Used Reduce for sale (2,535)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Geiselwind

Geiselwind

18,473 km

Primary reduction gearing transmission for creel drive

LinckVG

Call

Condition: excellent (used), Heavy Linck reduction gear for sash drive up to 160 KW

Shaft diameter 110 mm. Triple bearing.

Pgedpfx Ahsfn Rigs Hog

1 pulley 1250 x 315. 1 pulley 630 x 315 mm.

Other transmissions also available.

Listing

Austria

Austria

18,654 km

EMCO E45

EMCOE45

Call

Condition: ready for operation (used), Year of construction: 2019, spindle motor power: 13,000 W, spindle speed (max.): 6,300 rpm, number of axes: 2, This EMCO E45 turn-mill centre was manufactured in 2019. It features a KK5 spindle with a bar capacity of 45 mm and a speed range up to 6300 rpm. The 12-position VDI30 tool turret supports 6 driven tools, enhancing versatility. Equipped with SINUMERIK 828D OPERATE control for precise operations and a robust design with a chip conveyor and high-pressure coolant system. Reach out for more information about this machine.

• Connection: KK5 (DIN 55026)

• Bar capacity: 45 mm

• Drive power: 13 kW

• Speed range: 0–6300 rpm

• C-axis on main spindleTool turret

• 12-position VDI30 axial

Pgedpfx Ahsyffgro Hog

• Directional logic for up to 6 driven tools

• Driven tools: max. 4 kW / max. 16 Nm

• Driven tools speed: 0–5000 rpmTailstock

• Programmable, hydraulically actuated

• Max. clamping force: 6000 N

• Morse taper: MK4

• Hollow clamping cylinder incl. draw tubeControl & software

• SINUMERIK 828D OPERATE

• SHOPTURN dialog programming

• USB interface

• Network / Ethernet

• 10.4" TFT color monitor

• 3D simulationMedia & machine features

• Machine light

• Coolant system incl. pump (3.5 bar)

• Hydraulic unit

• Chip conveyor interface

• CE certificate

• DocumentationTool measurement (E45)

• Measuring arm fixed in the work area

• Tool measurement on the turret

• Short setup times / precise measurement / cost-efficientWorkpiece clamping

• 3-jaw chuck KK5

• Max. speed: 6300 rpm

• Diameter: 20 mm

• Soft + hard jawsOther (machine-related)

• Water gun

• Air to spindle

• Oil/coolant separator

• Automatic coolant monitoring

• Electronic handwheel

• Tool change guard

• Hydraulic connections

• Pneumatic connections

• Machine packaging: pallet + roll-up cover

Additional equipment

Bar feeder / magazine (SL1200 – as referenced)

• Bar length: 850–1200 mm

• Bar diameter: Ø 8–95 mm

• Max. feed rate: 60 m/min

• Bar change: approx. 3 s

• Magazine change: approx. 15 s

• Material support area: 550 × 1210 mm

• Material capacity: 10 × Ø 55 mm

• Operating side: right

• Power supply: 240 V DC/DC

• Air supply: 6 bar

• Dimensions: 1700 × 1250 × 1090–1380 mm

• Weight: approx. 500 kg

• Safety device: CE

• High-speed function

• DocumentationSpindle extension (for bar feeder use)

• E45 / MT45 / HT45 → DM45

• For 45 mm spindle

• Short bars up to 1100 mm

• With reducing sleeves (3 pieces)

• Required for use with SL1200Chip conveyor

• Hinged belt conveyor

• Discharge height: 1200 mmHigh-pressure coolant unit

• 14 bar / 50 Hz

• Additional high-pressure pump

• For tools with internal coolant

• Interface & softwareRobot interface

• PROFI-NET interface

• 24 V signals

• Safety release

• Automatic/manual operation switchingAdditional components

• PC keyboard USB (QWERTY)

• Machine status LED: Green (Automatic), Red (Alarm), White (Material handling)Installation & mounting hardware

• 4× vibration absorbers

• 4× mounting brackets

• 4× heavy-duty anchorsParts collection device

• Pneumatically operated

• Max. part length: 120 mm

• Max. diameter: 45 mm (51 mm)

• Max. weight: 2 kg

• Collection box / conveyor belt

Listing

Zwevegem

Zwevegem

18,754 km

Twin shaft paddle mixer, Barmix 180L.

BarssoDubbele peddelmenger, Type Barmix 180L

Call

Condition: new, new !

all stainless steel

2 speeds

2 mixing directions

1,8 kW – 2,5 kW

safety lid

Suitable for loader with “Easy Connect”

Easy clean

Hinged safety gard

CE-approved

overall dimensions (l x w x h) : 1.676 x 830 x 1.428 mm (open lid: H: 1.985 mm)

Pgedpsyfd Rcjfx Ah Hjg

The Barmix 180 litre twin shaft paddle mixer is an ideal machine for mixing all types of food products within the meat, poultry, fish, vegetables, dairy, cereal, confectionery, petfood and sandwich filling industry.

Mixing for meat and vegetarian burgers, sausages, meatballs, coleslaw, potato salad and other wet salads, mash potato, vegetables fresh and frozen, cereals, raw petfood the mixer is ideal for mixing many products that are free flowing and easy to move around.

The Barmix 180 features a special paddle shaft arrangement with one slightly higher than the other to give a more effective and quality mix.

The effective mixing action with high peripheral wing speed gives good protein extraction and uniformed distribution of spices, additives and liquids.

Also the Barmix 180 Litre Mixer produces a gentle mixing action which reduces particulate destruction maintaining the product structure and its original quality.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing unit

Construction &Delolition Waste RecyclingPE600x900 stone crusher

Call

Condition: new, Year of construction: 2026, functionality: fully functional, power: 55 kW (74.78 HP), ### Introduction to Jaw Crushers

A jaw crusher is a type of primary crusher used in mining and ore processing plants. It works by using compressive force to break down large rocks into smaller, more manageable pieces. The machine consists of a fixed jaw and a movable jaw, which together create a V-shaped cavity called the crushing chamber. The movable jaw exerts force on the rock by forcing it against the stationary plate, causing it to break.

Key Components:

- Fixed Jaw Plate: Mounted in a fixed position.

- Movable Jaw Plate: Mounted on a pitman that moves in a reciprocating motion.

- Flywheel: Provides the necessary inertia for the crushing action.

- Toggle Plates: Serve as a safety mechanism, ensuring that the jaw crusher operates efficiently and prevents damage.

### Working Principle

The working principle of a jaw crusher is based on the reciprocating movement of the movable jaw against the fixed jaw:

1. Feeding: Large rocks are fed into the top of the crusher.

2. Crushing: As the movable jaw moves back and forth, it crushes the material against the fixed jaw.

3. Output: Crushed material is discharged from the bottom of the crushing chamber.

### Applications of Jaw Crushers

Jaw crushers are versatile and can be used in a variety of industries and applications, including:

Podeq Nf Tvopfx Ah Hegg

1. Mining and Mineral Processing:

- Primary crushing of mined ore (gold, copper, iron, etc.).

- Size reduction of rocks to facilitate further processing (e.g., milling).

2. Construction and Demolition:

- Crushing of concrete, bricks, and other construction materials.

- Recycling of building materials to create aggregate for new construction.

3. Aggregates Production:

- Crushing of raw materials to produce aggregates for concrete and asphalt.

- Production of road base and railway ballast.

4. Industrial Applications:

- Crushing materials in chemical processing plants.

- Size reduction of materials for production processes in various industries.

5. Environmental Management:

- Processing of materials for landfill cover.

- Recycling operations to reduce waste and promote sustainable practices.

### Advantages of Jaw Crushers

- High Crushing Ratio: Capable of producing a range of material sizes with a single pass.

- Durability and Reliability: Built to withstand heavy-duty use and harsh conditions.

- Simple Structure: Easy to maintain and repair, with fewer components compared to other types of crushers.

- Versatility: Suitable for various types of materials and a wide range of applications.

- Energy Efficiency: Efficiently uses energy, making it cost-effective for operations.

### Examples of Use Cases

- Mining Operations: Jaw crushers are used as primary crushers in mine sites to crush large rocks before being processed further in the milling process.

- Construction Sites: Used to break down concrete and other building materials for recycling and re-use.

- Aggregate Production: Integral in producing the base materials for construction and infrastructure projects.

- Demolition Projects: Efficiently crushes and recycles materials from demolished structures.

By understanding the introduction and applications of jaw crushers, businesses can make informed decisions about integrating this machinery into their operations for efficient and effective material processing.

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Used Sidel Alsim PET bottling lines for carbonated water and drinks - 14.000 bph

ACI

Call

Condition: used, machine/vehicle number: LC594, Technical Specifications & Performance Data

This complete PET bottling line is engineered for carbonated water and soft drinks, delivering consistent output and reliable quality for beverage production. It combines high-efficiency blowing, isobaric filling, labeling, packaging, and end-of-line automation into a cohesive used bottling line suitable for second hand industrial packaging operations.

Production speed: 13,000–14,000 bottles per hour

Containers: PET bottles, neck finish 28 1881

Blow molder: Sidel SBO10, 10 cavities

Preform handling: Sidel EBH 2050 preform hopper

Air conveyor: Sidel-Alsim

Rinser/Filler/Capper monoblock: Sidel-Alsim PET Trybloc Asmojet 1T RV-P 48/60/10K

Rinser: 48 clamps, 1 water treatment

Filler: 60 isobaric valves

Capper: 10 heads

Premix/Mixer: Sidel-Alsim, 30 m³/h output

Bottle dryer: ACI

Pedpfx Ahsydn A Hj Hegg

Labeling machine: Krones Contiroll, rotary, 15 stations, PET wrap-around, roll-fed

Shrink wrapper: Acmi Fenix, film-only configuration

Handle applicator: Smipack HA 35-50-70

Palletizer: Alsim Valiant 1I 1P, fully automatic, push-type

Pallet wrapper: PM Pragometal OBS Rotomatic Standard

Advanced Automation & Control Systems

The line integrates component HMIs and automatic control features at each station to streamline operation and changeovers. The isobaric filling block ensures precise filling for carbonated beverages, while the roll-fed rotary labeling system supports continuous, high-speed label application. Quick-change mechanical adjustments and format components help maintain uptime and reduce setup times in beverage production environments.

Production Line Integration Capabilities

Designed for inline operation from preform loading through palletizing, the system features smooth bottle transfer via air conveyors and synchronized starwheels in the filling monoblock. It integrates upstream blowing with downstream labeling, shrink wrapping, handle application, and palletizing, creating a complete packaging machinery solution. The line is suitable for carbonated water and soft drinks and supports multiple PET bottle formats and heights associated with the 28 1881 neck finish.

Machine Condition & Maintenance History

This second hand line is available for sale and is presented in ready-for-operation condition. Component years range from 1996 to 2019, reflecting a well-curated selection of bottling equipment. Buyers can arrange inspection to assess performance, equipment condition, and overall line integration prior to deployment in beverage production.

Operational Performance & Versatility

Optimized for carbonated products, the isobaric filler provides accurate CO₂ retention and foam control. The Sidel blow molder delivers stable bottle quality, while the Krones Contiroll rotary labeler ensures precise PET wrap-around label application at the stated throughput. Downstream packaging includes film-only shrink wrapping and automated handle application for multipacks, with automated palletizing and pallet w...

Listing

Nattheim

Nattheim

18,550 km

CNC machining center

SCMMorbidelli M100

Call

Condition: used, Year of construction: 2023, Exhibition Machine Garbsen CNC-CONTROLLED MACHINING CENTER morbidelli m100 Drilling and Milling Made for You! This numerically controlled machining center is equipped with a comprehensive range of accessories and tools for milling and drilling, enabling it to meet every requirement in the field of wood processing. Highly efficient – with drilling spindles reaching up to 8,000 rpm – and featuring technology that includes the most robust spindle available on the market, offering more than 1,000 hours of maintenance-free operation. Fully equipped – the suction cups can be individually configured with the TV FLEX worktable to adapt the machine precisely to your requirements. Easy and intuitive programming thanks to the integrated Cad-Cam MAESTRO CNC software. User-friendly operation is ensured by the lowered machine frame, which provides unrestricted access to the worktable at all times. The control cabinet and vacuum pump are integrated into the machine base, and the PRO SPACE variant requires no additional structural safety measures.

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

- Reduced processing times due to improved acceleration

Podpfxoydmg Dj Ah Hsgg

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

Listing

Zdziechowice

Zdziechowice

17,909 km

Sawdust extractor,dust extraction ALKO

AL-KOECO JET 43/4 HD

Call

Year of construction: 1998, condition: good (used), Sawdust extractor,dust extractor,self-cleaning filter,vacuum ALKO ECO JET

Filter cleaned pneumatically by impulses of compressed air during operation, thus high efficiency of the device.

Ideally suited for all kinds of dry dust in various technological processes.

It is possible to replace the filter bags according to the requirements and purpose.

Year of manufacture 1998

5.5 Kw fan located on the clean side which reduces the risk of explosion initiation to a minimum

Inlet diameter 250 mm

Capacity 4320 m3/h

Filtration area 29 m2

Vacuum 3700 Pa

Extinguishing system "fireman"

Air return

Pedpfx Ahjiu Hq De Hjgg

ATEX flap

flap

noise damper

Extinguishing system *firefighter*.

Control cabinet with automation to run 8 machines

Technical documentation

Dimensions of Extraction:

Height - 3.05 m

Base width - 2.75 m x 1.00 m

Listing

Nattheim

Nattheim

18,550 km

CNC machining center

SCM morbidelliM 800

Call

Condition: used, Year of construction: 2011, Base Machine M800 X5 TV 1 WORKING RANGE X: 5,020 mm Y: 1,830 mm Z: 675 mm Clearance Height: 300 mm (from 50 mm suction cup height) MACHINE STRUCTURE The base structure is a monolithic construction made from thick-walled steel. It is reinforced across the entire machine bed with welded components, providing exceptional stability. The table design, with its large base, is the key to ensuring lasting precision and stability. The machine’s layout enables the operator to achieve optimal workflow with minimal space requirements. The mobile gantry is built as a solid monoblock. It is positioned in the X direction on prismatic, ground guides with recirculating ball carriages. The machining unit is mounted on this mobile support carriage, also on prismatic, ground guides and recirculating ball carriages. AXIS MOVEMENT All axes travel on prismatic linear guides with large cross-section and recirculating ball shoes with a wide contact surface, which ensures optimal sliding, even at high speeds and accelerations. The precise and fast positioning of the movable gantry (X-axis) is achieved via helical rack and pinion. Large cross-section recirculating ball screws ensure accurate positioning of the machining unit along the movable gantry (Y and Z axes). The perfect mechanical dynamics and maximum positioning accuracy are controlled by high-quality drives and brushless motors. Max. axis speeds: · X-axis = 90 m/min · Y-axis = 90 m/min · Z-axis = 30 m/min Safety device with bumper and light barrier 1 Bumpers with sensors are fitted to the movable upright, and a light barrier system is installed at the front of the machine. If the operator enters the active zone, the X-axis travel speed is reduced to a lower value of 25 m/min without stopping the machine. This system allows parts to be loaded during pendulum operation without the limitation of access areas, as seen with pressure mat systems. This prevents unwanted interruptions in the machining cycle and offers greater freedom of movement around the worktable. CE certification for the safety system 1 Safety protection fence 1 Side and rear protection fence Automatic central lubrication controlled via CNC 1 The lubrication of the X, Y, and Z axes is controlled by the CNC; intervals are regulated automatically, without manual intervention. Central extraction connector 1 All individual extraction connections of the machining units are collected into a central extraction port. Inside the port, there are various slider valves controlled by the NC. This reduces the required extraction air volume. Chip conveyor 1 Maxi – 5-axis electrospindle 11 kW HSK-63 “Prisma K 1 5-axis electrospindle, 11 kW at 20,000 rpm S1 (100% duty cycle) Speed: max. 20,000 rpm Rotation direction: left/right Liquid cooling Tool interface HSK 63F Inverter 18 kW, stepless, smooth power delivery Max. rotation B-axis = 200° (+-100°) C-axis = 650° Thanks to the non-orthogonal axes, it is possible to perform complex horizontal positioning in a small workspace. This enables the machining of complex geometries without the risk of collision.

Pjdsxy Tmnopfx Ah Hogg

Listing

Fevziçakmak

Fevziçakmak

16,807 km

Wet Dust Filter

Air Wet - Wet Dust Collector UnitTFON AIR WET Dust Collector Unit

Call

Condition: new, Year of construction: 2025, -Smart Safety Clean Air Enhanced Efficiency

-Elevate your workplace safety with the TFON Airwet Series — a state-of-the-art wet-type air suction system engineered to eliminate sparks and dust produced during deburring processes. The Airwet Series significantly reduces the risk of fire and explosion, protecting both your workforce and your facility.

-Fire & Explosion Prevention:

Effectively minimizes hazardous particles and ignition sources right at the source

-Enhanced Air Quality:

Captures and removes airborne contaminants, creating a cleaner and healthier work environment

Seamless Integration:

Compact, space-saving design allows for easy installation into existing machinery and workflows.

Increased Safety & Regulatory Compliance:

Pgsdpfx Ahevg U Dxj Hsg

Supports compliance with occupational health and safety standards, boosting overall operational safety

Listing

Fevziçakmak

Fevziçakmak

16,807 km

Sheet metal deburring machine

TFONSurfacer® TF-RBC 3013 PLUS

Call

Condition: new, Year of construction: 2025, -TFON Edge Rounding & Surface Processing System.

Designed for superior versatility and precision, this system is engineered to process mild steel, aluminum, and stainless steel materials with thicknesses from 0 to 120 mm. It offers advanced edge rounding and surface cleaning capabilities tailored to demanding industrial applications.

-Material Compatibility

-Mild Steel, Aluminum, Stainless Steel

-Working Thickness Range

-0 – 120 mm

Edge Rounding:

Radius 2 edge rounding for smooth, safe edges that enhance both aesthetics and functionality

Precision Control:

Integrated Siemens automation system delivers accurate, consistent control throughout processing.

Independent Processing Stations:

Multiple stations allow simultaneous or sequential processing, offering flexible workflow configurations.

Table Size Options:

Pgsdpfx Aei E Tkajh Hjg

Available with 650 mm, 1000 mm, or 1300 mm working widths to suit diverse production requirements.

Table Types:

Magnetic, vacuum, or magnetic-vacuum tables provide secure, adaptable support for various materials and part sizes.

Plasma & Oxygen Technology:

Advanced plasma and oxygen systems efficiently remove heavy burrs and dross after cutting, ensuring cleaner surfaces.

Surface Purification:

Effectively eliminates dirt, rust, oxide, and scale, preparing parts for subsequent processing such as welding or coating

Edge Rounding for Coating:

Produces uniform, defect-free edges ideal for painting and coating applications.

Industry Applications:

Steel Service Centers, Energy, Mining, Construction, Automotive — engineered for heavy-duty, high-performance use.

Uniform Edge Results:

8 flap wheels work together to deliver consistent radius edges on every part.

Pneumatic Oscillation System:

Extends abrasive band life and maintains consistent performance by reducing wear through pneumatic oscillation.

Engineered for industrial precision. Built for durability. Designed for versatile applications.

TFON – Excellence in Edge Processing and Surface Preparation.

Listing

Fevziçakmak

Fevziçakmak

16,807 km

Sheet metal deburring machine

TFONSurfacer® TF-RB 2510

Call

Condition: new, Year of construction: 2025, -TFON Precision Edge Rounding & Finishing System.

-Designed for superior surface finishing and edge rounding across a wide range of materials and industries, the TFON system combines advanced automation with versatile configurations to meet your exact production needs.

Pgsdpfxehq A Txe Ah Hjg

-Material Compatibility:

Suitable for aluminium, stainless steel, and mild steel applications.

-Wide Thickness Range:

Efficiently processes materials from 0 to 120 mm thick.

-Finishing Excellence:

Engineered to deliver high-quality surface finishes that enhance product aesthetics and functionality.

Industrial Versatility:

Ideal for medical devices, commercial kitchen equipment, automotive parts, and metal accessories industries

Edge Rounding Precision:

Provides precise Radius 2 edge rounding, improving safety and enhancing the final product appearance.

Advanced Automation:

Integrated Siemens control system ensures enhanced precision and operational reliability.

Independent Processing Stations:

Enable flexible, efficient multi-stage processing tailored to complex workfl

Multiple Table Width Options:

Available with table widths of 650 mm, 1000 mm, or 1300 mm to accommodate diverse production requirements.

Customisable Conveyor Options:

Choose from vacuum, semi-magnetic, or semi-vacuum conveyor systems for safe and secure part handling.

Surface Cleaning:

Effectively removes rust, oxides, and surface contaminants to prepare parts for downstream processing

Improved Operator Safety:

Edge rounding station minimizes risks of cuts and injuries from sharp edges.

High-Performance Finishing:

Equipped with Scotch abrasive technology to deliver smooth, even finishes.

Extended Abrasive Life:

Pneumatic oscillation system maximizes abrasive band and Scotch abrasive longevity, reducing downtime

Consistent Radius Output :

Six flap wheels ensure uniform edge radii on every part for consistent quality.

Engineered for performance. Designed for safety. Built for industrial versatility

TFON – Surface perfection, every time.

Listing

Fevziçakmak

Fevziçakmak

16,807 km

Sheet metal deburring machine

TFONSurfacer® TF-RBF 2510

Call

Condition: new, Year of construction: 2025, -TFON Precision Edge Rounding & Finishing System

Designed for superior surface finishing and edge rounding across a wide range of materials and industries, the TFON system combines advanced automation with versatile configurations to meet your exact production needs.

-Material Compatibility:

Suitable for aluminium, stainless steel, and mild steel applications.

-Wide Thickness Range:

Efficiently processes materials from 0 to 120 mm thick

-Finishing Excellence:

Engineered to deliver high-quality surface finishes that enhance product aesthetics and functionality.

Industrial Versatility:

Ideal for medical devices, commercial kitchen equipment, automotive parts, and metal accessories industries

Edge Rounding Precision:

Provides precise Radius 2 edge rounding, improving safety and enhancing the final product appearance

Advanced Automation:

Integrated Siemens control system ensures enhanced precision and operational reliability

Independent Processing Stations:

Enable flexible, efficient multi-stage processing tailored to complex workflows.

Multiple Table Width Options:

Available with table widths of 650 mm, 1000 mm, or 1300 mm to accommodate diverse production requirements.

Customisable Conveyor Options:

Choose from vacuum, semi-magnetic, or semi-vacuum conveyor systems for safe and secure part handling.

Surface Cleaning:

Effectively removes rust, oxides, and surface contaminants to prepare parts for downstream processing.

Improved Operator Safety:

Edge rounding station minimizes risks of cuts and injuries from sharp edges.

High-Performance Finishing:

Equipped with Scotch abrasive technology to deliver smooth, even finishes.

Extended Abrasive Life:

Pneumatic oscillation system maximizes abrasive band and Scotch abrasive longevity, reducing downtime.

Pjdehq Dbmjpfx Ah Hsgg

Consistent Radius Output:

Six flap wheels ensure uniform edge radii on every part for consistent quality.

Engineered for performance. Designed for safety. Built for industrial versatility.

TFON – Surface perfection, every time .

Listing

Tönisvorst

Tönisvorst

18,577 km

Exhausting system

RINGLERRE 201.D5,5

Call

Condition: used, Year of construction: 2009, Dimensions (L/W/H) mm

Filter capacity 14 m²

Number of filters St.

Dimensions (L/W/H) mm

engine output 5,5 kW

0 2.800 m³/h

low pressure 5.000 Pa

suitable for dust removal from graphite and metals

electromotive filter cleaning

Pgodou Sbkaspfx Ah Heg

including mechanical filter unit ME-FI 2000

Manufacturer W+W Filtersysteme

The suction fan is located behind the filter on the clean side, which reduces

the risk of explosion to a minimum.

Listing

Germany

Germany

18,384 km

Vollautomatische Bandsäge

BehringerHBE321A Dynamic

Call

Condition: used, Year of construction: 2023, machine/vehicle number: 0102-260003, The HBE321A Dynamic automatic band saw from BEHRINGER is a precise metal band saw for industry and the steel trade. It offers low cutting deviations, vibration damping thanks to cast iron band guides and a servo feed system for precise saw feeds. The linear guide system ensures stability and precise cuts. The auto-feed control automatically adjusts the feed and cutting speed. An electrically driven chip brush and sensitive cutting pressure control increase the cutting performance. The automatic guide arm minimizes the adjustment effort. Modern drives reduce energy consumption by approx. 30%. A touch control enables simple operation and the double vice ensures process reliability.

HBE321A Dynamic high-performance band sawing machine Technical specifications:

Pgsdpfjyc R Rqox Ah Hjg

Smallest dimension to be sawn around 10 mm

Smallest dimension to be sawn flat (W x H) 10 x 8 mm

Band saw blade drive: Drive power 2.6 kW frequency-controlled

Cutting speed 15 - 110 m/min (49 - 361 ft/min)

Total drive power: approx. 7.6 kW (machine only without additional equipment)

Voltage 400 V ± 10 %, 50 Hz with neutral conductor, control and valve voltage 24 V-DC

Material feed length: 640 mm per stroke, maximum 5,760 mm

Minimum cut-off length in automatic operation from 10 mm

Minimum remaining piece length in automatic operation from 70 mm, in manual operation from 10 mm

Saw feed: Regulated servo feed via ball screw spindle

Material feed with ball screw

Hydraulic material clamping

Hydraulic saw blade tensioning, electrically monitored

Saw band cleaning with electrically driven chip brush with quick-change device, driven synchronously to the main drive.

Coolant device with delivery rate 40 l/min at 2 m delivery height

Coolant tank capacity approx. 70 l

Length of the machine 1,850 mm, width of the machine 2,300 mm

Height of the machine 2,400 mm with the hood open on the feed side, approx. 1,880 mm transport height

Material support height 800 mm

Base machine paint finish: light gray - RAL 7035, cover paint finish red-violet - RAL 4002

Cutting range 90° round 320 mm

Cutting area 90° square 320 x 320 mm

Cutting area 90° flat 350 x 320 mm

Feed length single stroke 650 mm

Drive power 2.6 kW

Cutting speed 15 - 110 m/min

Saw blade dimensions 4,440 x 34 x 1.1 mm

Machine weight 1,900 kg

Listing

Menslage

Menslage

18,398 km

Tecnoimpianti W. T. MINI STAB 300 SINGLE Ion Exchange Unit (2017)

Tecnoimpianti W. T.Ionenaustausch-Einheit

Call

Condition: used, Year of construction: 2017, Overview The Tecnoimpianti MINI STAB 300 SINGLE is a compact system for the acid stabilization of must and wine using the ion exchange process. It was built in 2017 by the Italian manufacturer Tecnoimpianti Water Treatment S.r.l. and was rarely used by the original owner and is now being sold due to a change of ownership. The machine is therefore in very good condition and available immediately. It is ideal for wineries, breweries or the production of carbonated beverages. Technical details Capacity: approx. 300 l/h Area of application: Acidification / stabilization of must and wine Process: Ion exchange with strongly acidic cation exchange resin Compressed air requirement: min. 6 bar Power supply: 400 V / 3 Ph + N / 50-60 Hz Installed power: 3.2 kW Operation: Touchscreen HMI Protection class: IP65 Compressor tank: 400 L, 3 bar operating pressure Certification: EU-compliant / CE Special features Fully automated process control Precise pressure and temperature control Stainless steel construction (hygienic & durable) Plug-and-play system with touchscreen Built-in nitrogen feed Effectively reduces potassium bitartrate formation

Psdpfowm Rfkex Ah Hegg

Listing

Menslage

Menslage

18,398 km

Auxiemba BASIC 600-10-CF-I-DR Cold Glue Labeler (2010)

AuxiembaKaltleim / Nassleimetikettierer

Call

Condition: used, Year of construction: 2010, Overview This rotary cold-glue labelling machine was manufactured in 2010 by the Spanish company Auxiemba. The model BASIC 600-10-CF-I-DR is designed for applying paper or polypropylene labels onto cylindrical glass bottles using cold-glue technology. It is equipped with formats for 330 ml, 500 ml, and 750 ml bottles, making it suitable for wineries, breweries, and beverage producers. The machine is being sold due to the closure of a production line and is available in very good working condition. Technical data Capacity: up to 10,000 bottles/hour Bottle formats: 330 ml, 500 ml, 750 ml Bottle height range: 50–360 mm Bottle diameter range: 40–160 mm Label length range: 30–140 mm Rotation direction: Clockwise Number of bottle plates: 10 Number of labelling stations: 1 Air consumption: 125 L/min Power consumption: 17.3 kVA, 400 V Working height: 1,100 ± 50 mm Construction: Stainless steel frame, enclosed safety housing Control system: Micro PLC with touch-screen for speed, production, and fault management Key features: Cold-glue labelling head with oil-bath lubricated mechanisms Central carousel with centering bases for precise bottle positioning Pneumatic heated pump for adhesive circulation and return system Automatic bottle synchronization with infeed screw to prevent breakages Micrometric glue adjustment to reduce film thickness and ensure clean labelling Bottle retainers for smooth handling and reduced congestion Gear-driven transmission with clutch and emergency stop system Compact, fully enclosed design for hygiene and safety

Pgsdpoxl Di Dsfx Ah Heg

Listing

Menslage

Menslage

18,398 km

ALWID ATEX Filling Line (2021)

ALWIDAbfülllinie

Call

Condition: used, Year of construction: 2021, Overview The filling line was manufactured in 2021 by the German company ALWID. The filling line is new and can fill chemical products into plastic containers. With the exception of the bottle feeder and Posimat, glass bottles can also be processed. Due to ATEX certification, explosive products can be processed with the line. The equipment comes with a 2-year warranty (in single-shift operation) and all components of the equipment can be purchased separately. Technical details Capacity: 9000 containers/h (varies according to bottle volume and product). Container Max. Diameter: 100mm Max. Height: 300mm Control Siemens S7 Single machines Bottle Hopper | ALWID | POSIMAT-ACCESS-N15 Bottle feeder with hopper 2000 l, in stainless steel, chassis and supports in mild steel painted Positronic control system for optimal adaptation to downstream filler Machine, completely internally wired with attached control cabinet in mild steel, painted Machine according to CE guidelines; i.e. max. noise level of ≤ 80 dB +/- 2 Combined filling and closing machine (block machine) | ALWID | SUPERIOR-16MDM-5SK Fully automatic rotary filler Filling system: mass flowmeter system, type: Endress+Hauser LPG MASS Number of filling stations: 16 filling stations Filling valve diameter: Ø12mm Max. tank dimensions: height: 50-300 mm, Ø: 20-100 mm Fully automatic round capper Number of capping heads: 5 With torque adjustment via slip clutches With fully automatic cap sorting and cap feeding via BONINO disc sorter with elevator With inside drop switch to switch off the machine in case of missing closures Checkweigher | ALWID | OCS-HC-M-2000-1 Applied safety and machinery directives CE compliant Industrial load cell with stainless steel housing based on the principle of electromagnetic force compensation Force shunt free current transfer at the load cell Front protection to reduce interference on the weighing result Stainless steel control cabinet Graphics-capable color TFT touch screen, 10.4 inch, VGA resolution Flexible operability due to tiltable stainless steel operator terminal Freely configurable user interface with simple, intuitive operation Inkjet Printer | Domino | Ax350i Fast printing of text and multi-line codes at high speeds Labeler | ALWID | SES-120-III Tandem design Max. Label height: 120mm Photocell for label scanning 2 x automatic winding station incl. counter pressure plate Mounting device with height adjustment for lateral label dispensers With adjustable side guides - passage width up to 150mm

Podpfx Aomfqm Deh Hsgg

Listing

Menslage

Menslage

18,398 km

Markl Bavaria 40/8 Isobarometric Filler (2019)

MarklDruckfüller

Call

Condition: used, Year of construction: 2019, Overview This isobarometric filling and capping machine was built in 2021 by the German manufacturer Markl. The machine was built for filling glass bottles and crown caps but can be modified to can filling by the manufacturer. Technical Details Type: Bavaria 40/8 Isobarometric filler for glass bottles Capacity: 3,000-13,500 bottles/hour at 0,33L; 3,000-12,000 bottles/hour at 0,5L Number of long-tube filling valves: 40 Number of capping heads: 8 Formats: 0,33L longneck 0,33L Steinie 0,5L NRW Pre-evacuation system to reduce oxygen pickup Counter-pressure filler hygienic bottle table made of stainless steel (AISI 304) Running direction: left - right machine in good condition

Psdpfx Ahsx Natvs Hogg

Listing

Menslage

Menslage

18,398 km

Framax DEPAL, RLA, Modulblock RFCI Line for Non-Returnable Glass Bottles (2016)

FramaxAbfülllinie für Glasflaschen (Einweg)

Call

Condition: used, Year of construction: 2016, Overview This complete filling line for glass bottles is part of a brewery and used for filling beer in 330 ml glass bottles with crown caps. It consists of an automatic glass depalletizer, self-adhesive labeller, filling triblock and a carton packer. The entire equipment was installed in 2017 by Italian manufacturer Framax. All the equipment is still installed and can be viewed in person during production. Technical details Production capacity: 2,400 bph (at 0,33l) Formats recently used: 0,33l Bottle diameter: 60mm, height is adjustable 26mm crown cap Packaging: 6x4 carton box Scope of delivery Automatic depalletizer | Framax | DEPAL SS-3000 | 2017 Automatic sheet removal Photocells for depalletizer Selfadhesive labeller | Framax | RLA-H06-S3-L3-D480 | 2016 3 stations for 3 labels (front, back, neck) Date/ batch printer Isobaric filler | Framax | Modulblock RFCI-16/16/1-DPS/C | 2016 Nominal capacity: 3.000 bph 16 Rinsing positions 16 Filling positions Single head capping unit for crown caps with cap feeding unit Double air pre-evacuation with CO2 Water spray device before capping, for reducing the amount of residual oxygen Automatic carton packer | Framax | CP-0700-1T | 2017 Box erecting and inserting machine With taping machine Accessories such as conveyors, cooling, pumps

Pgjdpjtt Um Refx Ah Hjg

Listing

Menslage

Menslage

18,398 km

Emerito 1.8 Solo Screw Capper (2023)

EmeritoSolo Schraubverschließer

Call

Condition: used, Year of construction: 2023, Overview This capping machine is designed for capping twist off jars and vacuum detection of jars and bottles. Built with high-quality stainless steel (AISI 304L / 316L) and CE-certified, the system ensures efficiency, flexibility, and compliance with food industry standards. The machine is suitable for speeds up to 60–70 containers per minute. It's almost new. It's on sale because the company went bankrupt and stopped producing Technical Details Twist-Off Capping Machine – Emerito CAP 1.8 Automatic multiformat capping machine for glass, PET, and other rigid containers. Designed to handle a wide range of jars and caps without additional tooling. Includes automatic cap feeding system with hopper. Key Features: Motorized height adjustment for quick format change Independent adjustment of mechanisms with external controls Synchronization via frequency converters Independent control cabinet (IP67), connected via Harting connectors Optional installed steam injection for vacuum creation Automatic jam detection with accumulation sensor at the outfeed Technical Specifications: Model: CAP 1.8 Production: up to 70 cpm (≈ 4,200 units/hour) Container sizes: Ø30–106 mm, height 40–260 mm Cap sizes: Ø27–82 mm, height 5–18 mm Power: 1.1 kW / 2 HP Vacuum Detector – Emerito DVI400 Safety vacuum detector for jars and cans. Verifies correct closure, presence of vacuum, cap placement, and detects dents or deformities. Key Features: Digitalized vacuum and closure parameter control Counts inspected, correct, and rejected containers Adjustable ejection timing for flexible positioning of reject device Works regardless of cap color, gloss, or moisture Reject tray for defective containers included Technical Specifications: Model: DVI400 Max Production: 600 cpm Container sizes: Ø30–160 mm, height 40–260 mm Cap sizes: Ø30–110 mm Conveying System & Turntables Straight conveyor: 3 m with hinged chain, ending in a curve. Outfeed Turntable: Ø800 mm for filled and closed containers. Reject collection tray included after vacuum detection. Construction & Components Brands Material: Stainless steel AISI 304L / 316L Motors: ABB Gear reducers: Motovario Frequency inverters: Omron PLC & electronics: Omron & Schneider Bearings: SKF self-lubricated Pneumatics: SMC Conveyor chains: Magris, Eurobelt/Intralox Hoses: Trelleborg Hoses

Pjdpfxsyb S Hwo Ah Hsgg

Listing

Friedrichsdorf

Friedrichsdorf

18,546 km

Articulated Jib Platforms

Manitou180 ATJ

Call

Condition: used, functionality: fully functional, Year of construction: 2007, operating hours: 6,100 h, load capacity: 200 kg, empty load weight: 8,100 kg, construction height: 2,530 mm, fuel type: diesel, total length: 7,770 mm, drive type: Diesel, arm reach: 10,600 mm, construction width: 2,300 mm, working height: 17,650 mm, Articulated Boom Lift

Transmission: Hydrostatic

Technical Condition: Good

Front Tire Type: Solid Rubber

Front Tire Condition: 80 - 100%

Pjdpfx Asx Nz D Ajh Hegg

Rear Tire Type: Solid Rubber

Rear Tire Condition: 80 - 100%

Description: The articulated platform Manitou 160 ATJ+180 ATJ is ideal for outdoor work on uneven or inclined surfaces. With a lifting capacity of 230 kg, an articulation height of 7.38 m, and a working height of 16 - 18 m, it ensures a wide working range. Featuring a diesel engine and four-wheel drive combined with three control modes, the 160 ATJ+180 ATJ stands out for its high performance and autonomy. The ergonomic control panel design provides a clear and user-friendly workspace. Thanks to hydraulic speed control, noise levels and fuel consumption are reduced.

Trust Seal

Dealers certified through Machineseeker

Listing

Friedrichsdorf

Friedrichsdorf

18,546 km

Articulated Jib Platforms

Manitou180 ATJ 4RD ST5 S1 RC

Call

Condition: used, functionality: fully functional, Year of construction: 2024, operating hours: 125 h, load capacity: 230 kg, empty load weight: 7,600 kg, construction height: 2,530 mm, fuel type: diesel, total length: 7,770 mm, drive type: Diesel, arm reach: 10,600 mm, construction width: 2,300 mm, working height: 17,650 mm, Articulated boom lift

Transmission: Hydrostatic

Condition: As new

Pjdpfxoupauqs Ah Hegg

Technical condition: Very good

Front tyres type: Solid rubber

Front tyres size: 18

Front tyres condition: 80 - 100%

Rear tyres type: Solid rubber

Rear tyres size: 18

Rear tyres condition: 80 - 100%

Description: The 180 ATJ articulated boom lift offers a lifting capacity of 230 kg with a working height of 18.19 m. It meets all requirements for outdoor work on uneven, sloped, and obstructed surfaces. Its off-road capability makes it the ideal working partner on construction sites with rough terrain. Thanks to the new progressive hydraulic speed control, both noise levels and fuel consumption are reduced. Like other engine-powered work platforms, its 4-wheel drive and 3 steering modes make maneuvering and positioning the machine easy on congested or tight sites. The design of the control panel ensures a clear operating environment for quick handling and immediate productivity.

230 V generator and sockets in the platform basket, SMS Safe Man System

Listing

Friedrichsdorf

Friedrichsdorf

18,546 km

Rough terrain forklift truck

ManitouMSI 50 H

Call

Condition: used, functionality: fully functional, Year of construction: 2021, operating hours: 1,880 h, load capacity: 5,000 kg, lifting height: 5,500 mm, free lift: 1,900 mm, fuel type: diesel, mast type: triplex, construction height: 2,780 mm, power: 55 kW (74.78 HP), fork length: 1,200 mm, empty load weight: 8,695 kg, total length: 4,910 mm, drive type: Diesel, construction width: 1,720 mm, Rough Terrain Forklift

Load Center: 600

ISO Class: ISO Class 4 = 5,000 – 10,000 kg

Mast Type: Triplex

Pgodoxcb Sqspfx Ah Hsg

Transmission: Hydrostatic

Speed Class: 15

Technical Condition: normal

Front Tires Type: Pneumatic

Front Tires Condition: 80 – 100%

Rear Tires Type: Pneumatic

Rear Tires Condition: 80 – 100%

Description: The MSI 50 is a uniquely designed semi-industrial mast forklift capable of lifting up to 5 t. It is easy to maneuver on paved or semi-paved surfaces, thanks to its two drive wheels and a choice of tires tailored for various applications. This telehandler is ideally suited for recycling operations or the timber industry. It features a hydrostatic transmission that ensures smooth approach and load handling, significantly increasing work efficiency. The operator's cabin is accessible from both sides and features a suspension system to reduce vibration exposure for the operator.

Additional features:

Side shifter, 3rd and 4th hydraulic valve, front and rear work lights, heater, full cab, full free lift.

Listing

Cesena

Cesena

18,569 km

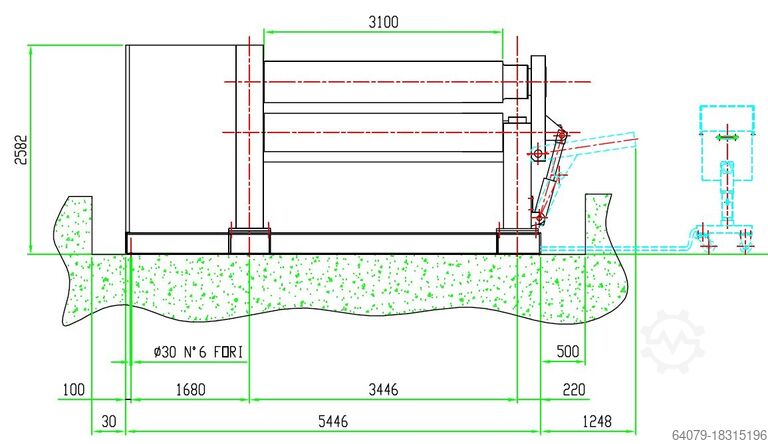

Round bending machines

MG3ROLL3000X50MM

Call

Condition: as good as new (ex-display), functionality: fully functional, Year of construction: 2024, machine/vehicle number: 3ROLL3000X50MM, roller (bottom) diameter: 460 mm, roller (top) diameter: 500 mm, roller diameter: 500 mm, roller length: 3,100 mm, working width: 3,000 mm, sheet thickness steel (max.): 50 mm, overall weight: 26,000 kg, type of input current: three-phase, working length: 3,000 mm, Equipment: documentation/manual, emergency stop, model 3 roll planetary with pre-pinch 3000x50 mm

upper roll size 500 mm

CAPACITY

plate width 3000 mm

plate thickness 50 mm

prebending 36 mm

diameter rolling 2200 mm

performance on plate quality 355 MPa

----

Psdsvr S S Ropfx Ah Hogg

reducing plate width 2000 mm

capacity thickness 55 mm

--- minimum diameter of rolling 600 mm

all the accessories installed

hardened rolls

conical attachment

digital position readout

power installed 50 Hp

weight of the machine 26Ton

Listing

Bünde

Bünde

18,406 km

Magnetic Clamping Plate

WAGNERSE 50 / 120

Call

Condition: used, length 1200 mm

width 500 mm

Pgodjtq I Rqepfx Ah Hsg

floor-plate height 105 mm

weight of the machine ca. 400 kg

Electric magnetic plate from WAGNER, a transformer is required for operation /

Rectifier required. 110 volts, 2.86 amps. Reduced special price.

Machine dealer with own stock of 1600 m².

We make it easier for you to find: "reduce"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Reduce (2,535)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month