Used Balancing Machine for sale (64,027)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Viljandi

Viljandi

17,138 km

Balancing machine for rotors

CEMBZB200/TC/TA

Call

Condition: used, Year of construction: 2003, functionality: fully functional, machine/vehicle number: 101402, type of input current: three-phase, input current: 50 A, input frequency: 50 Hz, input voltage: 400 V, power: 20 kW (27.19 HP), CEMB ZB200/TC/TA rotor balancing machine in good working condition. Used for rotors in sizes 160-250. Fully operational. Last test on 17/04/2025.

Rsdpfeygbfgjx Adaon

Listing

Deinze

Deinze

18,734 km

Balancing machines

Balance SystemsBB 4000

Call

Condition: ready for operation (used), Maximale diameter onderdeel: 200 mm

Balansringprocedures volgens ISO 1940

PC-gebaseerde grafische interface

HSK 63

Gereedschapsinstelling: 9BB4KP00002000

Softwareversie: R150F09

De BB 4000 is een dynamisch balanceerapparaat voor roterende onderdelen.

Het ontmoet onbalans (massa × excentriciteit) terwijl het werkstuk draait en geeft exact aan:

Redpfx Aoycmnxsdaen

Hoeveel onbalans er is

Waar de onbalans zit (hoekpositie)

In welk vlak (links / rechts of enkel vlak)

Een BB 4000 wordt typisch gebruikt voor:

-Elektromotor-rotoren

- Ventilatoren en blowers

-Pompas-rotoren

-Turbo

-Rollen / assen / spindels

make:: 230V

Distance between centres :: 600 mm

Weight of workpiece :: 20 Kg max

Listing

Bydgoszcz

Bydgoszcz

17,832 km

Balancing Machine

CIMAT

Call

Condition: as good as new (ex-display), Compact balancer with vertical spinning axis and load capacity up to 50 kg. Thanks to its compact design, the machine takes up relatively little space and does not require foundations, so it can be easily relocated to the desired location. The balancing process is controlled by the latest measuring system "ROTORTEST 9.5" with dedicated software equipped with workshop programs, which convert the unbalance into a convenient correction method, e.g. into drilling or milling parameters.

Vertical axis balancing machine is recommended for balancing rotors mounted on a bore, e.g. fan rotors, pulleys, flywheels, tools, pumps and many others. The biggest advantages of this type of balancing machine are its universal application, the possibility of using dedicated self-centring chucks giving high measuring accuracy, simple and quick calibration method, so called "manufacturer's calibration", which does not require calibration runs to be carried out before starting the measurements. The whole procedure consists only in entering basic rotor parameters into the software.

Rjdpfof Nvwpjx Adaon

This machine is an excellent choice for balancing single pieces of various rotor models, and in particular for balancing large series of the same rotor model.

Parameters

Maximum rotor weight - 50 kg

Maximum rotor diameter - 650/850 mm

Maximum rotor height - 500 mm

Listing

Hamburg

Hamburg

18,230 km

Balancing machine

TIRAKV 10

Call

Condition: ready for operation (used), Year of construction: 2007, Available immediately from site:

CNC Vertical Balancing Machine TIRA

Model KV 10

Year of manufacture: 2007

Rsdjyaycdepfx Adaon

Rotor mass: 1 – 10 kg

Rotor height up to 400 mm

Rotor diameter up to 400 mm

Max. balancing speed up to 2000 rpm

Max. display sensitivity (gmm): 0.5

Drive power: 2.2 kW

Weight: 1500 kg

Price: EUR 7,500—plus VAT, ex site

Listing

Odesa

Odesa

17,113 km

Vertical balancing machine

97V10 (10kg)

Call

Condition: new, workpiece weight (max.): 10 kg, rotor diameter: 250 mm, High-Precision Vertical Balancing Machine for Disk-Type Rotors up to 10kg

The 97V10 is a versatile vertical balancing machine designed to efficiently balance disk-type rotors without their own bearing surfaces. Ideal for serial, small-scale, and single-piece production, it ensures optimal performance and reliability of your products.

HIGHLIGHTS

• High Accuracy: Delivers precise unbalance measurement with an accuracy of at least 4 g∙mm/kg.

• Versatile Design: Accommodates a wide range of disk-type rotors, including:

- Discs of various designs

- Pulleys and flywheels

- Fan impellers

- Brake discs and drums

- Couplings

- Pump impellers

- Cutting tools

Rjdpfxsu U Nqdj Adajn

• Efficient Operation:

- Vertical axis of rotation for quick part replacement and easy access.

- Semi-automatic mode for streamlined operation.

- Protective covers and compliance with CE and ISO safety standards.

• Flexible Configuration:

- Customizable with drilling or milling modules for in-situ unbalance correction.

- Available with various spindle fits (cylindrical or tapered) and mandrels.

- Options for pneumatic or manual collet chucks and hydraulic jacks for heavy workpieces.

SPECIFICATIONS

Weight range of balanced rotors 0.1 - 10 kg

Maximum rotor diameter 250 mm

Maximum rotor height 150 mm

Minimum achievable residual specific unbalance 4 g*mm/kg

Number of measurable rotor correction planes 1 & 2

Rotor speed range 300 – 1500 rpm

Electric motor power 1.0 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

For more information and to discuss your specific balancing needs, please contact our sales team.

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Discover more used machines

Listing

Germany

Germany

18,260 km

Balancing Machine - Vertical

SCHENKVM3/2

Call

Condition: used, Year of construction: 2007, Technical details:

balancing body max.: 100 kg

balancing body diameter: max. Ø 800 mm

swing diameter: 630 mm

Balancing revolution per minute: 120 - 1200 U/min

drive power: 4 kW

Weight approx.: 0,6 t

dimension machine xH: 1,8 x 1,2 x 1,4 m

dimensions electric cabinet: 650 x 700 x 1900 mm

Rjdpfxsvc Apze Adasn

Vertical balancing machine

The balancing machine is used to measure and balance the static or dynamic unbalance of rotors.

Unbalance static=2 and dynamic=3

Measuring device CAB 803

Display Screen

Computer RS232C

Basic system dynamic unbalance in 2 levels

Operation via control panel on the switch cabinet / 2x foot switch

No printer available!

*

Listing

Germany

Germany

18,260 km

Universal Balancing Machine for Rotors

HOFMANNUHK 26

Call

Condition: used, Year of construction: 2004, Technical details:

balancing body max.: 12500 kg

balancing body diameter w/o machining unit: 1500 mm

bed length: 3000 mm

swing diameter: 2400 über Maschinenbett mm

rotor-shaft: Ø 1500 über Bandantreb

voltage: 400 / 50 V/Hz

drive power: 22 kw

connected load: 25 kVA / 20 kW

compressed air: 6 bar

Weight approx.: ca. 5,5 t

dimension machine xH: 3,3 x 1,5 x 2,0 m

dimensions electric cabinet: 650 x 610 x 2150 mm

Rsdpfx Adou Iczreaon

Horizontal balancing machine, functional see video, dismantled, ready for loading ex Leipzig.

The balancing machine is used to measure and balance the static or dynamic unbalance of rotors.

Drive block/balancing speed:

5-speed and reverse gear (manual gearbox) max. 80 rpm; 160 rpm; 290 rpm; 470 rpm; 630 rpm.

incl. PCX measuring electronics

Measuring method force-measuring

Measuring range of the electronics Speed 60 to 30,000 rpm.

Bearing journal Ø 40 - 178mm / 140 - 445mm

2 base bodies (cast steel body), storage length between the bearing pedestals up to approx. 3000mm, adjustment with hand ratchet via toothed rack, with extension 1500mm

2 bearing pedestals/swing bearing blocks:

Center height 1200mm measured in bed; 2x rollers Ø 195 x 56mm; 2x rollers; center distance 205mm; adjustment travel 350mm vertical

*

Listing

Germany

Germany

18,260 km

Universal Balancing Machine for Rotors

SCHENKH4U

Call

Condition: used, Technical details:

balancing body max.: 800 kg

Rsdpfou Upp Tsx Adasn

balancing body diameter: 1250 mm

Balancing revolution per minute: 190 - 3600 U/min

bed length: 2600 mm

voltage: 380 V/Hz

drive power: 7,5 kw

Weight approx.: 1,5 t

dimension machine xH: 3,5 x 1,7 x 2,0 m

dimensions electric cabinet: B:650 x T:250xH:800 mm

Horizontal balancing machine

The balancing machine is used to measure and balance the static or dynamic unbalance of rotors.

Balancing body weight max. 800 kg with equal load distribution, i.e. 400 kg per bearing pedestal

Power transmission by means of cardan shaft

Bearing journal Ø min./max.: 16-95 / 95-180 mm

Bearing distance center distance min. 125 mm and shaft end bearing center max. 2070 mm

Measured speed:

1st gear = 190 - 650 rpm.

2nd gear = 400 - 1250 rpm

3rd gear = 700 - 2100 rpm.

4th gear = 1200 - 3600 rpm.

2 pick-up blocks whose displacement is manual over the entire bed

Schenk measuring device with digital display

and some accessories, e.g. many rotor shafts with different Ø and different rotor mounts, please ask!

*

Listing

Germany

Germany

18,260 km

Balancing Machine for car wheels

HeinlATH-550

Call

Year of construction: 2010, condition: used, Technical details:

range of revolution per miute: 180 U/min

voltage: 220/ 50 V/Hz

machine weight approx.: 150 kg

dimension machine xH: 1,2 x 0,8 x 1,3 m

total power requirement: 550 kW

Car tire balancing machine

Rjdpfxou Ic Ais Adasn

The balancing process is automatic with wheel braking.

Program selection can be chosen between 11 balancing methods.

Microprocessor controlled LED display with digital weight display.

Center hole of rim Ø 40 - 154mm

Shafts Ø 36mm

Measuring speed 120 rpm.

Measuring time 5 - 10 sec.

Cone sizes: Ø 44 - 63mm; Ø 61 - 79mm; Ø 77 - 114mm; Ø 107 - 154mm

Wheel dimension:

Rim width: 1,5" - 18"

RimØ max. 10" - 24"

Wheel Ø max. 890mm

Wheel weight max. 65kg

*

Listing

Germany

Germany

18,260 km

Balancing Machine - Vertical

SCHENKVM2/2

Call

Condition: used, Year of construction: 2006, Technical details:

balancing body max.: 50 kg

balancing body diameter: 0 -800 mm

Balancing revolution per minute: 120-1200 U/min

swing diameter: 800 mm

drive power: 2,2 kw

Rodpex Hi D Ssfx Adajn

Listing

Marxzell

Marxzell

18,650 km

Dittel MBA 2000 Mechanic balance machine

DittelF20367

Call

Condition: new, For sale is a Dittel MBA 2000 Mechanic balance machine.

The item is new and fully functional.

Item number: F20367

Serial number: 356-0629

Part No.: 816/118 B

Shipping or pickup can be arranged at any time.

Rodpspky U Eefx Adaon

If you have any further questions or are interested just contact me.

Listing

Dieren

Dieren

18,531 km

Balancing Machine with Vertical Shaft

CEMBVPECS 30

Call

Condition: ready for operation (used), Year of construction: 2001, functionality: fully functional, machine/vehicle number: 11311, workpiece weight (max.): 30 kg, type of input current: three-phase, input current: 12 A, input frequency: 50 Hz, input voltage: 400 V, rotor diameter: 1,000 mm, Balancing Machine, vertical shaft.

Measurement in two planes.

Maximum rotor weight: 30 kg (tooling included).

Automatic Indexing (rotor will, after measurement be positioned with correction location at the front).

Rjdpfxex H Aa Ts Adasn

Rotor speed can be set for each programmable standard workpiece type.

Some tooling is included.

Machine is available because fans are no longer built by the customer.

Listing

Kerava

Kerava

17,045 km

Balancing machine

SchenckH 50 V/B

Call

Condition: used, functionality: fully functional, Used Schenck Balancing Machine H 50 V/B with used CAB 690 H measuring unit.

(Can be upgraded to a new CAB 920 unit for an additional (18 000–20 000€)

Rjdpfx Aex Ein Sedaon

The machine comes with original foundation drawings, documentation and manuals.

The machine can be test run in Kerava.

Rotor Capacity

- Rotor weight range: 20 – 6 000 kg

- Maximum symmetrical load on pedestal bearing: 7 500 kg

- Maximum symmetrical load on stand bearing: 3 750 kg

- The machine can be loaded freely with lower weights when following recommended procedures.

- Maximum rotor length between pedestals:1 600 mm (belt drive)

- Maximum diameter over machine base: 2 100 mm

- Clamped rotor diameter ranges: 25–180 mm, 180–380 mm

- Machine bed length: 3 500 mm

- Balancing speed n depends on the rotor’s moment and must be selected to avoid overloading the drive.

- Maximum permissible G·n² value: 1400 × 10⁶ kg/min²

- Applies to a rigid symmetrical rotor mounted on pedestal bearings.

- May be exceeded during dynamic tests on flexible rotors and strength tests.

- End drive / FU motor: 7,5 kW

- 4-speed gearbox: 120–2520 rpm

- Belt drive BU 5 / FU: 7,5 kW

- Unbalance Umar 0,5 gmm/kg: 0 gmm/plane

Listing

Essen

Essen

18,539 km

Balancing machine

SchenckSENSiQ® RTN – 4,7 t – C3

Call

Condition: used, functionality: unexamined, machine/vehicle number: S/N: 002815GL, 8x Schenck load cells SENSiQ® RTN – 4.7 t – C3

Used, good condition – S/N: 002815GL

Rjdpfx Adjxyi Aleaon

For sale are eight high-quality Schenck load cells of the SENSiQ® RTN type, each with a capacity of 4.7 tons and accuracy class C3.

The load cells were removed from a fully operational system and are in good, used condition. They have always been handled with care and professionally dismantled.

Listing

Odesa

Odesa

17,113 km

Cardan shaft balancing machine

BVI-03-74

Call

Condition: new, Cardan shaft balancing machine BVI-03-74

Available in stock in Poland !!!

Delivery time: one day!!!

.

.

Machine for driveshafts weighing up to 150kg and up to 4700mm long. Suitable for small workshops with a large range of different shafts, including trucks.

This balancing machine has high productivity and serves to balance the cardan shafts of cars and trucks. It makes the process of balancing the cardan shaft easy thanks to many technical solutions, while the machine has an affordable price, which reduces your financial burden and allows you to develop your business effectively.

.

.

TWO TIMES faster than your machine.

This balancing machine is majored to balance the shaft not only qualitatively, but also quickly.

If you can balance in 2-2.5 times faster, then this is your real competitive advantage.

.

.

HIGH PERFORMANCE ACCESSORIES

The machine is equipped with three main types of adapters:

1. Fast clamping universal adapters. It has two main advantages: The first is that due to the special design the driveshaft flange is clamped within 5 seconds. This advantage is due to the fact that the driveshaft flange does not need to be fixed with bolts.

THE SHAFT CAN BE CLAMPED 4 TIMES FASTER WITHOUT BOLTS.

The second advantage is the centering rings. The driveshaft is mounted in the adapters with centering rings that can be made on an ordinary lathe to fit most common driveshafts.

2. KV Flange adapters. Used for balancing shafts with cross-tooth flanges. Applies to four flange sizes: 120, 150, 180, 205 mm. Usually used on truck driveshafts.

3. Adapter with slots. Used to mount various flanges with holes. Mounting the driveshaft is the same as on universal adapters, with the help of centering rings.

KEY FEATURES

• Balancing of 2, 3 and 4-support cardan shafts

• Shaft length up to 4700mm, weight up to 150kg

• Cardan installation in 1 minute

• Standard set of adapters - Installation of 80% of cardan shafts;

• Three ways of fixing the center bearing

• Soft-bearing type machine - high sensitivity to any vibration

• Machine is operated by one worker

• Sliding bearing supports - quick changeover, comfortable operation

• Safety bracket with clamp for quick installation

• Measurement in all planes at one time

• Calibration of the machine by the operator

• Displays imbalance in real time

• Create and print reports

SPECIFICATIONS

Maximum cardan shaft weight 150 kg

Maximum flange diameter 300 mm

Maximum length of cardan shaft 4700 mm

Number of machine supports 4

Number of simultaneously measured planes 2, 3, 4

Minimum achievable residual specific imbalance, 10 g mm/kg

Rjdpfx Aspbv Tfedaen

Rotor speed range 1000-2000 rpm

Power supply 380V, 3 Ph, 50Hz

Power, minimum, 2,2 kW

Dimensions (length x width x height) 6000 х 1100 х 1450 mm

Weight 700 kg

! We manufacture а full range of equipment

for drive shaft balancing and repair service.

Please contact us to get the best offer!

Listing

Frankenblick

Frankenblick

18,396 km

Horizontal Balancing Machine Hofmann KKT

KKTUniversal BA & KA Auswuchtmaschine

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, workpiece weight (max.): 50 kg, total width: 400 mm, total length: 1,200 mm, total height: 1,800 mm, overall weight: 950 kg, Equipment: documentation/manual, The KKT Universal BA & KA balancing machine is a horizontally operating industrial balancing machine for precision balancing with belt drive and cardan shaft drive. It is suitable for balancing motor armatures of various sizes, as well as shafts, fan impellers, grinding wheels, cardan shafts, and similar rotors. We offer this machine in various versions, both as a used machine and as a new machine built to meet customer requirements. Please feel free to contact us - we will be happy to provide you with comprehensive advice and support.

Rjdpef Sqiqsfx Adasn

Listing

Monheim am Rhein

Monheim am Rhein

18,574 km

Balancing machine

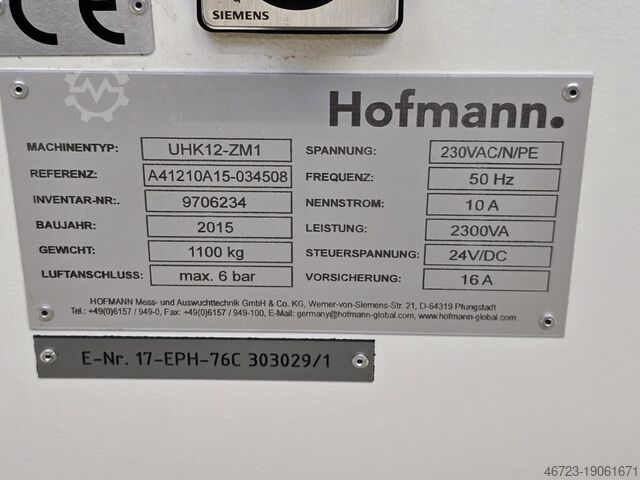

HofmannUHK 12 - ZM1

Call

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

Redpfjwg A Siox Adaen

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

Listing

Odesa

Odesa

17,113 km

Lightweight balancing machine

9A710 (3kg)

Call

Condition: new, workpiece weight (max.): 3 kg, rotor diameter: 400 mm, rotor length: 300 mm, High-Precision Rotor Balancing for Small Batch Production.

The 9A710 balancing machine excels at balancing various rotor designs up to 3 kg. Its exceptional accuracy and high sensitivity allow you to detect and correct even the slightest imbalances. This makes it ideal for single-piece and small-batch production, ensuring smooth operation of your rotors.

Key benefits:

• High precision: Detects minute imbalances for optimal performance.

• Wide application: Handles diverse rotor designs within the weight limit.

• Simple & reliable: User-friendly design ensures long-term operation.

• Increased productivity: Streamlines balancing processes in small-scale settings.

Originally designed for small-batch production, the 9A710's versatility makes it a valuable asset in repair shops as well.

This machine is perfect for balancing:

• Small motors & generators

• Shafts for various mechanisms

• Impeller fans & pumps

• Precision machine tool components

• Rotating drive elements

! Upgrade your balancing capabilities and achieve exceptional results with the 9A710.

SPECIFICATIONS

Weight range of balanced rotors 0.03 - 3 (5) kg

Maximum rotor diameter (above the bedding) 400 mm

Distance between centres of rotor supports 4 – 300 mm

Support type Prisms

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.1 g*mm/kg

Rotor speed range 600 – 3000 rpm

Rodpeu Urwgjfx Adajn

Electric motor power 0.09 kW

Parameters of the supply network 220V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

17,113 km

Horizontal Dynamic Balancing Machine

9K719

Call

Condition: new, workpiece weight (max.): 10,000 kg, rotor diameter: 2,500 mm, Horizontal soft-bearing Balancing machines 9K719 with load capacity from 100 to 10000 kg are designed for high-precision balancing of rotors of electric motors, pumps, compressors, blowers and exhausters, gearboxes, turbines of power engineering.

Self-aligning rollers ensure proper rotor alignment, simplifying setup and reducing balancing time.

Combined Drive System has a unique configuration with two axial drives and a belt drive mounted on a single bed.

Overall, this machine is highly versatile and effective in balancing various types of rotors, making it ideal for repair and production shops.

HIGHLIGHTS

• Soft-Bearing System: This system ensures linear sensitivity across the entire speed range during balancing. The result is exceptionally high balancing accuracy, achieving up to 0.04 g·mm/kg across all rotor mass ranges.

• Self-Aligning Roller Cassette automatically adjusts to the rotor along two axes, eliminating the need for precise centering. This design reduces machine setup time and, consequently, the overall time required for balancing.

• Wide Contact Area Rollers: The cylindrical rollers provide a broad contact surface, preventing scoring or deformation of the rotor's support surfaces. This is crucial when balancing heavy rotors for extended periods, minimizing the risk of damage due to prolonged contact or improper loading.

• Combined Drive System: Rotors of relatively low mass can be driven by “belt drive”, which makes the machine more versatile and allows balancing a very wide range of parts. Heavy rotors are rotated by "axial drive" using a cardan shaft.

• Rotor Jacks: Specialized loading devices can be integrated to ensure smooth and precise rotor placement onto the roller supports. This minimizes the risk of damage to the delicate roller assembly, particularly when handling heavy or sensitive rotors.

• High balancing accuracy due to automatic calibration of the balancing machine directly for each rotor by determining the influence coefficients. Its ease of use, high measurement accuracy, and integrated specialized features enable balancing professionals to achieve outstanding results in the shortest possible time.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

• No need for special foundations and vibration isolation, no need to fix the machine to the floor.

SPECIFICATIONS

Weight range of balanced rotors 100 - 10'000 kg

Maximum rotor diameter (above the bedding) 2500 mm

Rsdpewdgptsfx Adajn

Distance between centres of rotor supports 400 – 5600 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 1000 rpm

Electric motor power 30 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

17,113 km

Balancing machine modernization kit

PAK-1 Unbalance Measuring Unit

Call

Condition: new, PAK-1 Unbalance Measuring Unit is designed to modernize your balancing machine.

A balancing machine has a long mechanical life, but prolonged use leads to gradual failure of electronics and measuring instruments, causing problems with spare parts and lack of technical support.

Minimize downtime and ensure the reliability of your balancing machine by upgrading it with a new advanced measuring unit.

The PAK-1 unbalance measuring unit works in all balancing machines of most existing designs and manufacturers.

Confidence in results and ease of use: Easy to set up and work with, our devices do not require any special theoretical knowledge.

Wide range of functions for your balancing machine: The use of modern microprocessor technology and many years of experience of our developers allows us to implement functions that were previously unavailable to other manufacturers.

Your machine complies with ISO 21940: Balancing machines equipped with the PAK-1 unbalance measuring unit fully meet the precision requirements of modern standards.

HIGHLIGHTS

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

INCLUDES: 1) vibration sensor signal processing unit, 2) fanless industrial computer with touch screen, 3) new vibration and speed sensors, 4) metal protected cable set.

SEQUENCE OF WORKS for modernization of the measuring unit

- Replacement of the existing measuring system with the balancing complex PAK-1 based on an industrial computer;

- Installation of new vibration sensors and rotor speed sensor

- Replacement of all connecting cables;

- Adjustment of the measuring unit on the balancing machine;

- Training of personnel with skills to operate the machine.

Rsdpfxeq Ttn Do Adaen

VTM GROUP offers to upgrade your balancing machine.

We repair and modernise various old balancing machines of all types from all manufacturers.

It's cost effective.

An alternative to buying a new balancing machine in 95% of cases.

Urgent.

Work can be done at customer site within 1-2 days.

New components for modernization of your machine:

• Installation of new measuring system and vibration and speed sensors.

• Installation of new electrical equipment

• Manufacturing or repair of the rotation drive

• Manufacturing of new rollers

Every business is different. Let's discuss your task.

We can offer a solution for any balancing machine.

Please contact us to get the best offer!

👇

Listing

Malsch

Malsch

18,657 km

Balancing Machine

HOFMANNEO-Re

Call

Condition: used, workpiece weight 100 kg

workpiece length 1000 mm

diameter 500 mm

centre height 280 mm

total power requirement 2,5 kW

Redpfev Nq Swsx Adaon

weight of the machine ca. 1 t

dimensions of the machine ca. 1,6x 1x1,6 m

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Sachsen

Sachsen

18,264 km

Horizontal balancing machine for rotors

HOFMANNUHK 26

Condition: ready for operation (used), Year of construction: 2004, functionality: fully functional, TECHNICAL DETAILS

Maximum balancing weight: 2,000 kg

Balancing body diameter without machining unit: 10 mm

Bed length: 3,000 mm

Swing diameter over machine bed: 2 mm

Rotor shaft via belt drive: 10 mm

Drive unit balancing speed (5 gears): Max. 80 / 160 / 290 / 470 / 630 rpm

Measurement method: force measuring

Electronics speed measurement range: 60 to 30,000 rpm

Center height measured in bed: 1,200 mm

Rollers: 2x 195 x 56 mm

Axle spacing: 205 mm

Adjustment travel: 3 mm vertical

MACHINE DETAILS

Redpfjw T Sqmjx Adaen

Drive power: 22 kW

Compressed air: 6 bar

Connected load: 25 kVA / 20 kW

Machine weight: approx. 5,500 kg

Machine dimensions approx. (L x W x H): 3.3 x 1.5 x 2.0 m

Control cabinet dimensions: 6 x 610 x 21 mm

EQUIPMENT

- Measuring electronics PCX

- Base frame (cast steel body)

- Mounting length between bearing supports up to approx. 3,000 mm

- Adjustment with hand ratchet via rack

- Bearing supports/swing bearing blocks: 2 pieces

Listing

Bydgoszcz

Bydgoszcz

17,832 km

BALANCING MACHINE

CIMATCMT-50VSTR

Call

Year of construction: 2024, condition: as good as new (ex-display), Rim Balancing Machine:

- Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck

- Automatic brake and wheel positioning

- Fast balancing cycle time

Redpfx Ast Tuqbodaon

- Made of well-known brands heavy duty components

- Fast tool changeover time

- Servomotor as a spindle drive motor

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Electrodynamic balance shaft balancing machine, vertical balancing machine; balancing machine, balan

SCHENCK RoTecEBLY

Call

Condition: used, Electrodynamic balance shaft balancing machine, vertical balancing machine, balancing machine

SCHENCK RoTec Type EBLY

Manufacturer No. 1FLY, Year of Manufacture 2000

Workpiece/Test Specimen: Balance shafts

Number of measuring planes: 2

Number of balancing planes: 2

Angle of balancing components: 145 - 215°

Test specimen weight: max. 10 kg

Indicated unbalance: 2 gmm/square

Lowest value per scale value: 8 gmm/square

Balancing spindle speed: 1200 rpm

Scale disc with test specimen holder Ø 320 mm

Test specimen diameter max. 400 mm

Vibration sensor: P01 force sensor

Angle position sensor: HBBC incremental encoder

CAB 750 microprocessor measuring device

RS232 serial interface

Rodpfxswgnu No Adasn

Workpiece weight: 2.2 kg

Workpiece length: 250 mm

Workpiece diameter: 70 mm

Power supply: 400 V, 50 Hz

Rated current: 16 A

- SCHENCK M341 balancing indicator

Space requirement: L x W x H: 2000 x 1800 x 2000 mm

Weight: 620 kg

Good condition

Listing

Dreieich

Dreieich

18,560 km

Balancing Machine

TIRAK 150 B

Call

Condition: used, Year of construction: 1998, workpiece weight 150 kg

Rsdpfxjwcg Els Adasn

workpiece length 2500 mm

diameter 160 - mm

balancing speed variable 100 - 3000 U/min

dia. axle journal 160 - 350 mm

voltage 400 V

total power requirement 1,5 kW

weight of the machine ca. 1,5 t

dimensions of the machine ca. 7,50 x 1,30 x 1,60 m

Control 0,60 x 0,60 x 1,85 m

Software TIRA X9000

Operating System Windows XP

Software update 2007

Serial No.: R 32/98

Max display sensivitiy: 0.5 gmm

Balancing speed 100 - 3000 RPM

We make it easier for you to find: "balancing machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Balancing Machine (64,027)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you