Used Welding Force for sale (11,440)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Rheda-Wiedenbrück

Rheda-Wiedenbrück

18,445 km

Laser welding machine Industry 4-1

Tec-Point GmbHLMH-2000

Call

Condition: new, Year of construction: 2025, functionality: fully functional, type of input current: AC, overall weight: 170 kg, type of cooling: water, input current: 16 A, laser power: 2,000 W, input frequency: 50 Hz, continuous power: 3 kW (4.08 HP), Equipment: documentation/manual, type plate available, LMH-2000 – Industrial Laser Welding Machine – 2000 W Fiber Laser – 4-in-1

Description

The LMH-2000 is a state-of-the-art 4-in-1 fiber laser welding machine of the latest generation. It combines welding, cutting, brazing, and surface treatment in a single system.

Based on the proven LMH-1500, the LMH-2000 offers even greater power and flexibility with its 2000 W laser source – ideal for thicker materials and demanding applications.

Featuring an energy-efficient fiber laser, stable cooling system, and ergonomic hand-guided operation, this machine is perfectly suited for continuous industrial 24/7 operation.

Technical Data

Model: LMH-2000 (4-in-1)

Laser Source: 2000 W (Raycus / MaxPhotonics – depending on configuration)

Laser Type: Fiber Laser

Functions: Welding, Cutting, Brazing, Surface Treatment

Operating Mode: Continuous operation possible

Cooling System: Integrated water cooling

Materials: Stainless steel, carbon steel, aluminum, copper, galvanized sheets and more

Energy Efficiency: Up to 80% savings compared to conventional methods

Operation: Ergonomic hand-guided torch, optional wire feeder

Advantages

4-in-1 functionality – highly versatile

Increased power (2000 W) for maximum welding speed and material thickness

CE compliant according to Machinery Directive 2006/42/EC and relevant EU standards

Clean weld seams with minimal post-processing required

Rugged design for industrial use

Dkedpfx Acjxc Ebcs Noh

Flexible applications in metal construction, production, and maintenance

Special Notes

Immediately available from stock in Rheda-Wiedenbrück (Germany)

Demonstration/Test: Machines can be tested and demonstrated at our facility at any time – see the quality for yourself.

Initial Training: Instruction on operation and application is available by appointment.

Extras & Accessories

Wire feeding system

Shielding gas solutions

Replacement nozzles and wear parts

Extras & accessories (optional)

Replacement nozzles and wear parts: Ideal for workshops, mechanical engineering, metal fabrication, automotive bodywork, or maintenance.

🔒 Certified & Safe:

CE certificate including risk assessment in accordance with EU directives. Delivery includes all required documentation.

📍 Manufacturer / Distributor:

TEC-POINT GmbH

Kupferstraße 10, 33378 Rheda-Wiedenbrück, Germany

🚚 Shipping & Invoice:

By freight carrier (pallet shipping) within Germany & the EU – shipping costs on request.

🧾 Invoice with VAT shown will be issued.

✅ Buy now and have it delivered ready for immediate use!

Listing

Rheda-Wiedenbrück

Rheda-Wiedenbrück

18,445 km

Laser – Welding Device 4-in-1 3000W

Tec-Point GmbHLMH-3000

Call

Condition: new, Year of construction: 2025, functionality: fully functional, The LMH-3000 is a state-of-the-art, next-generation 4-in-1 fiber laser welding machine. It combines welding, cutting, brazing, and surface processing in a single system.

Building on the proven LMH-1500, the LMH-3000 offers even greater performance and flexibility with its 3,000 W laser source – ideal for working with thicker materials and demanding applications.

Thanks to its energy-efficient fiber laser, stable cooling, and ergonomic handheld operation, this machine is perfectly suited for continuous industrial 24/7 use.

Technical Data

Model: LMH-3000 (4-in-1)

Laser source: 3,000 W (Raycus / MaxPhotonics – depending on configuration)

Laser type: Fiber laser

Functions: Welding, cutting, brazing, surface processing

Operating mode: Continuous operation possible

Cooling system: Integrated water cooling

Materials: Stainless steel, carbon steel, aluminum, copper, galvanized sheet metal, and more

Energy efficiency: Up to 80% savings compared to conventional methods

Operation: Ergonomic handheld torch with optional wire feeder

Advantages

- 4-in-1 functionality – versatile applications

- Higher output (3,000 W) for maximum welding speed and material thickness

- CE-compliant in accordance with Machinery Directive 2006/42/EC and relevant EU standards

- Clean weld seams with minimal reworking

- Robust design for industrial use

- Flexible use in metal construction, production, and maintenance

Special Notes

Immediately available from stock in Rheda-Wiedenbrück (Germany)

Demonstration/Testing: Machines can be tested and demonstrated at our facility at any time – see the quality for yourself.

Dodpsxc Ec Tjfx Ac Njkh

Initial Training: Operating and application training can be arranged by appointment.

Extras & Accessories

- Wire feeder system

- Shielding gas solutions

- Replacement nozzles and wear parts

- Extras & accessories (optional)

Replacement nozzles and wear parts—Ideal for workshops, mechanical engineering, metalworking, body shops, or maintenance departments.

🔒 Certified & Safe:

CE certificate including risk assessment in accordance with EU guidelines. Delivery includes all required documentation.

📍 Manufacturer / Supplier:

TEC-POINT GmbH

Kupferstraße 10, 33378 Rheda-Wiedenbrück, Germany

🚚 Shipping & Invoice:

Shipped by freight carrier (on pallets) within Germany and the EU – shipping costs on request.

🧾 Invoice issued with VAT shown separately.

✅ Buy now and have it delivered ready for immediate use!

Listing

Кюстендил

Кюстендил

17,727 km

Single corner welding machine

MURATKB 512

Call

Year of construction: 2009, operating hours: 500 h, condition: ready for operation (used), functionality: fully functional, machine/vehicle number: 888386, Single-head welding machine KB 512

Designed for welding PVC profiles with a weld seam thickness of 0.2 mm on the visible surface. The technology enables the production of a thin, aesthetically pleasing seam on laminated profiles, significantly improving the appearance of the finished product.

The machine’s construction allows welding of profiles from 45° to 180°, making it possible to manufacture non-standard structures.

Dkedpfxjyhl Dvo Ac Njh

All operating cycles are fully automatic.

The electronic system enables selection of various welding modes (melting time, pressing time, pressing force) and provides continuous monitoring. The control panel’s electronic display gives information about the operating cycles and any system errors.

Pneumatic clamping of the profile is controlled by a foot pedal.

Features a quick-change system for the Teflon coating.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Sempach

Sempach

18,767 km

Spot welding machine

SchlatterP 3.372.53.32

Call

Condition: used, Year of construction: 1990, functionality: fully functional, input voltage: 380 V, overall weight: 1,100 kg, warranty duration: 2 months, welding power (max.): 149 kVA, total width: 750 mm, open-circuit voltage: 7 V, air pressure: 5.5 bar, working range: 220 mm, Equipment: documentation/manual, type plate available, We are offering this used Schlatter P 3.372.53.32 spot welding machine, year of manufacture 1990.

Input voltage U1: 380 V

Short-circuit power Sc: 160 kVA

Reactance X: 50%

Mains frequency f1: 50 Hz

No-load voltage U20: 7.1 V

Dodpfx Acoyhgvte Nekh

Secondary voltage U2: 5.0 V

Welding current I2c: 22.6 kA

Welding current I2cc: 28 kA

Primary current I1: 300 A

Secondary current I2: 640 A

Maximum apparent power Smax: 149 kVA

Coolant flow rate p: 14 - 22 l/min

Distance e: 220 mm

Dimension A: 480 mm

Dimension B: 750 mm

Maximum force Fmax: 30.0 kN

Operating pressure p: 5.5 bar

Coolant pressure Pa: 3 - 4 bar

Must be collected with an appropriate vehicle.

If you have any questions or require further information, please feel free to send us a message or give us a call.

Listing

Euskirchen

Euskirchen

18,615 km

Welding set

SELCOGenesis 260GSM

Call

Condition: ready for operation (used), On offer here is a bellied welding machine from Seleco type Genesis. The device is in good condition and was still in use 2 weeks ago.

The device is being sold without the hose package, which was stolen from me a few days ago.

Dedjyhf Hqspfx Ac Njkh

The device can be tested on site if the buyer brings a suitable hose package.

1x SELCO Genesis 260GSM

1x SELCO type WU 14

1x transport trolley

!!!Without hose package, as shown!!!

Welding current max. 260 A

260 A at 60% ED

201 A at 100%ED

Remote control SELCO RC08

Space requirement L - 560 x W - 240 x H - 400 mm

Weight approx. 37 kg

Listing

Valkenswaard

Valkenswaard

18,619 km

OTC 500 AMP ACDC Welding machine

DEMO - OTCA500P ACDC

Call

Condition: excellent (used), Year of construction: 2023, operating hours: 1 h, functionality: fully functional, machine/vehicle number: A500P, type of input current: three-phase, ground cable length: 4,000 mm, warranty duration: 24 months, type of cooling: water, hose package length: 8,000 mm, welding current at 60% duty cycle: 500 A, welding current (min.): 2 A, welding current (max.): 500 A, Demo OTC A500P – Water-cooled TIG ACDC Welding Machine

24-month warranty

Demo Model, Ready for immediate use for manual welding or robotics.

Suitable for:

Robotic welding, aluminium, steel and stainless steel production welding, heavy construction, machine building.

Not suitable for:

On location, hobby.

Specifications:

2-500A

60% ED 500A

380 Volt

AC TIG / DC TIG / AC-DC TIG

Pulse

Synergistically adjustable

Water-cooled

2/4 Step

High frequency

Pre gas / Post Gas

Start current / end current

Up slope / Down slope

AC Balance / AC Frequency

Pulse Frequency

Spot welding

Programme Memory

Electrode option

Includes:

PRO30 8-metre welding torch, ground cable, and gas hose.

Visits by appointment only.

Test welding is possible.

A video of the machine in welding condition is possible.

We also deliver to countries like Spain, Germany, Austria, Lithuania, Greece and all other countries inside and outside Europe with Euro pallets per freight.

All our machines have been serviced and are 100% ready to use unless otherwise indicated.

The pictures above show the real machine.

We can also offer you other types of machines such as:

Used, New, Mig, Mag, Co2, Tig, Pulse, AC/DC, Plasma, Water-cooled, Electrode,

Dkedpfx Acsyhdxxj Noh

Brands we offer:

OTC, Migatronic, Lincoln, Miller, Fronius, Kemppi, Parweld, Tico, Lorch, Rehm, Selco, Carl Cloos, Cebora, Esab, Saf, EWM, Ess, Kemper.

You always do business with Cjays Lastechniek itself and never with third parties.

Listing

Panevėžys

Panevėžys

17,334 km

Welding set

MerkleMobiARC 284 cel

Call

Condition: like new (used), Manufacturer: Merkle (Germany)

Model: mobiarc 284

Technology: IGBT Inverter

Welding Processes: MMA (Stick), TIG DC (Lift-Arc)

Input Power: 400 V, 3-phase, 50/60 Hz

Product Description

The Merkle mobiarc 284 is a modern, lightweight inverter-based welding power source, designed for professional use in workshops, construction sites, assembly companies, and industrial maintenance. Thanks to its compact design and low weight of only 19 kg, it is highly portable and ideal for on-site and confined-space welding.

Dedjyhdduspfx Ac Njkh

This unit delivers excellent welding characteristics, smooth current control, and advanced arc control functions. It is approved for welding in confined spaces and marked with the “S” safety symbol, making it suitable for demanding and safety-critical environments.

Key Features

• Advanced IGBT Inverter Technology – Efficient, compact, and reliable

• Smooth Welding Current Adjustment – Precise control for high-quality welds

• Digital Display – Clear indication of all welding parameters

• Remote Control Socket – 10-pole connector with polarity switch

• MMA Welding with Cellulosic Electrodes – Stable arc, suitable for vertical-down welding

• TIG DC Welding (Lift-Arc) – TIG welding without high-frequency ignition

• Confined Space Approved (S Symbol) – Safe operation in restricted areas

• Lightweight & Portable Design – Ideal for site work and field repairs

MMA (Stick) Welding

The mobiarc 284 is designed to weld all types of coated electrodes with diameters from 1.6 to 6.0 mm. It includes advanced arc control functions:

• Arc Force: Automatically increases welding current to prevent electrode sticking

• Hot Start: Adjustable current and time for reliable arc ignition

• Anti-Stick: Immediately cuts current if the electrode sticks, allowing easy re-ignition

• Excellent Performance with Cellulosic Electrodes

TIG Welding (DC Lift-Arc)

The unit is also well suited for DC TIG welding with filler wire using Lift-Arc ignition. A separately available TIG torch with integrated gas valve, pressure regulator, and shielding gas cylinder are required.

Applications

• Repair and maintenance

• Civil construction projects

• Agricultural equipment repair

• Assembly and installation companies

• Industrial and general fabrication

Suitable Materials

• Alloyed and unalloyed steel

• Stainless steel

• Cast iron

Technical Specifications

• Input Voltage: 400 V, 3-phase, 50/60 Hz

• Welding Current Range: 15 – 280 A

• Welding Voltage Range: 20.6 – 31.2 V

• Duty Cycle (eta) 40 °C (10 min):

o 35% – 250 A

o 50% – 250 A

o 60% – 240 A

o 100% – 210 A

• Open-Circuit Voltage: 90 V

• Current Consumption (MMA / TIG): 14 A / 12 A

• Power Consumption (MMA / TIG): 9.7 kVA / 8.3 kVA

• Maximum Input Current (MMA / TIG): 21 A / 16 A

• Electrode Diameter: 1.5 – 6.0 mm

• Power Factor: 0.98 cosφ

• Protection Class: IP23

• Insulation Class: H

• Remote Control Interface: 10-pole connector with polarity switch

• Connection Socket: 50 mm²

• Standards: EN 60974-1, CE, “S” marking

• Dimensions (L × W × H): 495 × 210 × 450 mm

• Weight: 19.0 kg

Listing

Panevėžys

Panevėžys

17,334 km

Welding set

MerkleLiteTIG 300 AC/DC

Call

Condition: like new (used), functionality: fully functional, Manufacturer: Merkle (Germany)

Model: LiteTIG 300 AC/DC

Technology: IGBT Inverter

Welding Processes: TIG AC/DC, TIG DC Pulse, MMA (Stick)

Input Power: 400 V, 3-phase, 50/60 Hz

Product Description

The Merkle LiteTIG 300 AC/DC is a compact, high-performance professional TIG welding power source, developed using advanced inverter technology to deliver excellent arc characteristics and outstanding functionality. The machine supports both AC and DC welding, making it ideal for welding aluminium as well as steel, stainless steel, and a wide range of non-ferrous metals.

Designed for professionals, the LiteTIG 300 AC/DC combines simple front-panel operation with a powerful Expert Mode, allowing experienced welders to fully customize all welding parameters for maximum precision and weld quality.

Control & User Interface

• Digital Display (Standard) – Clear monitoring of current, time, frequency, and welding parameters

• Standard & Expert Modes – Programmable modes for beginners and professionals

• Multi-Language Menu

• Control Panel Lock with PIN Code

• Rotary Control Knob – Fast and intuitive parameter adjustment

• Memory Functions – Save and recall complete welding programs (up to 28 jobs)

Advanced TIG Technology

• AC/DC TIG Welding – Suitable for aluminium, magnesium, copper, and other non-ferrous metals

• HF & Lift-Arc Ignition – Clean and reliable arc start

• High-Frequency DC Pulse up to 12 kHz – Enables extremely narrow, focused arcs for superior control and heat input reduction

• AC Frequency Control (50–200 Hz) – Adjustable arc shape and penetration

• AC Balance Control – Optimized oxide cleaning vs. penetration

• Selectable AC Waveforms – Square, soft, and sinusoidal

• Pulse Modes: Slow pulse, fast pulse, and high-frequency pulse

Dsdpfx Acsyhdbas Nskh

• Spot Welding Function – Adjustable from 0.01 to 2.5 s

_____

MMA (Stick) Welding

The LiteTIG 300 AC/DC also supports MMA welding with coated electrodes from 1.6 to 4.0 mm (electrode holder required if not included):

• Hot Start – Adjustable for reliable arc ignition

• Arc Force – Prevents electrode sticking

• Anti-Stick – Automatically cuts current if the electrode sticks

Additional Features

• Two Welding Currents (I1 / I2) – Switchable via Merkle TIG torch

• 2T / 4T Operation Modes

• Pedal Control Support

• Temperature-Controlled Cooling Fan

• Air or Water-Cooled Torch Compatibility

• Confined Space Approved (“S” Symbol)

• Optional Water Cooling Unit

Applications

• Professional TIG welding

• Industrial production and fabrication

• Maintenance and repair work

• Automotive and motorcycle repair

• Precision welding of thin materials

Technical Specifications

• Input Voltage: 400 V, 3-phase, 50/60 Hz

• Output Current Range: 5 – 300 A

• Output Voltage (TIG / MMA): 10 – 22 V / 20 – 32 V

• Duty Cycle 40 °C (10 min):

o 50% – 300 A (TIG)

o 60% – 280 A (TIG) / 270 A (MMA)

o 100% – 250 A (TIG) / 230 A (MMA)

• TIG DC Pulse Frequency: 0.2 Hz – 12 kHz

• Open-Circuit Voltage: 70 V

• AC Frequency: 50 – 200 Hz

• AC Waveforms: Square, soft, sinusoidal

• Electrode Diameter (MMA): 1.5 – 4.0 mm

• Power Factor: 0.95 cosφ

• Protection Class: IP23

• Insulation Class: H

• Torch Connection: Merkle TCG, 5-pole

• Power Connection: 50 mm²

• Cooling: Air or water

• Dimensions (L × W × H): 600 × 300 × 575 mm

• Weight: 39.2 kg

Listing

Ludwigshafen am Rhein

Ludwigshafen am Rhein

18,611 km

Welding robot

DALEX / KUKASpotwelding Cell Robot manipulated

Condition: excellent (used), Year of construction: 2017, operating hours: 2,700 h, functionality: fully functional, arm reach: 2,033 mm, type of input current: three-phase, total height: 2,360 mm, total width: 5,203 mm, total length: 7,442 mm, load capacity: 600 kg, overall weight: 10,000 kg, input voltage: 400 V, type of cooling: water, workpiece weight (max.): 600 kg, protection type (IP code): IP54, year of last overhaul: 2025, compressed air connection: 6 bar, repeat accuracy: 0.06 mm, Equipment: cabin, We are offering this very well-maintained DALEX / KUKA spot welding cell with robot handling, year of manufacture 2017.

Manufacturer: DALEX / KUKA

Model: Spotwelding Cell Robot Manipulated

Machine type: Welding Robot

Year of manufacture: 2017

The machine is a specialized welding system designed for spot welding pre-formed stainless steel components. The welds are created with pneumatically operated resistance spot welding tongs or a pneumatic spot welding unit. The setup includes one robotic arm for performing the resistance welding process and a second robotic arm for positioning and handling the welded parts.

Out of operation since 2024.

Annually maintained, including maintenance scheduled for 2025!

Cell dimensions: 7442 mm x 5203 mm

Robotized spot welding cell in compliance with EC conformity 200/427EG

2004/108/EU Electromagnetic Compatibility (EMC) / 2006/95/EU Low Voltage Directive / 2003/10/EG Noise Emissions

2x KUKA KR60-3 robots (service by KUKA scheduled for 01/2025)

Dsdeyhcipspfx Ac Nokh

Operating hours: Robot 1: 4,500 h / Robot 2: 8,200 h

Nominal payload capacity: 600 kg

Maximum reach: 2,033 mm

Mounting position: Floor

Repeatability (ISO 9283): 0.06 mm

Controller: KR C4

Number of axes: 6

Ambient operating temperature: 10 °C to 55 °C (283 K to 328 K)

Protection rating (IEC 60529): IP65

2x KUKA KR300 R2500 ultra robots (service by KUKA scheduled for 01/2025)

Operating hours: Robot 1: 2,700 h / Robot 2: 6,100 h

Nominal payload capacity: 300 kg

Maximum reach: 2,496 mm

Mounting position: Floor

Repeatability (ISO 9283): 0.06 mm

Controller: KR C4

Number of axes: 6

Ambient operating temperature: 10 °C to 55 °C (283 K to 328 K)

Protection rating (IEC 60529): IP65

Control software: SW8.3.30

Resistance welding unit

Harms & Wende mid-frequency inverter

2x Genius HWI408

If you have any questions or require more information, please send us a message or give us a call.

Listing

Dn10 4Es

Dn10 4Es

18,607 km

Force feed depositor

Apple

Call

Year of construction: 2005, condition: used, Apple engineering MM975

Djdpfxob Ucqlj Ac Njkh

Mini Force Feed Depositor

Stainless mobile height adjustable single head pneumatic depositor with variable speed scroll feeder in hopper for positive product feeding

Listing

Wiefelstede

Wiefelstede

18,341 km

Mobile welding fume extraction

Kemper0,75 kW

Call

Condition: good (used), Welding fume filters, welding fume extraction systems, soldering fume extraction systems, mobile filter units, welding fume extractors

Dsdpfx Acex I Aknj Nekh

-Manufacturer: Kemper, mobile welding fume extraction

-Drive: 0.75 kW

-Extraction arm: Ø 150 mm x 5000 mm

-Fan wheel: Ø 290 mm x 60 mm

-Quantity: 3 pieces available

Price: per piece

-Transport dimensions: 1200/800/H780 mm

-Weight: 38 kg/pc.

Listing

Benedita

Benedita

19,670 km

Welding machine (window production)

Graf SynergySL4-FF

Call

Condition: used, Year of construction: 2013, functionality: fully functional, Graf Synergy SL4-FF 4028

Extended dimension 4000x2800mm

Weight 2700

Vaccum cleaner

In working condition, can be seen at work.

Barcode Reader

Veka Profiles

Dodpeyg Ruwofx Ac Nokh

Listing

Hadsten

Hadsten

17,999 km

Spot welding machine

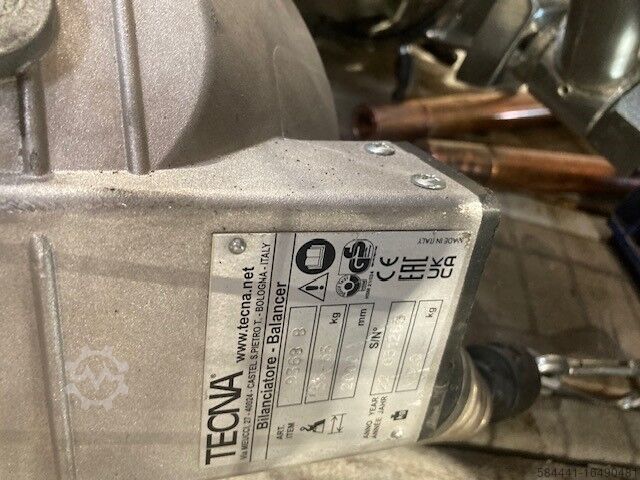

Tecna3322/400/50

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, machine/vehicle number: B0220047, type of input current: three-phase, throat depth: 508 mm, nominal power at 50% duty cycle: 23 kVA, short-circuit current: 21,000 A, input voltage: 400 V, type of cooling: water, welding power (max.): 65 kVA, sheet thickness steel (max.): 5 mm, air pressure: 6 bar, input frequency: 50 Hz, Very little used TECNA 3322 resistance welder with newly refurbished Bundgaard BK2 cooler. Balance suspension included.

Dsdpfx Ast Di Uvec Njkh

Listing

Кюстендил

Кюстендил

17,727 km

Four-head inline CNC welding machine

MuratKD 658/20 +CN 770/20

Call

Condition: ready for operation (used), Year of construction: 2016, operating hours: 400 h, functionality: fully functional, input voltage: 400 V, input current: 50 A, Equipment: Bluetooth, USB port, MURAT KD 658 Horizontal Four-Head Welding Machine

MURAT AK 032 Gasket Pressing System

AK 002 Barcode Scanner

CNC;

Touchscreen;

Simultaneous welding of all four corners at 90°;

Control panel supporting 5 languages (including Bulgarian);

Control module for storing welding parameters for 200 profile types, with customizable characteristics for each: manufacturer name, profile width, profile height, profile number and color, support number, heating time, pressing time, and cooling time;

Processing of white and colored profiles (automatic recognition of white and colored profiles);

0.2 mm weld seam on the visible side when welding colored profiles;

3 mm weld seam on the visible side when welding white profiles;

Teflon tape dispenser for heating elements;

Centralized lubrication system;

Safety locking system with optical sensors to protect personnel;

Electronic control ensuring temperature accuracy and stability;

Dkedpfx Aeyg Ifmoc Njh

Heated pressing system;

Gasket pressing system;

Barcode system for reading cutting information;

Minimum frame dimensions: 520 x 570 mm;

Maximum frame dimensions: 3000 x 2585 mm;

Profile height: max 180 mm, min 30 mm

MURAT CK 187 Auxiliary Cooling Table for CNC Cleaning Machine

Moves the frame from the welding station to the cleaning machine. Cooling time is computer-controlled.

MURAT CK 180 Positioning System for CNC Cleaning Machine (CN770)

Automatic feeding and rotation of the frame during cleaning.

Listing

Stara Zagora

Stara Zagora

17,489 km

Industrial welding robot

KIBERYSKIBOT R2200

Call

Condition: new, Year of construction: 2024, warranty duration: 12 months, 6-AXIS WELDING ROBOT WITH TWO 2-AXIS SERVO-DRIVEN POSITIONERS

KIBOT R2200 is multi-axis welding robotic system. with arms moving in horizontal plane and robust construction with precision guides. It achieves high speed and accuracy thanks to digital servo-controlled motors.

The jointed two-link arm covers a 360° area around the robot base without any blind-spots to reach. While the linear vertical axis provides high access equally at any point of the robot’s work-area. The tool center point (TCP) optimizes the robot motion to a minimum reaching the desired position in the work space. The unique kinematics offer unmatched reach and versatility for any welding application.

The electrical cabinet (robot controller) has been integrated in the robot base to minimize floor space requirements.

Application

KIBOT R2200 welding robot has a cylindrical work-area with radius of 2200mm by the two rotational axes and vertical motion of 1200mm by the linear axis. The maximum range of the tool center point is 3000mm.

The unique design allows 360° reach around the robot’s base creating multiple work-zones. The three rotational axes for welding torch rotation and inclination offer infinite capabilities of welding all joint types and positions.

MOTION RANGE

Maximum reach radius A1 + A2: 2200mm

Transverse stroke А1: ± 180°

Transverse stroke А2: ± 160°

Vertical stroke А3: 1200mm

Rotation range around A3: ± 360°

Range of torch tilting angle: ± 135°

Rotation range around А3: ± 360°

MAXIMUM SPEED

Rotational axis А1 + А2: 90°/s

Linear axis А3: 1 m/s

Rotational axis А4, А5, А6: 120°/s

Max. interpolated speed: 2 m/s

ACCURACY

Repeatability: ± 0.20mm

TWO 2-AXIS SERVO-DRIVEN POSITIONERS

- High accuracy and minimal backlash;

- Precise synchronization between robot and positioner;

-High accuracy and repeatability of positioning in details;

Number of axis - 2

Motor type - AC, servo

Payload - 500 kg

Max. speed of axis 1 & 2 - 60°/sec

Nominal torque axis 1 - 1040 Nm

Nominal torque axis 2 - 1040 Nm

Dodpfsvxi Hlox Ac Nskh

Repeatability of axis 1&2 - +/-0.01°

WELDING EQUIPMENT

Kemppi A7 450A MIG/MAG PULSE Power-source

ROBOTIC TORCH AND COLLISION SENSOR

Robotic torch set TRM612W, liquid cooled, 1.6m torch leads, collision sensor, hollow wrist

Listing

Stara Zagora

Stara Zagora

17,489 km

Welding Robot

KiberysKBWELD HDC

Call

Condition: new, Year of construction: 2026, Large-scale welding robotic systems

High-dynamic robotic, multi-axis automated welding system. KBWELD HDC is a console-type linear-drive system with a robust construction with precision guides. It achieves high speed and accuracy thanks to digital servo-controlled motors.

KBWELD HDC6 has a wide range of applications - complex, ribbed beams with slopes, panels, boards, ribbed sections; For straight and circular seams, various building elements, machine housings and more.

Number of axes (all in interpolation) - 6

Axis type - 3 linear and 3 rotary for torch

Motor type - AC, servo synchronous motors

Motion principle - Rack and pinion on linear axes, high precision cycloid reducers on rotary axes

Longitudinal stroke (along the rail) - on request

Transverse stroke - Y axis - 2000 - 4000 mm

Vertical stroke - 1500 - 2500 mm

Rotation range around Z-axis +/- 360 °

Range of torch tilting angle +/- 90 °

Linear axes speed range 0 – 30 000 mm/min

Rotary axes speed range 0–120°/s

Positioning accuracy +/-0.3 mm/m

Repeatability +/-0.1 mm

Supply voltage 3-phase, 380V +/-10%, 50Hz

Nominal consumption 3.5 kW

Dedpfoh Imyasx Ac Njkh

PROCESS MANAGEMENT

• A library of settings that includes all parameters

• Welding speed, power source parameters

• Ability to change the welding mode during welding

• Arc start delay

• Delay of motion at the arc end for the crater filling time

• Separate control of arc burning times and cold wire feed in TIG process

• Weaving function with frequency and amplitude adjustment

• Seam (part) search function with touch sensing with wire , gas nozzle or other sensor

• Seam tracking through arc current and weaving motion

▲ WELDING EQUIPMENT OPTIONS:

450A KEMPPI A7 - PULSED MIG/MAG WELDING

- Full welding parameters robot control

Mains connection voltage 3~ 50/60 Hz 400 V, -15 …+20 %

Supply current (maximum) 32 A

Supply current (effective) 25 A

Fuse (delayed) 35 A

No-load voltage (peak) U0 = 80 V – 98 V

Open circuit voltage (average) 85 V – 103 V

Operating temperature rang -20…+40 °C

Degree of protection IP23S

Efficiency (100 % duty cycle) 87 %

Power factor at max. current 0.88

OR

▲ TANDEM (TWIN-WIRE) WELDING MIG/MAG EQUIPMENT

2 x 450A KEMPPI A7 - Full robot control

▲ ROBOTIC PERIPHERALS OPTION:

1-axis Servo-positioners - payload on request from 500 to 6000kg

2-axis Servo-positioners - payload on request from 250 to 2000kg

DESCRIPTION KBSPOS500

Payload 500 kg

Number of axes 1

Type of motor AC, servo

Max Torque 860 Nm

Max Load inertia 100 kgm2

Max Speed 70°/sec

Flange diameter 400 mm

DESCRIPTION 2-axis Servo-positioner KBS2AxPos 500

Number of axes 2

Type of motor AC, servo

Payload 500 kg

Max Torque Axis 1 1700 Nm

Max Load inertia Axis 1 400 kgm2

Max Speed Axis 1 30°/sec

Max Torque Axis 2 860 Nm

Max Load inertia Axis 1 100 kgm2

Max Speed Axis 1 70°/sec

Flange diameter 400 mm

▲ INSTALLATION AND TRAINING INCLUDED

Approximate installation and training period - 10 days

Listing

Iserlohn

Iserlohn

18,518 km

Socket welding machine

GEORG FISCHERGF+ESA 24S

Call

Condition: good (used), Year of construction: 2000, Lechmann*MÜH plastic sleeve welding machine, make GEORG FISCHER

Dksdevk D D Nepfx Ac Noh

GF+ESA+24 S, year of manufacture approx. 2000.

Listing

Netherlands

Netherlands

18,654 km

PANASONIC TA-1800WG Welding Robot

PANASONICTA-1800WG Welding Robot

Call

Condition: ready for operation (used), Year of construction: 2008, number of axes: 6, This 6-axis PANASONIC TA-1800WG Welding Robot was manufactured in 2008. It includes a 350A welding source, a VWP 316/351/95-3 welding gun, a BRG 2000 mechanical cleaner, an 800mm plinth, and a 750 H-manipulator. If you are looking to get high-quality welding capabilities, consider the PANASONIC TA-1800WG machine we have for sale. Contact us for more information.

• 6-axis welding robot

Dkedpfsyfd N Ejx Ac Neh

Additional equipment

• Welding source: 350A (SP-Mag / Hyper Dippulse)

• Welding gun: VWP 316/351/95-3

• Mechanical cleaner: BRG 2000

• Plinth: TA, H=800 mm

• H-manipulator: 750

Listing

Iserlohn

Iserlohn

18,518 km

Welding machine

DALEXVARIO MIC 400L

Call

Condition: excellent (used), Year of construction: 1999, Welding machine make DALEX Type:VARIO MIC 400L year 1999

in very good condition, little used.

Dksdpfx Aofgvvaoc Neh

Listing

Iserlohn

Iserlohn

18,518 km

Welding fume extraction

ESTASRF-2000

Call

Condition: used, Year of construction: 1988, Welding fume extractor Fabr.ESTA Type:SRF - 2000 Year 1988

Djdeu Hlppjpfx Ac Nekh

Ready for use.

Listing

Iserlohn

Iserlohn

18,518 km

Welding and straightening table

RABOMART2000

Call

Year of construction: 1980, condition: used, Sweat and straightening table.

Dkjdoiuia Hspfx Ac Njh

2000 mm X 2000 mm height 800 mm.

Trust Seal

Dealers certified through Machineseeker

Listing

Iserlohn

Iserlohn

18,518 km

Welding and straightening table

PÜSCHELRST 1700

Call

Year of construction: 1980, condition: used, Straightening and welding table Fabr.PÜSCHEL

Year 2010 .

Table dimensions

Length: 1700 mm X Width: 1700 mm Height 760 mm.

Table top thickness 30 mm

with adjustment screws in good condition.

Dsdpfxsq Ru Hxj Ac Nskh

Listing

Velen

Velen

18,509 km

Welding table equipment

WMTSonderset

Call

Condition: new, number 96 Positionen

weight 600 kg

condition neu

28 mm

Special 31-piece set, 28mm system, consisting of:

Dksdpfeygxz Sex Ac Njh

1x Tool trolley

10x Locking pins

10x Ball lock pins

3x Professional screw clamps, 300 x 150mm

3x Professional screw clamps, 300 x 200mm

2x Professional pipe clamps, 180°

2x Professional pipe clamps, 45°

Material: Burnished quality steel

ATTENTION!!! Tools are designed for 25mm thick tabletops.

Listing

Velen

Velen

18,508 km

Rotary Welding Table

PROTARC ZAARPT-DTS-250 HW

Call

Condition: used, Year of construction: 1992, table diameter 600 mm

table load 250 Kg

swivelling range 0 - 135 Grad

turning speeds 0,03 - 2,0 U/min

Dkodpfoygxzrex Ac Neh

connected load frequency 400 V

weight 0,4 t

Dimensions (LxWxH) 1,1 x 0,9 x 1,0 m

Welding turntable including:

- Foot switch

- Wired remote control

- 315mm chuck

Listing

Siedlce

Siedlce

17,614 km

Welding fume extractor

CORMAKOS2400

Call

Condition: new, Year of construction: 2026, CORMAK OS2400 is a mobile welding fume extractor designed for effective removal of welding fumes and exhaust gases directly at the source. The unit combines strong suction power with a high airflow rate, while the sound-insulated fan chamber ensures quiet and smooth operation.

Additional advantages include an integrated pneumatic filter cleaning system, airflow regulation at the suction inlet, and a robust, industrial-grade design.

Automatic Filter Cleaning – Consistent Performance

The CORMAK OS2400 is also designed with ease of operation and long-term performance stability in mind. For this reason, it is equipped with an automatic pneumatic filter cleaning system. In practice, this means the filter is regularly “pulsed” to remove accumulated contaminants without the need for frequent manual intervention.

The effect is twofold: first, the extractor maintains a constant level of efficiency; second, service downtime and operating costs are reduced. In a production environment, this is critical, as any unplanned downtime or loss of suction affects workflow and the quality of working conditions at the workstation.

Adjustable Suction Power Tailored to the Task

Another key advantage is airflow regulation at the suction inlet. This solution allows the extraction power to be adjusted to actual working requirements: different for short spot welds, different for long continuous welding, and different again for grinding operations. Regulation at the inlet enables quick, operator-focused adjustment without time-consuming configuration changes.

This makes it easier to maintain a balance between effective extraction and operator comfort (for example, when working with smaller parts where excessive suction could hinder handling).

Solid Construction and Mobility

The OS2400 is designed for everyday use, which is why great emphasis has been placed on high build quality. Its solid construction performs reliably in workshop and industrial environments—where equipment is frequently relocated, operates for many hours a day, and must withstand intensive use.

Its mobility makes it easy to use the extractor at multiple workstations without investing in a permanent installation throughout the entire facility. This is a practical solution for both companies with several workstations and those that frequently change layouts or carry out varied projects.

Wide Range of Applications

In practice, the OS2400 is suitable wherever air contaminants are generated: welding (MIG/MAG, TIG), metalworking, grinding, and other processes that produce dust and fumes. Its purpose is to improve working conditions by reducing pollutants in the operator’s breathing zone. This solution contributes to employee health, work comfort, and the perception of the workplace as modern and safe.

Technical Specifications

Model Airflow (m³/h) Pressure (Pa) Filter Efficiency (%) Power (kW) Voltage (V) Weight (kg)

OS2400 2400 2000 99.9 2.2 400 80

OS3500 3500 2000 99.9 3.0 400 122

*The power cable and plug are not included due to varying connection infrastructures and customer requirements.

Dkodpeyguclofx Ac Njh

We make it easier for you to find: "welding force"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Welding Force (11,440)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month