Used Brochure Production for sale (16,377)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Production line for rock & concrete processing

Henan Mingyuan sand production line50-600 t/h sand gravel production line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, 🚧 50-600 T/H Sand & Gravel Production Line – Transforming Raw Materials into High-Quality Aggregates! 🚧

🌟 General Introduction

Looking for a reliable and efficient solution for your sand and gravel production needs? Our 50-600 T/H Sand & Gravel Production Line is a high-performance system designed to meet the diverse requirements of construction, infrastructure, and industrial projects. Whether you need coarse aggregates or fine sand, this production line ensures precision, efficiency, and scalability.

---

🏗️ Wide Range of Applications

Our sand and gravel production line is perfect for:

- Construction Projects: Producing aggregates for concrete, asphalt, and roadbeds.

Rsdpfeq Nywxsx Ahzjbt

- Mining Operations: Processing various ores and minerals.

- Infrastructure Development: Creating high-quality materials for bridges, dams, and highways.

- Commercial Sand Supply: Meeting market demand for sand and gravel in bulk.

---

💎 Key Advantages

### 1. High Capacity & Versatility

- Produces 50-600 tons per hour, easily scaling to match project demands.

- Handles a wide range of raw materials, including limestone, granite, basalt, and river stones.

### 2. Advanced Technology

- Incorporates cutting-edge crushing, screening, and washing equipment for consistent quality.

- Optimized for energy efficiency, reducing operational costs.

### 3. Customizable Solutions

- Configurable to meet your specific requirements, from particle size to layout design.

- Offers flexibility in combining different crushers (jaw, cone, impact) and vibrating screens.

### 4. Durable & Low Maintenance

- Built with robust materials to withstand heavy-duty operations.

- Easy-to-maintain design minimizes downtime and extends equipment lifespan.

### 5. Environmentally Friendly

- Features dust suppression systems and water recycling units to reduce environmental impact.

- Promotes sustainable practices in aggregate production.

---

🚜 Your Complete Solution

Our production line includes:

- Primary Crushing: Breaks down large rocks into manageable sizes.

- Secondary Crushing: Refines materials to desired specifications.

- Screening Equipment: Ensures uniform sizing and quality control.

- Washing System: Removes impurities for cleaner, higher-grade aggregates.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Stone crushing production lineStone crushing screening plant

Call

Condition: new, Year of construction: 2025, A stone crushing plant for sand and aggregate making is a facility where stones and rocks are crushed into smaller pieces or gravel. It typically includes several stages of crushing and screening to produce various sizes and grades of sand and aggregate materials, which are essential in construction, landscaping, and other applications. Here's an introduction to the components and processes involved in a typical stone crushing plant:

### Components of a Stone Crushing Plant

1. Primary Crusher:

- Purpose: The primary crusher, often a jaw crusher or gyratory crusher, initially breaks down large rocks into smaller pieces.

- Function: It handles raw materials from the quarry or mine and prepares them for further processing.

2. Secondary Crusher:

- Purpose: A secondary crusher, such as a cone crusher or impact crusher, further reduces the size of the crushed stones.

- Function: It refines the material after primary crushing, producing smaller and more uniform-sized aggregates.

Rbedpfx Ahoq N U Duszet

3. Tertiary Crusher (Optional):

- Purpose: In some configurations, a tertiary crusher like a vertical shaft impactor (VSI) may be used for shaping and fine crushing.

- Function: It produces finely crushed materials for specific applications, such as concrete production or road base.

4. Screening Equipment:

- Purpose: Screening equipment like vibrating screens or trommel screens separates the crushed materials into different sizes.

- Function: It classifies the aggregates into various grades according to size, ensuring uniformity and meeting specifications.

5. Conveyor Systems:

- Purpose: Conveyor belts transport materials between different stages of crushing and screening.

- Function: They ensure efficient material handling and continuous operation within the plant.

6. Washing Equipment (Optional):

- Purpose: Washing equipment, such as sand washers or scrubbers, may be used to remove impurities from sand and aggregate products.

- Function: It improves the quality of the final products by cleaning them and removing fines or contaminants.

### Processes Involved

- Primary Crushing: Large rocks are fed into the primary crusher and reduced to a manageable size.

- Secondary Crushing: The crushed materials from the primary crusher are further processed by secondary crushers to achieve the desired aggregate sizes.

- Screening: The crushed and sized materials are screened to separate them into different sizes and grades.

- Material Handling: Conveyor systems transport materials between different stages of the crushing and screening process.

Final Product Handling:Finished products, such as sand and various sizes of aggregates, are stored or loaded for transport to customers or construction sites.

Applications

- Construction: Used in the production of concrete, asphalt, and road base materials.

- Landscaping: Provides decorative and functional aggregates for gardens, pathways, and driveways.

infrastructure: Essential for building foundations, drainage systems, and structural fill.

As for the capacity we have 30 t/h, 30-50 t/h, 50-100 t/h, 100-150 t/h, 150-200 t/h, 200-300 t/h, 300-500 t/h, and both stationary crushing plant and mobile crushing plant are available for option.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing equipment

Sand Aggregate crushing production lineAggregate & Ballast Crusher Equipment

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Aggregate and ballast crusher equipment are used in the crushing and processing of various materials for construction and infrastructure projects. These crushers are designed to break down large rocks, gravel, or stones into smaller pieces, producing aggregates and ballast that are essential components in the construction industry. Here are some key aspects related to aggregate and ballast crusher equipment:

1. Jaw Crusher:

- Jaw crushers are commonly used for primary crushing in aggregate and ballast production. They operate by compressing the material between a stationary and a movable jaw.

2. Impact Crusher:

- Impact crushers are suitable for shaping and producing fine aggregates. They use impact force to crush the material, making them suitable for various types of rock and ore.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They are efficient for producing well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They use the "rock-on-rock" crushing principle, where rocks are fed into the rotor to be accelerated and crushed against the stationary anvils.

5. Gyratory Crusher:

- Gyratory crushers are primarily used in mining, but they may also be used in the production of aggregates. They have a conical head and a concave surface, which crushes the material between the head and concave.

6. Mobile Crushers:

- Mobile crushers, including mobile jaw crushers and mobile impact crushers, provide flexibility and mobility for on-site crushing of aggregates and ballast. They are often used in construction projects where materials need to be processed directly at the job site.

7. Screens and Scalpers:

- Screens and scalpers are used to separate different sizes of aggregates after the initial crushing stage. Vibrating screens are commonly employed to classify and separate materials based on size.

8. Conveyors:

- Conveyors are crucial for transporting materials between various stages of the crushing process and for stockpiling the final products. They enhance efficiency in material handling.

9. Dust Suppression Systems:

- Crushing operations can generate dust, and dust suppression systems are used to minimize environmental and health impacts. These systems may include water sprays or chemical suppressants.

10. Quality Control:

- Quality control measures, such as particle size analysis and gradation testing, are essential to ensure that the produced aggregates and ballast meet the required specifications and standards.

11. Environmental Considerations:

- Crusher equipment should adhere to environmental regulations, and measures like dust control, noise reduction, and proper waste disposal should be implemented.

Rsdpfxjq Nxrxo Ahzobt

When selecting aggregate and ballast crusher equipment, factors such as the type of material, required product size, production capacity, and mobility requirements should be taken into consideration. Additionally, adherence to safety and environmental standards is crucial in the operation of crushing equipment.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Powder equipment for sand & micro powder

Mingyuan Powder production equipment1.83X11m Micro Powder Ball Grinding Mill

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Ball Mill with Air Classifier: The Ultimate Powder Processing Equipment

In the world of industrial powder production, precision, efficiency, and flexibility are paramount. Whether producing ultra-fine powders for high-tech applications or coarser materials for everyday products, the combination of a Ball Mill with Air Classifier offers unparalleled performance. This dynamic duo provides a comprehensive solution for industries ranging from chemicals and ceramics to paints, plastics, and pharmaceuticals.

This article introduces the ball mill with an air classifier, explores its applications, and highlights the key advantages of this essential powder equipment.

General Introduction to Ball Mill with Air Classifier

ball mill with air classifier is an advanced grinding and classification system designed for efficient, high-quality powder production. The system consists of two main components:

1. Ball Mill: A cylindrical grinding device filled with grinding media (such as steel balls) that operates by rotating around its axis. The raw material is reduced to smaller particle sizes through impact and friction within the mill.

2. Air Classifier: A sophisticated device that separates particles based on size using airflow. Fine particles are carried away, while coarser particles are returned to the ball mill for further grinding.

The combination of these two components creates a closed-loop system that ensures consistent particle size distribution, high efficiency, and minimal waste.

Rbjdpfx Ahsvlwkxjzjt

Applications of Ball Mill with Air Classifier

The ball mill with air classifier is a versatile solution used in a wide range of industries to process various materials. Key applications include:

1. Mineral Processing

The system is widely used in the production of minerals such as calcium carbonate, quartz, feldspar, and talc. These finely ground minerals are essential for industries like ceramics, paints, plastics, and rubber.

2. Cement and Construction Materials

Cement and other construction materials require precise particle size control for optimal performance. The ball mill with air classifier ensures uniformity and enhances the quality of construction materials.

3. Chemicals and Pharmaceuticals

Fine powders play a critical role in the chemical and pharmaceutical industries. From active pharmaceutical ingredients (APIs) to industrial chemicals, this system delivers the consistent quality required for these applications.

4. Paints, Coatings, and Pigments

The production of paints and coatings demands ultra-fine powders to achieve smooth finishes and vibrant colors. The ball mill with air classifier produces high-quality powders for superior results.

#### 5. Food and Agriculture

Food-grade powders such as additives, preservatives, and agricultural products like fertilizers can be efficiently processed using this system, meeting stringent regulatory requirements.

Industries That Benefit from Ball Mill with Air Classifier

Several industries rely on the capabilities of this system to produce fine powders with specific characteristics:

- Ceramics: Produces high-purity powders for tiles, insulators, and advanced ceramics.

- Rubber and Plastics: Creates fillers and additives for improved durability and performance.

- Pharmaceuticals: Ensures consistent particle size for APIs and excipients.

-Construction: Delivers materials for concrete, plaster, and other applications.

Listing

Latvia

Latvia

17,265 km

Metal rainwater system production line

metal rain water system production line

Call

Condition: used, Rain gutter, downpipe and elbow forming machines, complete line. Three machines.

1. Rain gutter forming machine, strip cutting with band saw.

Produced gutter diameter: 80 x 100 mm

Used sheet metal dimensions:

Redpfx Asv Evctshzjbt

Width: 350 mm.

Thickness: 0.43 – 0.55 mm.

2. Downpipe forming machine, can form 127 mm and 152 mm (standard) sizes. Cutting with guillotine.

Used sheet metal dimensions:

Width: 300 mm.

Thickness: 0.43 – 0.55 mm.

3. Elbow forming machine: 400V/3

If you have any further questions, we will be happy to answer them.

Discover more used machines

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

18,542 km

3d printer

MarkforgedFull Metal X Production Farm

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2021, operating hours: 3,300 h, No reserve price – guaranteed sale to the highest bidder!

Auction of a complete additive manufacturing production facility comprising several metal printers, sintering and washing units, as well as additional composite printers! The offering includes the following components:

3 Metal X

1 Sinter II

Rsdpfx Ajyc Ub Tshzobt

1 LMI Washing Unit

1 Mark Two Plastic Printer

1 OnyxOne Plastic Printer

MACHINE DETAILS

Operating hours: 3,300 h

EQUIPMENT

- Regularly serviced and maintained

- Intuitive operation via touch displays

- Software for print preparation and completion

- Processing of a wide range of metal materials

- Complete solution from design to finished component

- Easy integration into existing setups

Listing

Newton Aycliffe

Newton Aycliffe

18,490 km

Olive Oil Production Line with Capacity 7 Tons/hour

PIERALISI7 TPH

Call

Condition: used, Used olive oil production line with output capacity of 7 tons/hour. The equipment was made by Pieralisi in 2004 and is currently still in operation.

Major equipment includes:

- Leaf remover

Rsdpfx Ahsx Nim Sozsbt

- Olive washing machine

- Olive crusher

- 700 litre Malaxer Panorama

- 1000 litre Malaxer Panorama

- Electric panels

- Decanter centrifuge Elephant S 470/2

- Vibrator filter for Elephant S 470/2

- Decanter centrifuge Jumbo 2

- Decanter centrifuge Major 3

- Vibrator filter for Major 3

- Separator 1500-2000

Full equipment list on request.

Listing

Reiden

Reiden

18,777 km

Band saw

BomarProduction 280

Call

Condition: excellent (used), Saw blade dimension 4910x34x1.1 mm

Cutting speed 20-120 m/min.

Feed length single stroke 750 mm

Max. Feed length 9999 mm

Electrical equipment

Supply voltage ~3x400V,50Hz,TN-C-S/TN-C

Total connected load 8.5 kW

Max. Fuse rating 25 A

Redpfxstp Tcgo Ahzobt

Protection class IP 54

Sound pressure level

Production 280 78 dB

Drive unit

Type MDERAXX 100-32J B14

Supply voltage ~3x400V,50Hz

Power 3 kW

Nominal motor speed 1420 m/min.

Hydraulic unit

Type 92.001.048 (731-0507)

Power 6.5 MPa/2.2 kW

Coolant device

Type 3COA4-12

Volume of coolant 40 dm3

MICRONISER possible

Machine size

LxWxH 2370x1600x2050 mm

Machine weight

Weight 1800 kg

Listing

Sierakowska Huta

Sierakowska Huta

17,772 km

Parquet production line

FOD BYDGOSZCZ*DDCA DDGA

Call

Condition: excellent (used), CATALOG NUMBER 7816

TECHNICAL DATA

Rbjdpsxxxbnsfx Ahzjt

DDCA

- Maximum batten length: 85 mm

- Minimum batten width: 180 mm

- Maximum batten width: 845 mm

- Minimum batten height: 10 mm

- Maximum batten height: 45 mm

- Spindle diameter: 30 mm

- Maximum blade diameter: 250 mm

- 5 spindles:

- Left side:

1) Vertical top spindle 2.2 kW

2) Horizontal bottom spindle 2.2 kW

- Right side:

1) Vertical bottom spindle 2.2 kW

2) Vertical top spindle 2.2 kW

3) Horizontal bottom spindle 2.2 kW

- Spindles adjustable up/down, right/left

- Material hold-down: 2 pcs

- Stepless feed speed adjustment: 0–10 m/min

- Spindle diameter: 5x100 mm

- Dimensions (L/W/H): 1870/2230/1320 mm

DDGA

- Maximum batten width: 130 mm

- Maximum batten height: 100 mm

- Spindle arrangement:

1) Bottom spindle 5.5 kW

2) Right spindle 5.5 kW

3) Left spindle 5.5 kW

4) Top spindle 5.5 kW

- Spindles adjustable up/down

- 6-knife cutterheads mounted on top and bottom spindles

- Spindle diameter: 40 mm

- Shaper cutters mounted on right and left spindles, max diameter 50 mm

- Spindle diameter: 30 mm

- 2 feed speeds: 4.9 kW

- Central chain lubrication by oil pump

- Spindle diameter: 4x125 mm

- Dimensions (L/W/H): 3100/1300/1700 mm

ADVANTAGES

- Manufactured in Poland

- 5 spindles

- Unpainted

- Very good condition

- Used production line

- High quality, low price

Net price: 52,900 PLN

Net price: 12,600 EUR

Net price calculated at an exchange rate of 4.2 PLN/EUR

(In the event of significant exchange rate fluctuations, the price may change)

Listing

Sierakowska Huta

Sierakowska Huta

17,772 km

Parquet production line

FOD BYDGOSZCZ*FLPA DDCA DDGA

Call

Condition: excellent (used), Catalogue number: 7817

TECHNICAL DATA

DDCA - Double-End Tenoner

- Minimum panel width: 180 mm

- Maximum panel width: 850 mm

- Minimum panel height: 10 mm

- Maximum panel height: 45 mm

- Spindle diameter: 30 mm

- Maximum blade diameter: 250 mm

- 4 blades included

5 spindles:

Left side:

1) Top vertical spindle 2.2 kW

2) Bottom horizontal spindle 2.2 kW

Right side:

1) Bottom vertical spindle 2.2 kW

2) Top vertical spindle 2.2 kW

3) Bottom horizontal spindle 2.2 kW

- Spindles adjustable up/down and left/right

- 2 material hold-downs

- Stepless feed speed adjustment: 0–10 m/min

- Central lubrication via oil pump

- Pump motor: 2.2 kW

- Extraction port diameter: 5 x 100 mm

- Dimensions (LxWxH): 1900 x 2230 x 1530 mm

DDGA - Four-Sided Planer

- Maximum panel width: 130 mm

- Panel height: 10–60 mm

- Minimum workpiece length: 200 mm

Spindle arrangement:

1) Bottom spindle 5.5 kW

2) Right spindle 5.5 kW

3) Left spindle 5.5 kW

4) Top spindle 5.5 kW

- Spindles adjustable up/down

- Top and bottom spindle diameter: 40 mm

- Right and left spindle diameter: 30 mm

- 4 feed speeds: 13/20/26/40

- Central chain lubrication via oil pump

- Extraction port diameter: 4 x 120 mm

- Dimensions (LxWxH): 3200 x 1370 x 1830 mm

Rbodpoxwytijfx Ahzjt

DBCA - Tenoner Infeed Conveyor

- Maximum feed speed: 40 m/min

- Maximum panel width: 150 mm

- Motor: 0.55 kW

- Overall dimensions (LxWxH): 2320 x 600 x 1150 mm

DBGA - Strip Infeed Conveyor

- Strip length: 200–600 mm

- Strip width: 30–120 mm

- Strip thickness: 10–40 mm

- Stepless feed speed adjustment: 10–40 m/min

- Motor: 0.75 kW

- Overall dimensions (LxWxH): 1500 x 500 x 980 mm

- Total weight: approx. 4900 kg

– Polish production

– DTR technical documentation included

– 5 spindles

– Unpainted

– Very good condition

– Used machine

Net price: 63,900 PLN

Net price: 15,200 EUR, according to the exchange rate of 4.2 EUR

(Prices may vary according to exchange rate fluctuations)

* MAR-MASZ guarantees the quality of your purchase, but is not an authorized representative of the manufacturer. All trademarks and names are used purely for informational purposes to allow identification of the goods. We only resell items that have already been put on the market by the manufacturer. We have no business relationship with the manufacturer.

Listing

Thisted

Thisted

17,992 km

Milk & dairy production

Alfa LavalType: MRPX 314 HGV-74C

Call

Condition: used, Year of construction: 1996, Item: AL-010188-Alfa Laval Separator MRPX314HGV-74C

Alfa Laval MRPX 314 HGV-74C Milk Clarifier Separator

Pre-owned Alfa Laval MRPX 314 HGV-74C self-cleaning clarifier separator in stainless steel construction.

Manufactured by Alfa Laval Separation A/S, Søborg, Denmark.

Complete unit in good used condition – ideal for clarification of milk or other low-solids dairy liquids.

Technical Details

Type: MRPX 314 HGV-74C

Manufacturing No.: 2969923

Product No.: 881007-01-00

Bowl speed: approx. 8,000 rpm

Drive motor: approx. 11 kW

Operation: self-cleaning (automatic sludge discharge)

Material: acid-resistant stainless steel (AISI 316 L)

Bowl volume: approx. 6 L

Capacity: up to 10,000 L/h for milk clarification

Design: hermetic bottom feed with paring-disc liquid outlet

Features

• Continuous separation of milk and whey with minimal product loss

• Gentle, hermetic feed system – prevents air entrainment and foaming

• Automatic solids discharge system

• Includes complete bowl assembly:

- Top Part No.: 538544-80

- Bowl No.: 537872-80

- Bottom Part No.: 537503-64

Condition

Machine disassembled, cleaned, and stored indoors in Denmark.

Available for inspection by appointment.

Rsdoxqqqlepfx Ahzjbt

Price

Price on request (EXW Denmark)

Listing

Striegistal

Striegistal

18,238 km

Production line

Boschkompl. Fertigungslinie für Heizsegmente

Call

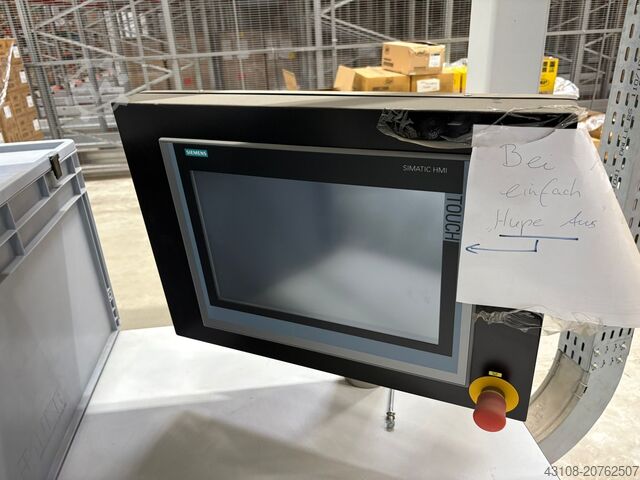

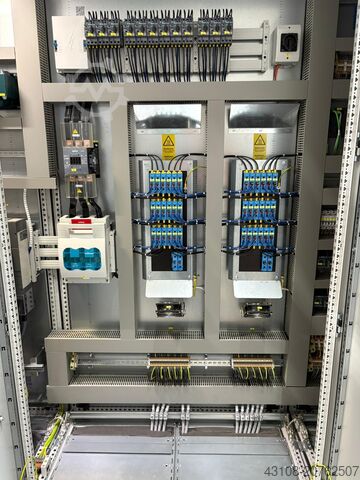

Condition: ready for operation (used), functionality: fully functional, A special machine is for sale. It is a complete production line for the manufacture of heating segments. The production line was built and developed by Bosch itself. The heating segments are suitable for instantaneous water heaters. You can see a picture of the segments in the 2nd picture of the picture gallery.

Rbsdpfx Ahsydlgvjzst

The production line also includes a test station. Everything is apparently available in terms of documentation.

Listing

Zwevegem

Zwevegem

18,754 km

Product supply bunker + spiral screw

HeckmannProduct aanvoerbunker + Opvoervijzel

Call

Condition: used, Product supply bunker “Heckmann”

with hopper ± 2.000L

with driven shafts with fingers to separate the product

input height: ± 3,400 mm

2 x 3kW, 1500 / 16 rpm

dimensions (l x w x h) : ± 2.700 x 2.600 x 3.400 mm

+

Elevating spiral screw “Heckmann”

all stainless steel

discharge height: ± 5.800 mm

diameter of the screw : ± 600 mm

length of the screw : ± 8.500 mm

dimensions hopper: ± 1.300 x 1.000 mm

dimensions: (l x w): ± 9.200 x 1.600 mm

safety grille

Rbsdpfx Asydk Ifjhzjt

5.5kW, 1500/20 rpm

Listing

Rosmalen

Rosmalen

18,589 km

Window production line

WEINIGConturex C4500

Call

Condition: good (used), Year of construction: 2011, Weinig Conturex C4500 CNC Window production machine

Description;

Year of construction: 2011

Working width 25-260mm

Working heigth 10-150mm

Powergrip clamping table 3.000 mm

Workpiece length 180-4500 mm

First processing unit

- 20 kW Motor

- HSK 63F toolholder

- Speed electr. adjustable 0-18.000 t.p.m. (left-right)

- Tooldiameter max 330 mm

- Sawblade diameter 280 mm

- Toolwarehouse 18 positions (100mm distance)

Second processing unit

- 20 kW Motor

Rbedeydkzxspfx Ahzjt

- HSK 63F toolholder

- Speed electr. adjustable 0-18.000 t.p.m. (left-right)

- Tooldiameter max 330 mm

- Sawblade diameter 280 mm

- Toolwarehouse 18 positions (100mm distance)

Powergrip outfeed

Tool warehouse 110 positions (87,5 mm distance)

Waste conveyorbelt

Full description on request

Available approx. wk 30/31 - 2026

(Despite our great care all changes, mistakes in technical data, prices and all information is subject to (typing) errors. No guarantee on printed data!

Availability subject to prior sales).

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen vorbehalten! Keine Garantie auf gedruckte Daten!.

Verfügbarkeit vorbehaltlich Zwischenverkauf).

Prices excl. advertisement cost MachineSeeker / Preise exkl. Inserierungskosten MaschinenSucher

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Zevenbergen

Zevenbergen

18,629 km

CNC Hor. Production line with 14 pallets

MazakFH 880 PMC

Call

Condition: used, Year of construction: 1997, travel distance X-axis: 1,300 mm, travel distance Y-axis: 1,100 mm, travel distance Z-axis: 1,000 mm, controller manufacturer: Mazatrol, controller model: M-Plus, overall weight: 36,000 kg, tool weight: 2,200 g, CNC Horizontal Machining Centre with Palletech

Table size 800 x 800 mm.

Table NCRT.

Rbsdpfx Aheyddfdjzjt

Number of pallets 14.

Movement x-Axis 1300 mm.

y-Axis 1100 mm.

z-Axis 1000 mm.

Table indexing 0,001°.

Number of tools in magazine 237 pieces.

Maximum spindle speed 35-7.000 min.

Tool taper DIN 69871A-50.

CNC control M-plus

If you have any questions concerning the machine, please do not hesitate to contact us by phone or e-mail.

Feel free to view our other advertisements for a complete overview of our stock.

Listing

Częstochowa

Częstochowa

17,870 km

Complete production line

Deutscher Hersteller

Call

Condition: excellent (used), Sale of 4 complete roll forming lines + 1 spare part. Production of spacers and glazing beads made of aluminum and stainless steel. Modernized lines: two equipped with servo motors, the remaining with cardan shaft drive. Lines feature automatic loading, cutting, high-frequency welding, as well as automatic collection and packaging. Individual lines can be purchased separately.

Freely selectable cardan shaft-driven lines at a price of €42,000 per unit / 2 units available.

Servo motor-driven lines at a price of €95,000 per unit

Quantity: 2 units

PRICES FOR A PACKAGE OF 4 LINES + ONE SPARE LINE

Rbodex Da A Rjpfx Ahzst

Price: €299,000 – catalogue price

Price: €199,000 – special offer valid until 31 December 2025

Patents valid until 2033 and the HELIMA brand can also be acquired.

Listing

Częstochowa

Częstochowa

17,870 km

High-quality meltblown production line

ReifenhäuserReicofil MB 1600

Call

Condition: like new (used), High-Quality Meltblown Production Line for Nonwovens

A complete machine inspection was carried out by the manufacturer's service team on 17.12.2025.

Inspection report available.

Commissioning at the customer's site can be offered upon request.

Operating hours: 80 hours (commissioning only)

Price for a new machine: EUR 7,500,000

• Manufacturer: Reifenhäuser GmbH & Co. KG Maschinenfabrik

• Model: Reicofil MB 1600

• Year of manufacture: 2021

• Last commissioning: 2022

Technical specifications:

• Working width: 1,600 mm

• Material: Polypropylene (PP), MFI 230 / 2.16 > 400 g/10 min

• Output: Up to 65 kg/h per meter width

• Product weight: 10–80 g/m²

• Production speed: 5–80 m/min

• Die head: MB 1600, 50 h/in

• Extruder: RT-1101-1-100, L/D 30

• Heating capacity, rotary beam: 65–172 kW

• Winder: contact winder with preset reel change

• Max. winding diameter: 1,250 mm

• Web width: 1,700 mm

• Winding tension: 10–100 N/m

Additional equipment and accessories:

• 3-component dosing system

Rjdpsx Hx Rnofx Ahzebt

• 80 mm automatic seat changer

• Ultrasonic cleaning system

• Pyrolysis unit

• Ozone extraction

• Cutting knives

• Central control panel with touchscreen and data entry

Listing

Germany

Germany

18,384 km

Window production line

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Call

Condition: used, Number of machnines 9 Stk.

Wooden window production line for sale on behalf of a customer.

Machines still in operation can be viewed. Sale includes machines, tools, and programming of the systems produced.

Includes angled window and arched window production.

Item 1: Weinig Powermat 500, year of manufacture 2010, window version

-----

- ??6 spindles, 5 of which are PowerLock

- 8,000 rpm

- Equipment for glazing bead removal

- Large PowerCom control system

- Includes existing Leitz planing and molding tools

- Linked to a Maweg Saturn Duo single-piece wood sander, year of manufacture 1985,

and a workpiece return conveyor system

Item 2: SCM Windor 40 R window system, year of manufacture 2006

-----

- 2 long CNC-controlled slotting spindles

- 3 long CNC-controlled profile spindles + top and bottom unit

- Rebating carriage for small sashes

- ROTATEN: Angled window attachment

- Includes Leitz window and door tools

- Includes separate OKOMA UF 3 rebating machine with tools

Item 3: HOMAG CNC machining center BMG310/42/F/K, year of manufacture 2018

-----

- Gantry machine, 5-axis Drive 5C+ with 15 kW

- Ceiling laser

- Working dimensions 4200 mm length, 1350 mm depth

- 32-position disc changer

- 8-position linear changer

- Fixed drilling head with 18 spindles V12/H6/S0/90 degrees

- 8 consoles

- 6 lifting rails

- Connection for 8 PowerClamp clamps

- Approx. 30 vacuum clamps

- 4 x PowerClamp clamps

- WoodWop

- Chip conveyor belt

- Various small solid wood clamps, used for casement windows

- Including Leitz tools for Homag with arched window production

- Including Barbaric vacuum lifter, year of manufacture 2015

Item 4: Löwer MZP 1 mini dovetail press

-----

- ??For arched window production

Item 5: S+S frame press type Bavaria 200 L, year of manufacture 2014

-----

- Working dimensions 4000 x 2600 mm

- With center pressure beam and cross pressure device

- Motorized width adjustment

- Basic equipment counter profiles

- Slanted window control

- Pendulum pressure plates + extension for pointed windows

- Intermediate insert for small-scale crimping

- Various carrier plates for counter profiles and counter profiles

Item 6: Striffler sash fitting table

-----

Rjdpfx Ahoyclwxszebt

- With automatic screwdriver and screw feeder

- Fitting rack

- Punch for Roto fitting

Item 7: Stegherr KF counter milling machine

-----

- With existing tools

Item 8: Tools

-----

All tools belonging to the machines for the

wood+wood-aluminum systems IV 72 + 92 mm shown in the PDF

- Windows

- Lift-and-slide doors

- Round and angled windows

- Box windows

- Entrance doors in many variations

- Putty rebate variations

- ...

Sale of the tools in their current condition, scope, and with accessories as they are currently available. Note regarding window cuts, tool drawings, and tool system listings:

Engelfried GmbH does not guarantee that the tools actually present correspond to the systems listed and drawn.

(Technical specifications according to the manufacturer, without guarantee!)

-----...

Listing

Germany

Germany

18,384 km

Window production centre

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Call

Condition: used, Wooden window production line for sale on behalf of a customer.

Machines still in operation can be viewed. Sale includes machines, tools, and programming of the systems produced.

Includes angled window and arched window production.

Item 1: Weinig Powermat 500, year of manufacture 2010, window version

-----

- ??6 spindles, 5 of which are PowerLock

- 8,000 rpm

- Equipment for glazing bead removal

- Large PowerCom control system

- Includes existing Leitz planing and molding tools

- Linked to a Maweg Saturn Duo single-piece wood sander, year of manufacture 1985,

and a workpiece return conveyor system

Item 2: SCM Windor 40 R window system, year of manufacture 2006

-----

- 2 long CNC-controlled slotting spindles

- 3 long CNC-controlled profile spindles + top and bottom unit

- Rebating carriage for small sashes

- ROTATEN: Angled window attachment

- Includes Leitz window and door tools

- Includes separate OKOMA UF 3 rebating machine with tools

Rodpfoyclwfjx Ahzsbt

Item 3: HOMAG CNC machining center BMG310/42/F/K, year of manufacture 2018

-----

- Gantry machine, 5-axis Drive 5C+ with 15 kW

- Ceiling laser

- Working dimensions 4200 mm length, 1350 mm depth

- 32-position disc changer

- 8-position linear changer

- Fixed drilling head with 18 spindles V12/H6/S0/90 degrees

- 8 consoles

- 6 lifting rails

- Connection for 8 PowerClamp clamps

- Approx. 30 vacuum clamps

- 4 x PowerClamp clamps

- WoodWop

- Chip conveyor belt

- Various small solid wood clamps, used for casement windows

- Including Leitz tools for Homag with arched window production

- Including Barbaric vacuum lifter, year of manufacture 2015

Item 4: Löwer MZP 1 mini dovetail press

-----

- ??For arched window production

Item 5: S+S frame press type Bavaria 200 L, year of manufacture 2014

-----

- Working dimensions 4000 x 2600 mm

- With center pressure beam and cross pressure device

- Motorized width adjustment

- Basic equipment counter profiles

- Slanted window control

- Pendulum pressure plates + extension for pointed windows

- Intermediate insert for small-scale crimping

- Various carrier plates for counter profiles and counter profiles

Item 6: Striffler sash fitting table

-----

- With automatic screwdriver and screw feeder

- Fitting rack

- Punch for Roto fitting

Item 7: Stegherr KF counter milling machine

-----

- With existing tools

Item 8: Tools

-----

All tools belonging to the machines for the

wood+wood-aluminum systems IV 72 + 92 mm shown in the PDF

- Windows

- Lift-and-slide doors

- Round and angled windows

- Box windows

- Entrance doors in many variations

- Putty rebate variations

- ...

Sale of the tools in their current condition, scope, and with accessories as they are currently available. Note regarding window cuts, tool drawings, and tool system listings:

Engelfried GmbH does not guarantee that the tools actually present correspond to the systems listed and drawn.

(Technical specifications according to the manufacturer, without guarantee!)

-----...

Listing

Juszczyn

Juszczyn

17,874 km

Cross-cut multi-blade saw for beam production

TVR

Call

Condition: excellent (used), functionality: fully functional, Cross-cut multi-blade saw for the production of squared timber and turning blanks

Rbodpfjych N Dox Ahzet

Listing

Миколаїв

Миколаїв

17,581 km

Chain production machine

VITARI

Call

Condition: ready for operation (used), Year of construction: 1980, functionality: fully functional, Complete production line for Chain

Manufacturer - VITARI

Year - 1980

Line Consists :

1.Wire drawing machine SKP8 T.I. 95647

1.1. Producer: Tecno Impianti

1.2. Model SKP 8 2P Serial Nr 9564/7

1.3. Year of production 1995 -1999(depends on condition)

1.4. Country of origin Italy

2.Bending machine for roundlink chain production

2.1. Producer:Abbondio Vitari S.p.A .

2.2. Model CC18

2.3. Year of production 1973-1987

2.4. Country of origin Italy

3.Contact welding machine for roundlink chain production

3.1. Producer:Abbondio Vitari S.p.A .

3.2. Year of production 1978-1981

3.3. Country of origin Italy

4.Contact welding machine for roundlink chain production

4.1. Producer:Abbondio Vitari S.p.A .

4.2. Year of production 1978-1981

4.3. Country of origin Italy

5.Calibrating machine for roundlink chain production

5.1. Producer: Delmatic SNC

5.2. Model KTR 1

5.3. Serial Number K113-06-05-7

Rsdpfoyfg Tgox Ahzebt

5.4. Year of production 2006-2007

5.5. Country of origin Italy

6.Manual contact welding machine for roundlink chain production

6.1. Model N12

6.2. Producer: CEA COSTRUZIONI ELETTROMECCANICHE ANNETTONI S.p.A.

6.3. Year of production 2005-2007

6.4. Country of origin Italy

Partly renewed (Pneumatic system, cooling system, etc)

Production tool included

For today got 6 same type lines, ready to use, ready for check. Any of them can be connected for check up. Delivery to EU included in price

Our company also offers training and, if required, start-up services for putting the line into operation

Trust Seal

Dealers certified through Machineseeker

Listing

Nattheim

Nattheim

18,550 km

Window production plant

WeinigUnicontrol 10

Call

Condition: used, Year of construction: 2000, Storage location: Nattheim

Rbodpevwdmwofx Ahzot

Listing

Falkenberg

Falkenberg

17,853 km

ZEROLABOR ROBOT SYSTEM / Wall Production

RANDEK AB, SchwedenZEROLABOR

Call

Condition: new, Year of construction: 2023, ZEROLABOR ROBOTIC SYSTEM for Timber Frame Work

The Randek ZEROLABOR Robotic System is a fully automated robot cell that performs various working processes fully automatic. The system is flexible and can be configured to customers need. The robotic cell can be integrated into existing production lines or work as a stand alone unit. The system can handle production of walls, floors and roofs.

Automated processes:

- Sheet handling, the sheet is picked using vacuum cup system from various stacks and placed on building components according to CAD-file. The system is flexible and can handle various sizes of sheets.

- Fastening of sheets by screwing, stapling and/or nailing.

- Cut out for openings such as electrical hoses, windows etc.

- The system can handle 1, 2 or 3 layers of sheets.

- Marking of component using inkjet.

- Gluing

- Waste handling, gypsum waste and OSB waste i.e. ist placed in different places if needed, i.e. directlc in waste bin/recycle bin.

Rsdpfx Aheduub Uezjbt

- Effective dust extraction system.

- Straightening of building component using working table

- Straightening of studs before nailing, ensuring placement of nails on stud.

Listing

Kolhapur

Kolhapur

12,110 km

Beverage production machine

20016Tatatarapack

Condition: used, Year of construction: 2016, functionality: fully functional, Tatarapack bevarage for juice

Rjdeyc I U Hspfx Ahzobt

Listing

Germany

Germany

18,384 km

FFP2 mask production line

RuhlamatMPL FFP2/016

Call

Year of construction: 2020, condition: good (used), FFP2 Mask Production Machine Production Line

Manufacturer: Ruhlamat

Model: MPL FFP2/016

Year of manufacture: 2020

Mask Production Line N95/FFP2 Masks

Installation dimensions LxWxH: 8921 x 1494 x 1985 mm

Clearance around the machine: 1500 mm all around

50 Hz / 2.6 kVa

Pressure: 6 bar

Approx. weight: 2500 kg

FFP2 masks are made of 3 to 6 layers of nonwoven fabric.

This machine can produce masks with up to 6 layers.

The system is comprised of five stations:

Station 1: Unwinder

Rjdpjrm R Hdsfx Ahzobt

Station 2: Punching nose clip and embossing roller welding

Station 3.1: Printing and welding ear loops

Station 3.2: Aligning folding edge

Station 4: Contour welding and cutting mask

We make it easier for you to find: "brochure production"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Brochure Production (16,377)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month