Vertical machining centerStarrag

HEC 400 F

Vertical machining center

Starrag

HEC 400 F

ONO plus VAT

€135,000

Year of construction

2016

Condition

Used

Location

Warstein

Show images

Show map

Machine data

- Machine type:

- Vertical machining center

- Manufacturer:

- Starrag

- Model:

- HEC 400 F

- Year of construction:

- 2016

- Condition:

- good (used)

- Functionality:

- fully functional

- Operating hours:

- 27,412 h

Price & Location

ONO plus VAT

€135,000

- Location:

- Warstein, Germany

Call

Technical details

- Travel distance X-axis:

- 650 mm

- Travel distance Y-axis:

- 650 mm

- Travel distance Z-axis:

- 680 mm

- Controller manufacturer:

- Siemens

- Controller model:

- 840D sl

- Table width:

- 400 mm

- Table height:

- 30 mm

- Table length:

- 500 mm

- Table load:

- 500 kg

- Spindle speed (max.):

- 18,000 rpm

- Operating hours of spindle:

- 9,956 h

- Coolant supply:

- 80 bar

- Spindle motor power:

- 32,400 W

- Equipment:

- chip conveyor, documentation/manual, rotational speed infinitely variable

Details about the offer

- Listing ID:

- A20768872

- Update:

- 20.01.2026

Description

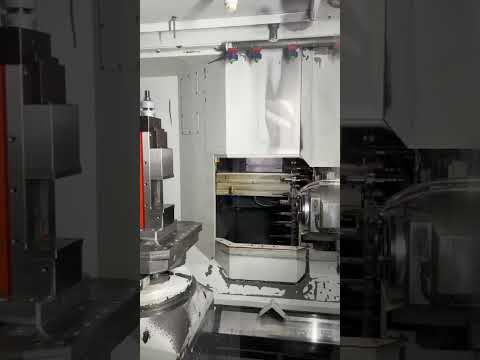

For sale is a Starrag HEC 400 F 4-axis machining center, which was fully inspected and overhauled at the Starrag factory in 2022. All relevant components were checked and replaced or adjusted as needed during this process.

Since its installation in 2022, the machine has been in operation at our facility and is currently under power for ongoing production. It is in well-maintained technical condition and has been serviced regularly.

Technical Highlights

• Starrag HEC 400 F – 17211, 4-axis machining center for milling / drilling / turning

• Control: Siemens Sinumerik 840 D solution Line with NCU710 and PLC integration

• Spindle: HSK-A63 motor spindle, speed range 50 – 18,000 rpm, torque 130 Nm (25% duty cycle), power 32.4 kW / 24 kW (100% duty cycle)

• Factory inspection in Chemnitz (2022): all assemblies checked, adjusted, and renewed as needed

• Direct-drive NC rotary table, 80 rpm, 400 Nm drive torque, 3,000 Nm tangential torque

• Siemens spindle diagnostics & remote diagnostics (TeamViewer)

• Energy-efficient system with regeneration and standby mode for energy savings

Working Area & Dimensions

• Travels (X/Y/Z): 650 / 650 / 680 mm

• Pallet size: 400 × 500 mm with 57 × M12 threaded holes

• Max. workpiece height: 850 mm

• Max. load per pallet: 500 kg

• Pallet changer: 2 pallets – automatic, changeover time approx. 8 s

• Tool magazine: 60 tool positions (chain magazine), chip-to-chip time 3 – 4 s

• Chip conveyor: scraper belt conveyor with vacuum gap sieve, discharge height 1,050 mm

• Machine dimensions (L × W × H): approx. 5,150 × 2,800 × 3,025 mm

• Machine weight: approx. 11,500 kg

• Noise emission: ≤ 80 dB(A) according to EN ISO 3744

Additional Equipment

• 6-channel clamping hydraulics (90 bar) at setup and working positions

• Increased spindle torque (130 Nm) for high-performance cutting

• Torque support with axial supports

• Coolant system: connection to central supply incl. return and temperature compensation

• Increased coolant pressure to 80 bar through spindle center

• Optical measuring probe Renishaw OMP60 incl. Siemens measuring cycles

• Tool breakage detection (mechanical, parallel to main time)

• Pallet sequence operation + crane loading/unloading (software)

• Signal lamp (4-color) for operating status

• Work area/machine equipment: shower nozzle, rinsing pistol, vortex nozzle, extraction interface, foot switch blow nozzle

• Documentation: fully digital (PDF)

Operating Hours / Run Times

• Power-on hours: approx. 27,412 h (as of Oct 2025). The counter runs as soon as the machine is switched on – including during setup, maintenance, or idle times.

• Total spindle running time: 9,956 h

Special Features

• OPTIONAL: With perfect post-processor and CAD/CAM software TOP Solid (at extra cost)

• Under power – demonstration possible at any time

• Directly from production – not a dealer sale

• Complete technical documentation available

• Support with dismantling, loading and transport available (at extra cost)

The tool holders and vise visible in the photos are not included in the offer, but can be purchased separately if desired.

Cpodpfx Asx H Idksc Nou

Price: €135,000 net, negotiable for quick completion.

All information has been provided to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

The listing was translated automatically. Translation errors are possible.

Since its installation in 2022, the machine has been in operation at our facility and is currently under power for ongoing production. It is in well-maintained technical condition and has been serviced regularly.

Technical Highlights

• Starrag HEC 400 F – 17211, 4-axis machining center for milling / drilling / turning

• Control: Siemens Sinumerik 840 D solution Line with NCU710 and PLC integration

• Spindle: HSK-A63 motor spindle, speed range 50 – 18,000 rpm, torque 130 Nm (25% duty cycle), power 32.4 kW / 24 kW (100% duty cycle)

• Factory inspection in Chemnitz (2022): all assemblies checked, adjusted, and renewed as needed

• Direct-drive NC rotary table, 80 rpm, 400 Nm drive torque, 3,000 Nm tangential torque

• Siemens spindle diagnostics & remote diagnostics (TeamViewer)

• Energy-efficient system with regeneration and standby mode for energy savings

Working Area & Dimensions

• Travels (X/Y/Z): 650 / 650 / 680 mm

• Pallet size: 400 × 500 mm with 57 × M12 threaded holes

• Max. workpiece height: 850 mm

• Max. load per pallet: 500 kg

• Pallet changer: 2 pallets – automatic, changeover time approx. 8 s

• Tool magazine: 60 tool positions (chain magazine), chip-to-chip time 3 – 4 s

• Chip conveyor: scraper belt conveyor with vacuum gap sieve, discharge height 1,050 mm

• Machine dimensions (L × W × H): approx. 5,150 × 2,800 × 3,025 mm

• Machine weight: approx. 11,500 kg

• Noise emission: ≤ 80 dB(A) according to EN ISO 3744

Additional Equipment

• 6-channel clamping hydraulics (90 bar) at setup and working positions

• Increased spindle torque (130 Nm) for high-performance cutting

• Torque support with axial supports

• Coolant system: connection to central supply incl. return and temperature compensation

• Increased coolant pressure to 80 bar through spindle center

• Optical measuring probe Renishaw OMP60 incl. Siemens measuring cycles

• Tool breakage detection (mechanical, parallel to main time)

• Pallet sequence operation + crane loading/unloading (software)

• Signal lamp (4-color) for operating status

• Work area/machine equipment: shower nozzle, rinsing pistol, vortex nozzle, extraction interface, foot switch blow nozzle

• Documentation: fully digital (PDF)

Operating Hours / Run Times

• Power-on hours: approx. 27,412 h (as of Oct 2025). The counter runs as soon as the machine is switched on – including during setup, maintenance, or idle times.

• Total spindle running time: 9,956 h

Special Features

• OPTIONAL: With perfect post-processor and CAD/CAM software TOP Solid (at extra cost)

• Under power – demonstration possible at any time

• Directly from production – not a dealer sale

• Complete technical documentation available

• Support with dismantling, loading and transport available (at extra cost)

The tool holders and vise visible in the photos are not included in the offer, but can be purchased separately if desired.

Cpodpfx Asx H Idksc Nou

Price: €135,000 net, negotiable for quick completion.

All information has been provided to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

The listing was translated automatically. Translation errors are possible.

Seller

Note: Register for free or log in, to access all information.

Send inquiry

Telephone & Fax

+49 2902 ... show

Your listing has been deleted successfully

An error has occurred