Used Fruit Juice for sale (807)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gargždai

Gargždai

17,502 km

Fruit and Vegetable Washer

ProFruit MachineryAQUA 3000

Call

Year of construction: 2024, condition: new, Fruit and vegetable washer AQUA 3000 is designed for washing and cleaning fruits and vegetables before processing. Fresh water and soft brushes leave product intact, wash gently and cleanly.

Capacity – 3000 kg/h.

- Entirely made of stainless steel.

- Mounted on pivoting wheels.

- Easy cleaning of the whole washer after use.

- Washer cover can be opened for inspection and cleaning.

- Operation at the central command box.

- The speed of the washer is adjustable – the speed of the washer dictates the capacity of the processing line.

Nwedpfxoflpg Ne Ah Heb

- Gradual exchange of water during the washing: the inflow of fresh water comes in at the exit of the washer, the outflow of the wastewater goes out through the small tube at the entrance of washer.

- Long slide at the outlet for draining fruits and removal of dirt (e.g. leaves, branches, etc.).

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Nwsdpfxeflpnye Ah Hob

Listing

Gargždai

Gargždai

17,502 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Nwsdpfxjflppls Ah Hob

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Gargždai

Gargždai

17,502 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 1000

Call

Year of construction: 2024, condition: new, The fruit washer mill is made from stainless steel. Firstly, the operator of machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 1000 kg/h.

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

Nwjdpfxeflpfbo Ah Heb

- Machine has additional table in front of the basin for putting fruits or boxes on it. It facilitates the process of pouring the products into the basin.

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

- Belt conveyor has a water drainage and speed regulation system.

- The speed of the belt conveyor is adjustable in the control panel.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

- The mill does not damage the fruit seed.

- Machine is easy to clean after using.

- Powerful 2.2 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

- Machine is entirely made of stainless steel.

Listing

Gargždai

Gargždai

17,502 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 3000

Call

Year of construction: 2024, condition: new, The fruit washer elevator mill is made from stainless steel. Firstly, the operator of the machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 3000 kg/h.

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

- Machine has additional table in front of the basin for putting fruits or boxes on it.

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

- Belt conveyor has a water drainage and speed regulation system.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

- The mill does not damage the fruit seed.

- Powerful 4 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

Nedjflpmkepfx Ah Hswb

- Machine is entirely made of stainless steel and easy to clean after using.

Discover more used machines

Listing

Gargždai

Gargždai

17,502 km

Belt press for juice

Profruit machineryPOWERPRESS 800

Call

Year of construction: 2023, condition: new, Belt presses POWERPRESS 800 are designed for pressing fruit, berry and vegetable mass. Fruit mass is placed on the belt which presses it against cylinders.The obtained juice flows in the collection trays under the belt presses. Pressing is continuous.

Capacity: 800 kg/h

The most evolutionary feature of our belt press POWERPRESS line is integrated pump and juice collection tank into the press itself. That means that you save money and do not need an additional juice collection tank and pump which otherwise would use much space and money.

There is a filtration sieve integrated into the juice collection tank. Because of that the machine filtrates the juice even during the pressing stage providing cleaner and more pure product.

Entirely made of stainless steel.

Has adjustable feet.

The belt presses function automatically. When the tank of the mass is full, all other machines which come before belt press turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

Includes High pressure washer.

Nwodpfohu Ab Dex Ah Hsb

Has an integrated pump.

Belt tension is adjustable.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

The cleaning of the belt is automatic with high pressure cleaner, scraper and brush.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Listing

Gargždai

Gargždai

17,502 km

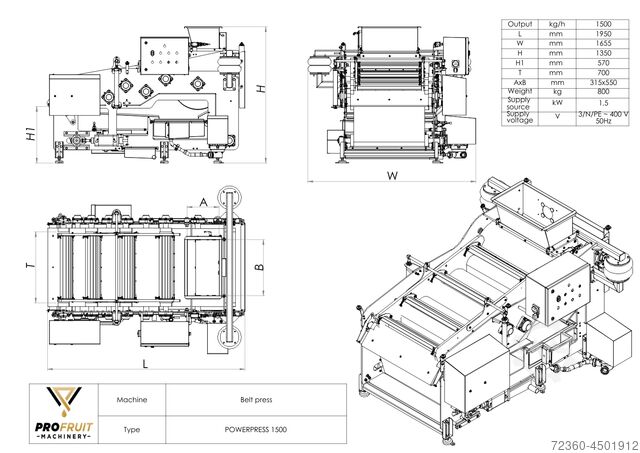

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

Nwjdpfeflpp Eex Ah Hsb

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

17,508 km

Juice Pasteurizer - Filler

ProFruit MachineryROCKET

Call

Year of construction: 2024, condition: new, Pasteurizer-Filler Rocket is used for the pasteurization of juice and other liquid products and filling it to bottles or Bag in Box packaging. The machine has a built-in heating boiler. Inside of it there is a tubular heating spiral made from stainless steel. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria. If the boiler temperature rises more than set, an automatic temperature sensor turns off the heaters. Juice temperature is monitored manually.

Capacity: 150 – 200 l/h

Maximum heating temperature – 90 ºC.

Nwjdpfx Ahoq Nlz To Hsb

-A tubular spiral made of hygienic thin-walled stainless steel.

-Spiral is integrated into the boiler which provides saving of space and prevention of heat loss when pumping the water into external heat exchanger. This saves the heating energy up to 15-20%.

-Pasteurizer has an automatic water temperature control with a digital thermostat.

-Safety sensors for dry run protection. Pasteurizer does not start until the water level is correct.

-Easily interchangeable filling heads to Bag in Box or bottle.

-Bag in Box filling table with scales for weight monitoring.

-Bag in Box closing handle is moved by a spring – this ease the opening and closing process.

-Automatic bottle filling – filling will stop when bottle is full.

-Bottle filling table is adjustable according to bottle dimensions.

-Manual juice temperature monitoring by digital thermometer.

-Fast and easy cleaning.

Listing

Peskojai

Peskojai

17,508 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2024, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Nwodpfx Ahot Rft Uj Hob

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Stary Sącz

Stary Sącz

17,816 km

Filling machine for beverages, juices, and alcohol

STORK VS 24/8 Vacum Glass bottlesAfter general renovation

Call

Condition: reconditioned (used), Year of construction: 2018, STORK VS 24/8 Monobloc Bottling Line, fully refurbished by the professional company Z.M. ROBAK.

The machine is virtually unused, with the protective film still on the housing. Currently, it is set up for filling glass containers – it has been test run for bottling alcohol.

Filling valves: 24 pcs (with light vacuum for still beverages)

Capping heads: 8 pcs (configured for aluminum screw caps)

Output: approx. 7,000 bph (700 ml)

Capable of operating with bottles of the following dimensions (after format adjustment):

- Diameter: 45 mm to 110 mm

- Height: 105 mm to 400 mm

- Standard neck diameter: 28 mm

- Optional neck diameter (after format change): 18 mm to 43 mm

Machine dimensions:

Njdpfju Nhiqjx Ah Hswb

- Width: 2,900 mm

- Height: 2,200 mm

- Depth: 2,200 mm

Weight: 3,200 kg

Installed power: 5.5 kW

Required air pressure: 0.6 MPa

Year of manufacture/modernization: 2018 – has not been used in production since refurbishment

Condition: The machine is practically as new, with negligible signs of use.

The machine comes with original electrical documentation.

Listing

Skopje

Skopje

17,829 km

Bucher press HP5000/ Fruit press

Bucher press HP5000

Call

Condition: excellent (used), Year of construction: 1988, functionality: fully functional, Fully functional and well maintained

Complete with control cabinet, fences and hydraulic unit, valves etc.

Nwjdsw Adkfspfx Ah Hjb

Various fruits such as apples, pears, grapes, berries, raspberries, strawberries, quinces, pectin, carrots and other fruit and vegetable can be processed on this press.

Prompt delivery.

Listing

Szczecin

Szczecin

18,007 km

Line for juice production

Flottweg

Year of construction: 2008, condition: good (used), A complete line for the production and packaging of fruit and vegetable juices. The line consists of machines: fruit-vegetable pulp milling and production line (MEGA bunker hopper, MEGA 2012 rotary sieve, MEGA 2008 batching rung elevator, MEGA 2008 brush dripper, roller inspection conveyor- MEGA 2008, 2017 screw conveyor, pulp impeller pump, pulp tank, belt press-FLOTTWEG 2008, rinse water tank-FLOTTWEG 2008, juice cooling system- STM 2018), packaging line (triblock arrow-STM 2014, buffer tank STM 2014, bottle orientator STM 2013, capping machine STM 2013, HITACHI printer 2016, labelling machine 2018).

We also have a second smaller bottling and packaging line for sale.

Nwedpfx Aepqxvxeh Hob

Listing

Privalj

Privalj

18,155 km

Wine and juice filtering machine

cadalparotating vacuum filter caldapa

Call

Condition: ready for operation (used), vacuum filter used in the winery

Nwedpfxevq Ntpe Ah Hob

Listing

Piera

Piera

19,459 km

Vegetable and fruits puree line

MARRODAN

Call

Year of construction: 2009, condition: good (used), functionality: fully functional, Production of 2000 kg/day (6h)

Composed of:

URBASA Q908.010b slicer

MARRODAN PR32318 B/T elevator to load scalder. With PVC/Polyurethane 3C 500 band with studs. overall length: 3000mm. useful width: 500mm. Power 0,37 Kw

MARRODAN PR32217 Linear mesh scalder, for vegetable products.

Nsdpov Ivcxefx Ah Hswb

The regulation of the scalding/hydrating system is carried out by means of a temperature controller connected to a PT100 probe. The forward speed is regulated by a frequency variator.

Basic construction in AISI 304 STAINLESS STEEL

Polypropylene mesh type A-1061mm

Total installed power: 4.7kW

Group of 2 pulping machines and 250-litre heated tanks for mixing and cooking

INOXPA HYGINOX SE centrifugal pump of STAINLESS STEEL, driving the product to exchanger.

UNICUS type HRS dynamic heat exchanger with scraper device to increase the heat transmission coefficient

AVAILABLE DOCUMENTATION

Listing

Emmeloord

Emmeloord

18,487 km

Fruit and vegetable processing

EillertC-25-H

Call

Condition: used, * Constructie: RVS 304

* Vulinhoud: ± 25 kg.

Plug and play potato scrambler.

TECHNICAL DATA

- Capacity: ± 450 kg per hour input. Depending on the type of product, desired scraping/peeling time, the quality of the product and the speed of the operator

- Construction : stainless steel 304

- Filling capacity: ± 25 kg

- Maximum product diameter: 150 mm. Capacity ± 100 – 600 kg. per hour depending on the type and quality of the product and the desired cutting size

- Control box : Integrated in machine

- Power supply : 400 Volt, 50 Hz, 3 phase + earth + neutral (European standard). 24 Volt on control buttons

- Number of engines : 1

- Total electricity consumption : max. 1.1 kW/hour

- Connection value : 3.3 Amp

- Plug : 16 A CEE, 5 pin

- Water consumption : Max. approx. 450 ltr/hour (adjustable as required)

- Air consumption (automatic only) : Depends on scraping time

- Weight: ± 200 kilos, unpackaged

- Quality mark : CE standardized

Nedpfxsku H Nas Ah Howb

- Build in 2005

Listing

Germany

Germany

18,384 km

Robot Arm

FruitcoreHorst600 Fast

Call

Condition: ready for operation (used), Year of construction: 2019, This 6-axis Fruitcore Horst600 Fast robot arm was manufactured in 2019. It features a nominal load capacity of 3 kg, a maximum range of 584 mm, and operates quietly at less than 70 dB(A). The robot arm is designed for a compact installation area of 382 × 200 mm and is protected by an IP54 class. If you are looking to get high-quality automation capabilities, consider the Fruitcore Horst600 Fast machine we have for sale. Contact us for more information.

Application Types

Robotics

Nedpfxox D Nbvj Ah Hjwb

Listing

Gargždai

Gargždai

17,502 km

Destoning & Pulping Machine

Profruit machineryDESTONE

Call

Year of construction: 2024, condition: new, The inside of a destoning pulping machine consists of a screw, that is mounted in the middle, and sieve, that is attached to the sides of the machine. After the fruits or berries are loaded into the destoning and pulping machine, the screw fastly rotates the product and this way presses it through the sieve. This way machine presses clear fruit or berry puree through the sieve without any stones and peel. Stones, seeds and peel leave the machine through a special outlet. The puree comes out of machine through a separate outlet.

Available different capacities: 500 L/h, 1000 L/h, 2000 L/h.

For further processing and thinner puree, the pulping process can be repeated with another sieve or puree can be further loaded into the pneumatic press.

For further processing and thinner puree, the pulping process can be repeated with another sieve. Puree can also be further loaded into the belt press or rotational filter.

Machine comes with one integrated sieve. Client can order additional sieves according to his needs.

Destoning & pulping machine functions automatically.

Machine is easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Machine is entirely made of stainless steel and has pivoting wheels.

Available sieve options:

With 0,6-2 mm holes – for pressing puree from berries with small seeds or for repetitive pulping process of already destoned pulp.

With 3 mm holes – to get a puree from crushed pome fruits, such as apples, pears, guavas, etc.

With 3 or 5 mm holes – for cherries and small plums.

Nodpfx Aohu Aa Rjh Howb

With 8 mm holes – for bigger plums, apricots, peaches.

With 10 mm holes – for mangoes and similar fruits.

Listing

Gargždai

Gargždai

17,502 km

Diesel Pasteurizer

ProFruit MachineryHEAT 1000

Call

Year of construction: 2024, condition: new, Diesel/gas pasteurizer pasteurizes various liquids before the filling process. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria.

One of our highest machinery achievements is our energy-saving solution integrated into our pasteurizers. It saves the heating energy up to 15-20 % and results in incredibly low heating costs. Calculations show that it costs up to 2 Euro Cents to pasteurize 1 liter of liquid.

Capacity per hour – 900-1250 L of 80 ºC (176 °F) heated juice.

The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

Nwjdjflq Sgjpfx Ah Hjb

The maximum heating temperature of pasteurizer is 90 ºC (194 °F).

Our pasteurizers are equipped with highest quality German diesel and gas burners GIERSCH.

The heating power is 110 kW.

Pasteurizers’ heating chambers are covered with special heat-insulating paint which preserves high temperature for a longer time and increases heating capacity.

Diesel/gas pasteurizer has a digital thermostat which provides an automatic water temperature control.

Automatic regulation of juice temperature ensures an easy way to change the filling temperature on digital display.

The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20%.

Machine can use diesel or gas on client’s request.

Diesel/gas pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

17,502 km

Automatic Bag in Box Filler

ProFruit MachineryAUTOFLOW Filler

Call

Year of construction: 2024, condition: new, Machine fills packages fully automatically by pressing one button. Just insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag. The full filling process of 3 L bag takes ~7 seconds.

Nwodpfxjflrkuj Ah Heb

Capacity – 300 pcs. of 3 L bags per hour.

- Bag in Box filler AUTOFLOW is extremely versatile. It is perfect for filling various liquids: from juice, wine, milk, broth, oil, to cream, coffee, ice cream, soap, motor oil, chemicals, etc.

- Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L. It is also possible to fill 220 L bags with a special filling gun.

- Suitable for both hot and cold filling.

- The filler can have optional interchangeable filling heads. This way with one filler you can fill bags with different closures, such as tap, milk tube, screw cap, simple cap, etc.

- Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

- High-quality automatic filling head provides stable and smooth filling process.

- The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

- The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

- Error of volume repeatability is just ± 0,5 %.

- Filler comes with a touchscreen panel and multi-language menu.

- Easily adjustable filling table allows to easily fill different volumes of Bag in Box & Stand up Pouch packages.

- The filler is easy to clean after work with external and CIP cleaning.

- Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT 1000. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

17,502 km

Bag in box filler MINIFLOW

PROFRUIT MACHINERYMINIFLOW

Call

Year of construction: 2024, condition: new, A small, table version semi-automatic Bag in Box filler is an easy, economical and mobile solution for filling liquids into Bag in Box or Stand up Pouch packages. Insert the bag or pouch into the filler and pull the handle – the package is filled automatically. Return the filling handle into the start position, cap the bag and the filling process is finished.

Nwjdpfxeh S H A Ie Ah Heb

- Capacity ~250 pcs. of 3 L packages (depending on the pump).

- The weight of the machine is only 50 kg so it is especially easy to move or transport from one facility to another.

- There are two options of the machine: with or without pump. When purchasing machine without pump, you can connect your own pump or fill the packages by gravity.

- Hot and cold filling of bags and pouches is possible from 0,5 liter up to 20 liters.

- The machine is suitable to fill both Bag in box and stand up pouch packages with a tap.

- Bag in Box filler pre-vacuums the bags and pouches before filling.

- Machine comes with touchscreen panel and a multi-language menu.

- Repeatability of volumes with an error of ± 0,5 %.

- Easy-to-adjust filling table for different volumes of bags and pouches.

- Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

- The filler is easy to clean after work with external and CIP cleaning.

- The filler is reliable, simple and easy to use and maintain.

Listing

Gargždai

Gargždai

17,502 km

Bath pasteurizer for bottles

ProFruit MachineryBath pasteurizer for bottles

Call

Year of construction: 2024, condition: new, Bath pasteurizer option is the perfect solution for post fill pasteurization of your bottled or canned products. 97 units of standard 0.75 L bottles easily fits in 4 baskets.

Our bath pasteurizers can be produced in two options:

1. Autonomous bath pasteurizer with electric heating elements and integrated control panel.

2. Bath pasteurizer as an option together with HEAT or ECOHEAT pasteurizers. Then water heating is done with our pasteurizer and the same control panel is used for controlling both devices.

Features:

Mounted on pivoting wheels.

Insulated heating bath to save the energy and temperature.

Can be used for glass bottles, jars, cans, any other heat resistant package.

Works with different products, like juices, jams, marmalades, puree, sauces, etc.

Automatic temperature and time control.

Water overflow protection.

Fast and easy loading and unloading of bottle trays.

Entirely made of stainless steel.

The bottles, cans, or jars are loaded into the trays and then trays are loaded into the bath. The desired pasteurization temperature and holding time settings can be set simply using the integrated control panel or on the HEAT or ECOHEAT pasteurizers.

At a start of process, bottles or jars are placed into the bath, then water is filled into the bath until it reaches bottle neck. Then pasteurizer is connected, temperature (max 90 C⁰) and time is set. Then it starts to heat up the water inside the bath. When set temperature is reached, timer turns on and pasteurization is started. In the meantime, in the new set of trays filled bottles can be loaded for a faster exchange process.

Nsdpfx Ahsrif Sms Hswb

When timer ends, water out of the bath pasteurizer is released and bottles are unloaded.

As the temperature is only measured in the bath, it is important to monitor the core temperature of your product to ensure that adequate pasteurization has been achieved.

Trust Seal

Dealers certified through Machineseeker

Listing

Gargždai

Gargždai

17,502 km

Screw conveyor

ProFruit MachineryScrew conveyor

Call

Year of construction: 2024, condition: new, The leftover fruit, berry or vegetable mash enters the loading hopper of the screw conveyor. The screw inside the machine is continuously turning and this way transports the mash from the loading hopper to the exit outlet at the top of the machine. The mash exits the machine.

Screw conveyor is made of stainless steel.

Machine has a closed tunnel.

Njdpfxoizbffo Ah Howb

Conveniently transports leftover pressed mash from press.

Listing

Gargždai

Gargždai

17,502 km

Bin tipper

Profruit MachineryUNLOADER 800

Call

Year of construction: 2024, condition: new, It is a first processing step during which machine transfers fruit, vegetable or berries to the next stages of processing: washing, sorting or crushing. Bin tipper lifts the box and pours out the products into sorting conveyor, AQUA or MAXIMILL.

Bin tipper is entirely made of stainless steel.

Machine has a hydraulic drive.

Nsdpfsichbbox Ah Howb

Controls of the machine are very simple: just put the box in and move the control handle to lift it up.

Suitable for boxes with different dimensions. Max size: 120x120x85.

Loading power – 800 kg.

Listing

Gargždai

Gargždai

17,502 km

Manual bottle filler GRAVITY

ProFruit MachineryGRAVITY

Call

Year of construction: 2024, condition: new, The manual bottle filler is specially easy to use. The filling mechanism works on the basis of gravity. The handle is pulled down and the strong stream of liquid flows out of the head.

Nwjdpfoizbb Hjx Ah Hsb

Capacity – 600 pcs. of 0,5 L bottles per hour.

The bottle filler is completely made of stainless steel.

Gravitational mechanism provides a strong stream as well as easy and effective work.

Comes with a buffer tank for fluid.

Buffer tank has an integrated flowmeter which helps to follow the liquid level on the buffer tank.

Suitable for various liquids that are similar to water consistency such as juice, wine, vodka, etc.

Mounted on the pivoting wheels.

Listing

Gargždai

Gargždai

17,502 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2023, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Capacity – 250 pcs. of 3 L bags/h

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Nwodpfx Aeflriueh Hob

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

We make it easier for you to find: "fruit juice"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Fruit Juice (807)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month