Used Sumab for sale (204)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Ulmen

Ulmen

18,639 km

Brochure production system

MKWTRANS UT12 / 35x62 / GS / RL

Call

Condition: as good as new (ex-display), Year of construction: 2024, functionality: fully functional, Showroom machine from the manufacturer!

Ideal brochure production and collating

-Built 2024

-Ideal brochures and collating line

-12 stations in special format - 35 cm x 62 cm for A4 landscape brochure

-Right-left run

-Running to the right - brochure production

-Running to the left - collating

Kedpfx Aeu Dmryoffsnf

-Clocked guide plate - alignment of the sheets with each cycle

-Motorized paper rail

-Cover creasing unit

-Automatic format adjustment of the following units

-TRANS SFT 350 S & TRANS T20 S

-Short-term delivery

Warranty Time

12 month spare parts warranty

(critical spare parts pack shipped with machine)

(not inclusive are belts, bulbs, rubber parts, suckers, …)

Package of free spare parts

A package of the most important spare parts and consumables

like rubber parts will be send together with the machine.

Validity of offer

Subject to prior sales

Detailed offer on request

Listing

Kootwijkerbroek

Kootwijkerbroek

18,541 km

SLS 3D Printer

EOSEOSINT P100 formiga

Call

Condition: reconditioned (used), For Sale: EOS P100 – Ready for Immediate Use

KNOW WHAT YOU BUY! Fully revised and with warranty!

This EOS P100 has been fully inspected and revised, making it ready for immediate use in your production environment.

Included in the package:

• 2 build frames

• Set of hoppers

Specifications:

• Technology: SLS (Selective Laser Sintering)

• Material class: Polymers

• Compatible materials: PA2200, PA3200, PA2201, Inframotion PA12, TPU, and more.

• Build volume: 200 x 250 x 330 mm

• Laser type: Synrad 48-3, 30W CO2 laser

• Minimum wall thickness: 0.4 mm

Consumables Highlight

We offer a wide range of plug-and-play materials, fully tested and optimized for use with EOS machines. Our Inframotion PA12 delivers top performance and provides significant cost savings compared to OEM powders, without compromising on quality. Choose our exclusive materials to drastically reduce your operational costs.

Included Services:

• Transport & Installation: Safe delivery in original EOS packaging and professional installation included.

• Warranty & Maintenance Plans: Flexible options tailored to your specific needs.

About Inframotion 3D (IM3D)

Kjdorm Tdwspfx Affjnf

At Inframotion 3D B.V., we specialize in high-quality refurbished EOS SLS machines with comprehensive support. As the only provider offering a complete solution for used EOS equipment, we distinguish ourselves through extensive expertise and unique services.

What we offer:

• Expert maintenance: Installation, servicing, repairs, and upgrades performed by experienced ex-EOS technicians.

• Exclusive materials: Cost-effective, high-quality consumables such as our plug-and-play PA12, specifically designed for EOS machines.

• Complete support: From transport to maintenance plans, we handle it all.

Trust IM3D for reliable machines, superior materials, and the expertise to optimize your SLS production.

Feel free to contact us for more information or inquiries!

Listing

Sonneberg

Sonneberg

18,396 km

Hacksaw Silestra

Call

Condition: good (used), Stock number: 2861

Type / Model: HN25 (presumably)

Cutting range round: 270 mm

Knodstuix Sjpfx Affef

rectangular: 270x 250 mm

blade length: 500 mm

opening: 310 mm

Control: conventional

Stroke rate: 85 and 110 double strokes per minute

Connection: 1.7 kW

Clamping jaws WxH: 180 x 120 mm

Accessories/equipment: automatic switch-off

Condition: good

weight: 0,7 t

Dimensions: 1,400 x 650 x 1,000 mm

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Saint-Nicolas-de-Redon

Saint-Nicolas-de-Redon

19,249 km

Panel saw

GMC MACCHINE SRLKGS 660S

Call

Condition: not inspected (used), Year of construction: 1998, functionality: limited functionality, machine/vehicle number: 13189, VERTICAL PANEL SAW WITH ELECTRIC MOVEMENTS & DIGITAL DISPLAYS FOR CUTS

Brand: GMC MACCHINE SRL

Model Type: KGS 660S Serial No.: 13189 Year: 1998

(Photos taken prior to any potential refurbishment, machine offered as-is)

MACHINING CAPACITIES:

- Max. horizontal cutting length: 5300 mm

- Max. horizontal cutting height: 2100 mm

- Max. vertical cutting height: 2200 mm

- Max. cutting depth: 80 mm

OTHER FEATURES:

- Power supply: 380V Three-phase+T

- Installed power: 7.5 kW

- Main motor power: 4.4 kW (6 hp)

- Saw blade speed: 5,200 rpm

Pneumatic blade feed

- Carbide-tipped saw blade: Ø 300 mm, bore Ø 30 mm

- Welded steel frame, PVC slat frame with automatic retraction via pneumatic cylinders

- Fully lengthwise pneumatic retractable intermediate support with 2 adjustable and retractable stops

- Retractable rollers for panel handling

- Pneumatic locking of the saw carriage

- 8 bar pneumatic feed

- Digital display for cuts

- Complete extraction system DPS

Back cover spans the entire rear of the machine

Lower longitudinal channel for sawdust collection

Multiple extraction points in the lower section

Extraction port: Ø100 mm

- Support for floor-mounted installation

- CE Marked

Total space required when mounted on supports: 6300 x 1600 x 3040 mm

(includes operator and maintenance area)

Transport dimensions, 2 packages:

. 1 frame 6300 x 860 x h.2620 mm

. 1 pallet 3150 x 1000 x 1000 mm

Total weight: 1250 kg

Please contact us for supply of consumables, accessories, and/or extraction systems.

Kodpfx Aeu R Ulhjffenf

Offered as a lot, without refurbishment or warranty.

Ex works price, excluding VAT.

Transport and services on request.

Listing

Oberkochen

Oberkochen

18,554 km

Deduster

NESTROEntstauber NE-J 300

Call

Condition: new, 0 300 mm

0 max./nom: 6.000/5.085 m³/h

0 v.V./nom: 2.950/2.400 Pa pa

Filter capacity 36,2 m² m²

weight ca. 1.300 kg

Dimensions (L/W/H) 3.880 x 1.020 x 2.250 mm

Dust extractor NE-J 300 3 ton. m. Jet filter regeneration

-----

Including a new type of extinguishing device with a drop flap and oxygen extraction,

5 m cable for junction box, high-efficiency reluctance motor IE5, FU control,

Wired 7" color touch panel, automatic start/stop start control

and monitoring of up to 10 woodworking machines included

automatic slide control, integrated emergency stop function and is

of course H3 tested.

The newly designed model fits into any standard shipping container. The suction nozzle

with injection box and non-return flap is located in the middle of the front

dust extractor. The highly efficient JET filter regeneration guarantees high

Filter service life, low filter resistance and therefore high suction performance.

The dust bins each have 4 swivel castors and a viewing window

Fill level control and with an inserted sturdy chip collecting bag

fitted.

Technical data / manufacturer description

-----

• Volume flow max./nom.: 6,000 / 5,085 m³/h

• Operating volume flow: 7,500 m³/h

• Negative pressure v.V./nom.: 2,950 / 2,400 Pa

• Suction side connection: Ø 300 mm

• Operating mode: continuous operation

• Type of current: three-phase current 400 V / 50 Hz

• Power consumption: 7.5 kW / 18.5 A

• Fan / drive: IE5, FU controlled, high-efficiency reluctance motor

Knsdou Uvarepfx Affjf

• Filter area: 36.2 m²

• Filter regeneration: JET / automatic

• Compressed air consumption per cycle: 560 liters.

• Chip disposal: Chip bin with PE bag

• PE bag (consumables): Item no. 500020

• Collection volume 3 x 0.16 m³

• Weight: approx. 1,300 kg

• Noise value according to EN 11201: 72-74 dB(A) according to MRI (+/- 4dB)

• Depth x width x height: 1,020 x 3,880 x 2,250 mm

Necessary connections:

• Compressed air standard coupling NW 7.2; 6 bar, dry compressed air and oil-free

• 1 x junction box/sub-distribution/backup fuse 25 A

In systems with a chip bag filling, due to different reasons

Suction volume and differing chip/dust proportions ensure a uniform

Filling cannot be guaranteed.

----- --

Total price: On request!

Assembly according to effort - on request!

----- --

(Technical information provided by the manufacturer is not guaranteed!)

Discover more used machines

Listing

Birmingham

Birmingham

18,725 km

Weighing and bagging system VFFS Bagger

Bilwinco14-h Weigher & Sandiacre TG400LDK

Call

Year of construction: 2003, condition: excellent (used), machine/vehicle number: 5479, REF: MM6231

Weighing and bagging system which has previously been used to pack 1.8kg and 2kg bags of grated cheese, comprising of:

1 x Bilwinco A/S 14-head weigher fitted with dimple pans and PLC control panel.

Knjdpjxnivuofx Affof

Technical specification ⚙️

✅ Model - BW114-W.

✅ Serial number - 5479.

✅ Date of manufacture - 2003.

✅ Weighing range - 10g to 1000g, per drop.

✅ Electrical requirements - 400 V / 50 hz / 3 phase.

✅ Power - 10 Amps.

✅ Compressed air - 8-10 bar.

1 x Stainless-steel purpose-built gantry structure.

Overall dimensions - 1750mm long/deep x 2320mm wide x 3500mm high.

1 x Sandiacre Packaging Machinery Limited vertical form, fill and seal bagging machine with Allen-Bradley touch-screen control panel and supplied with 2 x forming tubes.

This machine has vacuum and gas-flush sealing functions.

Technical specification ⚙️

✅ Model - TG400LDK.

✅ Serial number - 2607.

✅ Date of manufacture - 2000.

✅ Sealing jaws - Vertical: 540mm & Horizontal: 420mm.

✅ Maximum bag width - 400mm.

Previously running a 592mm wide film.

✅ Forming tubes - 180mm diameter to form bag 240mm wide.

✅ Footprint of system - 2500mm long/deep x 2320mm wide x 3600mm high.

NOTE: This system has recently been serviced, with new chains, belts and other consumables fitted at a cost of approximately £6,000.

Listing

Ulmen

Ulmen

18,639 km

Gathering machine

MKWRAPID UT16 / B3 / GS + HA350

Call

Condition: as good as new (ex-display), Year of construction: 2024, functionality: fully functional, Showroom machine from the manufacturer!

Ideal for collating calendars, folded sheets (signatures), cardboard boxes of all kinds, packaging, ...

Calendar collating machine

Type - MKW RAPID

UT - System Belt conveyor table

16 - Number of stations

B3 - Format 35 x 50 cm / 13.78" x 19.68"

GS - High pile up to 70 cm

1 Automatic Collator

Type MKW RAPID UT / B3 / GS

- With 16 stations Belt-Conveyor-Table

- Sheet sizes 10 x 14 cm up to 35 x 50 cm

- Sheet sizes 3.94" x 5.51" up to 13.78" x 19.68"

- High-Pile version with max. 70 cm / 27.55" stacking height

- Paper weights up to 1.000 g/m²

- Single sheets, folded sheets (signatures), carton, plastic foils, …

- Belt conveyor transport table for continuous sheet transport

- Timing belts radially adjustable for optimal sheet delivery

- Timing belts radial adjustment via electrical clutches

- Foldable transport fingers

- Adjustable tilt suction heads for optimal pick up of sheets

- Pressure-vacuum pump in sound-absorbing housing

- Clocked blown air for accurate sheet layering

- Electronically adjustable sheet layering

Knsdpfx Aour Ih Roffef

- Electronic machine control by Industry-PC system

- High quality 15'' color display for reliable and clear operation

- Self-learning electronic missing/double sheet control per station

- Missing/double-sheet control by Infrared sensor MKW IR

- Tandem function for double use 2 : 1 (TANDEM-Mode)

- Dynamic station selection for optimized pre-loading for the next job

- Inserting function at any station possible

- Alternating insert function at any station possible

- Alternating cardboard function at any station possible

- Speed display infinitely adjustable

- Advance counter with adjustable stop for number of sets and stop time

- Delivery control system for criss-cross with adjustable set interval

- Transport table lighting with LED-Lamps

- Jam control along the transport table

- Active safety: Transparent safety hoods made of unbreakable PC

- Ejector unit inclusive additional station at the delivery AW 3 incl.

(for ejection of faulty sets)

- Raising unit for delivery rollers AHB incl.

(for different paper formats in one set and signatures)

- Delivery Jogger-system integrated ASS i 3 incl.

(for normal and criss-cross delivery, incl. X-Jogger)

- LED signal lights to visualise the information of each station SOFU-HIVIS incl.

(enables simple status detection)

Alternative to Jogger:

1 High-Pile delivery

Type MKW RAPID HA 350-UT / PN + T-BELT

- Automatic high-pile delivery up to 30 cm piling of sets

- Format up to 35 x 50 cm

- Staggered delivery of sets

- Pneumatic drive unit for staggering of sets

- Automatic delivery on to buffer belt

- Buffer belt lenght approx 2,00 m

- Counter function for pile height

- Text display for operation and monitoring

Warranty Time

12 month spare parts warranty

(critical spare parts pack shipped with machine)

(not inclusive are belts, bulbs, rubber parts, suckers, …)

Package of free spare parts

A package of the most important spare parts and consumables

like rubber parts will be send together with the machine.

Validity of offer

Subject to prior sales

Detailed offer on request

Listing

Sunderland

Sunderland

18,454 km

Booklet Maker

Duplo150 Digital System

Call

Condition: excellent (used), Duplo 150 Digital Booklet System

Location: Glendale, UK

Availability: In stock

Condition: Refurbished by trained engineers – Excellent condition, perfect working order.

Overview

The Duplo 150 Digital Booklet System is a compact, modular solution designed for low to mid-volume digital print finishing. This complete configuration includes the DSF-2200 Sheet Feeder, DBM-150 Booklet Maker, and DBM-150 Trimmer, delivering high-quality booklets with speed and reliability. Producing finished sizes from A6 up to A4, as well as custom sizes between 320 × 460 mm and 120 × 210 mm, it offers flexibility and professional results in a space-saving footprint. Capable of producing up to 2,400 books per hour, it is the perfect near-line solution for today’s digital printer.

Key Features

Produce booklets from A6 to A4, plus custom sizes.

Handles up to 25 sheets (100 pages) per booklet.

User-friendly PC controller with job recall and automatic set-up.

Two feed trays for combining different media types.

Job integrity assurance for accurate, error-free production.

Fast operation with up to 2,400 books per hour.

Complete System Includes

DSF-2200 Sheet Feeder – High-capacity dual tray feeder with five different feed modes for maximum flexibility.

DBM-150 Booklet Maker – Compact, fully automatic booklet maker with precision folding and stapling.

DBM-150 Trimmer – Integrated fore-edge trimming for clean, professional edges on every booklet.

Why Choose the Duplo 150?

Ease of Operation – PC-controlled setup with automated adjustments for quick job changeovers.

Flexible Production – Handles a wide range of sizes and stocks, ideal for digital workflows.

Compact Design – A space-saving system combining feeding, folding, stapling, and trimming in one modular unit.

High Efficiency – Continuous production of up to 2,400 booklets per hour with no wastage.

Upgradeable System – Modular design allows additional Duplo devices to be added as business needs evolve.

Why Buy from Glendale?

Professionally refurbished and fully tested – every system is serviced by our trained engineers.

Expert operator training and ongoing support – we help you get the best results from your equipment.

Competitive pricing on consumables – keep running costs low with our affordable supplies.

Ksdpfx Afow Tmy Nefonf

Established and trusted supplier – years of experience in print finishing solutions, providing both new and used printing equipment.

Specifications

Manufacturer Duplo

Model 150

Stock Number 114956

Max sheet size 320 x 460mm

Min sheet size 120 x 210mm

Max booklet capacity 25 sheets (100 pages)

Max speed 2400 sets/hour

Staple heads Heavy duty Isaberg Rapid R952

Stapling width Adjustable - 70, 108, 160, 258 & 276mm

Paper type Fine quality: 64 to 127.9gsm, Art/Coated: 104.7 to 127.9gsm Cover: Fine quality, Art/Coated within 300gsm

DSF-2200 Sheet Feeder Specifications:

Feeding System Belt suction, top feed, air separation

User features Ultrasonic double sheet detection, hand feeding, active anti-static bar

Paper capacity 200mm and 60mm in each tray

System power requirements 240v 50HZ

Full system weight 260kg

Full system dimensions W2540mm x D750mm x H840mm

Listing

Berlin

Berlin

18,139 km

Refrigerator body van

MERCEDES-BENZSprinter 516 cdi THERMO KING V300 MAX|2,2t NUTZL

Call

Condition: used, mileage: 159,800 km, power: 120 kW (163.15 HP), first registration: 09/2016, fuel type: diesel, overall weight: 5,000 kg, next inspection (TÜV): 11/2025, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 10 m³, loading space length: 3,450 mm, loading space width: 1,880 mm, loading space height: 1,510 mm, Year of construction: 2016, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), soot filter, No. 57 - You will find this and many other inspected Mercedes Benz vans on our homepage:

----Mercedes-Benz Sprinter 516 CDI, EURO 6, Frigopan refrigerated box with Thermo King V300 Max cooling unit. Temperature range -22°C / +20°C. Very robust vehicle with a high payload of 2,150 kg. Drive and stationary cooling are available. The vehicle is in good visual and technical condition. HU/AU (TÜV) valid until 11/2025. Permissible total weight: 5 t, Unladen weight: 2,850 kg, Payload: 2,150 kg.----The refrigeration is running but does not cool down to the set temperature. Presumably, there is too little refrigerant in the system. Cause unknown.----The box stands out for its sturdy and practical construction (reinforced front wall, rear doors, side doors right and left, aluminum floor with collision protection).

----The vehicle is from the first owner, has a complete service history, and is in good visual and technical condition. The service was carried out at KM 47, 104, 134, 151.----Permissible total weight: 5 t

Unladen weight: 2,850 kg

Payload: 2,150 kg

Cargo area LxWxH in cm: 345 x 188 x 151

Emission class: EURO 5

Long wheelbase: 3665 mm

VIN: WDB9061531N663635

All-weather tires

2 keys

----* Mercedes-Benz Sprinter 516 CDI in good condition

* Deep-freeze box

* Frigopan refrigerated box

* Thermo King V300 Max cooling unit, deep freezing down to -22°C

* Temperature recorder

* Drive and stationary cooling

* Tachograph

* Cruise control

* Lane keeping assistant

* Becker Map Pilot navigation system

* Reinforced stabilizer at front, reinforced front axle

* 3 seats

* Audio system Audio 15

* Electric windows

* Electrically adjustable exterior mirrors

* Airbag

* Central locking

----Errors, modifications, and prior sale reserved.

Special Equipment:

Knodpfswtcfpsx Affsf

1 DIN slot at the front under the headlining, Audio system Audio 15 (radio with color display), exhaust before rear axle left, outside temperature display, single-pole battery disconnect switch, roof control unit with reading light on driver/passenger side, digital tachograph, downloadable, 180 A generator, folding lid for storage compartment, fuel filter with water separator, front PTO with bracket for additional coolant compressor, Becker MAP Pilot navigation system, spare wheel Super-Single tires (235/65 R16), spare wheel holder under the end of the frame including jack, front mud flaps, seats in cab: passenger double seat, seats in cab: driver's comfort seat, reinforced front stabilizer, rear wall lining, fleece battery 95 Ah, heat protection glazing (windscreen with top band filter)

Additional Equipment:

Adaptive brake light, driver's airbag, washer fluid level indicator, electrically adjustable and heated exterior mirrors, both, exterior mirrors with integrated indicator, battery 74 Ah, brake assist, braking system with ABS+ASR, roof lining in cab, driving assistance system: lane keeping assistant, lockable glove compartment, body/construction: platform, fuel tank: main tank 75 liters, headlight range adjustment, truck registration, model update, engine 2.1 liters - 120 kW CDI CAT, wheelbase 3665 mm, smoker package, tires 285/65 R16C super-single tires on rear axle, low emissions according to Euro 6 emission standard, seat belt system with warning device (driver's side), seat cover/upholstery: fabric Lima, seats in cab: adjustable passenger seat, service interval indicator Assyst, permissible total weight 5.00 t, twin tires on 2nd axle/rear axle

Listing

Saint-Nicolas-de-Redon

Saint-Nicolas-de-Redon

19,249 km

4-sided moulder with 5 spindles

LeadermacLMC 523SU

Call

Condition: excellent (used), Year of construction: 2008, functionality: fully functional, machine/vehicle number: 0803024, 4-SIDED PLANKER-MOULDER

5 REINFORCED MOTOR TOOL HOLDERS

& 3.00 M CHROME TABLE

Brand: LEADERMAC Type: SMARTMAC 523

Model: LMC-523SU Serial No.: 0803024 Year: 2008

(Photos taken before servicing & cleaning)

MAKING CAPACITIES:

- 4-sided planer and moulder

- Max. cross-section: 130 x 230 mm

- Thicknesses: 10 to 130 mm

- Widths: 15 to 230 mm

- Minimum length for single workpiece: 600 mm

Kodpfxjv Tzw Eo Affsnf

> 760 mm with use of the universal spindle

- Adjustable infeeds: max. 10 mm

- Spindle speed: 6000 rpm

PLANKER COMPOSITION:

- Robust frame Welded machine shop

- Secure, soundproof, and fully panoramic enclosure on gas struts

with interior lighting

- Digital counters (Siko type) for precise manual adjustments of each operation

- Raised control panel and operator face

- Cast steel infeed table (LxW): 2980 x 255 mm

Table height from ground: 900 mm

- Side infeed spring-loaded pusher

- Digital pass-taking indicators

1) Planer spindle 7.5 kW

Tool holders Ø125 x L.230 mm

2 & 3) Right & left vertical spindle 12 kW

Tool holders Ø125 x L.130 mm

4) Upper horizontal spindle with independent adjustment 11 kW

Tool holders Ø125 x L.230 mm

- Adjustable pressure shoe at the output

5) 360° universal spindle 11 kW

Spindle Ø 50 x L. 240 mm

- Vertical idler wheel presser

DRIVE:

- Feed with variable speed drive: 6 to 24 m/min

Drive motor: 3 kW

- Helical steel infeed roller in the table

Cardan shaft drive

- 7 pneumatic pressure rollers

2 notched steel rollers

3 (1 retractable) + 2 rubber-coated rollers

- One smooth steel roller in the table at the planer outlet

OTHER FEATURES:

- Main power supply: 400V. Three-phase + T 50 Hz

- Installed power: 53 kW (72 hp) IN 95.6 A

- Automatic star-delta starting

- Motors with brakes

- Toothed belt drive

- Electrical thickness adjustment by raising and lowering the beam. 0.37 kW motor

- Shaft diameter: Ø50 mm

- Minimum working air pressure: 6 bar

- Suction: 5 x Ø 120 mm

Recommended flow rate: 6100 m3/h

Speed: 20 to 28 m/sec depending on the humidity of the wood being machined

- CE marking

- Padlockable contactor, mushroom stops

Dimensions in operating order (W x H): 3000 x 2250 mm

Dimensions: 5100 x 2000 x H 1810 mm

Weight: 4300 kg

Machine supplied with mounted sharpening irons, manual, spare parts list, and diagrams.

Please contact us for consumables, accessories, and/or vacuum systems.

Upon request, the machine will be serviced and brought into compliance, with inspection and dynamic functional testing.

With a 3-month warranty and certificate of compliance.

Ex-stock price excluding VAT. Delivery and additional services upon request.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Excavator bucket, probably ditch cleaning bucket, trench bucket, excavator shovel, grading bucket

Caterpillar

Call

Condition: used, Excavator bucket, ditch cleaning bucket, presumed CAT

Bucket width: 1500 mm

Carrier machine: from 20 t

Excavator attachment presumably Caterpillar

- Pin distance: 375/445 mm

- Pin diameter (top): 80 mm

- Pin diameter (bottom): 70 mm

- Pin width / quick coupler width: 320 mm

Bucket dimensions (L x W x H): 1500 x 1000 x 780 mm

Kjdpfx Afexcixfofsnf

Overall dimensions (L x W x H): 1500 x 1150 x 1050 mm

Own weight: approx. 550 kg

In very good condition

Auction

Auction ended

Bayern

Bayern

18,450 km

Dip coating plant

FISACCB 40 UV + 2x RB 50

Year of construction: 2017, operating hours: 29,187 h, condition: not inspected (used), functionality: unexamined, total length: 20,000 mm, machine/vehicle number: 46236, Submission of a bid obligates the buyer to collect the equipment by 26.09.2025. Dismantling will require at least one week!

Up for auction is a comprehensively equipped dip coating system with extensive accessories!

No minimum price - guaranteed sale to the highest bidder!

The system is divided into 16 stations. The following components are included in the offer:

- FISA CCB 40 UV

- FISA RB 50 (2 units, serial no. 49052)

- 5 tanks

- Buffer and coating area

- Heraeus UV light system

- DYMAX Blue Wave 200

- EuroChiller air filter package

- Pre-filters (2 units)

- Absolute filter

- Modular product carriers

- Loading tables

Ksdpfjxbyc Sjx Affsnf

- Racks for Kanban consumable dispensers

- Liquid filter package

- Stainless steel frame

Additional equipment:

- Various spare parts (filters, replacement pump, hoses, gaskets)

- Numerous connectors, inspection windows, maintenance openings, rinse pumps, circulation units

MACHINE DETAILS

Dimensions:

- Total length: approx. 20 m

Operating hours: 29,187 h

Note: The machine has not been tested by the seller but was in use until recently. Further information about the system can be found in the attached documents.

Listing

Rinteln

Rinteln

18,386 km

Industrial robot

KUKAKR210 2700 extra

Call

Condition: like new (used), Year of construction: 2018, operating hours: 1 h, functionality: fully functional, machine/vehicle number: 568746, overall weight: 1,068 kg, load capacity: 210 kg, arm reach: 2,700 mm, controller manufacturer: KUKA, controller model: KRC4, teach pendant manufacturer: KUKA, input voltage: 400 V, type of input current: AC, Details about the robot:

Year of manufacture: 2018

Operating hours: Only 0.6 hours

Condition: As new, flawless

Model: Kuka KR 210-2700 Extra

Inspection & Test: The robot can be inspected and tested on site at any time.

This robot is ideal for applications demanding the highest precision and reliability. It has been carefully stored and is in impeccable technical condition.

Note: Sale as a used consumable machine with exclusion of any liability for material defects.

Kjdpfxswtx Imo Affsnf

Listing

London

London

18,794 km

Watson Marlow 620 Du/R Peristaltic pump

Watson Marlow620 Du/R

Call

Condition: used, This listing is for the Watson Marlow 620 Du/R Peristaltic pump

The unit is in full working condition and is ready for immediate use

The 620DU is a process peristaltic pump (i.e. hose pump) designed for metering, dosing, and transfer of fluids.

Because it is a peristaltic design, the fluid is contained entirely within the tubing, avoiding contact with internal moving parts (other than the tubing).

It is suitable for remote control, automation, and integration into control systems (SCADA, factory logic, etc.).

Wide control range & precision: The large turndown (2,650:1) gives flexibility to handle both very low and high flow rates with fine control.

Remote / automation capabilities: Because it supports analog and digital interfaces, it’s well-suited for integrated systems.

Pump protection & security: PIN locking helps avoid unintentional changes in process-critical applications.

Low maintenance on non‑wetted parts: Since only the tubing contacts fluid, mechanical wear is mostly on the tubing, making part replacement simpler.

Safe to run dry: Peristaltic pumps typically tolerate running dry without damage (unlike many positive displacement pumps).

Reversible / ability to back‑flush: This is helpful when attempting to clear lines or avoid clogging.

Kedexhdt Iepfx Affonf

Limitations / Considerations

Tubing wear / life: The hose or tubing is the consumable component. Chemical compatibility, pressure, and mechanical stress affect how often tubing needs replacement.

Upper pressure / flow limit: While it handles decent pressure (~2 bar standard, possibly up to 4 bar variant), it’s not suited for very high-pressure pumping tasks.

Enclosure limitations (non-“N” model): The standard 620DU is not fully sealed, so it may not be ideal for wet or harsh environments unless you use the “N” variant.

Cost / complexity: More features, interfaces, and protection can make the system more complex (and costlier) to configure, install, and maintain.

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Complete Bottling Line

Call

Condition: used, Used Complete Bottling Line for wine immediately available for sale:

This used bottling line is made up of used equipment that can work mainly with still wine. The used Used Complete Bottling line has an isobaric monoblock that allows you to work both slightly sparkling and sparkling wines.

Currently, it is used for wines without gas but also for some production with sparkling wine. The cap in this case is a classic aluminium screw.

The used Complete Bottling Line wine-filling is completely automatic from the depalletizer to the palletizer.

The packing of the used line is made with three separate machines that form, box and close the American carton.

The operators currently used on the used Complete Bottling Line are 3 plus a quarter for the forklift during loading and unloading.

Some used equipment is also delivered to the used bottling line for wine.

These are for the standard 0.75 CL Bordeaux.

To sanitize the used line, they use disposable steam which still allows the taps \ central part to be washed well.

Used wine filling line services:

For this Complete Bottling Line used for the wine we can offer disassembly and packaging services, and reassembly in case of need. Furthermore, we can propose a new project for adding bottle format equipment in case of a new bottle shape.

A maintenance service can be negotiated for this Complete Bottling Line and implemented in about 75 working days from the confirmation of the order. All replaced parts are warranted except Filters, fuses, lubricants and consumables in general; they are subject to ordinary or scheduled maintenance.

The electrical components can be damaged by accidental electric shocks to the control panel and by the interruption of the general control. Damage due to the use of non-original parts.

Used Complete Bottling Line for wine subject to prior sale.

Knedevguphopfx Affof

Listing

Germany

Germany

18,384 km

Bandsaw - Horizontal

BERG & SCHMIDDGS 500/600 HA-I

Call

Condition: new, capacity 90 degrees: round 500 mm

capacity 90 degrees: square 420 mm

600x400

saw band length 5320x34x1,1 mm

band speed 15 - 100 m/min

table height 805 mm

total power requirement 3,0 kW

weight of the machine ca. 1,45 t

dimensions of the machine ca. 1,72 x 2,5 x 2,5 m

Double miter band saw, hydraulic semi-automatic, DGS 500/600 HA-I

• miter left + right 60°

• Frequency-controlled saw drive

• 34 mm saw band height

• Wear-free material support turntable, ball-bearing

• To position the saw blade guides using a very wide linear guide

• Strong, robust gearbox

• Large chipboards

• 2 integrated support rollers left and right

Knjdpfx Afeupxupjfef

• Removable chip tray (disinfection)

• Free-standing control panel, safe and ergonomic

• Storage space for tapes, consumables

• Hydraulic cutting pressure control valve

• Material height sensor (automatic cut start detection)

• Preload super fast (front loading)

• Hydraulic control of saw frame and vice

• LEDs for monitoring all safety functions

• Minimum cutting range from around 10 mm

Semi-automatic function:

1. Clamp material

2. Saw starts

3. Rapid lowering to the start of the material or the same for series cutting

cut

4. Saw band off

5. Raise the frame to just above the material

6. Open the vise

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Safe - Valuables cabinet - Security safe - Fireproof cabinet, Data protection cabinet

LIPS

Call

Condition: used, Safe - Security Cabinet - Fireproof Safe LIPS

presumably a data protection cabinet

Internal dimensions: W=1080 mm, H=1500 mm, D=440 mm

Presumably provides 120 minutes of fire protection

- 2-door

- Interior with 2 shelves

- Internal door for enhanced fire protection

- Bolt mechanism with 3-sided locking

- Key lock with one key

External dimensions: W=1400 mm, D=720 mm, H=1850 mm

Knjdpfoxcivkox Affsf

Weight: approx. 600 kg

in good condition

Listing

Petershagen

Petershagen

18,376 km

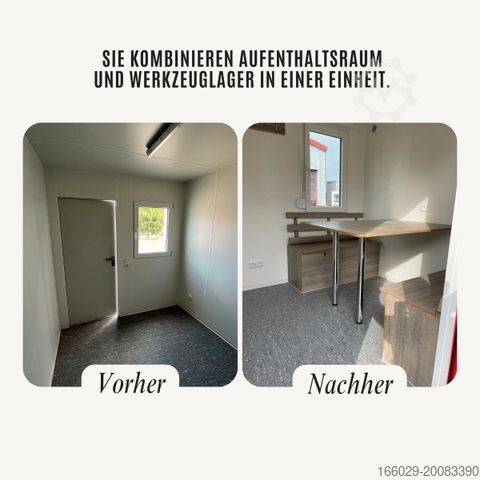

Swap body semitrailer

Kombicontainer Büro / Lager

Call

Condition: used, first registration: 01/2025, total width: 2,550 mm, General Description

This object is a converted shipping container designed for use as a mobile space. The unit has been upgraded to a high standard, featuring insulated and clad interior fittings as well as an independent electrical installation.

Exterior Shell

Base: Standard shipping container (presumably 20 ft), painted inside and out.

* Access: In addition to the container doors, an access door with window is installed.

Walls and Ceiling (Interior)

The walls are clad with light, smooth wall panels.

* The ceiling has been suspended and fitted with a lamp.

Floor

The floor is finished in a dark and durable design.

Knodpfjxf Rz Tjx Affjf

Windows and Doors

A window provides natural daylight and ventilation.

* The access door is permanently built-in and insulated.

Electrical Installation

A complete sub-distribution board, including fuse box, is installed.

* Several sockets (standard and high-voltage/CEE) are available.

* Ceiling-mounted lighting.

* An electric heater is installed.

Possible Uses

- Mobile office

- Break room

- Construction site container

For further information or specific details, please feel free to contact us. Just send us your inquiry!

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Capsuling machine

Robino & GalandrinoMonostadio Z9T

Call

Condition: used, Year of construction: 2007, Used Shrinkable Capsuling Machine Robino & Galandrino Monostadio Z9T

The Used Shrinkable Capsuling Machine Robino & Galandrino Monostadio Z9T is a shrinkable capsuling machine designed to optimize high-performance bottling lines. In fact, this model delivers an advanced technical solution, providing precise and reliable application of PVC shrinkable capsules on bottles of various sizes and types. This machine handles bottle formats with diameters ranging from Ø55 to 120 mm and heights from 220 to 360 mm.

Main Technical Features

Manufacturers produced the machine, model Monostadio Z9T, in 2007. It features a rotary multi-bell distributor with 9 heating heads. Consequently, this configuration ensures uniform heat distribution, which allows the capsules to shrink evenly and adhere perfectly to the bottle neck. Moreover, the multi-bell system optimizes capsule handling, minimizes downtime, and maintains continuous production without interruptions.

Engineers designed the clockwise rotation to optimize the capsuling machine’s integration into existing bottling lines. In this way, it reduces the necessary plant modifications and enhances the overall flow of the production process.

Production Performance of the used shrinkable capsuling machine

The Used Shrinkable Capsuling Machine Robino & Galandrino Monostadio Z9T achieves a production capacity of 15,000 bph. Therefore, it proves ideal for companies that require high production volumes while ensuring precise capsule application.

Capsule Types and Compatible Materials

This capsuling machine supports the use of standard PVC shrinkable capsules and features an advanced distribution and shrinking system. The machine precisely positions the capsules onto the bottle neck through a rotary distribution mechanism, ensuring accurate placement before initiating the heat-shrinking process. The shrinkable material securely seals the closure and enhances the product’s aesthetic presentation. Furthermore, the machine includes a standard capsule storage system, which facilitates refilling and handling of consumables while minimizing downtime.

Operational Advantages of the Robino & Galandrino machine

This used shrinkable capsuling machine offers operational reliability through its robust design and advanced heating technology. Indeed, the 9 heating heads allow precise temperature control, preventing overheating or uneven capsule shrinkage.

Ksdevxz Afopfx Affsnf

Additionally, the rotary distribution system aligns the capsules perfectly on the bottle neck. Consequently, it reduces production waste and improves the line’s overall efficiency. This improvement is particularly important for large-scale operations, where even small efficiency enhancements can translate into significant cost savings.

This machine also features a built-in dryer, which serves the crucial function of drying the bottle surface before the capsule application.

Listing

Germany

Germany

18,384 km

Bandsaw - Horizontal

BERG & SCHMIDDGS 350/450 HA-I Easy 34

Call

Condition: new, capacity 90 degrees: round 350 mm

capacity 90 degrees: square 330 mm

450x320

saw band length 4250x34x1,1 mm

band speed 40 + 80 m/min

table height 845 mm

saw band width 34 mm

total power requirement 2,2 kW

weight of the machine ca. 0,985 t

dimensions of the machine ca. 1,4 x 2,0 x 2,2 m

Double miter band saw, hydraulic semi-automatic, DGS 350/450 HA-I

· miter left + right 60° without machine conversion

· 34 mm saw blade width

· Large material support turntable, ball bearings

· To position the saw blade guides using a very wide linear guide

· Strong, robust transmission

Knsdpfx Aofgyicjffof

· Large chipboards

· Infeed and outfeed roller

Removable chip tray (disinfection)

· Free-standing control panel, safe and ergonomic

· Storage space for tapes, consumables

· Cutting pressure regulator Feed regulator

· Fully hydraulic vise

Preload super fast (front loading)

· Material height sensor (automatic cut start detection)

Semi-automatic function:

1. Clamp material

2. Saw starts

3. Rapid lowering to the start of the material or the same for series cutting

cut

4. Saw band off

5. Raise the frame to just above the material

6. Open the vise

Optimum, material-independent cutting result through fine adjustment of the

saw frame by means of:

*Pressure Control Valve (Cutting Pressure Force)

*Feed Control Valve (Speed)

*Switch with pictogram, easy and clear to use

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Slotting head for milling machine, slotting head; mounts in place of vertical milling head, milling

DECKELFP 2

Call

Condition: used, Slotting head, suitable for DECKEL type FP 2 milling machine

Manufacturer No. 2211 / 1895

Dovetail width: approx. 76 - 88 mm

Knsdpswbi Rbofx Affsf

Dovetail height: approx. 14.5 mm

Dovetail length: 320 mm

Dovetail leading edge to gear center: approx. 235 mm

Stroke size: max. 80 mm

Stroke rate: max. 210 double strokes/min.

Tool holder: square, 16 x 16 mm with clamping plate

- Stroke size adjustable via eccentric adjustment

- Driven by the machine gear, within the dovetail guide (as with a normal vertical head)

- This slotting head is inserted into the dovetail guide in place of the normal vertical milling head

(Mounted in place of the vertical milling head, milling head)

- Drive gear in the slotting head, 39 teeth, gear width 16 mm, presumably 20° pressure angle

- Slotting head on the flange plate can be rotated 360°, degree scale +/- 35°

Weight: 32 kg

Very good condition

DECKEL FP1 has a pressure angle of 15° on the drive gear

DECKEL FP2 + FP3 - has a pressure angle of 20° on the drive gear

Trust Seal

Dealers certified through Machineseeker

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Machine

BOSSAR

Call

Condition: used, Year of construction: 2000, Used doy pack filling machine Bossar B 2500

Kedpfxsvgubqo Affenf

Introduction and Structural Composition

In the landscape of technical solutions for packaging, the used Bossar B 2500 doy pack filling machine emerges as an advanced piece of equipment, thanks to its construction features and high-level functionality. Starting from its configuration, the Bossar B 2500 is a horizontal machine, specifically the B2500 L/STU-1 model. This designation is not accidental but indicates its ability to operate with a horizontal arrangement, fundamental for certain types of packaging and to maintain consistent production efficiency. This filling line works in various formats, from 200ml to 1l.

A crucial part of its architecture is the choice of stainless steel for the entire base of the automatic machine. This not only provides significant corrosion resistance but also a rigid and robust structure, which is indispensable in an industrial environment where equipment durability and resistance to various mechanical stresses are essential.

Sensing Technology and Power System of Used Doy Pack Filling Machine Bossar B 2500:

The Used doy pack filling machine Bossar B 2500 integrates an advanced sensing system, the photo sensor, which plays a vital role in ensuring precision during the filling process. Its function is to verify the correct position of the packaging material, preventing errors that could lead to waste or production defects. This technology represents a qualitative leap compared to traditional methods, offering greater operational reliability.

In tandem with the sensor, we find the exit conveyor belt. This component is no less important, as it manages the flow of consumables through the machine, ensuring that there are no interruptions or malfunctions that could compromise the entire production cycle. Its presence is further testimony to the technical sophistication of the Bossar B 2500.

Versatile Dosing Systems and Applications

Continuing the examination, we reach the heart of the filling process: the dosing system. This system, in particular the piston dispenser, is calibrated to deliver a precise volume of product in each cycle. This ensures consistency of dosage and integrity of the final product. The dispensing nozzles are specific to liquid products, while the nozzle tips are designed to handle paste products, underlining the machine’s ability to handle a variety of materials.

Film edge correction is another technical feature that distinguishes this equipment. This functionality is essential to maintain the correct tension and alignment of the packaging film throughout the entire process. The reason is to prevent damage and anomalies.

Conclusion and Final Considerations

The Used doy pack filling machine Bossar B 2500 is not just an assembly of mechanical components. It’s the result of years of innovation in the field of doy pack filling machines. It is important to note that Bossar, the original manufacturer of this line, was recently acquired by another company called SIG.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Hydraulic guillotine shear, cam-guided sheet metal guillotine shear, sheet metal shear, sheet metal

FASTI509 - 25/4

Call

Condition: used, Hydraulic guillotine shears FASTI Type 509 - 25/4

Machine no. No. 5418 Year of construction 1991

Cutting length 2535 mm

Cutting thickness 4 mm

Backgauge 5-1000 mm (controlled)

Cutting angle adjustable

Hydraulic pressure max. 290 bar

Kodpfst Apumox Affjnf

Motor power 7.5 kW

Mains connection 400 Volt, 50 Hz

- Back gauge with positioning control ELGO ELECTRIC type 85

- Sheet holding device under the back gauge

- Manual cutting gap adjustment with dial gauge display right and left

- stepless cutting length adjustment

- Hydraulic cutting angle adjustment via hand pump

- front angle stop left 1300 mm

- 14 sheet hold-down devices

- electric foot switch

- very solid and torsion-resistant welded construction

- 1 set of original FASTI replacement blades (4 pieces, presumably new and unused)

space requirement L x W x H 3100 x 2350 x 1700 mm

weight 3500 kg

good condition

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Power chuck, 3-jaw wedge bar lathe chuck

RÖHMVermutlich Duro 180

Call

Condition: used, Power chuck, 3-jaw wedge bar lathe chuck, type presumably Duro 1802W-411592

Chuck No. K W-411592

Outer diameter: 180 mm

Inner diameter: 45 mm

Thread connection for clamping drive: M52 x 1.5 mm

Cylindrical centering ring mount: Ø 140 mm

Mounting holes: 3x Ø11 mm

Bolt circle: 105 mm

Max. speed: 5000 rpm

Max. clamping force: 3000 daN

Base jaw dimensions (L x W x H): 64 / 74 x 20 x 29 mm

- 1 set of chuck jaws consisting of base jaws and reversible hard top step jaws

- 1 set of chuck jaws consisting of base jaws and reversible soft top step jaws

Knsdpfx Aoxcbmhoffof

- 3 sets of soft top jaws

Weight: 21.5 kg

Good condition

Additional sets of top jaws available under stock number 62056

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Conveyor belt, trough conveyor belt, trough conveyor, belt conveyor, transport belt, belt conveyor f

GASUSFB 400 x 5500

Call

Condition: used, Conveyor belt, trough belt conveyor, trough conveyor, presumably GASUS type FB 400 x 5500

Belt conveyor, transport belt, belt conveyor

Factory number: F Year of manufacture: 1996

Useful length: 5.5 meters

Belt width: 400 mm

Return roller diameter: 225 mm

Return roller width: 450 mm

Belt speed: approx. 30 meters/min

Motor power: 1.5 kW

Kodpfxehz U Azs Affonf

Mains connection: 400 Volt, 50 Hz

- Driven by tube motor

- Infeed hopper 600 x 400 mm

- The idler stations are two-part, troughed

- Metal carrying rollers with maintenance-free ball bearings

- Belt tension adjustable via threaded spindles

- Smooth rubber conveyor belt

- Sturdy tubular steel frame

- Removable cover plate above the belt

- For horizontal or slightly inclined transport of bulk materials

Overall dimensions L x W x H: 6400 x 850 x 950 mm

Weight: approx. 700 kg

Good condition

We make it easier for you to find: "sumab"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sumab (204)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month