Used Gear Testing Machine for sale (95,334)

Grüsch

Grüsch Bevel Gear Grinding Machine

KLINGELNBERGG 27

Düsseldorf

Düsseldorf Gear hobbing machine 1250 mm

LiebherrL1202

Barßel

Barßel Gear hobbing machine

Gleason-PfauterPE300

+44 20 806 810 84

Malsch

Malsch Gear Hobbing Machine - Vertical

MODUL SerWeMaZFWZ 03

Germany

Germany Gear Honing Machine

GLEASON-HURTHZHF 150

Discover more used machines

Düsseldorf

Düsseldorf CNC bevel gear milling machine

GleasonNo 631 CNC

Malsch

Malsch Gear Hobbing Machine - Horizontal

KOEPFER173

Germany

Germany Gear Deburring Machine

PRÄWEMASLV-R1

Malsch

Malsch Gear Deburring Machine

RAUSCHGratomat 300 H

Germany

Germany Gear Hobbing Machine - Vertical

LIEBHERRLC200

Germany

Germany Gear Grinding Machine

LIEBHERRLCS282

Germany

Germany Gear Hobbing Machine - Vertical

EMAGWF180

Germany

Germany Gear Hobbing Machine - Vertical

SAMPUTENSILIS130 CNC Modul

Germany

Germany Gear Hobbing Machine - Vertical

Gleason-PfauterGP 130

Germany

Germany Gear Deburring Machine

MODULCDA 250

Germany

Germany Gear Shaping Machine

LIEBHERRWSC 501

Germany

Germany Gear Shaping Machine

GLEASON PFAUTERP150S

Germany

Germany Gear Hobbing Machine - Vertical

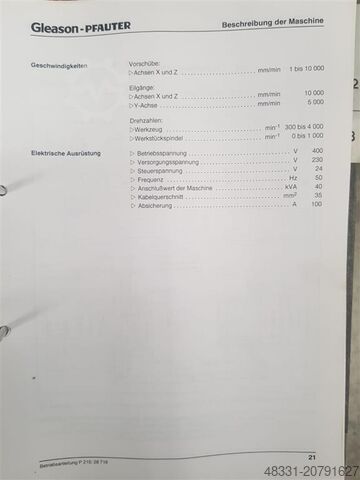

GLEASON PFAUTERP210

Germany

Germany Gear Grinding Machine

KAPPVAS 531 CNC

Germany

Germany Gear Hobbing Machine - Horizontal

GLEASON- PFAUTERP60

Germany

Germany Gear Hobbing Machine - Horizontal

GLEASON- PFAUTERP 100 L

Germany

Germany Gear Shaping Machine

PFAUTERPSA 300

Germany

Germany Gear Grinding Machine

LIEBHERRLCS 182

Germany

Germany Gear Hobbing Machine - Vertical

LIEBHERRLC 80

Germany

Germany Gear Grinding Machine - External

REISHAUERRZ362A

Used Gear Testing Machine (95,334)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84