Used Band Dryer for sale (6,080)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor with air dryer

CORMAKLUFT 1500 COMPACT

Call

Condition: new, Year of construction: 2025, LUFT 1500 COMPACT Screw Compressor with Refrigerated Air Dryer

The LUFT series screw compressor by the Polish brand Cormak represents the latest innovations in pneumatics, combined with the use of high-quality materials and components. Low operating costs, ease of use, ergonomic and robust design, and high performance guarantee efficient and trouble-free operation.

Key Features of the Screw Modules in CORMAK Compressors:

Modern Technology and Efficiency

The screw modules ensure excellent performance and outstanding energy efficiency. Their design focuses on maximizing output while minimizing energy consumption.

Precision and Control

Thanks to advanced engineering solutions, the screw modules allow for precise control of the compressed air generation process. This translates into stable pressure and optimal operation of the entire pneumatic system.

Durability and Reliability

The screw modules used in CORMAK compressors are built for longevity. Their sturdy construction and use of high-grade materials ensure reliability even under harsh industrial conditions, minimizing downtime and the need for frequent repairs.

Integrated Refrigerated Air Dryer – Top-Level Air Quality

Two-Stage Drying System

Effectively removes moisture and protects the pneumatic system.

Variable-Speed Fan

Automatically adjusts cooling capacity according to operating conditions, resulting in energy savings.

Dual Filtration System

A pre-filter with 3.0 µm accuracy removes larger solid contaminants.

A precision filter with 0.1 µm accuracy captures fine oil particles (aerosols) and other impurities, ensuring ultra-clean air.

Technical Specifications:

Parameter Value

Motor Power 11 kW

Voltage 400V / 50Hz

Gisdpfx Aoxnk Acogbol

Output (0–6 bar) 1620 L/min

Output at 6 bar 1580 L/min

Output at 8 bar 1350 L/min

Output at 10 bar 1230 L/min

Outlet Connection Diameter (G) 1"

Dimensions 1550 x 740 x 1150 mm

Weight 500 kg

Manufacturer: CORMAK

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor LUFT + air dryer + tank

CORMAKLUFT 1500 INVERTER + N20S + BUTLA 500L

Call

Condition: new, Year of construction: 2025, Set including LUFT 1500 Inverter Screw Compressor, 500L Vertical Air Receiver with Accessories, and IZBERG N20S Dryer

The LUFT 1500 screw compressor with inverter, combined with a 500-liter vertical compressed air tank equipped with fittings and the IZBERG N20S dryer, represents a comprehensive, high-performance pneumatic solution.

The LUFT series screw compressor by the Polish brand Cormak features state-of-the-art technology, top-quality materials, and reliable components. Its low operating costs, easy maintenance, ergonomic and robust construction, and high efficiency ensure dependable, trouble-free operation in demanding environments.

Technical Specifications – LUFT 1500 with Inverter

Motor Power: 11 kW

Voltage: 400V / 50Hz

Output at 0–6 bar: 1620 L/min

Output at 6 bar: 1580 L/min

Output at 8 bar: 1350 L/min

Output at 10 bar: 1230 L/min

Outlet Connection (G): 1"

Dimensions: 1170 × 730 × 1020 mm

Weight: 243 kg

Technical Specifications – IZBERG N20S Dryer

Inlet/Outlet Pipe Diameter (BSP): 1"

Maximum Operating Pressure: 10 bar

Maximum Inlet Air Temperature: ≤ 38°C

Dew Point Temperature: 3°C

Capacity: 2800 L/min

Power Consumption: 0.58 kW

Power Supply: 230V

Dimensions (L × W × H): 420 × 700 × 690 mm

Weight: 37 kg

Refrigerant Type and Quantity: R134a, 550 g

Technical Specifications – 500L Vertical Air Receiver

Tank Capacity: 500 liters

Working Pressure: 11 bar

Wall Thickness: 4 mm

Diameter: Ø 600 mm

Height: 2098 mm

Weight: 145 kg

Gedpjxnyfmefx Agboil

Connections: 6

Connection Sizes: 1 1/4", 2", 1/2"

Listing

Siedlce

Siedlce

17,614 km

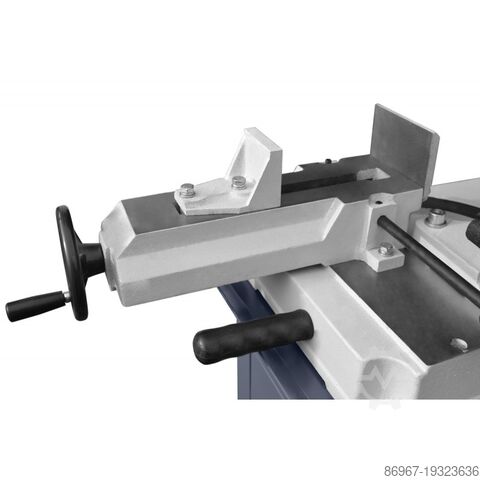

Automatic band saw 350mm

CORMAKHR350SA przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, The CORMAK H-350SA column band saw is a high-performance machine

for cutting solid workpieces and profiles in an automatic cycle. Robust

body and sturdy saw frame in combination with the column structure ensure

excellent rigidity and exceptional stability during

cutting even the most difficult-to-cut metals. The cutting-off machine is equipped with

PLC control and an easy-to-use touch screen. The undoubted advantage of

The unquestionable advantage of this model is its swivel head which allows cutting in the following ranges

0°- 60° - in automatic cycle as well as semi-automatic - infinitely adjustable angle.

angle adjustment.

Manual and Automatic mode: The cutting-off machine allows both manual operations from the machine control panel in manual mode and an automatic cutting cycle in automatic mode, eliminating the need for constant operator assistance.

Vise top pressure: The cutting machine is adapted to package cutting

Automatic Cutting Cycle: In automatic mode, the entire cutting process, including clamping the workpiece, moving it to the specified dimension, lowering the cutting arm and raising it after the cut is completed, is carried out without operator intervention.

Panel Controlled Parameters: Cutting parameters such as number of pieces, workpiece dimensions, belt speed, and more, are set and controlled via a control panel with an easy-to-use touchscreen.

Robust Construction: The machine body is made of cast iron set on a rigid, space-age slab chassis structure for exceptional rigidity and stability.

Cutting belt drive: A powerful three-speed motor, hydraulic belt tension and cooling system and cleaning brush contribute to precise and efficient cutting.

Safety System: If the cutting belt breaks, the machine stops automatically, increasing operator safety.

Hydraulic Material Feeding System: This system allows the machine to cycle fully automatically, with precise setting of the material feed length.

Innovation and ISO Standards: Cormak provides innovative solutions and production in accordance with ISO:90001 and ISO:140001, which demonstrates the high quality, safety and reliability of the product.

Technical data:

Cutting range Ø350 or 350 x 350

Belt 4515 x 34 x 1.1 mm

Cutting speeds 27/45/69 m/min.

Total power 4.8kW

Hydraulic power pack 0.75kW

Coolant pump 0,04kW

Belt tensioning hydraulic

Feeder stroke 500 mm

Load capacity 1500 kg

Table height 700 mm

Dimensions 2800 x 2200 x 1700 mm

Godpfswdunwex Agbsil

Weight 1500kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Siedlce

Siedlce

17,614 km

Automatic column band saw 280mm

CORMAKH-300SA przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, The CORMAK H - 280 SA column band saw is a highly efficient machine for cutting bars, pipes and profiles made of steel, cast iron and non-ferrous metals in an automatic cycle. The solid body and strong frame of the saw, combined with the column construction, provide excellent rigidity and an exceptional level of stability during the cutting process of even the most difficult metals to machine. The cutter is equipped with a PLC controller and an easy-to-use touch screen.

Automatic band saw work on manual and automatic modes.

Manual mode allows you to perform all activities manually from the machine's desktop.

Gsdpfjiz S Nyox Agbeil

Automatic mode - after switching on the machine, the entire cutting cycle, i.e. fixing the cut detail in the vice, its shift to a specific dimension to the cutting tape, leaving the arm to cut and its raising to the desired height after finished cutting takes place without the operator's operation.

Cutting parameters, such as the number of pieces of cut details, their dimensions, the speed of the cutting band, the speed of the arm's descent, are set on the control panel. The device automatically stops when the series is cut, the cutting band breaks or another failure identified by the cutter's control system is detected.

The body of the machine is a cast iron set on a rigid, spatial plate structure of the casing. Inside the housing there are: a hydraulic unit, a coolant tank with a pump and a chip feeder.

The drive of the cutting band based on an inverter-controlled motor ensures smooth regulation in a large range of speeds.

The hydraulically forced lowering of the arm is regulated in a wide range by a precise throttle valve. The fast feed system allows you to shorten the time of cutting individual elements.

Hydraulic material feeding system ensures a fully automatic working cycle of the machine. The controller equipped with an LCD display allows you to program the operation of the saw, signals the end of the material, communicates errors and informs about the number of cut sections after the programmed time. The maximum material feed length in one stroke is 500 mm with an accuracy of +/- 0.2 mm per stroke.

Innovativeness and production of CORMAK semi-automatic and automatic series cutters according to norms and standards compliant with ISO:90001 and ISO:140001 certificates, guarantee safety, quality and product reliability. The use of motors licensed by a well-known and respected manufacturer on the global market, one of the world's leaders, ABB, guarantees long and trouble-free operation.

Technical data

Cut range Ø280 or 280 x 280

Band saw blade

3505 x 27 x 0.9mm

Cut speeds 40/60/80 m/min.

Engine 3kW

Hydraulic power pack 0.75kW

Coolant pump 0.09kW

Feeder pitch 500mm

Load capacity 1500 kg

Dimensions 1750x1900x1550mm

Weight 1100 kg

Max. cutting range

angle

0º ø280 280 × 280

Standard equipment

work in automatic cycle

arm position memory function

built-in hydraulic unit

vise position memory function

change cutting speed

motorized belt cleaning brush

cooling system

bi-metal band saw

CE Declaration of Conformity

Manual in Polish and English

For more information visit our web page

Listing

Siedlce

Siedlce

17,614 km

Compressed Air-Dryer 3800l/m

CORMAKIzberg N30S

Call

Year of construction: 2025, condition: new, functionality: fully functional, The purpose of a compressed air refrigerant dryer is to lower the temperature of the compressed air and remove water and oil particles contained in the air flow. Refrigerant dryers are important in applications where moist air could cause corrosion, contamination or damage to tools, machinery or products. By removing moisture, the dryer increases the reliability and durability of compressed air systems.

The refrigerant dryer is designed for maximum efficiency and durability. The main design elements include:

1. Air-to-air heat exchanger

In the first stage of the process, the inlet air passes through a heat exchanger, where it is pre-cooled by the cooler air leaving the evaporator. By using countercurrent flow, heat recovery increases the energy efficiency of the entire system.

2. Refrigeration system evaporator

In the second stage, the compressed air is fed to the evaporator, where it is cooled to a dew point temperature of 3°C. This results in the condensation of water vapor and oil particles contained in it. 3. Condensate separator

After cooling, the gas and condensate mixture goes to an efficient separator, where the condensate is separated and automatically drained outside the device.

4. Fan control system

The variable speed fan technology allows intelligent adjustment of the cooling intensity to the actual demand, which reduces energy consumption and increases the service life of the components.

Giedpfx Agemt Dcqobsl

Technical parameters

Inlet/outlet pipe diameter (BSP) 1 1/2"

Maximum operating pressure 10 bar

Maximum inlet air temperature ≤ 38°C

Dew point temperature 3°C

Efficiency 3800 l/min

Power 0.9 kW

Supply voltage 230 V

Dimensions (L x W x H) 850 x 480 x 480 mm

Weight 95 kg

Type and amount of refrigerant R410a, 650 g

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 260mm

CORMAKHBS320

Call

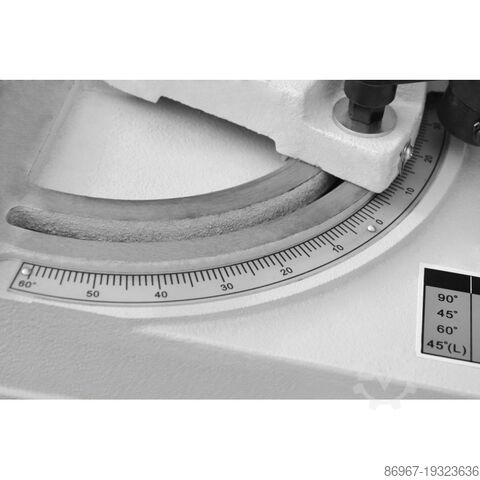

Condition: new, Year of construction: 2025, CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

Machine characteristics

Gedpoi D Dgwsfx Agboil

CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. The band saw arm is made of massive, uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of structural steel, stainless steel and tools. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. It has a huge impact on the band guiding, its durability, accuracy and cutting quality. The carbide guiding drastically reduces the wear of both the machine and the blade.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a double-sided swivel arm and a control panel.

The feed speed is controlled by the control panel. There are 2 cutting band speeds: 44 and 88 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Ø max 260 mm /perpendicular cutting

H×B max 320×160 mm /perpendicular cutting

Power supply - 3–phase, 400V

Total power - 1,5 kW

Arm lowering control - hydraulic cylinder

Band dimensions - 2740×27×0.9 mm

Band speed - 44 / 88 m/min

Vice base height - 920 mm

Dimensions - 1400×880×1550 mm

Weight - 280 kg

Cutting parameters

Angle

0º ---- ø260 320×160 255×255

45º R ø210 210×200 210×210

60º R ø135 135×130 130×130

45º L ø160 220×130 160×160

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Semi-automatic band saw 450mm

CORMAKS-440R przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, Semi-automatic CORMAK S440R band saw. Its arm is made of uniform cast iron and, together with a 34 mm wide cutting band, it enables cutting various profiles and shapes. The band saw uses a vice and a hydraulically raised and lowered arm.

Machine features

Semi-automatic band saws, after being switched, do the whole cutting cycle automatically, i.e. clamp the cut material in the hydraulic vice, switch on the cutting band, lower the cutting arm (adjustable speed), stop the machine after cutting, raise the arm up (adjustable arm height) and switch the hydraulic vice off. Machine's arm is made of uniform cast iron and, together with a 34 mm wide cutting band, it enables cutting various profiles and shapes. The band saw uses a vice and a hydraulically raised and lowered arm.

Technical data

Minimum cutting diameter Ø 5 mm

Gjdpoi Dx R Njfx Agboil

Minimum material length in vice 30 mm

Vice base from ground distance 780 mm

Cutting band dimensions 5200×34×1.1 mm

Total power 4.4 kW

Band speed 20/90 m/min

Dimensions (L×W×H) 2500×1900×1450 mm

Weight 1100 kg

Max. cutting range [mm]

Angle

0º ø450 620×440 610×440 450×450

45º R ø440 500×190 360×440 420×420

45º L ø440 510×180 460×390 390×390

60º R ø330 330×170 170×440 300×300

60º L ø350 350×170 330×310 310×310

Standard equipment

PLC controller

Semi-automatic operating cycle

Control console on a separate component

Control panel with an LCD display

Built-in hydraulic unit

Hydraulic control of arm motion (up – down) with possibility of smooth lowering speed control

Arm position memory function (arm returns to a defined height after cutting)

Hydraulically controlled vice's jaws (long stroke cylinder with position memory)

Cutting at angles of L/R 60o – 45o – 0o – 45o – 60o

Digitally displayed set cutting angle

Smooth band speed adjustability (inverter)

Powered brush for cleaning the band

Cooling system

Bi-metal saw blade

EC Declaration of Conformity

User manual

For more information please visit our web page or contact us.

Listing

Siedlce

Siedlce

17,614 km

Semi-automatic band saw machine 250mm

CORMAKS-200RH przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, Powerful, reliable and modern semi-automatic band saw for metal with automatic arm raising and lowering. The arm is rotational in both ways. The machine is fantastic for ironworking, e.g. cutting tubes and profiles.

Product features

CORMAK S-200RH band saw is by default equipped with automatic arm lowering and raising as well as with a precise arm height regulator. Due to an automatic hydraulic damper, the manual handling of the machine has been simplified to feed and clamping the cut material in a vice. The arm made of uniform iron casting, together with a refined, solid and stable construction, ensure S-200R's exceptional rigidity, resulting in failure-free handling and high cutting precision.

The innovativeness and production of semi-automatic and automatic series "CORMAK-PREMIUM LINE" band saws, compliant with the norms and standards consistent with ISO:910001 and ISO:140001 certificates, warrant safety, quality and reliability of the product. M3V motors from ABB, a renowned worldwide manufacturer, warrant long-term reliability. As an official and the only representative on the Polish market, we assure that the product is original and provide professional, customised warranty and post-warranty services.

Gijdei D D A Sjpfx Agbjl

Technical data

Type - semi-automatic

Arm raising and lowering - hydraulic with smooth arm lowering control

Band speed - 36/70 mm/min

Angled cutting - left to 45°, right to 60°

Vice - hydraulic

Minimum cutting diameter - Ø 5 mm

Minimum material length in vice - 30 mm

Vice base height - 780 mm

Cutting band dimensions - 27×0.9×2910 mm

Total power - 2.1 kW

Dimensions (LxWxH) - 1600×800×1400 mm

Weight - 530 kg

Angle

0º -----ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

Default equipment

Control panel on separate component

Built-in hydraulic unit

Hydraulic control of arm motion (up – down) with possibility of smooth lowering speed control

Arm position memory function (arm returns to a defined height after cutting)

Cutting at angles of L/R 45° - 0° - 45° - 60°

Brush for cleaning band

Cooling system

Bi-metal band saw

EC Declaration of Conformity

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor 15kW COMPACT Inverter

CORMAKTHEOR 20 COMPACT / Air dryer / Inverter

Call

Condition: new, Year of construction: 2025, A set containing THEOR 20 INVERTER screw compressor, N20S refrigeration air dryer. The screw compressor of the Polish brand CORMAK THEOR series is the most modern solutions used in pneumatics in combination with the use of high-quality materials and components. Low operating costs, ease of use, ergonomic and solid construction as well as high efficiency of the device guarantee effective and trouble-free operation.

Additional double filtration on the dehumidifier!

KIT INCLUDES:

THEOR 20 COMPRESSOR with inverter (version equipped with inverter)

REFRIGERATION AIR DRYER N20S

The set does not include a tank!

Possibility to buy additional cylinders

THEOR 20 COMPACT technical parameters

Compressor

Engine power 15kW

Dehumidifier

Giedpfx Agemqlqdebol

Engine power 0.69kW

General parameters

Capacity at 6 bar 1800 lpm

Capacity at 8 bar 1700 l/min

Capacity at 10 bar 1600 l/min

Departure G3/4"

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine

CORMAKHBS260 + 2 piły M42 + 5L Emulgol

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Giodpfoudi Uzsx Agbsl

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

Additionally

2 M42 saw blades

5L Emulsol

ZW580 magnetic chip collector

Listing

Siedlce

Siedlce

17,614 km

Double column band saw H-50/70

CORMAKH-50/70 przemysłowa dwukolumnowa

Call

Condition: new, Year of construction: 2025, CORMAK H-50/70 is a highly efficient column band saw for semi-automatic cutting of steel profiles, cast iron and non-ferrous metals. Its column design ensures rigidity during cutting, and employment of a completely different arm guiding technology than in pivot band saws provides cutting time reduction and accuracy increase.

Machine description

CORMAK H-50/70 is a highly efficient column band saw for semi-automatic cutting of steel profiles, cast iron and non-ferrous metals. Its column design ensures rigidity during cutting, and employment of a completely different arm guiding technology than in pivot band saws provides cutting time reduction and accuracy increase.

CORMAK H-50/70 semi-automatic band saws, after being switched on, do the whole cutting cycle automatically, i.e. clamp the cut material in the hydraulic vice, switch on the cutting band, lower the cutting arm (adjustable speed), stop the machine after cutting, raise the arm up (adjustable arm height) and switch the hydraulic vice off. Manual handling of the machine is simplified to feeding material towards the bumper. Solid uniform cast iron arm along with the refined, stable design ensure that CORMAK H-50/70 is rigid and reliable, providing very precise cutting.

Hydraulic band tension provides optimum cutting. In the case of band breakage the machine stops automatically. Precise guiding of the band is ensured by guides with bearings and cemented carbide inserts.

The innovativeness and production of semi-automatic and automatic series "CORMAK-PREMIUM LINE" band saws, compliant with the norms and standards consistent with ISO:910001 and ISO:140001 certificates, warrant safety, quality and reliability of the product. M3V motors from ABB, a renowned worldwide manufacturer, warrant long-term reliability.

Technical data

Type Semi-automatic

Arm raising and lowering Hydraulic, with stepless lowering adjustment

Band speed 26/41/66 m/min

Vice Hydraulic

Gijdpfxsizi T Ee Agbel

Cutting band dimensions 41×1.3×6430 mm

Total power 8 kW

Dimensions 3200×1100×2100 mm

Weight 2900 kg

Maximum cutting range [mm]

Angle

0º ø500 500×700

Default equipment

Control panel at the front of the machine

Semi-automatic work

Built-in hydraulic unit

Arm position memory function

Brush for cleaning the band

Hydraulic band tension

Semi-automatic work

Hydraulic band tension

Cooling system

Bi-metal cutting band

EC declaration of conformity

User manual

Listing

Siedlce

Siedlce

17,614 km

Automatic column band saw 260mm

CORMAKH-260SA przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, The CORMAK H - 260SA column band saw is a highly efficient machine for cutting bars, pipes and profiles made of steel, cast iron and non-ferrous metals in an automatic cycle. The solid body and strong frame of the saw, combined with the column construction, provide excellent rigidity and an exceptional level of stability during the cutting process of even the most difficult metals to machine. The cutter is equipped with a PLC controller and an easy-to-use touch screen.

Automatic band saw work on manual and automatic modes.

Manual mode allows you to perform all activities manually from the machine's desktop.

Automatic mode - after switching on the machine, the entire cutting cycle, i.e. fixing the cut detail in the vice, its shift to a specific dimension to the cutting tape, leaving the arm to cut and its raising to the desired height after finished cutting takes place without the operator's operation.

Cutting parameters, such as the number of pieces of cut details, their dimensions, the speed of the cutting band, the speed of the arm's descent, are set on the control panel. The device automatically stops when the series is cut, the cutting band breaks or another failure identified by the cutter's control system is detected.

The body of the machine is a cast iron set on a rigid, spatial plate structure of the casing. Inside the housing there are: a hydraulic unit, a coolant tank with a pump and a chip feeder.

The drive of the cutting band based on an inverter-controlled motor ensures smooth regulation in a large range of speeds.

The hydraulically forced lowering of the arm is regulated in a wide range by a precise throttle valve. The fast feed system allows you to shorten the time of cutting individual elements.

Hydraulic material feeding system ensures a fully automatic working cycle of the machine. The controller equipped with an LCD display allows you to program the operation of the saw, signals the end of the material, communicates errors and informs about the number of cut sections after the programmed time. The maximum material feed length in one stroke is 500 mm with an accuracy of +/- 0.2 mm per stroke.

Innovativeness and production of CORMAK semi-automatic and automatic series cutters according to norms and standards compliant with ISO:90001 and ISO:140001 certificates, guarantee safety, quality and product reliability. The use of motors licensed by a well-known and respected manufacturer on the global market, one of the world's leaders, ABB, guarantees long and trouble-free operation.

Technical data

Cut range Ø260 or 260 x 260

Tape 3150 x 27 x 0.9mm

Cut speeds 40/60/80m/min

Engine 2.2kW

Hydraulic power pack 0.75kW

Coolant pump 0.09kW

Feeder stroke 500mm

Load capacity 1500 kg

Gijdpfxsiz S I Ho Agbjl

Dimensions 1600 x 1800 x 1550mm

Weight 1000 kg

Max. cutting range

angle

0º ø260 260 × 260

Standard equipment

work in automatic cycle

arm position memory function

built-in hydraulic unit

vise position memory function

change cutting speed

motorized belt cleaning brush

cooling system

bi-metal band saw

CE Declaration of Conformity

Manual in Polish and English

For more information visit our web page

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor LUFT + air dryer + tank

CORMAKLUFT 1500 INVERTER + N20S + BUTLA 500L

Call

Condition: new, Year of construction: 2025, Set including LUFT 1500 Inverter Screw Compressor, 1000L Vertical Air Receiver with Accessories, and IZBERG N20S Dryer

Giodpoxnyhuefx Agbel

The LUFT 1500 screw compressor with inverter, combined with a 1000-liter vertical compressed air tank equipped with fittings and the IZBERG N20S air dryer, provides a complete, efficient, and modern solution for compressed air systems.

The LUFT series compressor from the Polish brand Cormak represents the latest technology in pneumatics, combining high-quality materials and precision-engineered components. Its low operating costs, ease of maintenance, ergonomic and durable design, and high performance guarantee reliable and efficient operation in industrial applications.

Technical Specifications – LUFT 1500 INVERTER

Motor Power: 11 kW

Voltage: 400V / 50Hz

Output at 0–6 bar: 1620 L/min

Output at 6 bar: 1580 L/min

Output at 8 bar: 1350 L/min

Output at 10 bar: 1230 L/min

Outlet Connection (G): 1"

Dimensions: 1170 × 730 × 1020 mm

Weight: 243 kg

Technical Specifications – IZBERG N20S Dryer

Inlet/Outlet Connection (BSP): 1"

Maximum Operating Pressure: 10 bar

Max. Inlet Air Temperature: ≤ 38°C

Dew Point Temperature: 3°C

Flow Capacity: 2800 L/min

Power Consumption: 0.58 kW

Power Supply: 230V

Dimensions (L × W × H): 420 × 700 × 690 mm

Weight: 37 kg

Refrigerant Type and Quantity: R134a, 550 g

Technical Specifications – 1000L Vertical Air Receiver

Tank Capacity: 1000 liters

Working Pressure: 11 bar

Wall Thickness: 4 mm

Diameter: Ø 808 mm

Height: 2300 mm

Weight: 230 kg

Number of Connections: 6

Connection Sizes: 2", 1/2"

Dimensions: 230 × 80.8 cm

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Godpfewq A Dyjx Agbjil

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Automatic column band saw 280mm

CORMAKC33 przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, functionality: fully functional, CORMAK C33 column band saw is an incredibly efficient machine in automatic cutting of tubes, steel and cast iron profiles as well as non-ferrous metals. Rugged body and strong frame of the saw ensure great rigidity and stability during cutting even the toughest metals.

Technical data

Type automatic column

Arm raising and lowering hydraulic with smooth control

Band speed 20–100 m/min

Steady and feeding vice hydraulic

Minimum cutting diameter Ø 5 mm

Minimum material length in vice 30 mm

Vice base height 780 mm

Cutting band 34×1.1×4115 mm

Main motor power 4.4 kW

Hydraulic unit power 1.5 kW

Coolant fluid pump power 0.75 kW

Dimensions (L×W×H) 2300×1780×1650 mm

Weight 1900 kg

Max. cutting range

Angle round square

0º ø300 300×400

Default equipment

Automatic cycle operation

Touchscreen LCD control panel

Programming numbers and lengths of cut details

Possibility of storing 5 various cutting macros

Electronic display of band speed

Arm position memory function

Built-in hydraulic unit

Vice position storage function

Smooth cutting speed adjustment (motor with an inverter)

Powered brush for cleaning the band

Cooling system

Bi-metal saw blade

EC Declaration of Conformity

User manual

For more information visit our web page

Giedpfx Ajrh Epksgbol

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 230mm

CORMAKHBS260

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Gisdsmrnk Espfx Agbjl

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

*Please note that machine is sold without CEE connector by default, since there are many different types of it. If you would like to receive it with the machine, please write it to the seller before making a purchase/during order proceeding.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Compressed Air-Dryer 1500l/m

CORMAKIzberg N10S

Call

Year of construction: 2025, condition: new, The purpose of a compressed air refrigerant dryer is to lower the temperature of the compressed air and remove water and oil particles contained in the air flow. Refrigerant dryers are important in applications where moist air could cause corrosion, contamination or damage to tools, machinery or products. By removing moisture, the dryer increases the reliability and durability of compressed air systems.

The refrigerant dryer is designed for maximum efficiency and durability. The main design elements include:

1. Air-to-air heat exchanger

Gisdpjmt Dbhsfx Agbol

In the first stage of the process, the inlet air passes through a heat exchanger, where it is pre-cooled by the cooler air leaving the evaporator. By using countercurrent flow, heat recovery increases the energy efficiency of the entire system.

2. Refrigeration system evaporator

In the second stage, the compressed air is fed to the evaporator, where it is cooled to a dew point temperature of 3°C. This results in the condensation of water vapor and oil particles contained in it. 3. Condensate separator

After cooling, the gas and condensate mixture is fed to an efficient separator, where the condensate is separated and automatically drained outside the device.

4. Fan control system

The variable speed fan technology allows intelligent adjustment of the cooling intensity to the actual demand, which reduces energy consumption and increases the service life of the components.

Technical parameters

Inlet/outlet pipe diameter (BSP) 1"

Maximum operating pressure 10 bar

Maximum inlet air temperature ≤ 38°C

Dew point temperature 3°C

Efficiency 1500 l/min

Power 0.58 kW

Supply voltage 230 V

Dimensions (L x W x H) 380 x 600 x 625 mm

Weight 31 kg

Type and amount of refrigerant R134a, 400 g

The price given is a NET price. The price does not include transport costs.

For more information, please contact us by phone or email. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 250mm

CORMAKS-200R manual

Call

Condition: new, Year of construction: 2025, Cormak S200R Manual band saw for cutting in large industrial facilities.

Features high accuracy metal cutting, even at 45º/60º.

Machine features

CORMAK S-200R MANUAL band saw with EC declaration, provides cutting metal at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Appropriate arm lowering speed is ensured by a valve controlling oil flow between the chambers.

Gedpfx Agofy Ttiobeil

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. Material is fed manually. This model is used in both low and high quantity production, and due to its solid construction allows for cutting various materials, including stainless steel, tool steel and profiles. The machine provides cutting at an angle due to rotary arm. The band saw arm is made of uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of various materials. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. The arm is equipped with an automatic blade tension sensor, at a 25° angle, thus increasing blade's durability.

There is a blade cleaning brush attached to the bottom of the arm. Machine drive is transmitted through a worm drive filled with gear oil. The machine is equipped with a three-phase motor with double winding and two cutting speeds. The motor is thermally protected.

Two cutting band speeds: 35 and 70 m/min. The construction: the arm, the vice and the rotating table are iron castings. Closed cooling system. The machine is equipped with a bumper with a ruler for setting the length of material cut. The base of the machine is a rigid cuboid made of steel sheets in which a fluid container with a flood coolant pump is located. Safety during cutting ensures an electrical system that meets all EC requirements. The machine is equipped with a limit switch which stops the machine after a cutting process is finished, an emergency button, and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened

Technical data

Type gravitational

Arm raising and lowering gravitational with stepless arm lowering adjustment

Band speed 36/70 m/min

Cutting at an angle from 45° left up to 60° right

Vice manual

Minimum cutting diameter Ø 5 mm

Minimum material length in vice 30 mm

Vice base height 890 mm

Cutting band dimensions 27×0.9×2910 mm

Total power 2.1 kW

Dimensions (LxWxH) 1600×800×1400 mm

Weight 500 kg

Max. cutting range [mm]

Angle

0º ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

For more information please visit our web page or contact us

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 250mm

CORMAKG5025

Call

Condition: new, Year of construction: 2025, A strong, big band saw for metals with a swivel arm, enabling cutting in the plane perpendicular to the axis of the cut material and at any angle from -45° (left) to + 60° (right). Band saws are perfect for cutting tubes, profiles and other materials.

Product features

Material cut can be fed manually or by any feeding device, with automatic tool feed. Appropriate cutting speed (band speed) is obtained through a change on a control panel. Rigid construction arm is made of profiled cast iron.

The drive from the electric motor directed to the cutting band driving wheel is transmitted by a motor with worm drive. The cutting band is tensioned on two cast iron wheels with a manual tightener and guided by adjustable rolling and linear carbide guides.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a -45° to + 60° swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds: 36 and 72 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Cutting band size - 2720×27×0.9 mm

Band tension - mechanical (manual)

Band speed - 36, 72 m/min

Arm lowering control - stepless – hydraulic cylinder

Vice base height - 765 mm

Minimum material length in vice - 100 mm

Power supply - 3-phase, 400 V

Total power - S1 100%: 1.5; S6 40%: 2.1

Godsi D Ddispfx Agbjil

Cooling pump motor power - 0.025 kW

Weight - 370 kg

Warranty - 12 months

User manual - yes

CE declaration - yes

Angle

0° --- ø250 310×210 240×240

45° R ø200 200×140 180×180

45° L ø165 185×145 160×160

60° R ø120 120×95 100×100

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 125mm

CORMAKBS-128HDRC 230V

Call

Condition: new, Year of construction: 2025, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Gjdpfxemrp Tlo Agbjil

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

17,614 km

Automatic column band saw 500mm

CORMAKHR500SA przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, CORMAK HR500SA is an advanced automatic band saw designed for cutting solid materials, pipes and steel profiles with large cross-sections. Thanks to its two-column design and reinforced frame, the machine provides the highest stability, precision and repeatability of cutting - even in continuous operation.

Technical data:

automatic band saw HR500SA

Cutting range Ø500 mm or 650 x 500 mm

Godpji Ab Dljfx Agboil

Band dimensions 6600 x 41 x 1.3 mm

Band speeds 27 / 45 / 69 m/min

Total power 6.5 kW

Band tensioning manual

Feeder stroke 500 mm

Table height 715 mm

Load capacity 3000 kg

Dimensions (L x W x H) 3200 x 3050 x 2115 mm

Weight 3200 kg

Standard equipment

touch control panel with settings memory,

automatic work cycle,

top package pressure,

hydraulic material feeding system,

three-speed cutting gear,

cooling system and cleaning brush,

bimetallic cutting band,

declaration of conformity CE, DTR instruction.

Trust Seal

Dealers certified through Machineseeker

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor LUFT + air dryer + tank

CORMAKLUFT 1000 INVERTER + N10S + BUTLA 270L

Call

Condition: new, Year of construction: 2025, Complete Compressed Air Set: LUFT 1000 INVERTER Screw Compressor + 270L Vertical Air Receiver + IZBERG N10S Air Dryer

This complete set includes the LUFT 1000 INVERTER screw compressor, a 270-liter vertical air receiver with full compressed air accessories, and the IZBERG N10S refrigerated air dryer. Designed for professional use, this system is ideal for industrial plants, workshops, and pneumatic installations that demand high performance, energy efficiency, and reliability.

The LUFT series screw compressors by the Polish brand CORMAK incorporate the latest advancements in pneumatic technology, paired with high-quality components and materials. Low operating costs, user-friendly operation, robust construction, and high output ensure efficient and hassle-free performance.

LUFT 1000 INVERTER Screw Compressor – Technical Specifications:

Parameter Value

Motor Power 7.5 kW

Voltage 400V / 50Hz

Output at 0–6 bar 990 L/min

Output at 6 bar 950 L/min

Output at 8 bar 950 L/min

Output at 10 bar 930 L/min

Outlet Connection (G) 1/2"

Dimensions (L x W x H) 810 x 610 x 850 mm

Weight 160 kg

IZBERG N10S Refrigerated Air Dryer – Technical Specifications:

Gijdpfoxazlrjx Agbjl

Parameter Value

Inlet/Outlet Pipe Diameter (BSP) 1"

Max Operating Pressure 10 bar

Max Inlet Air Temperature ≤ 38°C

Dew Point Temperature 3°C

Flow Capacity 1500 L/min

Power Consumption 0.58 kW

Power Supply Voltage 230V

Dimensions (L x W x H) 380 x 600 x 625 mm

Weight 31 kg

Refrigerant Type & Quantity R134a, 400 g

CORMAK 270L Vertical Air Receiver – Key Features:

This 270-liter vertical air tank with an operating pressure of 11 bar is a reliable solution for storing compressed air in industrial environments. It acts as both a buffer tank and a stabilizer for compressor operation.

Professional Pressure Vessel Construction – Made from high-grade, 4 mm thick steel, resistant to both pressure and corrosion.

UDT Certification & CE Marking – Compliant with EU safety and quality directives.

Operating Pressure of 11 bar – Suitable for most pneumatic systems, including those with higher pressure requirements.

High Storage Capacity (270 L) – Ensures steady air supply and reduces compressor cycling frequency.

Multi-connection Ports – Equipped with five outlets in 1¼", 2", and ½" sizes for versatile system integration.

Durable Finish – Internal and external anti-corrosive coating ensures long service life.

Space-Saving Vertical Design – Ideal for facilities where floor space is limited.

Ideal for:

Manufacturing facilities

Automotive and industrial workshops

Pneumatic tool and machine operation

Compressed air systems requiring stable pressure and high efficiency

This comprehensive compressed air solution offers excellent energy efficiency, stable pressure control, and long-term reliability, making it a perfect fit for demanding industrial applications.

Listing

Siedlce

Siedlce

17,614 km

Screw Compressor with air dryer

CORMAKLUFT 1000 COMPACT

Call

Condition: new, Year of construction: 2025, LUFT 1000 COMPACT Screw Compressor with Integrated Refrigeration Air Dryer

The LUFT series screw compressor from the Polish brand CORMAK represents the latest advancements in pneumatic technology, combined with the use of high-quality materials and components. Low operating costs, ease of use, ergonomic and robust design, and high performance guarantee efficient and trouble-free operation.

Key Features:

Innovative Design

Our compressors are built on advanced engineering and European manufacturing precision. The solid construction, enhanced with modern components, ensures long-lasting and reliable operation in all working conditions.

Integrated Refrigeration Dryer

The COMPACT version with an integrated dryer offers space-saving and comprehensive functionality in a single unit. The built-in refrigeration dryer ensures clean and dry air, protecting your system from corrosion and damage.

Quiet Operation & Comfort

Designed with attention to detail, our compressors operate with exceptionally low noise levels. Effective soundproofing and vibration reduction systems provide a comfortable working environment, enhancing operator focus and well-being.

Smart Control System

The intuitive MAM electronic control panel acts as the command center of your compressor. It allows precise monitoring of parameters, scheduling of maintenance, and quick diagnostics, ensuring system stability and protecting key components.

Tailored to Your Needs

We understand that every application is unique. CORMAK compressors can be configured with additional air treatment systems to perfectly match the specific requirements of your industry.

Dynamic Operating Pressure

Automatic pressure adjustment ensures that the compressor delivers exactly the amount of compressed air needed at any given moment, maximizing energy efficiency and minimizing losses.

Sustainable Development

We prioritize environmentally friendly solutions. The energy-saving technologies used in our compressors not only reduce your energy bills but also minimize environmental impact. The heat recovery option allows for maximum energy utilization.

Integrated Refrigeration Dryer – Top-Level Air Quality

Gisdpjxmg A Aefx Agbjl

Two-Stage Drying System:

Provides effective moisture removal and protection for your pneumatic system.

Variable-Speed Fan:

Automatically adjusts cooling performance to match working conditions, optimizing energy consumption.

Dual Filtration System:

Includes a pre-filter with 3.0 µm precision for removing larger solid contaminants, and a fine filter with 0.1 µm precision that captures oil aerosols and other fine particles, ensuring the highest level of air purity.

Technical Specifications

Parameter Value

Motor Power 7.5 kW

Voltage 400V / 50Hz

Air Delivery (0–6 bar) 990 L/min

Air Delivery at 6 bar 950 L/min

Air Delivery at 8 bar 950 L/min

Air Delivery at 10 bar 930 L/min

Outlet Connection Diameter (G) 3/4"

Dimensions (L x W x H) 1320 x 650 x 945 mm

Weight 320 kg

Listing

Siedlce

Siedlce

17,614 km

Band saw machine

CORMAKBS-530

Call

Condition: new, Year of construction: 2025, Powerful Band Saw equipped with a movable arm that can rotate from -45° to +60°, a portable vice with quick-locking mechanism, a strain gauge for band tension, and a hydraulically adjustable arm with smooth regulation. Additionally, it features an ergonomically designed control panel, ensuring safety and comfort during operation. The maximum cutting width is 490 mm.

Key Features of the Band Saw:

The band tensioning wheel is equipped with a dial strain gauge that indicates the proper band tension, ensuring optimal results and blade durability.

The saw frame is rigid, made of cast iron, and resistant to twisting. High-quality drive wheels are mounted inside, on which the cutting band is mounted.

The control panel is ergonomic, with clearly placed buttons such as the main switch, start, stop, cooling, and band speed control buttons (slow/fast). Additionally, the panel features an emergency stop button that complies with the latest EU safety standards.

The panel column contains hydraulic actuator controls, enabling precise regulation of the arm's descent speed and turning it on/off.

The drive is stable, thanks to high-quality hardened and ground gears. The powerful motor is appropriately matched to the sizes of the materials being cut.

The band’s guidance is reliable due to bearings in the guides that can be adjusted according to the width of the material being cut.

The saw is equipped with a mechanism for automatic shut-off when the arm is lowered.

The vice is solid and securely holds workpieces. A limiter for cutting workpieces is included in the set.

The hydraulic actuator is reinforced, allowing precise adjustment of the arm's lowering speed using a potentiometer. The saw arm can rotate from -45° to +60°, with the lifting force adjusted using a spring.

An efficient cooling system is built into the base of the saw.

Workpieces can be quickly clamped in the vice. The vice can be adjusted on both sides, enabling cutting at different angles.

The set includes a coolant tank with a pump.

The saw’s solid body is made of cast iron, ensuring stability during cutting.

The band saw's arm can be locked.

The base is rigid, allowing operation at a height of approximately 95 cm, which is standard with the saw.

Additional Advantages of the Band Saw:

Giodpfjv R Tgtjx Agbjl

Other features include band speed regulation (35/70 m/min), quick-lock vice, movable saw arm from -45° to +60° with a scale reading, a fully functional device with an excellent price-to-quality ratio, a solid construction ensuring precise, quiet, and vibration-free operation, infinitely adjustable hydraulic arm lowering, durable carbide roller guides, reinforced worm gear with bronze components, automatic end switch, and a liquid cooling system as standard equipment.

Technical Specifications:

Working height: 870 mm

Cutting speed: 35/70 m/min

Band saw dimensions: 3770 x 34 x 1.1 mm

Band saw width: 34 mm

Cooling system pump power: 0.1 kW

Total power: 2.8 kW

Voltage: 400V

Dimensions (width x depth x height): 2200 x 1400 x 1500 mm

Weight: 630 kg

Listing

Siedlce

Siedlce

17,614 km

Band saw machine

CORMAKBS260G

Call

Condition: new, Year of construction: 2025, The CORMAK BS 260G band saws, due to being equipped with a hydraulic cylinder, a cooling and an arm swivelling up to 60°, together with blades from renowned German Röntgen company, are used commonly in ironworking where precision, quality and cutting speed are important.

Godpfsvuf S Nox Agbsil

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or by any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality.

Machine's arm is made of profiled CAST IRON. Control panel is located by the arm. The drive from the electric motor directed to the cutting band driving wheel is transmitted by a motor with worm drive. The cutting band is tensioned on two cast iron wheels with a manual tightener and guided by adjustable rolling and linear set of carbide guides. A separate flood coolant container with an electropump is inside. The arm lowering speed (the cutting speed) is adjusted with a hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 36 and 72 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Cutting band saw dimensions

2455×27×0.9 mm

Band tension

mechanical (manual)

Band speed

36, 72 m/min

Feed speed

0–50 m/min (stepless feed)

Arm lowering control

stepless – hydraulic cylinder

Vice base height

900 mm

Power supply

3-phase 400V

Motor power

1.1 kW

Weight

216 kg

Warranty

12 months

Manual

yes

CE declaration

yes

Angle

0º

ø230

260×150

225×225

45º

ø165

180×130

165×165

60º

ø105

100×90

110×110

*Please note that machine is sold without CEE connector by default, since there are many different types of it. If you would like to receive it with the machine, please write it to the seller before making a purchase/during order proceeding.

We make it easier for you to find: "band dryer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Band Dryer (6,080)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month