Used Production for sale (16,233)

Leipzig

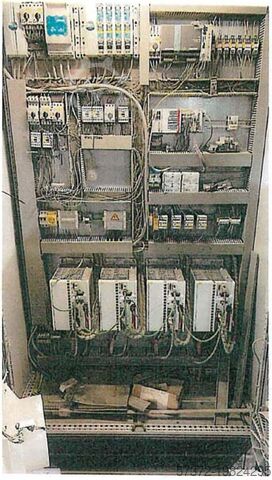

Leipzig CNC - production lines for window

Ingenierbüro Maschinenbau GmbH BJMRF-9L / H

Germany

Germany Sandwich Panel Production Plant

SANDWICH ANLAGEXBJ-II A Laminator

Pleystein

Pleystein Insulating glass production machine

Falk Wasseraufbereiter

+44 20 806 810 84

Pleystein

Pleystein Insulating glass production machine

LisecMolekularfüllgerät

Ruscova

Ruscova Parquet production line

Parquet line HOMAGFPR 225/FPR 226

Discover more used machines

Bobot

Bobot Paper Production Line 2050 mm

Papcel, PAMA

Udine

Udine Packaging line for boxes of dismantled beds or similar products

Zaandam

Zaandam Coating machine for digital production

PrintfinishingUltracoater 1000AQ

Prizren

Prizren Complete production line

elumatecVS 750 / EV 850

Baranów

Baranów POLPAK packaging machine for bulk products

POLPAK3000C7

Privalj

Privalj Production of milk and dairy products

Benz & Hilgers Benhil11

Privalj

Privalj Beverage production machine

Cober Mono blok punjac i zatvaracPunjac i zatvarac za boce staklo

Strenči

Strenči Pellet production line

Liptovský Mikuláš

Liptovský Mikuláš Pallet production machine

Störi MantelSMPA 500.2 ED

Χρυσούπολη

Χρυσούπολη Complete production line

Urbanaks 5310

Karsin

Karsin OMEV Pallet Production Line

OMEV

Karsin

Karsin STORTI Pallet Production Line

Storti

Ebikon

Ebikon Window production line

WEINIGUC Matic 15 / Powermat 500

Rīga

Rīga Milk & dairy production

Alistar EuropeS40 500kg/h cheese 2.2kW

Luckenwalde

Luckenwalde Automatic production machine for round material

PPS DIETLEPPS-GS2-03

Erndtebrück

Erndtebrück Beverage production machine

Abfüllstraße für FlaschenChina

Rennes

Rennes Beverage production machine

PAC ZimmermannCB 12-1-R-6.5 LII ng

Lielā Puderova

Lielā Puderova Pallet production machine

ENGELEREPAL Production Line

Germany

Germany Stone Production Plant

OmagTronic S22 140-90

Gifhorn

Gifhorn Milk & dairy production

Benhil8380

Used Production (16,233)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84