Used Saw Sharpening Machine for sale (65,468)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Salzburg

Salzburg

18,408 km

Sharpening machine

YanigavAP350G

Call

Condition: new, Year of construction: 2026, Yanigav AP350 Sharpener

• Weight: 750 kg

• Drive: Hub drive PTO

• Maximum opening: 350 mm

• Cylinder stroke: 750 mm

• 4 adjustable sharpening angles

Djdpfx Acer Ezfdj Nokh

• Blade holder with polyamide bushings

• Pedal-operated for left- and right-handed use

Listing

Kuchl

Kuchl

18,405 km

Circular sawing machines

HAMMERK3 WINNER COMFORT

Call

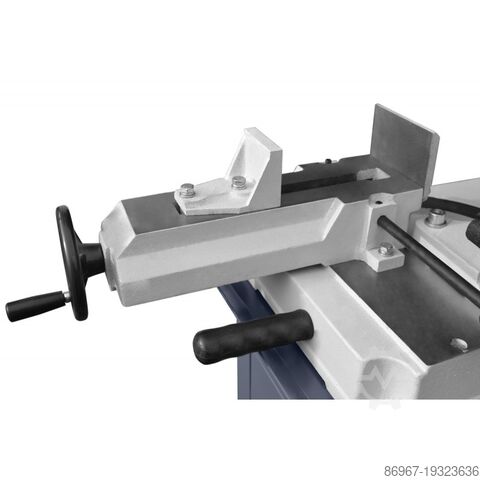

Condition: like new (used), Year of construction: 2023, For sale is a demonstration unit Hammer K3 Winner Comfort panel saw with a cutting length of 2000 mm. The machine is in mint condition.

Technical data:

- Sliding table: 2000 mm

- Outrigger table: 1100 mm

- Mitre fence: 1300 mm

- Angle indexer

Djdpfxevxrurj Ac Nskh

- Saw blade tiltable 90-45°

- Max. cutting height: 104 mm with blade diameter 315 mm

- Cutting width: 800 mm

- 5.5 HP (4 kW) motor, 400 Volt

- Year of manufacture: 2023

The panel saw is located in A-5431 Kuchl and can be inspected at any time during our opening hours. Subject to prior sale!

Related terms: saw, circular saw, Hammer, panel saw, sliding table saw

Reference: R-A0117

Listing

Wasbek

Wasbek

18,194 km

Circular Sawing Machine - KKS 275 T

KnuthKKS 275 T

Call

Condition: new, The KKS 275 T, a Manual Circular Saw Machine from KNUTH, is your essential tool for precise cutting in any workshop. Designed for machining smaller tubes and profiles, it features a robust yet easy-to-operate design, allowing for accurate miter cuts of up to +/- 45 degrees. The KKS 275 T is equipped with a high-precision rigid vise, which incorporates a quick-action clamping feature that is ideal for small batch production. With its built-in coolant system and an integrated rust-proof gear mechanism, it ensures durability and minimal maintenance. This model not only handles solid materials, tubes, and sections of steel and light metals efficiently but also provides a large cutting capacity with dimensions of up to 70 mm for round and 90x45 mm for flat workpieces. For optimal performance, request a quote for the KNUTH KKS 275 T, a reliable choice in the Circular Sawing Machines product group.

Dedpfxsuyifno Ac Nokh

Listing

Meeri

Meeri

17,094 km

Chain saw sharpener

Lakfam ASP-631 FWLN 800

Call

Condition: used, functionality: fully functional, Year of construction: 2021, SaeketaASP 631 F-WL(N) 800 for uniform sharpening of circular saw blades, with a pendulum head and four-axis control. Lakfam ASP-631 F sharpening machine.

Dksdpjyabvfefx Ac Njh

Listing

Wiefelstede

Wiefelstede

18,341 km

Saw blade grinding machine

Schmidt Tempo**G200

Call

Condition: good (used), Saw blade grinding machine, tool grinding machine, grinding machine, automatic sharpening machine for circular saw blades

Dkedpermt Sgsfx Ac Noh

-Saw blade sharpening machine with partial gear

-For grinding circular saw blades up to: Ø 200 mm

-Automatic delivery and power off

-Dimensions 900/830/H1490 mm

-Weight: 498kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Saw unit for edge processing machines

OttK 14 U 206

Call

Year of construction: 1994, condition: used, Double-end tenoner, edge processing machine, flush cutter, edge cutter, spindle motor, milling motor, saw unit, milling unit saw unit

-Manufacturer: Paul OTT, saw unit from edge banding machine U 206

Dkedpfx Asu Rv Ttjc Nsh

-Engines: Type K 14

-Power: 0.8 kW / 200 Hz

-Speed: 1200 rpm

-Saw blade: Ø 140 mm

-Saw blade spacing: 515 to 1070 mm

-Dimensions: 530/490/H600 mm

-Weight: 78 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Band saw machine

Pehaka320 x.150 mm

Call

Condition: good (used), Metal band saw, fully automatic, band saw machine, band saw, vertical band saw, horizontal band saw, hydraulic horizontal band saw machine, automatic band saw, metal band saw machine

Djdpfohwxb Tsx Ac Nekh

-Manufacturer: Pehaka, horizontal band saw automatic band saw

-Drive: 0.8 kW

-Cutting data flat: 320 x 150 mm

-Cutting data square: 150 mm

-Saw blade speed: continuously adjustable, 20 - 195 m/min

-Saw band: approx. 3700 mm

-Coolant system

-Dimensions: 1800/940/H1310 mm

-Weight: 528 kg

Listing

Marktl

Marktl

18,400 km

Welding machine for band saw blades

DrosteST260

Call

Year of construction: 2022, condition: as good as new (ex-display), DROSTE Welding Table for band saw blades:

for new blades and for welding cracks

Dkjdpfjuh Sp Nox Ac Nsh

ST260:

Automatic with TIG or MIG System

Automatic welding feed programable

Annealling System

Preheat plate

Technical Details:

Blade width: 30 – 260 mm

Blade thickness: 0,6 – 2.0 mm

Listing

Kampen

Kampen

18,495 km

Band saw machine

BauerVG 450-600

Call

Condition: used, functionality: fully functional, For sale: Bauer VG 450-600 sawing machine, specially designed for steel construction. This machine is suitable for cutting various steel profiles and structures. The Bauer VG 450-600 is renowned for its precision and reliability in steel construction.

Dkedjx Trhmjpfx Ac Njh

Listing

Rödermark

Rödermark

18,557 km

Circular metal sawing machine

BEHRINGER-EISELEVMS 350

Call

Condition: good (used), Year of construction: 2009, machine/vehicle number: 10014344, Offer 25481

Technical Data:

- Saw blade diameter up to 350 mm

- Saw blade feed via hand lever

- Maximum opening width of pneumatic vice: 205 mm

- Cutting capacity with saw blade diameter 350 mm:

- at 90° round: 120 mm

- square: 110 mm

- flat up to 200 x 90 mm

- or 140 x 110 mm

- at 45° round: 100 mm

- flat: 100 x 100 mm

- Mitre adjustment: left up to 45°, right up to 45° and 30°

- 2 saw blade rotational speeds: 17 and 34 rpm

- Drive: 400 V / 1.4 / 1.9 kW

- Air connection: 6 - 8 bar

- Micro-spray coolant system

- Space requirement approx.: W 850 x H 1750 x D 950 mm

- Weight approx.: 400 kg

Dedpfx Ajx Tqnfoc Nokh

Listing

Miastko

Miastko

17,843 km

Circular sawing machines

SCMHYDRO 2000

Call

Condition: excellent (used), 5.5 kW motor

Scoring unit

Dkjdpfjw U Th Aox Ac Neh

Table length: 200 cm

Ground clearance: 133 cm

Listing

Dinkelsbühl

Dinkelsbühl

18,523 km

Circular saw automatic machine for aluminum profiles

Pressta-EiseleProfilma 510 E-SA

Call

Condition: excellent (used), Year of construction: 2007, Complete saw line consisting of loading unit, fully automatic circular saw, and unloading unit.

Suitable for a wide range of applications, especially in the photovoltaic and automotive industries.

Loading Unit:

- Horizontal loading magazine model HLM

- 4-strand timing belt conveyor

- 6 compartments, each 285mm wide, for profile feeding

- Maximum material height according to the saw cutting area; round material up to max. diameter 130mm

- 3 sliding strips between timing belts as additional support

- Profile length min. 2,700mm, max. 6,500mm

Saw:

- Fully automatic circular saw Pressta-Eisele model PROFILMA 510 E-SA

- Saw blade diameter max. 500mm

- Continuously variable speed adjustment

- Hydro-pneumatic saw blade feed, infinitely adjustable, from rear to front

- Siemens S7-300 control system with touchscreen

- Reversing device with five-fold stroke up to max. 5,000mm

- Electric material feed 3 – 1,000mm (single stroke)

- Cutting gap extension on both sides

- Pneumatic unloading slide

- Scrap flap after saw for offcuts / remains

- Cut length depending on profile, from 8mm

- Menzel minimum quantity lubrication system

Dsdpfxsxvbvvj Ac Nskh

- Clamping pressure regulation

- Two extraction nozzles for chip extraction

Unloading:

- Table size 1,500mm x 2,500mm

- Pneumatic cross pusher

Listing

Timișoara

Timișoara

17,849 km

Machine saw

OMGATI 2500 SUPER

Call

Condition: excellent (used), Year of construction: 2009, functionality: fully functional, Circular saw in very good condition

Dkedst Uk Rmjpfx Ac Njh

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 205mm

CORMAKBS712SW 20mm 230V

Call

Condition: new, Year of construction: 2025, Professional, very powerful and efficient band saw for metal with 45° swivel arm. The perfect solution for ironwork, production and craft workshops. Unparalleled for many years, the design and solid construction make it a perfect solution.

Machine description

Professional, very powerful and efficient metal band saw with 45° swivel arm, CORMAK BS 712 SW is based on refined solutions making it unrivaled in its class.

Arm made of shaped spheroidal cast iron ensures rigidity during operation and absorbs all vibrations. Control panel is located on the arm of the cutter. It features high efficiency and simple handling. Provides cutting in vertical plane and in the plane perpendicular to the axis of the cut material, or at any angle in 45° – 90° range. Element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Suitable speed of arm lowering is obtained thanks to the valve controlling oil flow between hydraulic cylinder chambers.

Rugged, stable and refined construction as well as the arm made of uniform cast iron provide high rigidity and stability while cutting, ensuring accuracy and long-term reliability. The design of the 20 mm saw blade used in the machine makes it possible to cut large quantities of elements. Required band linear velocity is obtained by changing the ratio on the belt pulley between the worm gear and the driving motor.

Technical data

Motor power 1.1 kW

Band speeds 22/33/45/65 m/min

Power supply 230V

Band dimensions 2360×20×0.9 mm

Cutting range 45°L – 45°R

Dkjdpfxomtwktj Ac Noh

Weight 145 kg

Dimensions 1280x575x1140 mm

Angle

0°.....Ø 205.....215×205.....205×205

45° L.....Ø 150.....100×200.....130×130

45° R.....Ø 140.....140×90.....90×90

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine

CORMAKHBS275

Call

Condition: new, Year of construction: 2025, CORMAK HBS275 band saw, equipped with a hydraulic cylinder, a cooling system and an arm swivelling up to 60º, together with blades from renowned German company Röntgen, is used commonly in ironworking, where precision, quality and cutting speed are essential.

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or with any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality. Carbide guiding drastically reduces the wear of the machine and blades.

Machine's arm made of uniform cast iron as well as a 27 mm wide cutting band are capable of low and high quantity cutting of profiles and other materials. The vice is located in an adjustable bed, equipped with a quick clamp. Blade guides have cemented carbide plates and roller bearings. Its these cemented carbide guides that provide cut precision and straightness. The arm, positioned at an angle of 25º, thus increasing blade durability, is equipped with an automatic blade tension sensor. To the bottom of the arm a brush wire is attached, ensuring clean and functional brush. Machine's drive is transmitted through a worm drive. A 3-phase motor with 2 cutting speeds and motor thermal protection. This cutting machine also has a strain gauge - a band tension sensor and an automatic switch-off in case the cutting band breaks. Upper part of the base constitutes a tank for flood coolant draining and chips produced during cutting. A cast iron workbench is attached to the base, with a swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band and the arm lowering feed. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 37.5 and 75 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Total power

1.5 kW

Power supply

400V 50Hz

Arm lowering control

hydraulic cylinder

Band dimensions

2455 x 27 x 0.9 mm

Band speed

37.5/75 m/min

Vice base height

900 mm

Weight

215 kg

Angle

0º

ø220

260 x 140

Dkjdpfxeudi Uns Ac Noh

200 x 200

45º R

ø160

160 x 140

160 x 160

60º R

ø100

120 x 100

100 x 100

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 205mm

CORMAKBS712SW 20mm 400V

Call

Condition: new, Year of construction: 2025, Professional, very powerful and efficient band saw for metal with 45° swivel arm. The perfect solution for ironwork, production and craft workshops. Unparalleled for many years, the design and solid construction make it a perfect solution.

Machine description

Professional, very powerful and efficient metal band saw with 45° swivel arm, CORMAK BS 712 SW is based on refined solutions making it unrivaled in its class.

Arm made of shaped spheroidal cast iron ensures rigidity during operation and absorbs all vibrations. Control panel is located on the arm of the cutter. It features high efficiency and simple handling. Provides cutting in vertical plane and in the plane perpendicular to the axis of the cut material, or at any angle in 45° – 90° range. Element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Suitable speed of arm lowering is obtained thanks to the valve controlling oil flow between hydraulic cylinder chambers.

Rugged, stable and refined construction as well as the arm made of uniform cast iron provide high rigidity and stability while cutting, ensuring accuracy and long-term reliability. The design of the 20 mm saw blade used in the machine makes it possible to cut large quantities of elements. Required band linear velocity is obtained by changing the ratio on the belt pulley between the worm gear and the driving motor.

Technical data

Motor power 1.1 kW

Band speeds 22/33/45/65 m/min

Power supply 400V

Band dimensions 2360×20×0.9 mm

Cutting range 45°L – 45°R

Weight 145 kg

Dimensions 1280x575x1140 mm

Angle

0°.....Ø 205.....215×205.....205×205

45° L.....Ø 150.....100×200.....130×130

45° R.....Ø 140.....140×90.....90×90

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Dedpfxsw U Skvo Ac Nskh

Listing

Siedlce

Siedlce

17,614 km

Semi-automatic band saw machine

CORMAKBS-530H

Call

Condition: new, Year of construction: 2025, CORMAK BS530H Metal Band Saw – A Professional Tool for Cutting Pipes and Profiles

The CORMAK BS530H metal band saw is an efficient semi-automatic bandsaw designed for precise cutting of steel elements, pipes, and profiles at various angles. Its solid cast-iron construction, reinforced blade guidance system, and advanced hydraulics make it ideal for serial production and demanding industrial environments. The integrated control panel allows a single operator to manage all functions, significantly reducing operation time and improving workplace ergonomics.

Key Advantages of the Machine

Semi-automatic operation – hydraulic arm lifting/lowering and vise control via control panel.

Worm gearbox with bronze components ensures smooth, vibration-free, and precise operation.

Stepless cutting speed adjustment from 20 to 70 m/min – suitable for various materials.

Carbide and ball-bearing blade guides for durability and precise blade tracking.

Quick-release vise, manually or hydraulically controlled, adjustable left/right.

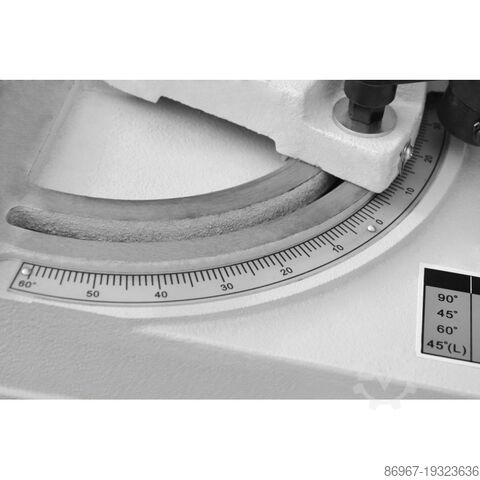

Miter cutting range from -45° to +60° with precise angle scale reading.

Heavy-duty cast-iron frame ensures cutting stability and long machine life.

Hydraulic feed rate control with adjustable return height of the saw arm.

Construction and Technology

The BS530H model features a reinforced drive system and industrial-grade hydraulics, ensuring reliable performance under intensive use. The massive frame construction minimizes vibration and ensures consistent cutting performance. An ergonomic control panel allows full process control from one location. The coolant system, integrated into the base, efficiently removes heat and debris, protecting the blade from overheating.

Cutting Precision and Efficiency

With stepless speed control, manual or semi-automatic operation modes, and a dial gauge blade tension meter, the BS530H delivers repeatable, high-quality cuts, even in long production runs. A material support roller and arm lock after the cutting cycle enhance operational safety and efficiency.

Applications

The CORMAK BS530H is dedicated to industrial production facilities, metalworking shops, and companies performing serial cutting of profiles, pipes, and solid steel sections. It’s ideal for serial manufacturing, prefabrication, and component preparation for welding or further processing.

Standard Equipment

Control console with semi-automatic functions

Hydraulic vise

Blade cleaning brush

Coolant system with pump

Front material roller

Dial gauge blade tension meter

CE certificate and technical documentation (DTR)

Technical Specifications:

Parameter Value

Working height 965 mm

Cutting speed 20 – 70 m/min

Blade dimensions 3770 × 34 × 1.1 mm

Coolant system power 0.1 kW

Total power 3.0 kW

Dedpjw U Svlsfx Ac Nekh

Power supply voltage 400 V

Dimensions (W × D × H) 2200 × 1400 × 2050 mm

Weight 730 kg

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 260mm

CORMAKHBS320

Call

Condition: new, Year of construction: 2025, CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

Machine characteristics

CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. The band saw arm is made of massive, uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of structural steel, stainless steel and tools. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. It has a huge impact on the band guiding, its durability, accuracy and cutting quality. The carbide guiding drastically reduces the wear of both the machine and the blade.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a double-sided swivel arm and a control panel.

The feed speed is controlled by the control panel. There are 2 cutting band speeds: 44 and 88 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Dkjdpfxoi D Dgwj Ac Neh

Technical data

Ø max 260 mm /perpendicular cutting

H×B max 320×160 mm /perpendicular cutting

Power supply - 3–phase, 400V

Total power - 1,5 kW

Arm lowering control - hydraulic cylinder

Band dimensions - 2740×27×0.9 mm

Band speed - 44 / 88 m/min

Vice base height - 920 mm

Dimensions - 1400×880×1550 mm

Weight - 280 kg

Cutting parameters

Angle

0º ---- ø260 320×160 255×255

45º R ø210 210×200 210×210

60º R ø135 135×130 130×130

45º L ø160 220×130 160×160

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine

CORMAKHBS260 + 2 piły M42 + 5L Emulgol

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

Dkjdpfxjudi Uze Ac Njh

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

Additionally

2 M42 saw blades

5L Emulsol

ZW580 magnetic chip collector

Listing

Siedlce

Siedlce

17,614 km

Semi-automatic band saw machine 250mm

CORMAKS-200RH przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, Powerful, reliable and modern semi-automatic band saw for metal with automatic arm raising and lowering. The arm is rotational in both ways. The machine is fantastic for ironworking, e.g. cutting tubes and profiles.

Product features

CORMAK S-200RH band saw is by default equipped with automatic arm lowering and raising as well as with a precise arm height regulator. Due to an automatic hydraulic damper, the manual handling of the machine has been simplified to feed and clamping the cut material in a vice. The arm made of uniform iron casting, together with a refined, solid and stable construction, ensure S-200R's exceptional rigidity, resulting in failure-free handling and high cutting precision.

The innovativeness and production of semi-automatic and automatic series "CORMAK-PREMIUM LINE" band saws, compliant with the norms and standards consistent with ISO:910001 and ISO:140001 certificates, warrant safety, quality and reliability of the product. M3V motors from ABB, a renowned worldwide manufacturer, warrant long-term reliability. As an official and the only representative on the Polish market, we assure that the product is original and provide professional, customised warranty and post-warranty services.

Technical data

Type - semi-automatic

Arm raising and lowering - hydraulic with smooth arm lowering control

Dedei D D A Sjpfx Ac Nekh

Band speed - 36/70 mm/min

Angled cutting - left to 45°, right to 60°

Vice - hydraulic

Minimum cutting diameter - Ø 5 mm

Minimum material length in vice - 30 mm

Vice base height - 780 mm

Cutting band dimensions - 27×0.9×2910 mm

Total power - 2.1 kW

Dimensions (LxWxH) - 1600×800×1400 mm

Weight - 530 kg

Angle

0º -----ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

Default equipment

Control panel on separate component

Built-in hydraulic unit

Hydraulic control of arm motion (up – down) with possibility of smooth lowering speed control

Arm position memory function (arm returns to a defined height after cutting)

Cutting at angles of L/R 45° - 0° - 45° - 60°

Brush for cleaning band

Cooling system

Bi-metal band saw

EC Declaration of Conformity

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 230mm

CORMAKHBS260

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

*Please note that machine is sold without CEE connector by default, since there are many different types of it. If you would like to receive it with the machine, please write it to the seller before making a purchase/during order proceeding.

Dedpfx Acemrnk Ej Nskh

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Trust Seal

Dealers certified through Machineseeker

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 250mm

CORMAKS-200R manual

Call

Condition: new, Year of construction: 2025, Cormak S200R Manual band saw for cutting in large industrial facilities.

Features high accuracy metal cutting, even at 45º/60º.

Machine features

CORMAK S-200R MANUAL band saw with EC declaration, provides cutting metal at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Appropriate arm lowering speed is ensured by a valve controlling oil flow between the chambers.

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. Material is fed manually. This model is used in both low and high quantity production, and due to its solid construction allows for cutting various materials, including stainless steel, tool steel and profiles. The machine provides cutting at an angle due to rotary arm. The band saw arm is made of uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of various materials. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. The arm is equipped with an automatic blade tension sensor, at a 25° angle, thus increasing blade's durability.

There is a blade cleaning brush attached to the bottom of the arm. Machine drive is transmitted through a worm drive filled with gear oil. The machine is equipped with a three-phase motor with double winding and two cutting speeds. The motor is thermally protected.

Two cutting band speeds: 35 and 70 m/min. The construction: the arm, the vice and the rotating table are iron castings. Closed cooling system. The machine is equipped with a bumper with a ruler for setting the length of material cut. The base of the machine is a rigid cuboid made of steel sheets in which a fluid container with a flood coolant pump is located. Safety during cutting ensures an electrical system that meets all EC requirements. The machine is equipped with a limit switch which stops the machine after a cutting process is finished, an emergency button, and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened

Technical data

Type gravitational

Arm raising and lowering gravitational with stepless arm lowering adjustment

Band speed 36/70 m/min

Cutting at an angle from 45° left up to 60° right

Vice manual

Minimum cutting diameter Ø 5 mm

Minimum material length in vice 30 mm

Vice base height 890 mm

Cutting band dimensions 27×0.9×2910 mm

Total power 2.1 kW

Dksdpfx Acsfy Ttie Nsh

Dimensions (LxWxH) 1600×800×1400 mm

Weight 500 kg

Max. cutting range [mm]

Angle

0º ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

For more information please visit our web page or contact us

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Djdjwq A Dyspfx Ac Nekh

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Circular saw sharpener

CORMAKJMY-870

Call

Condition: new, Year of construction: 2025, The JMY-870 sharpener is an excellent tool for sharpening circular saw blades. The sharpener is equipped with a durable, diamond grinding disc. This ensures precise and effective sharpening. The solid cast iron construction guarantees stability during work, and the adjustment of the angle of inclination and the angle of the saw provide full control over sharpening. Additionally, rubber pads under the feet minimize noise, ensuring comfort of work. Standardly equipped with a 125 mm diamond grinding wheel, it is suitable for sharpening saws from 80 mm to 700 mm in size.

The most important advantages of this circular saw sharpener

The sharpener is equipped with a high-quality 125 mm diamond grinding disc, which guarantees extraordinary precision when sharpening carbide saws.

The cast iron base ensures stability during work. Thanks to this, the user can be sure that the device will not wobble or vibrate during sharpening.

The sharpener is equipped with a tilting blade support, which allows you to adjust the angle of inclination from -35° to +45°. This allows you to precisely adjust the blade setting to the specific needs of the user.

An additional function is the ability to set the saw's incisal angle in the range from +85° to -30°, which allows you to adapt the tool to different types of saws.

The saw sharpener has been designed with work comfort in mind. Thanks to the rubber pads under the feet, the device works almost silently, which has a positive effect on the comfort of use.

Application of the saw sharpener

The sharpener is designed for sharpening circular saws. The operation of the device is intuitive and simple, which means that even people who are not familiar with the technique will be able to use this tool. The JMY-870 circular saw sharpener is a professional tool that ensures high quality saw blade processing and work comfort. Thanks to the various adjustment options, it is an excellent choice for people who require a precise and effective tool for sharpening various types of saw blades.

THE SET INCLUDES A DIAMOND GRINDING WHEEL!

Technical parameters

MIN/MAX SAW DIAMETER 80mm - 700mm

HORIZONTAL SAW BLADE HOLDER TILTING -35° to +45°

GRINDING SET TILTING -20° to +20°

GRINDING DISC ROTATIONAL SPEED 2850 rpm

Djdju Tti Iopfx Ac Nskh

DISC DIMENSIONS 125 x 10 x 13 mm

MOTOR POWER 0.25 kW

SUPPLY VOLTAGE 230 V

NET WEIGHT 21 kg

DEVICE DIMENSIONS 750 x 750 x 350 mm

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 250mm

CORMAKG5025

Call

Condition: new, Year of construction: 2025, A strong, big band saw for metals with a swivel arm, enabling cutting in the plane perpendicular to the axis of the cut material and at any angle from -45° (left) to + 60° (right). Band saws are perfect for cutting tubes, profiles and other materials.

Product features

Material cut can be fed manually or by any feeding device, with automatic tool feed. Appropriate cutting speed (band speed) is obtained through a change on a control panel. Rigid construction arm is made of profiled cast iron.

The drive from the electric motor directed to the cutting band driving wheel is transmitted by a motor with worm drive. The cutting band is tensioned on two cast iron wheels with a manual tightener and guided by adjustable rolling and linear carbide guides.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a -45° to + 60° swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds: 36 and 72 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Cutting band size - 2720×27×0.9 mm

Dkjdpsi D Ddiofx Ac Njh

Band tension - mechanical (manual)

Band speed - 36, 72 m/min

Arm lowering control - stepless – hydraulic cylinder

Vice base height - 765 mm

Minimum material length in vice - 100 mm

Power supply - 3-phase, 400 V

Total power - S1 100%: 1.5; S6 40%: 2.1

Cooling pump motor power - 0.025 kW

Weight - 370 kg

Warranty - 12 months

User manual - yes

CE declaration - yes

Angle

0° --- ø250 310×210 240×240

45° R ø200 200×140 180×180

45° L ø165 185×145 160×160

60° R ø120 120×95 100×100

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

We make it easier for you to find: "saw sharpening machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Saw Sharpening Machine (65,468)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Band Saw Blade Sharpening Machine

- Band Saw Sharpening Machine

- Blade Grinding Machine

- Chisel Sharpening Machine

- Circular Saw Blade Sharpener Machine

- Circular Saw Sharpening Machine

- Hob Sharpening Machine

- Honing Machine

- Knife Grinding Machine

This may be of interest to you