Used Dna Sequencer for sale (467)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

17,614 km

Automatic column band saw

CORMAKH-500SA przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2026, The CORMAK H500SA automatic bandsaw is a technologically advanced double-column metal bandsaw designed for precise and efficient cutting of large steel components, tubes and profiles. With complete process automation, high cutting power and a durable structure, it performs perfectly in serial production and heavy-duty industrial operations.

Main Advantages

Automatic cutting cycle – the full cutting sequence from loading to arm return is performed without operator involvement.

Hydraulic vice and material feed – ensuring fast, firm and precise clamping and feeding of the workpiece.

High cutting capacity – suitable for materials up to Ø500 mm or 500 × 500 mm.

Hydraulic blade tensioning – automatically maintains optimal tension for stable cutting performance.

Cooling system and powered cleaning brush – extend blade life and improve surface quality.

Construction and Technology

The machine is based on a heavy-duty cast-iron and steel structure providing high rigidity and minimising vibrations during operation. The double-column design of the H500SA ensures cutting precision and long-term durability. Equipped with a 7.1 kW main motor and an independent hydraulic system, it delivers reliable performance under continuous use. The frame is inclined at a 3° angle to the work surface for more effective cutting of profiles and sections.

The blade is guided by carbide-insert and roller bearings that ensure perfect blade tracking. The movable guide head automatically adjusts to the material width, enhancing stability and reducing blade wear.

Precision and Productivity

Hydraulically controlled arm feed with smooth pressure adjustment allows precise adaptation to the material being cut. The LCD control panel enables programming of the number and length of cut pieces, as well as real-time monitoring of cutting parameters. The machine automatically detects the end of material, faults, and operation status, ensuring uninterrupted production with maximum efficiency.

Hodpeyctwmofx Adaoh

Applications

The CORMAK H500SA is an industrial metal bandsaw recommended for:

Steel structure fabrication plants

Serial production in metal workshops

Cutting heavy steel pipes and profiles

Large-scale steel processing and tool steel cutting operations

Standard Equipment

Full automatic cutting cycle

Arm and vice position memory

Hydraulic unit and feed system

Hydraulic blade tensioning

Powered blade cleaning brush

Coolant circulation system

Bimetal bandsaw blade

CE Declaration of Conformity

Technical Data

Cutting range Ø500 mm or 500 × 500 mm

Blade dimensions 5550 × 41 × 1.3 mm

Blade speeds 40 / 60 / 80 m/min

Main motor power 7.1 kW

Hydraulic power unit 1.5 kW

Coolant pump 0.09 kW

Blade tensioning Hydraulic

Feeder stroke 500 mm

Load capacity 3 t

Table height 600 mm

Machine dimensions (L × W × H) 2900 × 2200 × 1900 mm

Weight 2400 kg

Listing

Wakefield

Wakefield

18,590 km

Folding machine

MBOT800/444-RU Folding Machine

Call

Condition: excellent (used), Year of construction: 2012, Ref:11059 . 2012 MBO T800/444-RU Folding Machine.

Max. sheet size: 82 x 115 cm

Hodpex U Dc Sjfx Adaoh

16 page+ B1 high speed folding machine with ability to be run by single operator.

Equipped with:

R800 Round pile continuous feeder

Vacu-Infeed for mark free and smooth sheet running

Vacu-Alignment

MC-Control electronic sheet monitoring including total & batch counting.

Combi plates & Pre-slitter shafts on 1st & 2nd units

Eye-level control panel

FA 46ME presser/stacker/marker delivery

Folding sequence:

1st buckle unit 78cm with 4 plates

2nd mobile buckle unit 78cm with 4 plates

3rd 'U' mobile buckle unit 56cm with 4 plates - returns sheet to feed position.

Listing

Wakefield

Wakefield

18,590 km

Folding machine

MBOB30C-644 Folding Machine

Call

Condition: excellent (used), Year of construction: 2011, Ref:11058 . 2008 MBO B30C/644 Folding Machine

Excellent condition, very well maintained.

Equipped with:

R760 - Low profile round pile continuous feeder

Automatic total and batch counter

Buckle plates with swing-away deflectors

Sound hoods to all units

Eye-level control panel

Folding sequence:

1st buckle unit 76cm with 6 plates

2nd mobile buckle unit 76cm with 4 plates

3rd mobile buckle unit 38cm with 4 plates

SBAP-24ME Press Stacker

Specification:

Minimum Sheet Size: 150mm x 180mm

Maximum Sheet Size: 760mm x 1270mm

Mechanical Speed: 180 m/min

Hodjx U A E Espfx Adaoh

Listing

Sierakowska Huta

Sierakowska Huta

17,772 km

Round bar turning machine for logs

SERMIAC MBR 165 siłowniki pneumatyczneSAFO PROBST HAMECH

Call

Condition: excellent (used), CATALOGUE NUMBER 7660

TECHNICAL DATA

- maximum diameter of machined material: 160mm

- minimum input material length: 750mm

- machining allowance (on diameter): max 30mm

- knife head drive motor: 33kW

- stepless feed speed control via frequency inverter

- feed motor: approx. 2.2kW

- pneumatic actuators: 7 pcs

Sequence:

- 4 toothed feed rollers

- 3-knife head

- 3 smooth outfeed rollers

- dimensions (L/W/H): 3800x1100x2800mm

- weight: approx. 4000kg

ADVANTAGES

– French manufacture

– Robust construction

– Pneumatic actuators (hold-downs)

– Used peeling lathe

Hedpfex U Acksx Adaoh

– Very good condition

Net price: 85,900 PLN

Net price: 20,450 EUR (exchange rate 4.2 EUR)

(Prices may change with higher fluctuations)

Listing

Kalisz

Kalisz

17,897 km

Fully peeling & vacum potatoes line

Dornow20M-AT-MS

Call

Year of construction: 2020, condition: like new (used), Our Dornow potato peeling line is for sale, consisting of:

Storage bunker with conveyor belt (capacity approx. 1t raw material)

Potato peeler with knives 20M-AT-MS

Roller inspection table

Pre washer with transporter conveyers

Preserving and bagging device

Vacuum sealer

Extra sets of brand new blade for peeler included

This line can also peeling beetroots, celery and if you keep peeling cycle longer also carrots

For additional monies we can add it: (slicer, metal detector.. Subject to request)

The peeling line runs automatically in sequence:

The pot peeler is filled by the conveyor belt from the storage bunker after a continuously adjustable time. The peeler peels the potatoes for the infinitely variable preset time and then ejects the peeled product onto the inspection table and the sequence starts again.

Depending on the quality and size of the potatoes, the system peels approx. 300 - 1000 kg of raw product per hour

The pot peeler peels with minimal water consumption using a flat jet from a nozzle.

Kobhyc I Hovdvmpecedl

Pot peeler capacity approx. 40 kg raw material, optimum filling quantity for good peeling results approx. 25 kg

Inspection table with removable tuber rinsing device

Storage capacity in the water bath canning and bagging unit approx. 120 kg of peeled goods.

Preserving and bagging unit with discharge belt and dosing belt for the scale as well as draining section and air and water rinsing nozzles.

Single chamber vacuum sealer dimensions chamber: 600x400mm, vacuum pump capacity: 60m³/h

Year of construction 2020, in use until August 2023.

Hjdow R T Diopfx Adajh

In very good condition and fully functional.

Can be inspected on site by arrangement.

Discover more used machines

Listing

Poznań

Poznań

17,936 km

Fully peeling & vacum potatoes line

DORNOW20M-AT-MS

Call

Year of construction: 2020, condition: excellent (used), functionality: fully functional, Our Dornow potato peeling line is for sale, consisting of:

Storage bunker with conveyor belt (capacity approx. 1t raw material)

Potato peeler with knives 20M-AT-MS

Roller inspection table

Pre washer with transporter conveyers

Preserving and bagging device

Vacuum sealer

Extra sets of brand new blade for peeler included

This line can also peeling beetroots, celery and if you keep peeling cycle longer also carrots

For additional monies we can add it: (slicer, metal detector.. Subject to request)

The peeling line runs automatically in sequence:

The pot peeler is filled by the conveyor belt from the storage bunker after a continuously adjustable time. The peeler peels the potatoes for the infinitely variable preset time and then ejects the peeled product onto the inspection table and the sequence starts again.

Depending on the quality and size of the potatoes, the system peels approx. 300 - 1000 kg of raw product per hour

The pot peeler peels with minimal water consumption using a flat jet from a nozzle.

Kobhyc I Hovdvmpecedl

Pot peeler capacity approx. 40 kg raw material, optimum filling quantity for good peeling results approx. 25 kg

Inspection table with removable tuber rinsing device

Storage capacity in the water bath canning and bagging unit approx. 120 kg of peeled goods.

Hedpfx Adjw Sfg Ejajh

Preserving and bagging unit with discharge belt and dosing belt for the scale as well as draining section and air and water rinsing nozzles.

Single chamber vacuum sealer dimensions chamber: 600x400mm, vacuum pump capacity: 60m³/h

Year of construction 2020, in use until August 2023.

In very good condition and fully functional.

Can be inspected on site by arrangement.

Listing

Monheim am Rhein

Monheim am Rhein

18,573 km

Surface Grinding Machine - Horizontal

ABA / Z & BMULTILINE 2507 CNC

Call

Condition: good (used), Year of construction: 2008, functionality: fully functional, Technical details

grinding length 2000 mm

grinding width 850 mm

distance spindle center to table 900 mm

control Siemens 840 D

total power requirement 155 kVA

weight of the machine ca. 15 t

dimensions of the machine ca. 8815 x 4185 x 2963 mm

Additional information

Hjdox Uzn Eopfx Adash

CNC Precision Surface and Profile Grinding Machine

Technical Specifications:

Grinding length 2000 mm

Grinding width 850 mm

Travel, transverse 750 mm

Distance from table to spindle center 900 mm (or 800 mm with intermediate plate)

Magnetic plate size 2000 x 700 mm

Table load without magnet 3500 kg

Table speed 60 m/min.

Spindle drive 26 kW

Grinding wheel dimensions 500 x 150 x 203.2 mm

Grinding wheel peripheral speed 35 m/s

Equipment:

3-axis contouring control Siemens 840 D

Grinding programs:

Full-cut grinding

Face grinding

Plunge grinding

Path grinding X/Y-axis and Y-Z-axis

Profile grinding

Automatic program sequence with roughing, finishing, fine finishing

and spark-out grinding.

Multiple plunge grinding for economical production

Surface grinding with continuous, continuously programmable cross feed

Grinding wheel calibration

Plunge/step grinding

Face grinding

Dressing in the grinding cycle with lift-off amount

Fully automatic compensation of dressing amounts

Tool management

AC servo drives with ball screw and absolute measuring system in the X, Y, and Z axes

Preloaded precision roller guides in the X, Y, and Z axes with linear guides

Portable electronic handwheel

Automatic belt filter system

Coolant heating

Electro-permanent magnetic chuck

Fully enclosed

Direct measuring system in the vertical axis

Temperature-controlled machine bed for consistent accuracy

Linear motor in the X-axis, table speed max. 60 m/min.

Swiveling control panel

Continuous speed control of the grinding spindle

Electrical linear measuring device for cross-travel adjustment with

zero point setting in any position, resolution 0.001 mm

Electro-mechanical locking via position control of the headstock

in the cross direction for profile and plunge grinding

Mechanical extraction of coolant mist

TAG table dresser

Pre-profiling dresser VPG 190

Diamond grinding wheel, 190 mm diameter

Software program for pre-profiling dresser VPG

Rough profiling (roughing)

CNC table profile dresser TAD 190

Profile depth max. 45 mm

Contour accuracy +/- 0.0025 mm

Swivel angle +/- 65 degrees

Max. dressing speed 210 mm/min.

Diamond wheel for table dressing machine TAD 190

Regrinding package for diamond wheel

Intermediate plate for raising the magnet

WinWop profiling software

Import of CAD profile data

SP 60 JOB Listing expansion package

Additional holes for the magnet clamping plate to facilitate

removal of workpieces using compressed air

Ghost shift circuit for shutting down the machine after the end of the program

Listing

Wasbek

Wasbek

18,194 km

Press Brake - AHK M 1230 NC

KnuthAHK M 1230 NC

Call

Condition: new, The AHK M 1230 NC is a highly efficient press brake from KNUTH, designed specifically for sheet metal processing within the press brakes category. This machine offers a modern, cost-effective NC alternative to traditional CNC press brakes, making it ideal for operators accustomed to manual programming. Featuring a high-precision, stress-relieved steel frame and hydraulic cylinders, the AHK M 1230 NC excels in handling complex bending sequences effortlessly. Enhanced safety features, including light curtains and a CE-compliant design, ensure operator protection while maintaining productivity. The NC control system, complete with a user-friendly touchscreen, allows for easy input of bending sequences, accommodating up to 500 programmable data sets. You can confidently handle a variety of materials and shapes thanks to Promecam tool mounts and an adjustable back gauge with motorized X and R axes. With features designed for ease of use and reliability, now is the perfect time to request a quote for the AHK M 1230 NC press brake, ensuring your workshop benefits from superior capabilities in sheet metal processing.

Hsdpfx Asqc S Najdajh

Listing

Rottweil

Rottweil

18,683 km

FLAT GRINDING MACHINE

Geibel & HotzFS 60

Call

Condition: excellent (used), Year of construction: 2000, functionality: fully functional, grinding length: 700 mm, grinding width: 450 mm, NEW ARRIVAL

1 used hydraulic surface grinding machine GEIBEL & HOTZ FS 6040

The grinding area of the G & H FS 6040 is 600 x 450 mm - Year of manufacture: 2000 - Machine with automatic program sequence - roughing - finishing - spark-out - return to starting position.

The machine is equipped with 2-axis digital readout, stainless steel coolant system, various flanges, fine pole pitch magnetic chuck, wheel dresser.

Compatible flanges for Jung HF/JF 520.

Machine includes operating manual and electrical schematic - fully function tested.

Very lightly used machine from prototype/testing department (original paint).

Pricing: ex stock, unpacked, uninsured, domestic sales plus VAT.

Delivery time: immediately - subject to prior sale.

Hjdpfx Aevz A Dcodaoh

Payment: as customary in the trade - before collection - immediate upon receipt of invoice.

Best regards,

Induba GmbH

Mathias Becker

Listing

Silvi

Silvi

18,432 km

Automatic Tube Bending Machine

B.L.M.B/90/M

Condition: used, Automatic Tube Bending Machine

Hodpfxjx Swbis Adaeh

Brand: B.L.M.

Model: B/90/M

Description:

Automatic tube bending machine designed for industrial applications, equipped with automatic programming for producing multiple bends in sequence. The machine allows adjustment of the reference distance, ensuring high precision and repeatability in the bending process.

For all technical details, please refer to the technical data sheets available in the photos.

Listing

Wald

Wald

18,661 km

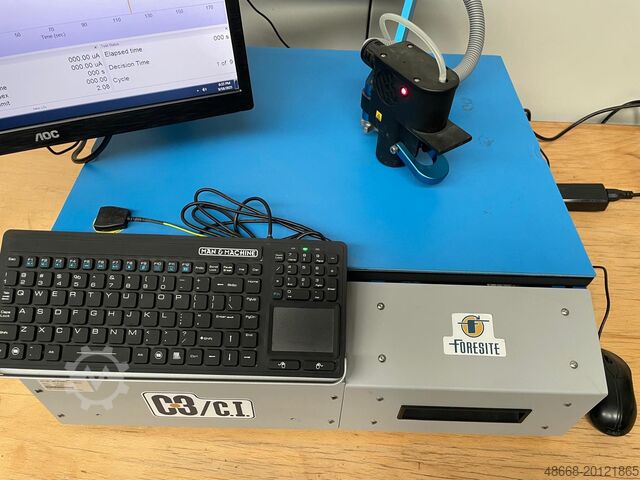

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

Hedpoxhcklofx Adaoh

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Germany

Germany

18,384 km

Multi-Spindle Drilling Machine

HüttenhölscherDrilling rig

Call

Condition: ready for operation (used), Year of construction: 2010, This Hüttenhölscher Drilling rig was manufactured in 2010. It features a PC-controlled function sequence under Windows 7, TwinCAT, and a used drilling system with a 6-station loading gantry. The rig includes a 2-axis gantry robot, Y/Z axes with servo motors, and a travel distance of Y-axis 8500 mm, Z-axis 1500 mm. It also has a suction crossbeam with a four-circuit vacuum supply. Contact us for more information about this machine.

Application Types

Hodpfx Aex Tkauedaeh

Boring & Drilling (Wood)

Listing

Bruckmühl

Bruckmühl

18,479 km

Minikran

BG LiftM400

Call

Condition: used, functionality: fully functional, Year of construction: 2025, load capacity: 4,000 kg, operating hours: 44 h, empty load weight: 4,300 kg, fuel type: diesel, drive type: Diesel, arm reach: 17,000 mm, Mini crane

Technical condition: New

Automatic speed increase, 3-phase 5.5kW - 400V - 50Hz electric motor with inverter and phase sequence detection

Hydraulic jib with two extensions and a working range of 195°

Hjdpfxsya Rkro Adash

Hydraulic winch below the telescopic boom

Lifting capacity 1,000 kg

Rope length 58 m

Rope guide rollers

Sheaves for fly jib

Sheave at the tip of the main boom

Four-position adjustable boom head at the tip of the telescopic boom

Support pads with holder on crane 400x400x50 mm

1 pair non-marking rubber tracks

LED light on main boom and jib

BG-Connect2.0 – for 1 year

Listing

Waiblingen

Waiblingen

18,599 km

Band saw

BERG+SCHMIDGBS 218 Eco AutoCut

Call

Condition: new, Year of construction: 2024, cutting range round steel at 45°: 108 mm, cutting range round steel at 90°: 108 mm, cutting height (max.): 150 mm, BERG+SCHMID GBS 218 Eco AutoCut double mitre bandsaw Speed: 25-80 m/min

- Mitre left 60°

- For cutting steel, stainless steel and aluminum profiles

- Quick-clamping vice with quick-clamping device a.

- Built-in blade tension control b.

- Saw blade guide made of carbide c.

- Electric automatic cooling system

- Machine base (supplied disassembled)

The AutoCut system consists of:

- Hydraulic cylinder, feed control, spring assembly,

limit switch and enables three work sequences:

Hodpfst I R Edsx Adaoh

1. automatic lowering of the saw frame via

hydraulic cylinder with infinitely adjustable

feed control valve and limit switch at the end of the cut

2. high-speed lowering of the saw frame from the

rest position up to the workpiece, then switching

to normal saw feed

3. manual operation - hydraulic cylinder works

as a brake cylinder

Saw blade dimensions: 2455x27x0.9mm

Further accessories such as saw bands, roller conveyors, measuring stops, minimum quantity lubrication etc. available on request!

Delivery time: ex stock Waiblingen Beinstein

Listing

Warstein

Warstein

18,471 km

Vertical machining center

StarragCWK 400D

Call

Condition: good (used), Year of construction: 2005, operating hours: 32,099 h, functionality: fully functional, travel distance X-axis: 625 mm, travel distance Y-axis: 650 mm, travel distance Z-axis: 650 mm, controller manufacturer: Siemens, controller model: Sinumerik 840D, total length: 5,800 mm, total width: 4,800 mm, table width: 400 mm, table length: 500 mm, overall weight: 12,800 kg, spindle speed (max.): 10,000 rpm, operating hours of spindle: 3,648 h, coolant supply: 50 bar, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, For sale is a 4-axis horizontal machining center from the manufacturer Starrag.

The machine is used, has been regularly maintained, and is in fully functional condition.

Machine Details

- Manufacturer: Starrag

- Model: CWK 400D

- Year of manufacture: 2005

- Operating hours: 32,099

- Control: Siemens Sinumerik 840D

- Machine weight: 12,800 kg

- Footprint (LxW): 5.8 x 4.8 m

Technical Data

Travel paths:

- X = 625 mm

- Y = 650 mm

- Z = 650 mm

- B axis: 360° (0.001° increments) / 100 rpm

- Spindle speed: 50 – 10,000 rpm (stepless)

- Motor power: 24 kW / 37 kW

- Torque: 250 Nm / 350 Nm

Hodpfx Aex Ib T Isdaeh

Table & Pallets

- 2 pallets, each 500 x 400 mm

- T-slots to DIN 55201

- Load capacity: 400 kg

- Pallet changer included (changeover time 8 s / 5 s)

Tool Data

- Interface: DIN 69893-HSK-A63

- Chain magazine with 60 tool positions

- Tool diameter: 80 mm (up to 160 mm with adjacent pockets free)

- Max. tool length: 350 mm

- Max. tool weight: 10 kg

- Total tool weight: 200 kg

Equipment & Extras

- Coolant system (emulsion, internal & external supply, approx. 1100 L)

- Knoll coolant unit with fleece filter (30, 40, 50 bar)

- Measuring probe: Renishaw

- Tool breakage monitoring in magazine

- Chip conveyor

- Flood wash, paper band filter, cleaning gun at setup station

- Fully enclosed working area to UVV safety standards

- Pallet sequence mode

- Network connectivity, Ethernet interface

- Technical documentation & layout plan included

Maintenance

- Carried out regularly

- Machine is fully functional

All details have been prepared to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

Listing

Warstein

Warstein

18,471 km

Vertical machining center

DMG MoriDMC 60H hi-dyn

Call

Condition: good (used), Year of construction: 2000, operating hours: 48,804 h, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 560 mm, controller manufacturer: Siemens, controller model: Sinumerik 840D, total length: 7,000 mm, total width: 5,000 mm, table width: 400 mm, table length: 500 mm, spindle speed (max.): 8,000 rpm, operating hours of spindle: 23,574 h, coolant supply: 50 bar, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, Very well-maintained 4-axis machining center from precision manufacturing. The machine has been serviced regularly, is immediately ready for operation, and comes with a pallet changer and extensive accessories. Ideally suited for tool and mold making or series production.

Technical Specifications

-Travel distances: X 600 mm / Y 560 mm / Z 560 mm

-B-axis: 360° x 0.001° (60 rpm)

-Spindle speed: 0 – 8000 rpm (stepless)

-Control: Siemens Sinumerik 840D

-Table size: 6 pallets, each 500 x 400 mm

-Table load: 350 kg

-Working feed: 1 – 60,000 mm/min

-Rapid traverse: 60 m/min

Tool & Magazine

-Tool holder: DIN 69871-SK40

-Chain magazine with 90 positions

-Max. tool diameter: 80 mm

-Max. tool length: 350 mm

-Max. tool weight: 10 kg

-Max. total magazine weight: 450 kg

-Tool change time: 5 sec

-Pallet change time: 6 sec

Machine Requirements & Dimensions

-Motor power: 13 kW / 20 kW

-Torque: 124 / 191 Nm

-Total power requirement: 20 kW

-Machine weight: approx. 16,000 kg

-Required floor space (LxW): 7 x 5 m

Equipment & Accessories

-Coolant system approx. 1100 L (internal & external)

-Knoll cooling unit with drum filter (30/40/50 bar via M-command)

-Chip conveyor

-Tool measurement: Renishaw probe

-Tool breakage detection in the machining area

-Pallet storage (4 positions)

-Pallet sequence operation

-Enclosed work area in accordance with UVV

-Network capability

-Technical documentation & installation layout available

Components Renewed

-Hydraulic system motor & pump replaced

-Some hydraulic and pneumatic hoses replaced

-Control cabinet LT module exchanged

-Drum of Knoll system replaced

Operating Hours / Run Times

- Power-on hours approx. 48,804 h (counter runs when the machine is switched on, including during setup, maintenance, or idle times)

- Spindle run time total 23,574 h

Special Features

- Machine live, immediately ready for use

- Inspection possible any time by appointment

- No dealer sale – machine comes directly from production

- Technically inspected, no known defects

Hedpfox Icyvex Adaeh

- Assistance with disassembly, loading, and transport possible (for an additional charge)

All information has been provided to the best of our knowledge and belief. Subject to alterations, errors, and prior sale.

Listing

Łaziska Górne

Łaziska Górne

17,918 km

Guillotine

ESPECNTA 16A/3150

Call

Condition: reconditioned (used), functionality: fully functional, cutting length (max.): 3,150 mm, ESPE HYDRAULIC guillotine shears model CNTA 16A/3150 FOR cutting sheet metal

Output parameters of the machine:

- maximum cutting length - 3150mm,

- maximum thickness of cut sheet metal - 16mm,

- table width - 160mm,

- cutting angle - 0.5 - 2.5 degrees hydraulically adjustable,

- working height of the table - 850mm,

- beam drive and sheet metal pressure - hydraulic,

- adjustable gap - electric drive,

- adjustable depth (width) of cut - depending on the set angle,

- main drive 30kW,

- auxiliary drives 2.5kW,

- adjustable numerically controlled bumper - AC servonap,

- friendly and simple CNC numerical control

Hsdpfx Adouq Eh Soajh

- weight about 16500kg,

CNC control:

Control built on the basis of industrial automation components (from Delta Electronics) equipped with a touch-screen operator panel for setting work parameters:

- setting the thickness of the material (automatic slot adjustment)

- setting the knife working depth (cutting width - reducing time when cutting narrow details)

- setting the position of the cut material bumper

- setting the working angle of the knife

- possibility to program a sequence of cuts up to 50 operations for one sheet (automatic change of depth setting, bumper setting, sheet thickness, knife angle setting, cutting width) after each cut. This makes it possible to cut the entire sheet in a preset sequence, without the need to constantly rearrange the sheets.

Listing

Altenstadt

Altenstadt

18,587 km

Bridge saw

Bombieri&VenturiFSBV 500 MG

Call

Condition: used, Year of construction: 2001, functionality: fully functional, travel distance X-axis: 3,150 mm, travel distance Y-axis: 3,600 mm, travel distance Z-axis: 150 mm, table width: 1,800 mm, table length: 3,200 mm, Bridge saw with tilting table

Sawing up to 15 cm height possible with automatic lowering and manual mode

Automatic cutting sequence with shut-off

German-language display operation and fault analysis

Manual rotary table with digital angle display

Tilting table with plug-in forks

Mechanical tilting of the saw head possible

500 mm saw blade diameter

Hodpjxiw Twofx Adaeh

Auction

Auction ended

Бургас

Бургас

17,348 km

Industrial robot

ABBIRB 7600 - 340

Condition: refurbished (used), Year of construction: 2013, functionality: fully functional, machine/vehicle number: 7600-101325, load capacity: 340 kg, arm reach: 2,800 mm, pivoting range: 360 °, warranty duration: 4 months, Equipment: documentation/manual, Robot with a 4-month warranty

General overhaul included:

- Cleaning: Thorough cleaning of the robot panel and surface.

- Oil change: Changing the oils for all six axes.

- Battery replacement: All internal batteries were replaced with new batteries.

- Mechanical maintenance: Gears and counterweight were inspected and serviced after repeatability and weight tests.

- Electronic maintenance: Drivers, electronic boards, teach pendant, and PC components were serviced.

- Polishing and repainting: The robot was polished and repainted in the original color or a custom color upon request.

TECHNICAL DETAILS

Reach: 2800 x 3171 mm

Payload: 340 kg

Control: IRC5

Axis 1 – Rotation motion: +180° to -180°

Axis 2 – Arm motion: +85° to -60°

Axis 3 – Arm motion: +60° to -180°

Axis 4 – Wrist motion: +300° to -300°

Axis 5 – Bend motion: +100° to -100°

Axis 6 – Turn motion: ±360° (standard), max. ±67 revolutions

Dynamics (max. rotation speed per axis)

Axis 1: 75°/s

Axis 2: 60°/s

Axis 3: 60°/s

Axis 4: 100°/s

Hsdpex Syivefx Adaoh

Axis 5: 100°/s

Axis 6: 160° °/s

Position and Path Precision

Position Accuracy (AP): 0.18 mm

Repeatability (RP): 0.27 mm

Stabilization Time (Pst at ±0.4 mm): 0.18 s

Path Accuracy (AT): 2.05 mm

Path Repeatability (RT): 0.23 mm

FEATURES

- 6-axis industrial robot with a high payload class

- Large swivel range on axis 6 with up to 67 revolutions

- Precise path guidance with repeatability of less than 0.3 mm

- High speed of the wrist axes for fast movements

- Perfectly suited for heavy-duty handling and precise motion sequences

Listing

Lemgo-Lieme

Lemgo-Lieme

18,406 km

Truck mounted crane

VOLVOFH 500 6x2 Container-Pritsche/FASSI 545RA.2.28

Call

Condition: new, power: 375 kW (509.86 HP), fuel type: diesel, overall weight: 26,000 kg, axle configuration: 3 axles, color: white, gearing type: automatic, loading space length: 6,500 mm, loading space width: 2,480 mm, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), navigation system, parking heater, soot filter, Internal reference number for customer inquiries: 3-382

----Vehicle with day registration on PAVIC

VOLVO FH 500 LL 6x2 CONTAINER FLATBED WITH FASSI 545RA.2.28 XE-DYNAMIC LOADER CRANE

Loader crane:

* FASSI F545RA.2.28 xe-dynamic

At 20.8 m, this crane can still lift 1,650 kg (optionally extendable with 2 manual extensions up to 24.9 m and 700 kg)

* Infinite slewing range

* Double linkage system with PROLINK (overextendable articulating arm up to 15 degrees)

* FASSI stability control

* Radio remote control with linear levers and load range display

* XF-System (Extra Fast)

* XP-System (Extra Power)

* FL-System (Full Lift)

* Outriggers controllable via remote control

* LED work lights

* Preparation for winch (winch of model Fassi V30 can be retrofitted at any time)

* Many more features

Vehicle description:

* Volvo FH 500 — latest model

* Low-profile container flatbed body

* 2 pairs of extendable container locks (up to 3 m) for handling 20-foot containers

* 4 warning boards with lighting, extendable up to 3 m

* Flatbed dimensions: 6,500 mm x 2,480 mm

* Side walls + tailboard 600 mm high

* Front wall 1,900 mm high

* Lashing rings at approx. 250 mm intervals

* Forklift collison protection

* Globetrotter safety cab, FH

* Diesel engine, 13 liters, 510 HP / 375 kW, 2,550 Nm

* Emissions in accordance with Euro 6E, with SCR, particulate filter and exhaust gas recirculation

* I-Shift, automated 12-speed gearbox

* I-Shift drive modes: Standard, Performance, and Economy

* Volvo Engine Brake (VEB+)

* Wheelbase: 5,600 mm

* Drive: 6x2

* Differential lock

* Air suspension front/rear

* Front axle tires: 385/55R22.5, Drive axle tires: 315/70R22.5, Tag axle tires: 385/55R22.5

Hsdpexnn Rdefx Adajh

* Rockinger 400 G 150 trailer coupling

* LED main headlights

* Rain sensor (sensor-controlled wipers)

* LED daytime running lights, “V-light” design

* LED tail lights, brake lights with emergency brake flashing sequence

* Stationary air conditioning

* Auxiliary heater

* Comfort driver’s seat, air-suspended, heated, seatbelt integrated

* Leather steering wheel

* Media/infotainment package with navigation

* Refrigerator with 33 L freezer compartment under bunk

* Roof hatch, electrically operated, tinted glass

* Close-range camera on passenger side for blind spot monitoring

* Adaptive cruise control (ACC) with collision warning and emergency braking

* Lane departure warning system

* Much more.

Financing / hire purchase, as well as leasing / partial amortization leasing is available through our leasing partner.

For further questions, our sales team will be happy to assist you.

This is a non-binding offer. Subject to prior sale, errors and changes.

Listing

Wasbek

Wasbek

18,194 km

Press Brake - AHK V 30175 CNC - Delem DA58 2D TX

KnuthAHK V 30175 CNC - Delem DA58 2D TX

Call

Condition: as good as new (ex-display), The AHK V 30175 CNC - Delem DA58 2D TX is a state-of-the-art press brake in the Press Brakes category, designed to meet the highest standards in modern manufacturing. KNUTH's AHK V CNC series excels in delivering superior quality, precision, and reliability, incorporating advanced design technology and robust construction. This machine boasts a steel frame that enhances rigidity and accuracy, precision-engineered components, and a spacious work area for complex bending sequences. The DELEM graphical touchscreen provides efficient CNC programming tools for seamless control over the bending process. Features like motorized lower crowning and a safety-focused design ensure optimal performance when working with thicker sheet metals. Additionally, the press brake includes robust hydraulic systems and premium components, promising long-lasting reliability. As you consider your options in Press Brakes, you'll find that the AHK V 30175 excels, making it an ideal choice for any shop focusing on sheet metal processing. Request a quote today to learn more about this adaptable and powerful machine tool.

Hodpfx Adov Rbxdsash

Trust Seal

Dealers certified through Machineseeker

Listing

Wasbek

Wasbek

18,194 km

Press Brake - AHK M 1230 NC incl. AKAS – LC II M

KnuthAHK M 1230 NC mit AKAS – LC II M

Call

Condition: as good as new (ex-display), The AHK M 1230 NC incl. AKAS – LC II M is a highly efficient press brake designed for sheet metal processing, offering a modern and cost-effective NC solution for bending tasks. This robust machine combines advanced technology with safety features, allowing for user-friendly operation without the need for CNC programming. Built from stress-relieved welded steel, the AHK M series provides a rigid frame and hydraulic system, which ensures precise upper beam positioning through a torsion shaft connected to the depth stops. Operators can easily manipulate the back gauge in the X- and R-axes via a touchscreen or access stored bending sequences for automatic operations. This model is ideal for producing workpieces with consistent materials and shapes, while its manual quick-action clamping system significantly reduces tool change times. Complimented by features such as an emergency stop switch and a reliable optical safety system, the AHK M 1230 NC press brake is engineered for high productivity and safety. For those looking for a superior press brake, request a quote today and enhance your sheet metal processing capabilities.

Hedpfov Rbv Ajx Adajh

Listing

Naprawa

Naprawa

17,865 km

Four Side Planer

A.CostaEURO 23B

Call

Condition: used, Technical specifications:

Max. planing width: 240 mm

Spindle diameter: 40 mm

Number of spindles: 5

Spindle sequence:

bottom

right

left

top

bottom

Each spindle driven by a separate motor

Number of upper steel feed rollers: 4

Number of upper rubber feed rollers: 2

Extraction port diameter: 150 mm

Infinitely variable feed speed control

Feed through cardan shafts

Lubrication pump for the work table

Pressure: 6 atm

Electric lifting of machine body

Hsdpfxev Hzh Dj Adash

Power supply: 380 V

Total power: 31 kW

Overall dimensions:

Length: 4000 mm

Width: 1740 mm

Height: 1730 mm

Listing

Heiligenhaus

Heiligenhaus

18,553 km

Industrial robot

KUKA PalettierroboterKR210 KR240 KR360

Call

Condition: new, Year of construction: 2024, The fully automatic robotic palletizing system is developed and manufactured by our company. Robotic palletizing systems are able to meet the needs of a very diverse range of sectors.

* Flour factories,

* feed factories,

* fertilizer factories,

* cement factories,

* construction chemicals factories,

* legume factories,

* Packaged products,

* Bagged products,

* Transportable products,

Features and benefits :

- Faster palletizing,

- Standard number of pallets,

- Saves work, energy and time,

- Correct placement thanks to automatic tolls,

Hodpfxouua Hqs Adash

- High robustness on the pallet with appropriate loading sequence,

- Can be arranged in various configurations; rows of pallets with free programming,

- 400-5000 packages/hour performance,

- From 5 to 50kg standard packages,

- Space requirement for installation is small and flexible,

- User friendly - low maintenance,

Basic elements high palletizer :

* Gripper for Robot,

* Conveyor belt,

* roller conveyor,

* Bag smoother,

* Rotation unit,

* loading platform,

* stretch wrapper,

* pallet feed unit,

* Empty pallet unit,

* Electrical & Automation & PLC,

* Fence and operator protection equipment,

Listing

Küssaberg

Küssaberg

18,737 km

Sheet metal deburring machine

Timesavers22-Serie-1100-WBB

Call

Condition: excellent (used), functionality: fully functional, Timesavers 22 Series 1100-WBB

1st Station: Abrasive belt for pre-grinding, ideal for removing burrs, laser scale, etc. Optionally, the abrasive belt can be switched to a Scotch-Brite/non-woven belt to achieve a surface finish on the parts. Easy belt change in under a minute thanks to quick-change system. The belt speed is continuously adjustable.

2nd & 3rd Station: Disc brushes for edge rounding, two stations in sequence with both left and right rotation for optimal results. Eccentric mechanism enables lateral oscillation of the disc brush stations (can be switched on or off). Easy brush change using the quick-change system. Disc brush speed is continuously adjustable.

Conveyor belt speed is steplessly adjustable.

Working width: 1100 mm

Maximum part thickness: 100 mm

The machine is fully operational and can be inspected and tested under power on site.

Hjdpjx Uwlaefx Adajh

We make it easier for you to find: "dna sequencer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Dna Sequencer (467)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you