Used Cnc Milling Center for sale (24,478)

Bremen

Bremen CNC turning and milling center

TRAUBTNA 480

Fevziçakmak

Fevziçakmak CNC turning and milling center

MiyanoLZ-01R

Wishaw

Wishaw CNC turning and milling center

MazakE-650H

Germany

Germany CNC Turning- and Milling Center

PFIFFNER-MANURHINKMX-XL32

Germany

Germany CNC Turning- and Milling Center

INDEXG300

Discover more used machines

Jelah

Jelah CNC turning and milling center

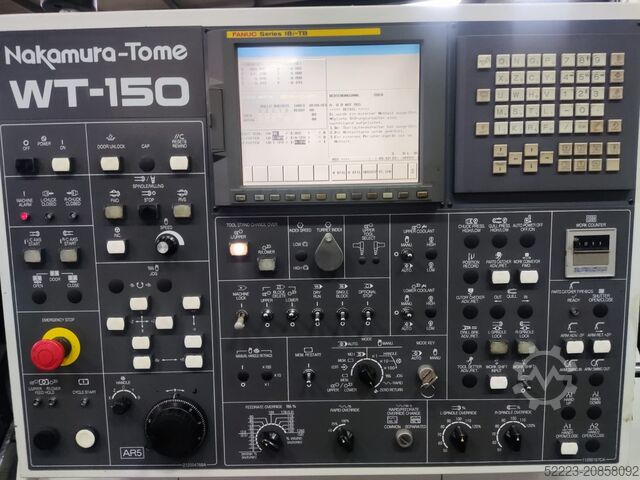

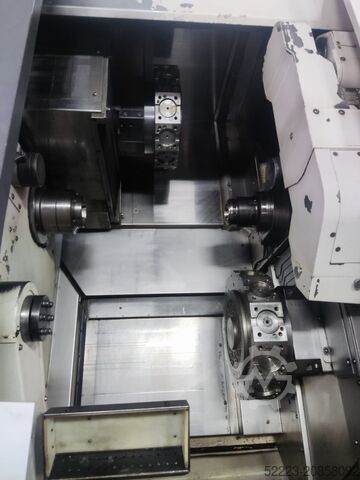

Nakamura-TomeWT150

Jelah

Jelah CNC turning and milling center

NAKAMURA - TOMEWT 150

Jelah

Jelah CNC turning and milling center

MORI SEIKINL2500Y/700

Berlingo

Berlingo Cnc turning and milling center

GildemeisterTwin 90

Uttendorf

Uttendorf CNC turning and milling center

MazakINTEGREX i 250H S

Tiefenbronn

Tiefenbronn CNC turning and milling center

MiyanoABX-64SY

Haifa

Haifa CNC turning and milling center

MazakIntegrex 300 3 ST

Hattingen

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Thurmaston

Thurmaston CNC turning and milling center

DOOSANPuma 5100 XLY

Germany

Germany CNC Turning- and Milling Center

MONFORTSRNC 500 AC

Alblasserdam

Alblasserdam CNC turning and milling center

Cnc lathe Hyundai WIAL200Y

Schweiz

Schweiz CNC Turning & milling center

MORI SEIKIZT 1500 YB

Lüdenscheid

Lüdenscheid CNC turn-mill center

BIGLIAB 470 YSM

Hessen

Hessen CNC turning and milling center

EMCOHYPERTURN 65-1300 (SM2Y2)

Burgoberbach

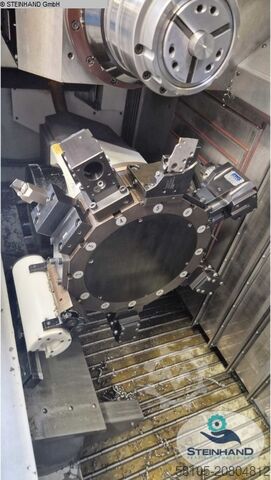

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

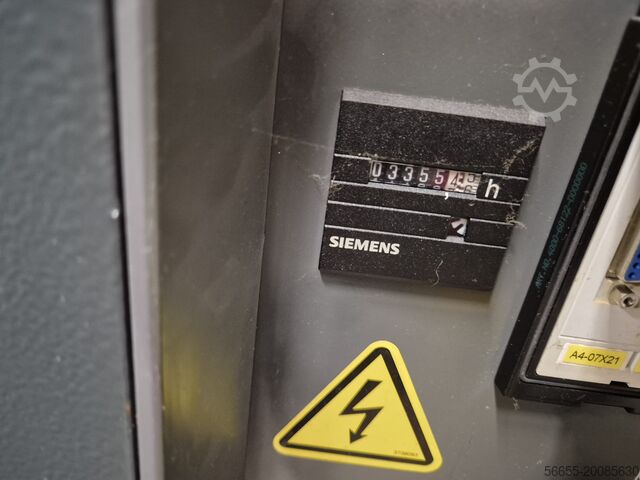

Burgoberbach CNC turning-milling center 6 AGW

GildemeisterCTX 310 Eco (nur 3.350 h)

Burgoberbach

Burgoberbach Milling Machine / Machining Center CNC

MAHOMH 300 C

Germany

Germany CNC Turning- and Milling Center

NILES-SIMMONSN30 - 3MC-2500

Hilden

Hilden CNC Turning- and Milling Center

NILES-SIMMONSN20-2 MC

Used Cnc Milling Center (24,478)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you