3D skyTUBE 6000 The Rohr Laser CenterPFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

3D skyTUBE 6000 The Rohr Laser Center

PFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Year of construction

2026

Condition

New

Location

Plauen

Show images

Show map

Machine data

- Machine type:

- 3D skyTUBE 6000 The Rohr Laser Center

- Manufacturer:

- PFEIFER technology & innovation Plauen D

- Year of construction:

- 2026

- Condition:

- new

- Functionality:

- fully functional

Price & Location

- Location:

- Rathenaupl. 8, 08525 Plauen, Deutschland

Call

Technical details

- Working range:

- 6,500 mm

- Type of input current:

- three-phase

- Total width:

- 1,629 mm

- Total height:

- 2,525 mm

- Total length:

- 10,500 mm

- Table length:

- 6,500 mm

- Overall weight:

- 5,500 kg

- Power:

- 15 kW (20.39 HP)

- Laser power:

- 6,000 W

- Warranty duration:

- 24 months

- Equipment:

- cooling unit, safety light barrier

Details about the offer

- Listing ID:

- A14903902

- Reference number:

- skyTUBE6500 FIBER

- Update:

- 09.02.2026

Description

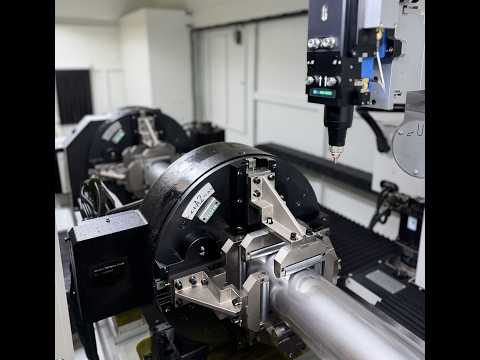

PFEIFER technology skyTUBE Pro 6500 X3 – Profile & Tube Laser Center 6500 x 15 – 160 mm Format

Ljdpferh Iw Tjx Aagohc

skytube-pro-6500×3 Profile and Tube Laser Fiber Laser Metal Cutting – fast material change with up to 6kW, delivering effective performance for your production, is the smart and efficient tube laser processing solution. Capable of laser cutting round tubes, square tubes, rectangular tubes, open profiles, and special profiles, this laser machine ensures maximum productivity during production changeovers. Task: Fiber laser up to 6kW for a wide range of metalworking applications!

Unrivaled Laser Cutting Performance

High axis speeds and accelerations, combined with a robust mechanical structure, ensure outstanding cutting performance and precision.

The tube and profile laser processing machine for production offers a compact footprint – simply smart! Ingenious solutions, 100% made in Saxony!

Tubes and profiles from 15 x 15 to 160 x 160 mm – 3D cutting with efficient fiber laser technology.

The semi-automatic 6-position profile-tube loading chain system allows fast job changes. With the optional bundle loader, you work independently.

Bevel Cutting

A revolutionary feature. With the ability of our machines to swivel their cutting head up to 50° on an additional fifth axis, we provide the solution to one of the biggest challenges in modern profile processing.

If the laser beam always strikes the tube at a right angle, you end up with an elliptical cut edge.

With the capability to swivel the tube laser cutting head, together with the feed axis, completely angled cuts are now possible.

Of course, when working with the skyTUBE Laser, safety comes first!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser emissions or reflections during operation.

For all our laser systems, nothing is more important than complete safety and compliance with the highest standards and directives.

Technical Specifications:

· Closed industrial housing, Class 1 laser (optionally Class 4)

· Working area, tube cutting system/chuck: Round tubes 15–160 mm, rectangular tubes 15 x 15 – 110 mm

· Working area on the tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

· Automatic material feed: up to 6 x 160 mm profiles, lengths 3500–7000 mm

· Automated material unloading system for profile sections, construction adjusted to profile length

· Z drive: ball screw axis system / with PTI SVZ system

· X/Y drive: linear axis system / with PTI AC-SERVO system

· Productive cutting speed: depending on material and laser combination, up to 50 m/min / 1.4G

· Software resolution: up to 2500 DPI

· Repeatability: ± 0.03 mm

· Max. footprint dimensions (LxWxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system according to profile section length

The listing was translated automatically. Translation errors are possible.

Ljdpferh Iw Tjx Aagohc

skytube-pro-6500×3 Profile and Tube Laser Fiber Laser Metal Cutting – fast material change with up to 6kW, delivering effective performance for your production, is the smart and efficient tube laser processing solution. Capable of laser cutting round tubes, square tubes, rectangular tubes, open profiles, and special profiles, this laser machine ensures maximum productivity during production changeovers. Task: Fiber laser up to 6kW for a wide range of metalworking applications!

Unrivaled Laser Cutting Performance

High axis speeds and accelerations, combined with a robust mechanical structure, ensure outstanding cutting performance and precision.

The tube and profile laser processing machine for production offers a compact footprint – simply smart! Ingenious solutions, 100% made in Saxony!

Tubes and profiles from 15 x 15 to 160 x 160 mm – 3D cutting with efficient fiber laser technology.

The semi-automatic 6-position profile-tube loading chain system allows fast job changes. With the optional bundle loader, you work independently.

Bevel Cutting

A revolutionary feature. With the ability of our machines to swivel their cutting head up to 50° on an additional fifth axis, we provide the solution to one of the biggest challenges in modern profile processing.

If the laser beam always strikes the tube at a right angle, you end up with an elliptical cut edge.

With the capability to swivel the tube laser cutting head, together with the feed axis, completely angled cuts are now possible.

Of course, when working with the skyTUBE Laser, safety comes first!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser emissions or reflections during operation.

For all our laser systems, nothing is more important than complete safety and compliance with the highest standards and directives.

Technical Specifications:

· Closed industrial housing, Class 1 laser (optionally Class 4)

· Working area, tube cutting system/chuck: Round tubes 15–160 mm, rectangular tubes 15 x 15 – 110 mm

· Working area on the tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

· Automatic material feed: up to 6 x 160 mm profiles, lengths 3500–7000 mm

· Automated material unloading system for profile sections, construction adjusted to profile length

· Z drive: ball screw axis system / with PTI SVZ system

· X/Y drive: linear axis system / with PTI AC-SERVO system

· Productive cutting speed: depending on material and laser combination, up to 50 m/min / 1.4G

· Software resolution: up to 2500 DPI

· Repeatability: ± 0.03 mm

· Max. footprint dimensions (LxWxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system according to profile section length

The listing was translated automatically. Translation errors are possible.

Documents

Seller

Note: Register for free or log in, to access all information.

Registered since: 2011

Send inquiry

Telephone & Fax

+49 3741 ... show

These listings may also fit your interest.

Listing

Plauen

Plauen

18,330 km

3D skyTUBE 6000 The Rohr Laser Center

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

Listing

Leipzig

Leipzig

18,263 km

Laser pipe cutting machine

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

Listing

Grebenau

Grebenau

18,468 km

Stamping and forming machine

BIHLERRM 35

BIHLERRM 35

Listing

Saerbeck

Saerbeck

18,451 km

Laser cutting machine

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Listing

Loire

Loire

19,255 km

Fiber Laser Tube cutting machine

Bodor T2

Bodor T2

Listing

Deinze

Deinze

18,734 km

Tube bending machines

ArloSPB60 CNC

ArloSPB60 CNC

Listing

Gondelsheim

Gondelsheim

18,626 km

Crane canopy Crane gantry crane

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Listing

Ludwigsstadt

Ludwigsstadt

18,377 km

Brush deburring machine

WeberTTS-1100

WeberTTS-1100

Listing

Enschede

Enschede

18,482 km

Tube laser cutting machines

Bodor K2

Bodor K2

Listing

Velen

Velen

18,508 km

Flanging and Seam Rolling Machine

OSTASKMRP-1,2

OSTASKMRP-1,2

Your listing has been deleted successfully

An error has occurred