Used Plunge Pool for sale (250)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

18,491 km

Edge banding machine

Holz-HerAuriga 1308 XL power mit Glue Jet PUR PRO

Call

Condition: new, Year of construction: 2024, New machine

Year of manufacture: 2024 (arrived 2025)

MACHINESEEKER ENQUIRIES:

Please understand that we do not offer this new machine outside our sales territory in Germany (Rhine-Main area and North Rhine-Westphalia). Such enquiries will not be answered.

Technical specifications:

Edge thickness, coil material: 0.4 – 3 mm (material dependent)

Edge thickness, strip material: 0.4 – 8 mm (material dependent)

Edge cross-section: max. 6 x 42 mm

Edge height: max. 65 mm

Workpiece thickness: 6 – 60 mm (restrictions possible for certain units)

Workpiece width: min. 65 mm

Workpiece length: min. 160 mm (without corner copying)

Workpiece length: 180 mm

Feed speed: 10 m/min

Configuration:

- Motorised pressure bridge adjustment

- Pull-out workpiece support XL, spacing 600 mm

- LED light at infeed, 3-colour

- Motorised infeed fence adjustment

- Extended infeed fence, 1,252 mm

- I-Tronic package

- Edge Control PPC 322 W controller

- IntelliSet: intelligent tool offset

- f.a.s.t = fast setting technology

- ECO-Mode energy saving function

- Prepared for RETURN connection (third-party product)

- BS 501 guiding system; precise right-angle workpiece feed for edgebanding of narrow parts on end grain

- Workpiece thickness: min. 10 mm

- Workpiece width: min. 60 mm

- Workpiece length: approx. 140 – 450 mm

- FG201 jointing unit with 2 milling heads, 64 mm high

- MG 301 edge feeder

- GluJet GJ 725 NC PUR PRO glue application system

- Automatic glue height adjustment via dosing sleeve and sensing nozzle to compensate for panel tolerances

- NC axis for height adjustment

- 90° swivelling for easy cleaning of the Glue Jet nozzle

- Includes vacuum pump for professional processing of PUR adhesives. The vacuum pump removes the reaction partner

(water molecules) from the PUR, allowing uncured PUR adhesive to remain in the system. The pump operates

independently of the machine’s power supply and automatically compensates for vacuum loss.

- Full control of PUR!

- DW 301 pressure unit with motorised NC axis; first roller driven with pneumatic plunge control, 2 conical follow-up pressure rollers

- GM301 spray unit after pressure section for high-gloss edges (slip agent)

- KA 501 end trimming unit, pneumatic (60 mm)

- Extraction hoods for end trimming unit

- FR301 MOT6 multifunction milling unit

- Shelf program

- FF 301 MOT1 profile milling unit

- ZK301 MOT4 scraper unit incl. high-gloss kit

- FK702 surface scraper

- Spray unit for separation and cleaning agent, complete

- GM 301 spray unit after pressure section (high-gloss edges)

- SW 501 buffing unit

Piping above the machine is not included in the scope of delivery.

Fjdpfsxymd Tox Ac Nsfu

Availability: short notice

Location: Hochheim

Listing

Siedlce

Siedlce

17,614 km

CNC Lathe 400x1000 LT1 driven tools

CORMAKCNC CKT 400x1000 LT1 napędzane narzędzia

Call

Condition: new, Year of construction: 2026, Efficient lathe with a flat bed with a wide range of applications for series and small series machining. The machine has the functions of turning external, internal, spherical surfaces and threads. Fixed cycles used in the control for cross-cutting, standard turning, cones, threading, plunge cutting and contouring. They significantly simplify machine programming and shorten processing time.

Technical data

Swing over bed Φ 400 mm

Fodpev A S N Dsfx Ac Nofu

Swing over cross slide Φ 210 mm

Maximum turning length 1000 mm

Spindle speed range 0-2000 RPM

Spindle bore Φ 52 mm

Spindle bore taper MK6

Number of tools in the holder 4 (6, 8)

Maximum tool holder size 20×20 mm

X/Z axes smallest setting unit 0.001 mm ; 0.001 mm

X-axis feed speed 8 m/min

Z-axis feed speed 10 m/min

Tailstock spindle taper MK5

Maximum tailstock spindle feed 120 mm

Main motor power 5.5 kW

(X) feed engine 6 Nm

(Z) feed engine 6 Nm

Dimensions 2640×1500×1770 mm

Weight 1800 kg

Listing

Bitburg

Bitburg

18,682 km

Panel saw upright

StriebigEvolution 6224

Call

Condition: new, Year of construction: 2024, EVOLUTION - precision, ergonomics and functionality perfectly combined

Automatic functions, such as automatic locking and swiveling

or automatic plunge-cutting and ejection of the saw unit, make your daily work much easier.

your daily work. You too can benefit from the advantages of an EVOLUTION. It can be controlled via a 12" touchscreen computer. The intuitive user interface ensures perfect processing of your orders in every detail.

Comprehensive standard equipment

12" touchscreen computer with optimum operator guidance

Laser-supported display of the horizontal cut

Digital measuring system DMS-XY

Automatic saw beam locking with interface detection

Automatic locking and swiveling of the saw unit

Automatic infeed and outfeed of the saw unit

Automatic fine adjustment of the saw unit

Operating hours counter

Tool database

ALU center support over the entire machine length

Integrated, powerful TRK dust extraction system. Dust limit value around 1mg/m³

Control cabinet attached directly to the saw frame

Supersilent sound insulation

Scoring unit: VSA scoring saw infinitely adjustable

Ffjdpfx Aohf Dqbjc Nju

Complete free-standing support

Paper holder

High-end grid made of synthetic materials

Small parts support aluminum complete

UPS 24 VDC for Touch PC Uninterruptible power supply

Weight of the saw approx. 1,100 kg

Cutting depth 80 mm

Saw motor power 5.5 kW (7.5 HP)

Saw blade diameter 300 mm

Saw blade bore 30 mm

Emission sound pressure level at the workplace LpA 83 dB *3

Saw blade speed 4800 rpm

1 extraction nozzle ø 140 mm

Compressed air connection 6-10 bar

Connected load 7.5 kW

Mains connection 3 x 400 V / 50 Hz

Dimensions in mm:

Type L H T1 free T2 wall

6224 6645 3018 1741 1361

Cutting range in mm:

Type LS HS(vert) HS horizontal

6224 5300 2240 2100

Location: Ex stock 54634 Bitburg

- immediately available -

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Cestona

Cestona

19,683 km

Thread rolling machine

ORTRP 18

Call

Condition: used, Year of construction: 2007, Manufacturer: ORT

Model: RP18

Year : 2007

Maximum rolling thrust 18 Ton

Roller shaft diameter 54 mm

Roller shaft key 12 mm

Minimum diameter workpiece to rolled 3 mm

Maximum diameter workpiece to be rolled 60 mm

Max.length workpiece rolled in plunge-feed 175 mm

Max.length workpiece to rolled in enfilade —

Maximum Pitch workpiece to be rolled 4 mm

Maximum roller diameter 185 mm

Ffedpfx Aev Tqdbec Neu

Main motor power 7,5 HP

Total installed power 11 HP

Maximum noise level 80 db

Net weight 1800 kg

Height Rolling shaft from the floor 1035 mm

Machine width 1450 mm

Standard machine depth 900 mm

Total machine height 1800 mm

Listing

Cestona

Cestona

19,683 km

Centerless grinding machine ESTARTA

ESTARTA312

Call

Condition: excellent (used), Brand: ESTARTA

Model: 312

Type: Centerless grinding machine

Grinding Wheel dimensions: 508 x304,8 x 160 mm

Ø min/max to grinding: 1,5 / 75 mm

Regulating wheel width: 160 mm

Regulating wheel dimensions : 304,8 x 190,5 x 160 mm

Fodpfxox Iu E De Ac Njfu

Maximum length to rectify in plunge : 160 mm

Maximum length to rectify in plunge : 160 mm

Grinding wheel head motor power : 11 kw

Machine size : 2015 x 1280 x 1440 mm

Weight : 3500 kgs

Listing

Korschenbroich

Korschenbroich

18,581 km

Double surface grinder

DISKUSDDS 750 XRE

Call

Condition: excellent (used), Year of construction: 2012, functionality: fully functional, machine/vehicle number: 2179, The Diskus DDS 750 XRE is a double-sided surface grinding machine from Diskus's DDS series, designed for precision flat and plunge grinding. Although the exact year of manufacture (2012) is not specified, the technical data for the XRE variant are as follows:

Technical Data of the Diskus DDS 750 XRE

* Grinding wheel diameter: 750 mm

* Maximum workpiece diameter:

* Through-feed grinding: 420 mm

* Plunge-cut grinding: 300 mm

* Grinding width:

* Through-feed grinding: up to 180 mm

* Plunge-cut grinding: up to 300 mm

* Maximum material thickness:

* Through-feed grinding: 30 mm

* Plunge-cut grinding: 80 mm

* Grinding spindle drive power:

* Spindle 1: 48 kW

* Spindle 2: 48 kW

* Feed system: rotary feed

* Feed rates:

* Maximum: 20 mm/min

* Minimum: 240 mm/min

* Dimensions:

* Required floor space (L × W): 4900 mm × 5000 mm

* Total height: 3100 mm

* Weight: approx. 13,000 kg

* Control system: Siemens 840 D CNC

* Measuring control: Diskus IONIC 17A

This machine is particularly suitable for machining workpieces made from corundum, CBN, or diamond and is used in sectors such as the automotive industry, gearbox manufacturing, hydraulics and pump technology, as well as the bearing industry.

Ffodpfewnrv Tjx Ac Nju

For further information or specific inquiries regarding the year of manufacture 2012, I recommend contacting Diskus Werke Schleiftechnik GmbH directly.

Listing

Düsseldorf

Düsseldorf

18,570 km

External cylindrical grinding machine

FortunaFS23S1000ASW45-cnc

Call

Condition: excellent (used), Year of construction: 1983, Model: Fortuna F23 S1000 ASW 45

Manufacturer: Fortuna-Werke Maschinenfabrik GmbH

Origin: Stuttgart-Bad Cannstatt, Germany

Year of Manufacture: 1983

Machine Type: Universal external cylindrical grinding machine

Control Type: Not CNC – semi-automatic with digital position indicators

Workholding: Grinding between centers with headstock and tailstock

Max. Grinding Length: 1000 mm

Main Motor Power: 26 kW

Voltage: 380 V

Frequency: 50 Hz

Connected Load: 50 A

Machine Weight: Approx. 4900 kg

Grinding Wheel & Spindle:

Wheel Diameter Options: 400 mm, 450 mm, 500 mm, 600 mm, 750 mm, 900 mm

Wheel Bore Diameter: 127 mm / 203 mm / 305 mm

Fsdpfxew Avhpj Ac Nsfu

Spindle Speeds (depending on wheel size): From 930 rpm to 1870 rpm

Surface Speed Compatibility: 35 m/s and 45 m/s

Spindle Design: Combined axial-radial bearing system for high rigidity

Oscillating Grinding Support: Yes – for improved surface finish and cooling

Grinding Functions:

External cylindrical grinding only (not centerless)

Longitudinal feed (table movement)

Plunge feed (cross movement)

Oscillation grinding (with adjustable stroke)

Digital input system (non-CNC but programmable logic based)

Manual fine adjustment via micrometer and scale plate

Notes:

Machine is designed for roughing and finishing of steel, cast iron, and aluminum

Built-in charts and formulas provided in the manual for infeed rates, stock removal, overspark passes, and optimal feed per material

Extremely rigid German construction, ideal for toolrooms or production environments seeking repeatable precision without CNC control

Equipped with electronic displays and control panel (not G-code programmable)

Power panel and internal logic controlled through Fortuna's relay/PLC interface

Listing

Germany

Germany

18,514 km

Grinding Machine - Centerless

JUNKERBBE 15 CNC

Call

Condition: used, Year of construction: 2001, Technical details:

grinding diameter max.: 3-220 mm

regulating wheel width: 400 mm

max. width of grinding wheel: 400 mm

grinding motor: 55 kW

peripheral speed: max. 45 m/sec

regulating wheel dimensions: 350 x 400 x 203 mm

dimensions of grinding wheel: CBN 500 x 400 x 304 mm

grinding wheel size: KORUND 600 x 400 x 304 mm

total power requirement: 75 kVA

weight of the machine ca.: 13 t.

dimensions of the machine ca.: 4,47 x 2,77 x 2,49 m.

Centerless Grindign Machine JUNKER JUPITER 500 CNC SIEMENS in good condition.

Including:

· 2 robots Kuka KR 16 Year 2007

· CNC loading and unloading device Promot EPL60NC Year 2007

The machine was lately used for grinding of guide bushes (through grinding). Plunge is possible.

JUPITER's Centerless grinding, also available with CBN. Junker this circular grinding method with CBN grinding wheels, which opens up significant productivity benefits from the long service life of the grinding wheel, especially at high volumes. In addition, the simultaneous removal takes on the entire Schleswig-Holstein, which provides both in mass production and in small batches for significantly reduced processing times.

The grinding process with JUPITER

When centerless grinding, there are two grinding processes: the through grinding and plunge. Both methods are possible with the JUPITER.

Applications through grinding:

Pin and Bushings Body, rings, smaller rings, piston parts (eg compressors), waves with constant diameter piston rods (eg shock), Small piston for hydraulic and fuel injection, precision wires and rods, piston pins.

Ffodottxg Iepfx Ac Neu

Applications Plunge:

Rotor shafts, transmission parts, bearing surfaces of camshafts, tube and pipe fittings for composite camshafts, universal joints, parts for needle injection, valve stems, barrel rolls.

*

Listing

Hövelhof

Hövelhof

18,428 km

Cylindrical grinding machine Nomoco M100

NomocoM 100

Call

Condition: not inspected (used), Year of construction: 1976, Spitzl. Cylindrical grinding machine Nomoco M100

Offered here is a grinding machine from the company Nomoco of the type M100.

Technical data:

Manufacturer: Nomoco

Type: M 100

year of manufacture: 1976

Fodjhc S Spopfx Ac Nofu

max. grinding diameter: 100mm

max. grinding length: 180mm

grinding wheels: Ø 400mm

max. grinding wheel width: 180mm

weight: 3,2t

grinding type: plunge grinding

Listing

Trondheim

Trondheim

17,332 km

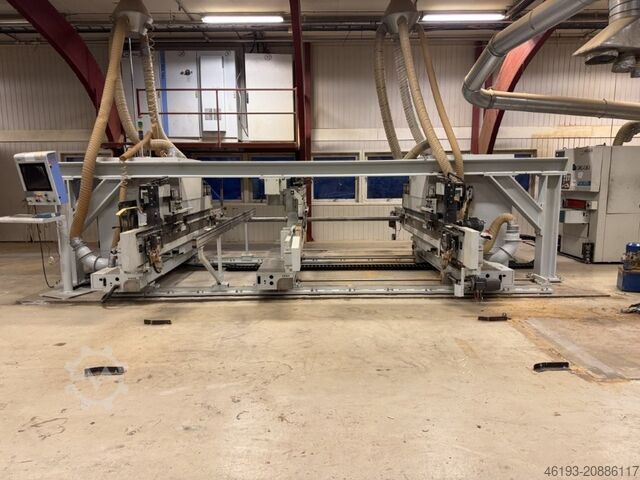

Double end tenoner

HOMAGFPL 626/03/40/W/3K

Call

Condition: ready for operation (used), Year of construction: 2009, functionality: fully functional, Equipment: documentation/manual, HOMAG FPL 626/03/40/W/3K

Double-sided HOMAG format processing machine for solid wood flooring in cross-feed through-feed operation.

Fixed reference side left, movable side right .

Technical data:

Feed speed, infinitely adjustable: 10–40 m/min

Format overhang: 3 mm (note profile depth)

Format thickness: 10–23 mm

Format length in front of lugs: max. 140–250 mm

Infeed length min: 2,400 mm

Infeed length max: 4,000 mm

Fjdpex Spxgjfx Ac Njfu

Working height to top of chain: 950 mm

Pneumatic connection: 7–8 bar

Standard Milling Unit SF20, 6.6 kW – Format Section - F.01 (1323) - 1 × left, 1 × right

For grooving and rebating from the top/bottom as well as from the side, in counter-rotation.

• 1 milling motor, 6.6 kW, 100 Hz, 6,000 rpm

• Motor shaft Ø35 × 70 mm with keyway

• Swivel range: 90°, manual

• Cross-slide with electro-pneumatic control for plunge milling

• Directional switch for rotation direction

• Extraction hood

• Groove position: minimum distance 10 mm from chain track or top pressure

• Maximum tool diameter: 200 mm

• Without tools

• Electronic frequency inverter with motor braking function

• Manual horizontal and vertical adjustment via spindle and counter

Free Space for additional milling unit - 715 mm – Standard Milling Unit - F.04 (1318) - 1 × left, 1 × right

• Including extension of sound enclosure and extraction connection ports

• Without electrical pre-installation

FOR MORE TECHNICAL SPECIFICATION PLEASE READ ATTAGED DOCUMENTS in PDF format.

This machine stands in south Norway on it orginal place. The company is now closed but it is possible to inspect the machine.

Rekman Maskin & Service since 1986

Listing

Fuente de Cantos

Fuente de Cantos

19,724 km

Centerless grinding machine

ESTARTA323

Call

Condition: used, TECHNICAL INFORMATION:

Grinding wheel dimensions (h x w x d x w) Ø610 x Ø304,8 x 254 mm

Ø min/max to be ground 1,5 / 125 mm

Width of regulating grinding wheel 254 mm

Number of regulating wheel speeds infinite

Diamond speed 225 min1

Plunge (auto/manual) 254 mm

Grinding wheel dimensions (h x w x d x w) Ø355 x Ø203,2 x 254 mm

Width of the grinding wheel 254 mm

Ffsdohzvk Eepfx Ac Nou

Maximum length to be ground in plongeé 254 mm

Motor power of grinding wheel head 30 kW

Hydraulic motor power 0,37 kW

Length 5.175 mm

Width 2.950 mm

Weight 8.375 kg

Listing

Fuente de Cantos

Fuente de Cantos

19,724 km

Centerless Grinder

ESTARTA327

Call

Condition: used, Grinding wheel dimensions (h x w x d x w) Ø 650 x Ø 304,8 x 500mm

Ø min/max to be ground 3 / 200 mm

Width of regulating wheel 500 mm

No. of regulating wheel speeds Infinite

Min/max. grinding wheel speed (r.p.m.) 10 / 255 r.p.m.

Diamond dressing (auto/manual) Longitudinal auto,manual penetration both wheels

Diamond dressing speed 255 r.p.m.

No. of cnc axes 1

Grinding wheel dimensions (h x w x d x w) Ø 350 x Ø 203,2 x 500mm

Grinding wheel width 500 mm

Maximum length to grind in plunge 500 mm

Grinding wheel head motor power 55 Kw

Fsdpfx Aceix N Ene Nefu

Hydraulic motor power 3 Kw

Total power 60 Kw

Voltage 220/380V

Length 2.300 mm

Width 2.800 mm

Height 2.100 mm

Weight 15.000 Kg

Listing

Kecskemét

Kecskemét

17,950 km

Surface grinder

OkamotoOGM 250 UNCIII

Call

Condition: like new (used), Year of construction: 2022, operating hours: 1,034 h, functionality: fully functional, machine/vehicle number: 26128, Okamoto OGM 250 UNC III

Machine Characteristics:

- OKAMOTO touch-screen NC controller with advanced OKAMOTO software

- 2-axis interpolation

- Step (shoulder) automatic probe for setting starting reference and face grinding

- Automatic wheel dressing with automatic compensation

- Up to 21 programs can be stored

- 6 types of grinding cycles, up to 10 steps each

- 5 types of wheel dressing cycles

- Zero point measuring device and air gap measuring device (optional)

- Extremely rigid, stress-relieved cast iron bed construction

- Double V-type prismatic slideways, only OKAMOTO machines are manufactured this way (with unique hand-scraped surfaces)

Technical Data:

Capacity

- Max. swing diameter over table: Ø 220 mm

- Distance between centers: 500 mm

- Max. grindable diameter: Ø 200 mm

- Max. workpiece weight between centers: 50 kg

- Max. workpiece weight in chuck, gross: 20 kg

- Grinding wheel size for universal grinder: Ø305 mm x 50 mm x Ø127 mm

- Max. peripheral speed (with inverter): 45 m/sec

- Wheel spindle X-travel: 215 mm

- Universal swiveling range: +/- 30°

- Diameter resolution: 0.0001 mm

- Rapid traverse in diameter: 4 m/min

- Table Z-travel: 762 mm

- Swivel angle: 0° ~ -9°

- Resolution: 0.0001 mm

- Rapid traverse: 8 m/min

- Workhead type: fixed and rotating centers, taper MK3

- Workhead bore diameter: Ø18 mm, speed 10 – 500 rpm

- Swivel angle - universal: 30°/ -90°

- Tailstock sleeve stroke: 20 mm, sleeve taper MK3

- Motors: Wheel spindle 3.7 kW, workhead AC servo 1.8 kW, table feed AC servo 1.2 kW, wheel feed AC servo 1.2 kW

- Total power requirement: 15 kVA

- Machine dimensions: length 3,400 mm, width 2,330 mm, height 1,950 mm

- Net weight: 3,300 kg

Standard grinding and wheel dressing software features:

- 10-step automatic grinding cycle

- Straight wheel dressing cycle

- Plunge oscillation grinding cycle

- Offset plunge (roughing) + cross-feed finishing grinding cycle

- Shoulder wheel dressing cycle for both left and right sides

- Profile wheel dressing cycle, programmable in ISO G-code

- Grinding cycle for workpiece shoulders, left and right sides

Standard Accessories:

- Grinding wheel Ø305x50xØ127 mm (UNC III), 1 pc

- 2 wheel arbors

- 3.7 kW spindle motor

- Max. grinding wheel peripheral speed: 45 m/sec

- Speed controller for workhead spindle

- FANUC 0i D CNC control (simultaneous 2-axis)

- 10.4" color OKAMOTO controller – vertical and cross-feed display

- Graphical teach software for creating grinding and dressing cycles

- Complete Fanuc push-button panel for ISO G-code programs with corner radius compensation

- Electronic handwheel (graduations: x1/x10/x100)

- Rapid traverse control lever (joystick) for cross and longitudinal directions

Ffedox R Tw Rspfx Ac Nsu

- Enclosed guard with safety interlocked sliding door

- LED machine lamp

- Automatic lubrication during operation

- Coolant nozzles and piping

- Coolant system for wheel dressing

- Permanent coolant installation to the table

- Carbide centers

- Step (shoulder) positioning device and software

- Gap sensor and software

- Leveling screws and base plates

- Tool kit

- Operating manual

- CE version

- Table rotation measuring device

- Coolant system with paper filter, DGS, 200 l

- Rinsing gun

- 2-point manual steady rest

- 130 mm manual chuck with backplate

- Motorized tailstock sleeve with foot pedal

- Status lamp (green/yellow/red)

- Balancing arbor

- Spare wheel arbor

Listing

Rumbula

Rumbula

17,283 km

INSULATION BLOWING MACHINE, 3 components

ISOCELLISOBLOW blowing machine

Call

Year of construction: 2024, condition: used, functionality: fully functional, Innovative machinery for on-site and prefabrication processing of cellulose insulation in timber element construction – tailor-made solutions for every requirement profile.

ISOBLOW blowing machines simplify and enhance the efficiency of cellulose insulation installation. Only top-grade cellulose fibers, high-performance blowing machines, and user-friendly accessories ensure superior quality and rapid application.

Components:

ISOBlow Plate 6122101 Blowing Plate

For dust-free and efficient insulation of single-sided sheathed elements

• Includes 7” touch display with memory function, USB interface, time and weight display

• User-friendly control panel

• Includes 6 pneumatic injection nozzles with pressure sensors, without line laser and operating button

• Optional machine control via wireless remote

• Includes contact plate and pause function

• Harting connectors and LAN ports as specified

• Includes crane lifting eyes

• Weight: approx. 500 kg

Product Data – ISOblow Titan Twin Turbo:

The ISOblow TiTAN TwinTurbo features two turbines with distinct characteristics – a true powerhouse for professional installers! The airlock is 50% larger, enabling increased throughput. Precisely balanced 5.5 kW air power allows air flow rates exceeding 720 m³/h and 450 mbar with 16A fuse protection, unmatched on the market! The ultimate blowing machine for cellulose and wood-fibre insulation.

Controlled via radio remote control.

- Width: 1010 mm

- Length: 1680 mm

- Height: 1840 mm

- Weight: 570 kg

- Capacity: 1503 L

- Electrical: 400 V / 50 Hz, 16 A

- Turbine: 7.5 kW

- Airlock drive: 1.1 kW

- Agitator: 1.1 kW

- Additional chopping unit: 0.55 kW

- Total power: 10.25 kW

- Max. air pressure: 450 mbar

- Max. air flow: 720 m³/h

- ISOCELL radio remote control: controls air and material feed

Ffsdpfx Acsx Rzn Re Nsu

- Hose connection: 3” (76 mm)

- Open blow: 1900 kg/h

- Dense pack: 1400 kg/h

- Roof cavities: < 50 cm deep

- Wall cavities: < 40 cm deep

Cleaning Station

Cleaning station for ISOblow Elements

• Capacity: 210 L, 420 m³/h extraction capacity

• 230 V / 50 Hz, 16 A

• Total output: 3.8 kW; weight: approx. 70 kg

• Dimensions (L x W x H): 116 x 77 x 112 cm

• Includes 7.5 m, 3” suction hose

• Vacuum pool cleaner

Listing

Bad Honnef

Bad Honnef

18,588 km

Panel saw HOLZ-HER 1255 SECTOR pro - Exhibition machine -

Holz-Her1255 SECTOR pro

Call

Condition: new, Panel saw HOLZ-HER 1255 SECTOR pro

- Exhibition machine -

Cutting height 2,200 mm

Cutting length 5,300 mm

Vertical perfection from HOLZ-HER

The vertical panel saws from HOLZ-HER combine

proven technology from over 50 years of experience and

a rock-solid design that offers you a unique price-performance ratio.

offer you a unique price-performance ratio.

Your advantages:

- Fully welded frame Extremely high rigidity

- Precise cutting quality

- Finished cut for immediate edge banding

- Powerful saw motor with 4 kW output

- Space-saving panel layout with a

installation area from 4 m²

- Smooth and ergonomic operation

TRK extraction system (optional in all CE countries):

Workstations must meet the highest requirements

when it comes to health and safety.

HOLZ-HER saws are among the cleanest and safest in the

safest in the world.

Accessories

The extensive range of accessories extends from

convenient digital dimension displays through to our

our patented Super Cut plus scoring system.

TECHNICAL DATA

Vertical panel saw for cutting panel-shaped wood materials

wood-based materials such as chipboard, MDF, veneer panels, multiplex, etc,

veneer panels, multiplex etc.

Basic machine:

Completely welded frame with extremely high

rigidity. Precise guidance of the saw beam / saw unit

saw unit for an accurate cut. Manual feed

feed for vertical and horizontal cutting.

Cutting depth: max. 60 mm

Saw beam:

Sturdy saw beam guided on precision guides.

Pneumatic locking of the saw beam at the top and bottom.

Electrically monitored in vertical cut

Saw unit:

Fjdpfsu R Syiox Ac Nofu

Smooth and ergonomic operation for plunging and

and removal of the saw unit. Immersion lever can be

lever can be folded down in the upper position for precise

immersion of the saw unit. Generously dimensioned

lever for easy pivoting. Housing cover opens the complete

opens the complete saw unit for easy tool change

change incl. ProLock quick-action chuck.

Light cut-out:

Riving knife can be retracted.

Control panel:

Efficient operation of the machine.

Ergonomically positioned at eye level.

Lower workpiece support:

Sturdy, wear-free stainless steel support.

Support up to the cutting line:

Narrow workpieces cannot tip or fall through

Extraction:

Effective extraction with two connections:

Saw unit Ø 120 mm, frame end Ø 100 mm

(with TRK variant)

Lifting roller transport system:

Manually liftable and lowerable rollers for easy and

and gentle panel transport.

Measuring tape:

For displaying dimensions for horizontal cutting with three

manual dimension displays:

Absolute dimension from the lower workpiece support

Absolute dimension from the middle workpiece support

Serial cuts from the top edge of the panel

This offer is an equipment package.

The following items and options are already included in the price:

- Sliding grid

- Manual longitudinal stop for vertical cutting

- Digital dimension display for horizontal cut

- 3 adjustable stop points in the saw beam

- TRK SH 2.200 suction device

- Strip stop for recurring horizontal cuts

- new exhibition machine -

Listing

Hilden

Hilden

18,565 km

Vertical Turret Lathe - Single Column

DÖRRIESVCE 1600/140 MC F

Call

Condition: excellent (used), Year of construction: 2010, swing diameter 1600 mm

faceplate diameter 1400 mm

Control Siemens Sinumerik 840D SL

turning height 1245 mm

max. table load 9000 kg

table drive 60 kW

Ffodpfx Aexylm Toc Nju

torque - table 13400 Nm

Table rpm 450 1/min

speeds c-axis 0,004-5 1/min.

feed range 18000 mm/min

dimensions of the machine ca. 8,5 x 5,3 x 5,7 m

weight of the machine ca. 47,4 t

Crossbeam support:

-Travel range X-axis: ± 950 mm

Crossbeam stroke W-axis: 600 mm

Ram :

-Cross-section Ram: 250 x 250 mm

-Plunging diameter: 340 mm

-Travel Z-axis Ram: 1100 mm

Drilling and milling device:

- Distance between milling spindle and machine table 1245 mm

- Tool holder SK 50

- Drive power 30 kW

- Speed range 2000 rpm

- Torque 1395 Nm

Equipment/accessories:

-16-40-fold pick-up magazine

-Protective device

-Various turning tool holders

-Various SK50 tool holders and tools

-Various clamping devices

-Coolant device with filter

-Chip conveyor

-Documentation

Listing

Hilden

Hilden

18,567 km

Gear Hobbing Machine - Horizontal

MONNIER & ZAHNERKOEPFER MZ 120

Call

Condition: used, Year of construction: 2006, max. wheel diameter 2 - 45 mm

gear width 250 mm

max. module 1,5 mm

min. module 0,5

weight of the machine ca. 2,2 t

Ffjdpfovq Sfzex Ac Nou

control Fanuc 18i-MB

max. workpiece length 250 mm

weight of the machine ca. 2200 kg

Milling cycles:

- straight, helical, crowned gearing

- radial, radial-axial, climb and conventional milling, roughing, finishing

- worm wheels, straight-toothed bevel wheels, face gearing (option: only in

partial process)

Technical Details:

- maximum workpiece length 250 mm

- maximum toothing length 150 mm

- maximum module in steel 1 mm (gear hobbing)

- maximum module in steel 1.5 mm (worm milling)

- maximum module in steel 0.5 mm (bevel gear hobbing)

- milling cutter diameter 16-32 mm (gear hobbing)

- milling cutter diameter 40-63 mm (worm milling)

- maximum setting angle of milling head ±45 deg. (Rolling)

- maximum setting angle of milling head ±30 deg. (worm milling)

- Shift travel 34 mm (CNC axis)

- Collet / retraction mandrel W20

- maximum speed of the workpiece spindle 770 rpm.

- milling spindle drive 0.55 kW

- Maximum speed of the milling spindle 8000 rpm.

CNC axis drives:

-X-axis = plunge travel 80 mm

-Z-axis = longitudinal feed travel 190 mm

-C-axis = workpiece axis 360 deg.

-Rapid traverse X/Z 6 m/min.

-Hydraulic unit 0.37 kW

-Dimensions 2100 x 1440 x 1700 (LxWxH)

Options:

-CNC shift axis 34 mm

-Adjustment angle with CNC axis

-Deburring device

Accessories:

- spiral conveyor

Listing

Wiefelstede

Wiefelstede

18,341 km

Plan and turning head

KruppSK50

Call

Condition: good (used), Boring head, spindle head, drill head, plunge drill head, plunge head, spindle drill head, boring head

Ffodpfxjb A Ncqs Ac Nsu

-Recording: SK50

Minimum bore diameter: 95 mm

-Max. bore diameter: 115 mm

-Suitcase

-Dimensions: 400/170/H140 mm

-Weight: 12 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Plan and turning head

KruppSK50

Call

Condition: good (used), Boring head, spindle head, drill head, plunge drill head, plunge head, spindle drill head, boring head

-Recording: SK50

Minimum bore diameter: 100 mm

-Max. bore diameter: 120 mm

-Suitcase

-Dimensions: 350/170/H135 mm

Ffsdeb A N Uzopfx Ac Nsu

-Weight: 12 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Boring head

KOMETSK50

Call

Condition: good (used), Boring head, spindle head, drill head, plunge drill head, plunge head, spindle drill head, boring head, spindle tool

Ffodpeb A Rlljfx Ac Nsu

-Recording: SK50

-Adjustment range: 20 mm

-Tool shaft: Ø 30 mm

-Weight: 10 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Boring head 2 pieces

KAISER145-230/225-310 mm

Call

Condition: good (used), Boring head, spindle head, drill head, plunge drill head, plunge head, spindle drill head, boring head, spindle tool

-Quantity: 2x spindle tools

-Recording: SK50

-Spindle dimensions: 145-230/225-310 mm

Ffodpeb A Hvpefx Ac Nou

Price: complete

-Weight: 14 kg/piece

Trust Seal

Dealers certified through Machineseeker

Listing

Iași

Iași

17,349 km

Threading machine

SENYD 75 B

Call

Condition: used, Year of construction: 2000, functionality: fully functional, machine/vehicle number: 308, Technical characteristics:

Ffodpoxx Nuxsfx Ac Nsu

⚙️ Core Specifications

Attribute Value

Thread Diameter Range: 3 mm to 75 mm

Rolling Pressure: 0.5 to 20 tons

Max Thread Length (Plunge): 160 mm

Max Thread Length (Through): 2000 mm

Speed Range: 24 to 114 rpm (8-step gearbox)

Tool Diameter: 145 mm to 200 mm

Roll Spindle Diameter: 54 mm

Shaft Distance: 130 mm to 200 mm

Machine Dimensions (L×W×H): 1880 (INCLUDING HYDRAULIC UNIT) × 991 × 1270 mm

Weight: ~1.6 tons

🧰 Features & Capabilities

Variable Rolling Pressure: Adjustable to suit different materials and thread profiles.

Heavy-Duty Construction: Built for long-term industrial use with high repeatability.

Manual or Semi-Automatic Operation: Depending on configuration and accessories.

Machine status:

WORKING

Listing

Castello di Godego

Castello di Godego

18,564 km

Bridge saw cnc

BretonBreton SmartCut S/NC500

Call

Condition: used, Year of construction: 2008, functionality: fully functional, total length: 4,500 mm, total width: 7,000 mm, cutting length (max.): 3,500 mm, cutting width (max.): 2,000 mm, feed rate X-axis: 60,000 m/min, feed rate Y-axis: 40,000 m/min, feed rate Z-axis: 20,000 m/min, spindle motor power: 17,000 W, Numerical control cutting centre with 4 interpolated axes, fixed worktable and twist head; the machine is specially engineered to cut/ shape (either in the plunge-cut or step-cut mode) items of granite, marble, engineered stone and suchlike.

Ffjdpfx Acevtdzte Nou

Listing

Bienne

Bienne

18,826 km

CNC AUTOMATIC LATHE

TORNOSSIGMA 8

Call

Year of construction: 2010, condition: excellent (used), machine/vehicle number: 9589 (232-0001), Manufacturing origin CH

Netweight 1600 kg

Custom position 8458.9120

Dimensions 167x87x165 cm

With bar-feeder LNS Tryton 112

TECHNICAL DATA

Control Fanuc série 32i-B

5 linear axes :

Longitudinal travel of main spindle Z1

Fjdpfxef Nqzqo Ac Nofu

Longitudinal travel of backwork counter spindel Z4

Cross travel of tools X1 (turning operations and cross milling)

Cross travel of tools Y1 (tools selection and milling operations)

Radial plunge of 2 tools (T21 et T22) X2

Spindel (mounted on Z1-axis) :

Max bar capacity 10 mm

Work travel 20 mm

Type of drawed collet W15

Max speed 15'000 min-1

Linear tools system mounted on 2 axes X1 and Y1

Tools system for turning comprising 2 slides controlled by X2-axis

Backwork counter-spindle with motor (on axis Z4) :

Max clamping 10 mm

Work travel 120 mm

Type of pushed collet F13 (76-00357)

Max speed 15'000 min-1

Spindles denomination S1 et S4

Least increment for axes programming 0.1 µ

Coolant pump max flow 50 L/min

Pump motor 1,1 kW

Oil tank 130 L

errors and omissions excepted-data given without obligation

Listing

Bienne

Bienne

18,826 km

Cylindrical grinding machine

KELLENBERGER600-U

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, machine/vehicle number: 1315/451, Completely overhauled:

Mechanics, geometry, hydraulics, and electrical parts (checked and/or replaced)

Wheelhead:

Disassembled, parts cleaned, worn or defective components replaced, motor overhauled, bearings replaced, belts replaced, spindle disassembled, seals and O-rings replaced, adjustments made. Newly painted.

Workhead:

Disassembled, parts cleaned, worn or defective components replaced, motor overhauled, belts replaced. New spindle bearings. Newly painted.

Tailstock:

Disassembled, inspected, overhauled.

Hydraulics:

Disassembled, motor checked, hoses replaced, defective and worn parts replaced. Hydraulic block checked.

X-axis:

Disassembled, all worn parts such as O-rings, seals, segments, etc. replaced, hydraulic piston overhauled, table ground.

Z-axis:

Disassembled, table ground, worn or defective parts replaced, hydraulic piston overhauled, newly painted.

Electrical cabinet:

Completely checked, various relays replaced.

Paintwork:

Colors: White RAL 9003 and Grey RAL 7011

Fsdpfx Ajw U Ry Njc Njfu

Geometry according to manufacturer's protocol.

Various accessories checked and cleaned.

Origin: CH

Voltage: 380 / 50 / 3

Net weight: approx. 2,200 kg

Customs tariff number: 8460.2920

TECHNICAL SPECIFICATIONS

Nominal distance between centers: 600 mm

Max. distance between centers (with extended headstock): 750 mm

Center height, standard: 125 mm

Center height with interchangeable pads for heads: 175–250 mm

Max. workpiece diameter (125 mm center height): 250 mm

Max. workpiece diameter with interchangeable pads: 350–500 mm

Swiveling range of table in each direction: 10°

Max. grinding length for flat surfaces (max. width = 200 mm): 900 mm

Continuously variable hydraulic table speed: up to approx. 6 m/min

Table reversal delay: 0–5 sec

Grinding wheel for external grinding, diameter - width - bore: 400x50x127 mm

Grinding wheel for flat surface grinding: 250x13x76 mm

Wheelhead spindle speed: 1,500/1,700/2,200/3,600 rpm

Wheelhead swiveling range: 270°, with indexing every 90°

Vertical travel of wheelhead, center height: 125–350 mm

Transverse travel of wheelhead: 285 mm

Hydraulic rapid traverse stroke: 40 mm

Intermittent infeed of wheel by table reversal: 0.001–0.03 mm/dia

Continuous infeed for plunge grinding: 0–0.9 mm/dia

Micrometric infeed stop, by division: 0.001 mm/dia

Workhead swiveling range: 360°

Workhead spindle speed, stepless: normal/special: 20–400 / 10–400 rpm

Internal taper of workhead/tailstock: Morse 5/3

Wheelhead motor: approx. 4 HP

All technical specifications are given without obligation and subject to errors or omissions.

We make it easier for you to find: "plunge pool"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Plunge Pool (250)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month