-FN13

Not the right equipment? It is no problem to configure the machine according to your wishes. Please feel free to contact us!

Counter readings:

Total: Approx. 4,419,328 pages

Colour: Approx. 3,524,210 pages

Black: Approx. 895,118 pages

Condition:

This offer is a used device, which may show signs of use (minor scratches or yellowing).

(minor scratches or yellowing).

Gsdpsu Ra Smjfx Ahzjin

The device has been tested for function

A test printout can be seen in the photo

Packaging and dispatch:

You are welcome to view the device during our business hours. Please make an appointment for this!

Seaworthy packaging and worldwide shipping available on request!

A function test will be recorded on video for you before dispatch or collection.

For further information, you can of course also contact us personally.

Listing

Oirschot

Oirschot

18,612 km

3D cutting line for frozen products

MaguritGalan 930

Call

Year of construction: 2006, condition: excellent (used), Type: Unicut 547

Serial number: 5435

Year of construction: 2006

Block size: max 1200 x 640 x 380 mm

Cutting width: 680 mm

Thickness: 10 - 60 mm

Gisdpfx Ahek Twx Hszsn

Air pressure: 6 Bar, 500 L/min.

Power: 3 x 400V, 50Hz, 15kW

Dimensions: 3400 x 1300 x 2650 mm

Weight: 2500 kg

Type: Galan 930

Serial number: 5431

Year of construction: 2006

Product size: max 370 x 160 mm

Product length: 6 - 130 mm

Cutting set: 20 mm

Belt width: 360 mm

Air pressure: 6 Bar, 20 L/min.

Power: 3 x 400V, 50Hz, 7kW

Dimensions: 4350 x 1250 x 1700 mm

Weight: 1000 kg

Listing

Saint-Genix-les-Villages

Saint-Genix-les-Villages

19,022 km

CNC tool grinding machine WALTER

WalterHelitronic Power Production

Call

Condition: ready for operation (used), Year of construction: 2003, functionality: fully functional, spindle speed (max.): 7,000 rpm, type of input current: three-phase, grinding wheel diameter: 200 mm, overall weight: 4,650 kg, grinding length: 350 mm, center height: 190 mm, feed rate X-axis: 15 m/min, feed rate Y-axis: 15 m/min, travel distance X-axis: 490 mm, travel distance Y-axis: 320 mm, travel distance Z-axis: 660 mm, grinding spindle motor power: 24,000 W, workpiece diameter (max.): 320 mm, input voltage: 400 V, nominal power (apparent): 35 kVA, spindle nose: ISO 50, swivel angle A-axis (min.): 360 °, CNC tool grinding machine WALTER Helitronic Power Production

TECHNICAL CHARACTERISTICS:

CNC control: HMC 500

Software installed: Tool Studio 2.1 R4

Number of axes: 5

Height of centers: 190 [mm]

Stroke X: axis 490 [mm]

Resolution X axis: 0.00001 [mm]

Stroke Y axis: 320 [mm]

Resolution Y axis : 0.00001 [mm]

Stroke Z axis: 660 [mm]

Resolution Z axis: 0.00001 [mm]

Traversing feeds X, Y and Z axes: 15000 [mm/min]

A axis: 360 [°]

C axis: +/- 200 [°]

Resolution C axis: 0.0001 [°]

Max. workpiece lenght: end face grinding: 320 [mm]

Max. grinding length: 350 [mm]

Max. grinding diameter: 320 [mm]

Grinding spindle attachment: NCT

Grinding spindle diameter: 80 [mm]

Grinding wheel max. speed: 7000 [rpm]

Grinding spindle motor power: 24 [kW]

Max. diameter grinding wheel: 200 [mm]

Internal workpiece spindle nose: ISO 50

Workpiece spindle max. speed: 60 [rpm]

Total power required: 35 [kVA]

Weight: 4650 [Kg]

EQUIPMENT INCLUDED:

x1 TRANSOR 12290-800A filtration unit

x1 MTA oil chiller model TAE 015

x1 DSL oil mist extractor model AES-GAMMA 30

x1 RENISHAW part probe

x1 disc-type tool loader 40 positions

x1 SCHUNK gripper

x2 grinding wheel arbor adapters

x1 fire protection system - to be inspected by the buyer through a certified organization

x1 electrical schematic manual

x1 Service Instructions manual

LICENSED WALTER WINDOW MODE (WWM) PACKAGES:

- Package 001 (cylindrical mills)

- Package 002 (tapered mills)

- Package 003 (drills)

- Package 004 (step drills)

- Package 006 (woodwork tools)

- Package 013 (reamers)

- Package 015 (insert seats)

- Package 016 (warmup program)

- Package 027 (flexible program)

- Package 090 (loader package)

- Package 091 (acm)

- Package 098 (loader package)

- Package 099 (loader package)

- Package 100 (reference data m.)

- HELICONE (flute calc. conical.)

- HELIDRILL (flute calc. drills)

- HELIFLUTE (flute calc. cyl. mill.)

- MCS (machine control .)

- SCHEIBE (wheels menu)

- TS_ADVANCED (toolstudio (v1.0-v.)

- TS_STANDARD (toolstudio (v1.0-v.)

- TS_STEPTOOLS (toolstudio (v1.0-v.)

LICENSED TOOLSTUDIO OPTIONS:

- Tool Studio 2.0 server/machinecontrol

- Tool Studio 2.0 standard license

- Tool Studio 2.0 advanced license

- Tool Studio 1.9 upgrade options

- Tool Studio 2.0 upgrade options

- Option steptools

Giodpfsyh Nf Iox Ahzjn

- Option profile light (contour roughing ...)

- Option calibration w/ touch probe

- Option drills

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Listing

Ulmen

Ulmen

18,639 km

Brochure production system

MKWTRANS UT12 / 35x62 / GS / RL

Call

Condition: as good as new (ex-display), Year of construction: 2024, functionality: fully functional, Showroom machine from the manufacturer!

Ideal brochure production and collating

-Built 2024

-Ideal brochures and collating line

-12 stations in special format - 35 cm x 62 cm for A4 landscape brochure

-Right-left run

-Running to the right - brochure production

-Running to the left - collating

-Clocked guide plate - alignment of the sheets with each cycle

-Motorized paper rail

-Cover creasing unit

-Automatic format adjustment of the following units

-TRANS SFT 350 S & TRANS T20 S

-Short-term delivery

Warranty Time

12 month spare parts warranty

(critical spare parts pack shipped with machine)

(not inclusive are belts, bulbs, rubber parts, suckers, …)

Gijdeu Dmryjpfx Ahzon

Package of free spare parts

A package of the most important spare parts and consumables

like rubber parts will be send together with the machine.

Validity of offer

Subject to prior sales

Detailed offer on request

Listing

Germany

Germany

18,384 km

Pasta Production Line

AxorP-145 C-400

Call

Condition: ready for operation (used), A complete Axor pasta production line for short goods and nest goods Nidi with integrated pressing, cutting, drying and cooling line is available. Thermal output: 320000kcal/h, electrical power: 145kW, press cooling thermal energy: 25000kcal/h, pasta cooling thermal energy: 50000kcal/h. Number of dosing units: 2, dosing type: semolina dosing, press type: P-145 C-400, number of screws: 2, screw diameter: 145mm, drying tunnel dimensions X/Y: 2000mm/1500mm, total number of pasta frames: 550, pasta frame dimensions X/Y: 2000mm/1500mm, circulating frames: 440. Documentation available. An on-site inspection is possible. This is a complete pasta production line for nest goods, however longer pasta products can also be produced.

Giedpsykbglefx Ahzsn

Listing

Gargždai

Gargždai

17,502 km

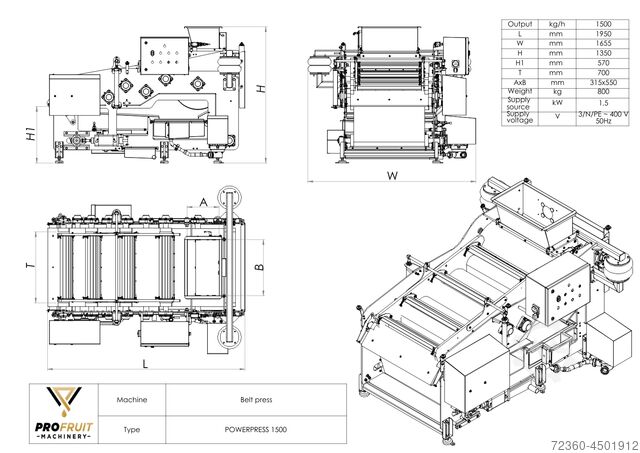

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

Giodpfx Asflpp Ejhzen

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

17,508 km

The Mobile Juice Production Line

ProFruit MachineryMobile Line

Call

Condition: new, Year of construction: 2026, The Mobile Fruit Processing Line is designed to conveniently accommodate all the machines necessary for juice production and a smooth work process. It contains:

-Fruit and vegetable washer elevator mill MAXIMILL 3000

-Belt press POWERPRESS 1500

-Transporter for leftover mash

-Stainless steel tanks

-Diesel pasteurizer

-Semi-automatic Bag in Box filler

-Juice filters

-Sink with a stainless steel table

Capacity: 1500 kg/h.

Other available capacities: 400 kg/h, 800 kg/h, 1200 kg/h.

Gijdpfx Ahoq Nl Afszen

Features:

-The mobile juice line conveniently contains all the machines required for fruit processing & juice production.

-Requires only 1 person to operate the whole line.

-Mobility is the biggest advantage which eliminates costs for premises and provides the ability to change location.

-The juice yield from apples is ~75 % .

-All machines are interconnected and controlled automatically.

-The mobile juice production unit includes a Bag in Box filler which fills the juice into both Bag in Box and Stand up Pouch packages.

-The mobile juice line can be customized on client’s request.

-The line is easy to operate and maintain.

-The mobile fruit processing line is installed in a specially made trailer which can be easily opened for work and shut when needed.

-The biggest advantage of our Mobile Fruit Processing Line is the ability to produce juice anywhere you like. This way the client avoids additional expenses for premises and gets the ability to change work location.

Mobility is the key aspect here which provides the client with more possibilities, such as developing a juice pressing service business at various apple farms or different towns.

Trust Seal

Dealers certified through Machineseeker

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Giodpeflpplsfx Ahzjn

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Gsdpoflpnyjfx Ahzein

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Listing

Humulești

Humulești

17,443 km

Complete line for steel wire fibers production

SpajicM-1 ZSN 35

Call

Year of construction: 2016, condition: like new (used), functionality: fully functional, Complete line for steel wire fibres production, Model M-1 ZSN 35

Fibre bending and cutting machine

Machine type: M – 1 ZSN 35

Dimensions and weight: 1200 x 1050 x 1620 mm; 1200 kg

Gisdpfx Ahowu Dadozon

Material to process: Low carbon steel wire %C 0.05 ÷ 0.12

Product to process: Hooked end fibre 0.75 x 35 / Hooked end fibre 1.00 x 50

Max. number of wires to process: 15

Wire pay-off device

Dimensions and weight: 5220 x 2500 x 2008 mm, approx. 2200 kg

Number of spools: 15

Max spool weight: 1000 kg

Wire diameter range: 0.6 – 1.2 mm

Spool type: Z2, Z3

PRICE: 190,000 EUR

Listing

Humulești

Humulești

17,443 km

Production of staples

WafiosKU 2

Call

Condition: used, functionality: fully functional, Year of construction: 1991, Production line for staples

Type KU 2

Manufacturer WAFIOS

previously used for iron wire

suitable for staple production

condition: used

Giodpfxowu Du Ue Ahzon

number of nails / minute: 200

technical condition: good

wire Ø min 1.8 mm

year of manufacture: 1991

wire Ø max 5 mm

maximum nail length: 50 mm

operating voltage: 380 V

frequency: 50 Hz

electrical cabinet: available

pay-off: not available

Serial no. 2 4160 034

country of origin: Federal Republic of Germany

We make it easier for you to find: "soap production"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Soap Production (15,838)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month