Used Dare Force for sale (6,106)

Auckland

Auckland Large Format Heat Press

Geo KnightMaxi-Press

Zheng Zhou Shi

Zheng Zhou Shi Crushing unit

Construction &Delolition Waste RecyclingPE600x900 stone crusher

Menslage

Menslage ALWID ATEX Filling Line (2021)

ALWIDAbfülllinie

+44 20 806 810 84

Heilbronn

Heilbronn Press Brake

MegobalPB 20.35

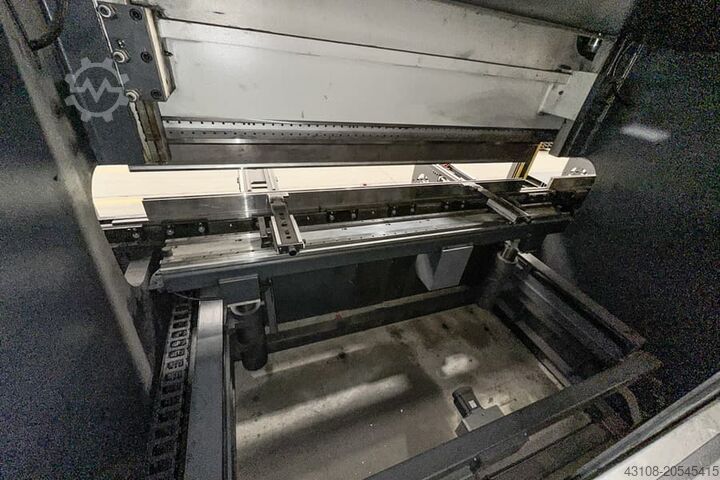

Heilbronn

Heilbronn Press Brake

TrumpfTrubend 3066

Discover more used machines

Austria

Austria Folding Machine

FINTEKAMH 2035

Hannover

Hannover Injection molding machine

EngelVC 750 / 220 Spex

Eilenburg

Eilenburg High top van

FORDTransit Kasten 350 L3H3 MH Trend Klima Tempomat

Eilenburg

Eilenburg Panel van

FORDTransit Custom Kasten 280 L1H1 LKW Trend Klima

Częstochowa

Częstochowa Cart

CEIT FTS3000 AFR

Częstochowa

Częstochowa Press brake

DENERPX 30320

Częstochowa

Częstochowa Laser cutting machine

AmadaHFE M2 2204 8 AXESL

Częstochowa

Częstochowa CNC press brake BYSTRONIC HÄMMERLE BM 20

BystronicHÄMMERLE BM 200 - 4100

Częstochowa

Częstochowa Injection molding machine

ARBURGAllrounder 270-S-500-60

Częstochowa

Częstochowa Injection molding machine

ARBURGAllrounder 270S-500-60

Częstochowa

Częstochowa Injection molding machine

ARBURGAllrounder 270-M-500-90

Częstochowa

Częstochowa Plate shear

EHTASS 8-30

Częstochowa

Częstochowa Press brake

BaykalAPHS 3106x120

Częstochowa

Częstochowa Pneumatic press

Schmidt24

Częstochowa

Częstochowa Injection molding machine

ARBURGAllrounder 270-S-500-60

Częstochowa

Częstochowa Run press

AmadaHFB 80

Częstochowa

Częstochowa Industrial robot

Universal RobotsUR10-CB3.1

Częstochowa

Częstochowa Press brake

AMADAITPS III

Częstochowa

Częstochowa Industrial robot

FANUCLR Mate 200iD/7L auf einer Bahn

Częstochowa

Częstochowa Injection molding machine

ARBURGAllrounder 370S-500-100

Used Dare Force (6,106)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84