Used Nesting for sale (256)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Auction

Auction ended

Steiermark

Steiermark

18,242 km

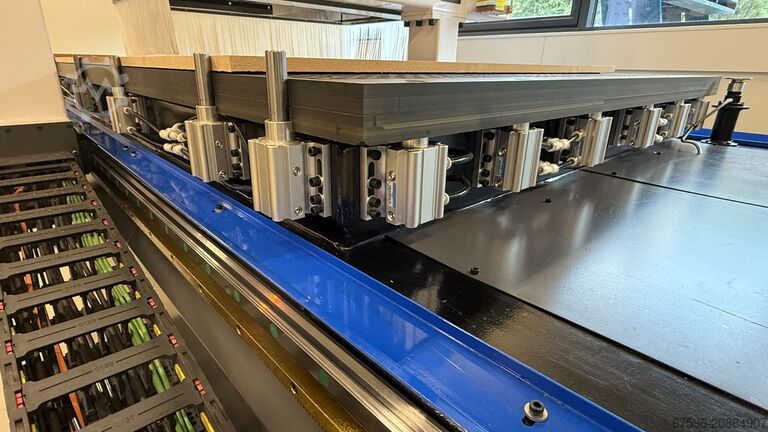

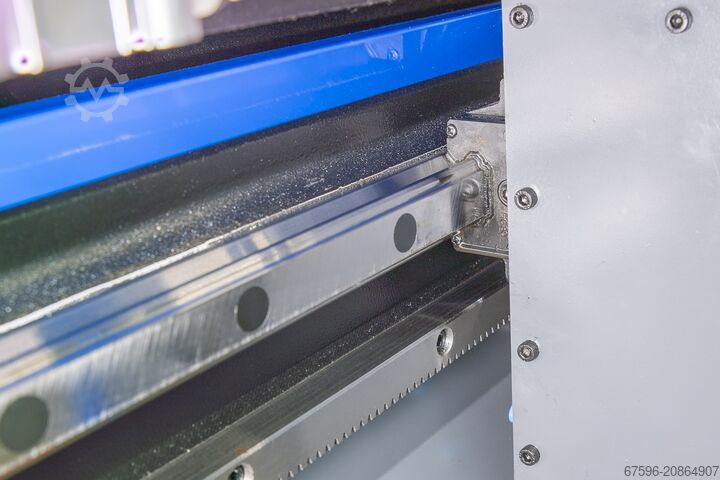

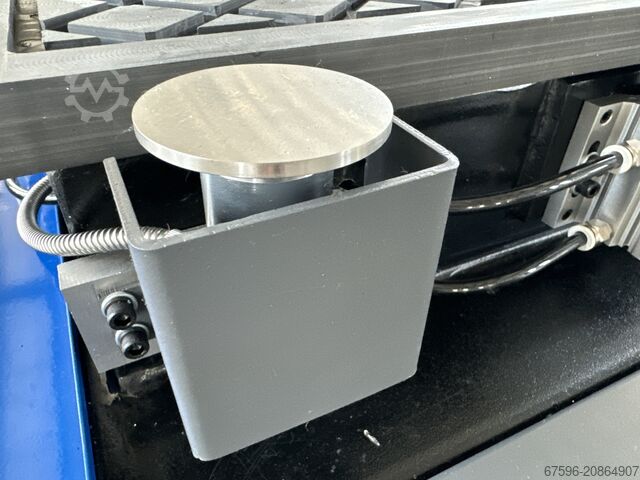

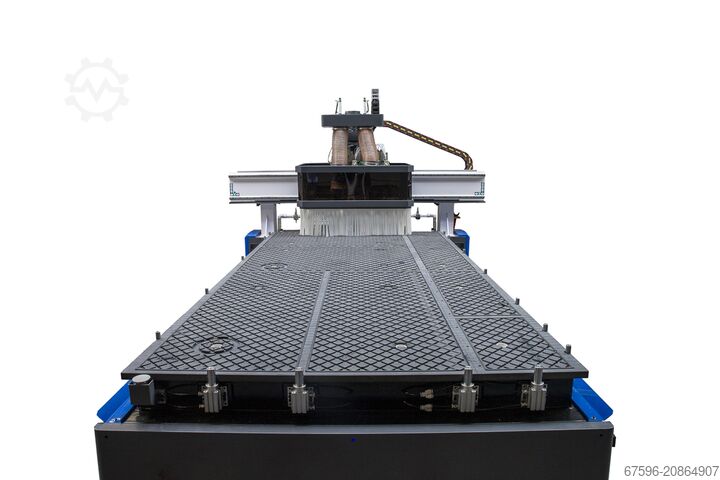

Fiber laser cutting machine + drilling spindle

MicroStepMSF Pro 4020 10 kW

Condition: excellent (used), functionality: fully functional, Year of construction: 2022, operating hours: 11,500 h, machine/vehicle number: 3098, laser power: 10,000 W, sheet thickness (max.): 30 mm, sheet thickness steel (max.): 30 mm, working width: 2,000 mm, travel distance X-axis: 4,020 mm, travel distance Z-axis: 150 mm, Machine was overhauled in 2024.

TECHNICAL DETAILS

Working area: 4,020 mm

Processing area: approx. 4,000 x 2,000 mm

Maximum sheet thickness: 30 mm

Maximum steel thickness: 30 mm

Cgsdswyaxmopfx Abbjn

Laser cutting head: EX-TRABEAM® Pro

Laser source: IPG YLS 10000 U fiber laser source

Laser power: 10,000 W

Power: 10 kW (13.60 hp)

Traverse speed: up to 100,000 mm/min

Z-axis positioning speed: 18 m/min

Z-axis travel: 150 mm

Z-axis acceleration: 0.75 G

Drilling

Drilling range: Ø4 mm – Ø30 mm

Holder: HSK-63

Thread cutting range: M5 – M20

Max. material thickness: up to 25 mm

Power: 21 kW

Revolutions: up to 10,000 rpm

Tool cooling: internal cooling

Tool change: automatic

Drilling tool measurement: automatic

MACHINE DETAILS

Ambient temperature: +10 °C to +35 °C

Relative humidity: 0 to 90%

Filter system: Donaldson DFPRO 6 Cyclopeel

Fan capacity: 7.5 kW

Volume flow: 4,500 m³/h

Mechanics and Control

Drives: maintenance-free Panasonic AC servo motors

Measuring system: IRC 2500 (incremental encoder)

Hold-down device: pneumatic

Chip brush: available

Laser hours: 6,900 h

EQUIPMENT

Documentation/manual

Cooling unit

Safety light barrier

Fully automatic shuttle table

Fully automatic HSK 63 drilling spindle

Cleaning and calibration station LU3K

Automatic nozzle changer with 8 nozzles

Donaldson® filter unit DFPRO 6 Cyclopeel

Asper Nesting® automatic nesting software

Witt gas mixer

Maintenance and support contract

Listing

Grońsko

Grońsko

17,981 km

Edge Bander

HEBROCKF4

Call

Condition: excellent (used), Hebrock F4 edge banding machine

Well equipped, option to inspect before purchase.

Pre-milling cutters,

Glue application with roller,

Equipped with glue discharge,

Codpfx Ajxq A Ebebbsgn

Interchangeable glue pot

Pneumatic pre-cut guillotine,

Pressure rollers,

Trimming saw for finishing,

Top and bottom milling aggregate, R1 – R2 pneumatically adjustable,

Profile scraper,

Corner rounding unit, pneumatically adjustable,

Flat scraper,

Nesting package included,

Maximum workpiece height: 45mm,

Maximum edge thickness in rolls: 3mm,

Feed speed: 7m/min,

Power requirement: 7.4KW,

Machine checked, ready for testing, in very good condition.

Only 15,000 meters worked.

Listing

Monzelfeld

Monzelfeld

18,659 km

Panel van

Plasma Pro 3000 / Wassertisch

Call

Condition: new, functionality: fully functional, overall weight: 1,000 kg, Year of construction: 2026, travel distance X-axis: 1,500 mm, travel distance Y-axis: 3,000 mm, travel distance Z-axis: 100 mm, controller manufacturer: CSMIO, controller model: IPM, sheet thickness steel (max.): 20 mm, control type: CNC control, degree of automation: automatic, sheet thickness stainless steel (max.): 20 mm, actuation type: electric, CNC controlled plasma cutting system with water table 3000x1500mm, comprising:

- Operator terminal - machine control / SimCNC - nesting and G-code generation / i3 Nest - drawing software / i3 CAD

- Parametric standard components / i3 Macro - repair tool / DXF / i3 DXF Cleaner - WIN 11 PRO - Processor / i7 / 3.8 GHz

- Memory / 16 GB RAM - Graphics / Radeon RX550/550 Series - Hard drive / 1TB Samsung SSD 980 M.2 - Mainboard / WIFI

- 24" monitor - USB 3.0 / data transfer

- THC / automatic height control

- Collision protection sensors

- Ohmic and floating touch sensing - engraving unit / FESTO pneumatics - workspace monitoring

- Servo drives on all axes

Csdpfxjx Sdtfo Abbogn

- Linear rail guides

- Rack and pinion drive

- Working area 3000x1500mm

- Welded machine bed

- Pipe cutting up to 120mm

- Positioning aid / point laser

- Plasma power source / Hypertherm SYNC 105A

- Maintenance unit / dry and clean air

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Årre

Årre

18,123 km

Plasma cutting machine

MicroStep

Call

Condition: excellent (used), Year of construction: 2008, Microstep plasma cutting machine cutting format 2000x6000MM power source Hypertherm 260 AMP year 2008 with nesting program

Codpfx Abot Uz Upobegn

on computer at the machine, incl. extraction and filter, many new wear parts

Listing

Lukovica

Lukovica

18,342 km

Machining center

MorbidelliAuthor 444S

Call

Condition: good (used), Year of construction: 2007, functionality: fully functional, travel distance X-axis: 5,000 mm, travel distance Y-axis: 1,700 mm, travel distance Z-axis: 180 mm, rapid traverse X-axis: 45 m/min, rapid traverse Y-axis: 45 m/min, rapid traverse Z-axis: 30 m/min, feed length X-axis: 4,500 mm, feed length Y-axis: 1,300 mm, feed length Z-axis: 180 mm, feed rate X-axis: 45 m/min, feed rate Y-axis: 45 m/min, feed rate Z-axis: 30 m/min, controller manufacturer: esa, controller model: kvara 6, workpiece length (max.): 4,500 mm, workpiece width (max.): 1,300 mm, workpiece height (max.): 180 mm, total height: 2,750 mm, total length: 7,000 mm, total width: 3,000 mm, table width: 1,200 mm, table height: 950 mm, table length: 4,500 mm, rotational speed (min.): 24,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 5,000 kg, spindle speed (min.): 24,000 rpm, spindle speed (max.): 24,000 rpm, spindle motor power: 7,500 W, number of spindles: 2, number of slots in tool magazine: 10, mount diameter: 200 mm, tool length: 200 mm, tool diameter: 150 mm, tool weight: 5,000 g, input voltage: 400 V, Equipment: documentation/manual, rotational speed infinitely variable, Electronic control with PC Office

Software Xilog Plus

Remote control device to manage the main functions of the machine

Working area: 4.400 x 1.300 x 180 mm.

Working table “Nesting” aluminum

Reverse flow system

Nr. 6 Back stops

Nr. 6 Drowned intermediate stops at 620 mm. from backside

Nr. 1 Electrospindle 7,5 KW – HSK 63

Tool changer RAPID at nr. 10 positions

Motor 2 manual tool change HSK63F

Disc unit 0-90 4 hp

Cjdpfx Abeufgg Robjgn

Boring unit:

Nr. 18 independent vertical spindles

Nr. 3 Independent horizontal spindles with double outlet, nr. 2 in “X” direction and nr. 1 in “Y” direction

Nr. 2 Vacuum pump of 250 m3/h

Automatic lubrication

Aspiration system optimized

Safety nets and bumper

CE Marks

Listing

Kruibeke

Kruibeke

18,685 km

Machining center with throughput

Igolden02P-WVQ

Call

Condition: excellent (used), Year of construction: 2023, functionality: fully functional, 4 axis nesting cnc machine for cabinet building - consists of 4 parts - part 1: automatic plate lift - part 2: automatic label machine - part 3: 4 axis CNC - part 4: automatic discharge table - 4 parts work together - including extraction installation - including vacuum pump CNC bed - compatible milling head ISO30 ER32 - including 3D cabinet program (Haixun software) Haixun quick design + Haixun quick production included - spare parts and labels included in this lot - dimensions control cabinet 80x60x 190 cm - dimensions extraction: 140x80x 140 cm - dimensions label machine: 4000x2700x1800 mm

Cgedpfx Aev Dupvebbsn

Listing

Almelo

Almelo

18,480 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

Codpsx R D Rnofx Abbsgn

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Listing

Almelo

Almelo

18,480 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

Cjdjx Rz Aujpfx Abbjgn

All axes servo-driven

Listing

Waregem

Waregem

18,746 km

Edgebander

SCMOlimpic k 230 evo

Call

Condition: excellent (used), Year of construction: 2022, functionality: fully functional, Edge banding machine

- R0.03.61 composition "T-ER1"

- 62.15.01 "AUTOSET"

- 62.14.93 Pre-heating panel

Cjdsx Rcu Eopfx Abbjgn

- 62.12.03 Anti-adhesive unit "AAR"

- Rectification unit "RT-V1"

- 62.15.06 Glue pot "SGP-E"

- 62.13.49 Sawing unit "K-2 radius"

- 62.15.02 Nesting kit

- Milling unit "R-K"

- Corner rounding unit "ROUND 1"

- Belt scraping unit "RAS-V"

- 62.12.61 Spraying unit for band finishing

- 62.15.04 Glue scraping unit "RC-N"

Listing

Iași

Iași

17,349 km

Cnc lathe

EMAGVL 2

Call

Condition: used, Year of construction: 2013, functionality: limited functionality, machine/vehicle number: 105032, Technical characteristics:

Work Area

- Maximum clamping plate diameter: 160 mm

- Maximum turning diameter: 160 mm

- Maximum machining diameter: 100 mm

- Maximum workpiece length: 150 mm

- X-axis travel: 700 mm / Rapid traverse in X: 60 m/min

- Z-axis travel: 375 mm / Rapid traverse in Z: 30 m/min

- Standard integrated automation (number of loading nests by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle according to DIN 55026: Size A5

- Maximum spindle speed: 6,000 rpm

- Spindle power (100%/40% duty cycle): 18.1 / 13.9 kW

- Spindle torque (100%/40% duty cycle): 77 / 59 Nm

Tool Turret with Driven Tools

- Tool holders according to DIN 69880: 12 positions - BMT65

- Maximum tool length including holder: 190 mm

- Maximum tool speed: 6,000 rpm

- Maximum torque: 27 Nm (10% duty cycle), 14 Nm (100% duty cycle)

Electrical Equipment

- Operating voltage: 400–480 V, 80 A

- Connected load: 27 kVA

Dimensions

- Overall dimensions: Length = 4,350 mm (with chip conveyor), Width = 1,600 mm, Height = 2,500 mm

- Weight: 5,500 kg

Cgodpoxxwztofx Abbon

Main Features and Capabilities:

- Vertical Design: Optimised for chip evacuation and easy loading/unloading

- Control: GE Fanuc FS 32i B

- High Precision: Positioning accuracy on X and Z axes ±0.001 mm, Haidenhain linear scales

- Main Spindle: High power output and wide speed range

- In-process Control: Marposs T25 measurement probe

- Automated Loading/Unloading: Parts are automatically loaded and unloaded by integrated automation

- Live Tooling: Capable of drilling and milling with driven tools

- Tool Life Monitoring with Sister Tool Management

- Chip Conveyor, Coolant System, Switchable Dual Cartridge Filter, High Pressure Pump (15 bar)

- Fully Enclosed Work Area, Work Area Lighting

- Documentation: Electronic available; paper manual not complete

Machine Condition:

WORKING

- Operator panel safety switch is broken

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL5 mLT

Call

Condition: used, Year of construction: 2007, functionality: fully functional, machine/vehicle number: 100864, Technical Specifications:

Work Area

- Maximum clamping plate diameter: 260 mm

- Maximum turning diameter: 260 mm

- Maximum machining diameter: 220 mm

- Maximum workpiece length: 110 mm

- X-axis travel: 570 mm / Rapid traverse X: 60 m/min

- Z-axis travel: 200 mm / Rapid traverse Z: 30 m/min

- Y-axis travel: 40 mm / Rapid traverse Y: 30 m/min

Cgsdsxxttfspfx Abben

- Standard closed automation (number of loading nests per workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle according to DIN 55026: Size 6

- Maximum speed: 4,500 rpm

- Power at 100/40% duty cycle: 18 / 27 kW

- Torque at 100/40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Tool holder shank according to DIN 69880: 12 - VDI40

- Number of turret positions: 12

- Maximum tool length including holder: 190 mm

- Maximum speed: 6,000 rpm

- Maximum torque: 37 Nm (10% duty cycle), 26 Nm (25% duty cycle), 14 Nm (100% duty cycle)

Electrical Equipment

- Operating voltage: 400 - 480 V

- Connected load: 42 kW

Dimensions

- Overall dimensions: Length = 2,680 mm (3,820 mm with chip conveyor), Width = 2,040 mm, Height = 2,400 mm

- Weight: 6,500 kg

Main Features and Capabilities:

- Vertical Design: Ensures optimal chip evacuation and easy loading/unloading operations.

- Control System: GE Fanuc Series 18i TB.

- High Precision: Positioning accuracy in X and Z axes: ±0.001 mm (Heidenhain linear scales).

- Main Spindle: High power and wide speed range.

- Automated Loading/Unloading: Parts are automatically fed and removed via integrated automation.

- Driven (live) tools: Enables drilling and milling operations in addition to turning.

- Chip conveyor included.

- Documentation: Electronic manual not available; printed book manual available.

Machine Status: Operational, in working condition.

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL5 mLT

Call

Condition: used, Year of construction: 2007, functionality: limited functionality, machine/vehicle number: P-30008793, Technical characteristics:

Work Area

- Maximum diameter of clamping plate: 260 mm

- Maximum turning diameter: 260 mm

- Maximum machining diameter: 220 mm

- Maximum workpiece length: 110 mm

- X-axis travel: 570 mm / Rapid traverse in X: 60 m/min

- Z-axis travel: 200 mm / Rapid traverse in Z: 30 m/min

- Standard closed automation (number of loading nests by workpiece Ø: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle mount: DIN 55026, size 6

- Maximum speed: 4,500 rpm

- Power at 100% / 40% duty cycle: 18 / 27 kW

- Torque at 100% / 40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Toolholder shank per DIN 69880: 12 stations – VDI40

- Number of positions: 12

- Maximum tool length incl. holder: 190 mm

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 37 Nm, at 25%: 26 Nm, at 100%: 14 Nm

Electrical Equipment

- Operating voltage: 400 – 480 V

- Connected load: 42 kW

Dimensions

- Overall dimensions: L=2,680 mm (3,820 mm with chip conveyor), W=2,040 mm, H=2,400 mm

- Weight: 6,500 kg

Main Features and Capabilities:

- Vertical design: Optimal chip evacuation and easy loading/unloading

Csdexxr Rpopfx Abbjgn

- Control: GE Fanuc Series 18i TB

- High precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High torque and wide speed range

- Automated loading/unloading: Integrated automation feeds and removes parts

- Driven/live tools: Enables drilling and milling operations in addition to turning

- Chip conveyor

- Documentation: Electronic not available, paper manual available

Machine status: WORKING

- Operator panel safety switch broken

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVT2-4

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 106374, Technical characteristics:

Work Area

- Chuck diameter: 160 mm

- Maximum weight of chuck + workpiece: 45 kg

Cjdpfxoxxtkws Abbogn

- Maximum workpiece diameter/height: 100/400 mm

- Distance spindle nose to origin of tailstock: 795.5 mm

- X1/X2 working stroke: 340 mm / Rapid traverse in X: 30 m/min

- Z1/Z2 stroke: 625 mm / Rapid traverse in Z: 30 m/min / Feed force: 18.7 kN

- Loading time: 5–6 sec

- Standard closed automation (number of loading nests by workpiece diameter): 14/(80–200 mm), 18/(30–160 mm), 30/(30–85 mm)

Main Spindle

- Spindle according to DIN 55026: Size KK5

- Maximum speed: 8,500 rpm

- Power at 100% / 40% duty cycle: 34 / 26.5 kW

- Torque at 100% / 40% duty cycle: 75 / 48 Nm

Tailstock

- Interface: MK3

- Clamping force: 120 N/bar

- Clamping stroke: 5 mm

Tool Holder with Motorized Tools

- Tool holders with cylindrical shank according to DIN 69880: 12 – BMT65

- Number of positions: 2 x 12 (1 gripper per turret)

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400–480 V, 120 A

- Connected load: 45 kVA

Dimensions

- Total dimensions: Length = 5,300 mm with chip conveyor, Width = 1,760 mm, Height = 3,650 mm

- Weight: 7,500 kg

Main Features and Capabilities

- Vertical design: Optimized chip evacuation and automatic loading/unloading

- Control: GE Fanuc FS 32i

- High precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High power and wide speed range

- Automation: EMAG O-type – Parts are loaded and unloaded automatically via integrated automation

- Live tools: Allows drilling and milling operations

- Tool life monitoring with sister tool management

- Chip conveyor, coolant unit, switchable dual cartridge filter, high pressure pump (15 bar)

- Fully enclosed working area, LED light in working area

- Documentation: Available both electronically and as hardcopy book

Machine Status: NOT WORKING

- X-axis drive

- Five electrical switches (Siemens)

- Hydraulic pump

- Operator panel (in stock, needs installation)

- Valve chiller

- Pressure switch for oiling unit

- Emulsion tank pump

- Four emulsion circuit switches (electrovalves)

- Pressure switch for hydraulic circuit

- Complete hydraulic block

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL 5 mLT

Call

Condition: repair required (used), Year of construction: 2007, functionality: not functional, machine/vehicle number: P-30010522, Technical characteristics:

Work Area

- Maximum clamping plate diameter: 260 mm

- Maximum turning diameter: 260 mm

- Maximum machining diameter: 220 mm

- Maximum workpiece length: 110 mm

- X-axis travel: 570 mm / Rapid traverse X: 60 m/min

- Z-axis travel: 200 mm / Rapid traverse Z: 30 m/min

- Standard closed automation (number of loading nests by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle according to DIN 55026, Size 6 !!! Brand new, replaced in 2024 !!!

- Maximum speed: 4,500 rpm

- Power, 100% / 40% duty cycle: 18 / 27 kW

- Torque, 100% / 40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Tool holders with cylindrical shank to DIN 69880: 12 - VDI40

- Number of turret stations: 12

- Maximum tool length (including holder): 190 mm

- Maximum speed: 6,000 rpm

- Maximum torque: 37 Nm (10% duty cycle), 26 Nm (25% duty cycle), 14 Nm (100% duty cycle)

Electrical Equipment

- Operating voltage: 400 – 480 V

- Connected load: 42 kW

Dimensions

- Overall dimensions: Length = 2,680 mm (3,820 mm with chip conveyor), Width = 2,040 mm, Height = 2,400 mm

- Weight: 6,500 kg

Main Features and Capabilities:

- Vertical design: Optimal chip evacuation and easy loading/unloading

- CNC control: GE Fanuc Series 18i TB

- High precision: Positioning accuracy in X and Z axes ±0.001 mm (Heidenhain linear scales)

Cjdpfx Ajxxkh Tebbjgn

- Main spindle: High power and broad speed range

- Automated loading/unloading: Integrated automation system for part feeding and removal

- Driven tools: Capability for drilling and milling operations

- Chip conveyor

- Documentation: Electronic unavailable, partial hard copy/manual available

Machine status: NOT WORKING

- Hydraulic solenoid valves: 4 units

- Coolant (emulsion) pump defective

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL5i F

Call

Condition: used, Year of construction: 2011, functionality: fully functional, machine/vehicle number: 102821, Technical characteristics:

Work Area

- Maximum diameter of the clamping plate: 250 mm

- Maximum turning diameter: 270 mm

- Maximum machining diameter: 220 mm

Cgjdpjxxikgofx Abbjn

- Maximum workpiece length: 175 mm

- X-axis travel: 660 mm / Rapid traverse in X: 60 m/min

- Z-axis travel: 300 mm / Rapid traverse in Z: 30 m/min

- Standard closed automation (number of loading nests by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle interface to DIN 55026: Size 6

- Maximum speed: 4,500 rpm

- Power at 100% / 40% duty cycle: 18 / 27 kW

- Torque at 100% / 40% duty cycle: 202 / 303 Nm

Tool Turret with Driven Tools

- Toolholders, cylindrical shank DIN 69880: 12x VDI40

- Number of stations: 12

- Maximum tool length including holder: 190 mm

- Maximum speed: 6,000 rpm

- Maximum torque at 10% duty cycle: 37 Nm, 25%: 26 Nm, 100%: 14 Nm

Electrical Equipment

- Operating voltage: 400 V

- Connected load: 36 kW / 80 A

Dimensions

- Dimensions (L x W x H): 3,120 mm (4,185 mm with chip conveyor) x 2,266 mm x 3,200 mm

- Weight: 7,500 kg

Main Features and Capabilities:

- Vertical design for optimal chip removal and easy access for loading/unloading

- CNC control: GE Fanuc Series 32i Model A

- High precision with X, Z, and Y axis positioning accuracy ±0.001 mm (Heidenhain linear scales)

- Powerful main spindle with wide speed range

- Integrated automation for part loading/unloading

- Driven tools available for both milling and drilling operations

- Workpiece detection sensor with compressed air gauge through spindle: SMW Autoblock Linear Position Sensor LPS-X

- In-process gauging: Marposs T25

- Chip conveyor included

- Documentation: Complete, both electronic and paper versions

Machine status:

IN OPERATION

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL2 V3.0.05

Call

Condition: repair required (used), Year of construction: 2017, functionality: not functional, machine/vehicle number: 108113, Technical Characteristics:

Work Area

- Maximum clamping plate diameter: 160 mm

- Maximum turning diameter: 160 mm

- Maximum machining diameter: 100 mm

- Maximum workpiece length: 150 mm

Csdpfxjxxip Ae Abbogn

- X-axis travel: 700 mm / Rapid traverse X: 60 m/min

- Z-axis travel: 375 mm / Rapid traverse Z: 30 m/min

- Standard automation with closed system (number of loading nests by workpiece diameter: 14/(80–200), 18/(30–160), 30/(30–85))

Main Spindle

- Spindle interface per DIN 55026: Size A5

- Maximum spindle speed: 6000 rpm

- Power (100% / 40% duty cycle): 18.1 / 13.9 kW

- Torque (100% / 40% duty cycle): 77 / 59 Nm

Tool Holder with Driven Tools

- Tool shank per DIN 69880: 12 – BMT65

- Number of stations: 12

- Maximum tool length including holder: 190 mm

- Maximum speed: 6000 rpm

- Maximum torque (10% duty cycle): 27 Nm; (100% duty cycle): 14 Nm

Electrical Equipment

- Operating voltage: 400–480 V, 80 A

- Connected load: 27 kVA

Dimensions

- Total dimensions (L x W x H): 4350 mm (with chip conveyor) x 1600 mm x 2500 mm

- Weight: 5500 kg

Main Features and Capabilities:

- Vertical Design: Optimized for chip removal and easy loading/unloading

- CNC Controller: GE Fanuc FS 32i B

- High precision: Positioning accuracy in X and Z axes ±0.001 mm with Heidenhain linear scales

- Main spindle: High power and broad speed range

- In-process control: Marposs T25 measuring probe

- Automated loading/unloading: Integrated automation for feeding and removing parts

- Live tools: Capability for drilling and milling operations

- Tool life monitoring and sister tool management

- Chip conveyor & Knoll coolant filtration unit with paper filter and 40 bar pumps (suitable for filtering two machines)

- Fully enclosed work area, with work area lighting

- Documentation: Electronic version available, printed booklet incomplete

Machine Status:

- NOT WORKING

- LT motor defective, repairable

- Operator panel, safety switch, and two buttons broken and need replacement

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL 2

Call

Condition: repair required (used), Year of construction: 2016, functionality: not functional, machine/vehicle number: 107965, Technical characteristics:

Work Area

- Maximum diameter of the clamping plate: 160 mm

Cgsdpfx Aboxw Sviobjn

- Maximum turning diameter: 160 mm

- Maximum machining diameter: 100 mm

- Maximum workpiece length: 150 mm

- X-axis travel path: 700 mm / Rapid traverse in X: 60 m/min

- Z-axis travel path: 375 mm / Rapid traverse in Z: 30 m/min

- Standard enclosed automation (number of loading nests in relation to part diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle interface according to DIN 55026: Size A5

- Maximum rotational speed: 6000 rpm

- Power at 100% / 40% duty cycle: 18.1 / 13.9 kW

- Torque at 100% / 40% duty cycle: 77 / 59 Nm

Tool Turret with Driven Tools

- Tool shank as per DIN 69880: 12 positions - BMT65

- Number of positions: 12

- Maximum tool length including holder: 190 mm

- Maximum speed: 6000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400 - 480 V, 80 A

- Connected load: 27 kVA

Dimensions

- Total machine dimensions: Length = 4350 mm (with chip conveyor), Width = 1600 mm, Height = 2500 mm

- Weight: 5500 kg

Main Features and Capabilities:

- Vertical construction: Optimized chip removal and easy loading/unloading

- CNC controller: GE Fanuc FS 32i B

- High precision: Axis positioning accuracy in X, Z ±0.001 mm (Heidenhain linear scales)

- Main spindle: High power and wide speed range

- Process control: Marposs T25 measuring probe

- Automated loading/unloading: Parts are loaded and removed via integrated automation system

- Live tooling: Enables drilling and milling operations in addition to turning

- Tool life monitoring with sister tool management

- Chip conveyor & coolant filtration system Knoll with paper filter and 40 bar pumps (capable of filtering 2 machines)

- Fully enclosed work area; integrated work lighting

- Documentation: Available electronically; hardcopy manuals incomplete

Machine status:

NOT WORKING

- Live tool drive motor

- Safety locking mechanism (Euchner) for loading door

- Turret drive motor

- Turret motor driver

- Lubrication pump

- Hydraulic manifold (4x electrovalves)

- Lubrication pressure system

- Rotary union

- Hydraulic cylinder for loading door

- Spindle clamping/unclamping sensor

Listing

Iași

Iași

17,349 km

Strung vertical

EMAGVL 2

Call

Condition: repair required (used), Year of construction: 2016, functionality: not functional, machine/vehicle number: 107964, Technical characteristics:

Work Area

- Maximum diameter of the clamping plate: 160 mm

- Maximum turning diameter: 160 mm

- Maximum machining diameter: 100 mm

- Maximum workpiece length: 150 mm

- X-axis travel: 700 mm / Rapid traverse in X: 60 m/min

- Z-axis travel: 375 mm / Rapid traverse in Z: 30 m/min

- Standard enclosed automation (number of loading nests by workpiece diameter: 14/(80...200), 18/(30...160), 30/(30...85))

Main Spindle

- Spindle interface according to DIN 55026: Size A5

- Maximum speed: 6000 rpm

- Power at 100% / 40% duty cycle: 18.1 / 13.9 kW

- Torque at 100% / 40% duty cycle: 77 / 59 Nm

Tool Holder with Motorized Tools

- Tool holders with cylindrical shank according to DIN 69880: 12 - BMT65

- Number of stations: 12

- Maximum tool length including holder: 190 mm

- Maximum speed: 6000 rpm

- Maximum torque at 10% duty cycle: 27 Nm, at 100% duty cycle: 14 Nm

Electrical Equipment

- Operating voltage: 400 - 480 V, 80 A

- Connected load: 27 kVA

Dimensions

- Total dimensions: Length = 4350 mm with chip conveyor, Width = 1600 mm, Height = 2500 mm

- Weight: 5500 kg

Cjdpfx Abexw Srksbjgn

Main Features and Capabilities:

- Vertical Design: Enables optimal chip evacuation and easy loading/unloading.

- CNC Control: GE Fanuc FS 32i B.

- High Precision: Positioning accuracy on X and Z axes ±0.001 mm with Heidenhain linear scales.

- Main Spindle: High power and wide speed range.

- In-process Measurement: Equipped with Marposs T25 measuring probe.

- Automated Loading/Unloading: Integrated automation for part loading and unloading.

- Live Tooling: Capability for driven tools expands machining to drilling and milling operations.

- Tool Life Monitoring: Sister tool management for tool life tracking.

- Chip Conveyor

- Fully Enclosed Work Area with Work Area Lighting

- Documentation: Electronic available; hardcopy/incomplete book.

Machine Status:

NOT OPERATIONAL

- Cooling pump x2 units

- Live tool drive motor

- Lubrication pump

- Operator panel - touchscreen needs replacement

- Hydraulic block valves x3

- Hydraulic loading door cylinder

- Rotary joint

- Lubrication pressure switch

- Safety door, Euchner type

Listing

Alytus

Alytus

17,414 km

Plasma cutting machine

MicroStepCOMBI-PL 12001.20

Call

Condition: used, Year of construction: 2003, functionality: fully functional, type of input current: AC, sheet thickness (max.): 200 mm, overall weight: 7,500 kg, input voltage: 400 V, cutting speed: 300 mm/min, cutting height (max.): 230 mm, table length: 13,975 mm, working width: 2,200 mm, table width: 2,200 mm, positioning accuracy: 0.5 mm, working length: 12,700 mm, 1 plasma & 1 gas (natural) torches

200 Amps Hypertherm HD4070 plasma source

1 owner throughout all service life

Good condition, still in operation

Set of technical documentation (users + maintenance manuals)

Filter unit GTV included

Codpfxjwltwao Abbogn

Nesting program Asper license + PC included

Assistance in dismantling, packing, loading (to be negotiated separately)

Organizing of transportation to countries of the European Union (at separate quotation)

Listing

Przełazy

Przełazy

18,037 km

Triple-stacked warehouse trolleys

Cordesmc200/250/270

Call

Condition: like new (used), We offer used warehouse trolleys designed for use in production, logistics, and storage facilities. Our business operates on a consistent, repeat supply model, mainly targeting business customers.

Offer:

• Warehouse/transport trolleys (various types and dimensions)

• Used trolleys, thoroughly inspected and prepared for further use

• Continuous availability – regular stock batches

• Option to assemble larger quantities

Who is it for:

• Manufacturing plants

• Logistics centers

• Warehouses and wholesalers

• Manufacturers (including the furniture industry)

Why partner with us:

• Focus on long-term cooperation, not one-off sales

• Repeatable assortment and clear terms

• Experience in B2B customer service

• Possibility of regular supply and batch reservation

📦 The photos show trolleys currently in stock – full inventory available.

💰 Pricing is determined individually – depending on quantity and business terms.

📞 If you are interested in a reliable supplier of warehouse trolleys, feel free to contact us.

Triple stacking capability.

Ø100 mm polyamide castors, 4 swivel wheels, 1 with directional lock.

Trolleys without goods can be nested inside each other for space savings.

Corletta trolleys can be used for in-plant transport and storage of almost any type of goods. Their triple stacking capability allows you to fully utilize your warehouse height.

We provide comprehensive trolley servicing.

Cjdex Nrvpjpfx Abbogn

This allows us to offer a 1-year warranty on used trolleys!

Delivery available throughout Europe!

Your specialist in Corlett sales and service: KAM-KUB Logistic & Trolleys Europe

Listing

Turkey

Turkey

17,207 km

2000x8000mm fiber laser machine

CRONOSSTECHCRONOSS FB 8020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 40 mm, travel distance X-axis: 8,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 15 kW (20.39 HP), Working Area: 8000 × 2000 mm (8020 Model)

STANDARD FEATURES

CNC-controlled fiber laser sheet metal cutting machine

High rigidity, heavy-duty steel frame and bridge structure, FEM-analyzed

Cgedpox Nqtmsfx Abben

Rack and pinion drive system

Laser cutting head with automatic motorized focusing

Automatic height control system with capacitive sensor

Automatic focus distance adjustment during cutting

High-precision linear guides and servo motor system

Advanced touchscreen CNC control unit (Windows-based)

User-friendly CNC interface with multi-language support

EtherCAT communication infrastructure

Monitoring of temperature, pressure, protective glass status, and back reflection at the cutting head

Internal and external machine monitoring system with camera support

LED status and warning indicators

Fiber laser beam transmission via fiber cable (no optical mirror/lens loss)

Automatic sheet recognition and alignment systems

Fly-cut (continuous serial cutting) capability

No Piercing mode for burr-free cutting of thin sheets

Controlled piercing mode for thick sheet cutting

Fully enclosed cabin design in accordance with CE standards

Special safety glass resistant to laser beams

CNC-controlled filtered ventilation system

Automatic nozzle cleaning and cutting head calibration

Conveyor slag and part discharge system

Moveable table system

Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

Dual pallet automatic table exchange system

Fiber laser resonator in various power options

Automatic sheet loading system

Automatic parts unloading system

Advanced CNC-controlled filtration unit

Camera-based automatic sheet recognition and nesting software

Remote monitoring and reporting package

Oil cooler / climate control system

Additional LED lighting inside the cabin

Special cutting head alternatives

Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (8020 MODEL)

Axes

X Axis: 8030 mm

Y Axis: 2030 mm

Z Axis: 120 mm

Motion Performance

Acceleration: 2.0 G

Max. axis speed: 140 m/min

Synchronized speed: 200 m/min

Positioning accuracy: ±0.05 mm

Repeatability accuracy: ±0.03 mm

Table and Loading

Max. table loading capacity: 3,500 kg

Table exchange time (optional): ~35 sec

Laser Power Options

4 kW / 6 kW / 8 kW / 10 kW / 12 kW / 15 kW

Cutting Capacities (max.)

Mild steel: 25 – 40 mm (depending on power)

Stainless steel: 10 – 30 mm

Aluminum: 10 – 30 mm

Gas Pressures

Oxygen: 13 bar

Nitrogen: 25 bar

Air: 13 or 25 bar

General

Machine weight: ~32,000 kg

Average power consumption: 30 – 110 kW/h (depending on laser power)

Trust Seal

Dealers certified through Machineseeker

Listing

Turkey

Turkey

17,207 km

2000x6000mm fiber laser machine

CRONOSSTECHCRONOSS FB 6020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 35 mm, travel distance X-axis: 6,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 12 kW (16.32 HP), Working Area: 6000 × 2000 mm (Model 6020)

STANDARD FEATURES

CNC-controlled fiber laser sheet metal cutting machine

Heavy-duty, high-rigidity, fully analyzed steel frame and gantry structure

Rack and pinion drive system

Laser cutting head with motorized automatic focusing

Automatic height control system (capacitive sensor)

Automatic focus adjustment during cutting

High-precision linear guides and servo motor system

Advanced Windows-based touch-screen CNC control unit

User-friendly CNC interface with multi-language support

EtherCAT communication infrastructure

Cutting head monitoring: temperature, pressure, protective glass status, and back reflection

Internal and external camera-assisted monitoring system

LED status and warning indicators

Fiber-optic delivery of laser beam (no optical mirror/lens losses)

Automatic sheet detection and alignment systems

Fly-cut feature for uninterrupted serial cutting

No Piercing mode for burr-free cutting of thin sheets

Controlled piercing mode for thick plate cutting

Fully enclosed CE-compliant cabinet design

Special protective glass blocking laser radiation

CNC-controlled filtered ventilation system

Automatic nozzle cleaning and cutting head calibration

Slag and part removal system with conveyor

Movable table system

Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

Automatic shuttle table system (dual pallet)

Fiber laser resonator options with various power ratings

Automatic sheet loading system

Automatic part unloading system

Advanced CNC-controlled filtration unit

Camera-based automatic sheet detection and nesting software

Remote monitoring and reporting package

Oil cooler / air conditioning system

Additional LED lighting inside enclosure

Special alternative cutting heads

Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (MODEL 6020)

Axes

X Axis: 6030 mm

Y Axis: 2030 mm

Z Axis: 120 mm

Motion Performance

Acceleration: 2.5 G

Maximum axis speed: 150 m/min

Synchronized speed: 210 m/min

Positioning accuracy: ±0.05 mm

Repeatability: ±0.03 mm

Table and Loading

Maximum table load capacity: 3000 kg

Table exchange time (optional): ~30 s

Laser Power Options

Cgjdpfxex Nqr Ns Abbsn

3 kW / 4 kW / 6 kW / 8 kW / 10 kW / 12 kW

Maximum Cutting Capacities

Mild steel: 20 - 35 mm (depending on power)

Stainless steel: 8 - 25 mm

Aluminum: 8 - 25 mm

Gas Pressures

Oxygen: 13 bar

Nitrogen: 25 bar

Air: 13 or 25 bar

General

Machine weight: ~26,000 kg

Average power consumption: 25 - 90 kW/h (depending on laser power)

Listing

Turkey

Turkey

17,207 km

2000x4000mm fiber laser machine

CRONOSSTECHCRONOSS FB 4020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 30 mm, travel distance X-axis: 4,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 10 kW (13.60 HP), Working Area: 4000 × 2000 mm (Model 4020)

STANDARD FEATURES

- CNC-controlled fiber laser sheet metal cutting machine

- Stress-relieved, rigid and heavy-duty steel body and bridge structure

- Rack and pinion drive system

- Laser cutting head with automatic motorized focusing system

- Automatic height control sensor

- Auto focus distance adjustment during cutting

- High precision linear guideways and servo motor system

- Advanced touch-screen CNC control unit (Windows-based)

- Multi-language supported, user-friendly CNC interface

- EtherCAT communication infrastructure

- Monitoring of cutting head temperature, pressure, protective glass status, and back reflection

- Internal and external machine monitoring camera system

- LED status indicators

- Fiber laser beam transmission via fiber optic cable (no consumable optics)

- Sheet detection and automatic alignment technologies

- Fly-cut feature (serial cutting without changing cutting direction)

- No Piercing technology for thin sheets

- Piercing mode for thick sheets

Cjdpfx Abjx Nqriebogn

- Fully enclosed cabin design compliant with CE standards

- Laser-proof special safety glass

- Filtered ventilation system (CNC controlled)

- Automatic nozzle cleaning and head calibration

- Conveyor-based slag and part removal system

- Movable table system

- Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

- Dual-pallet automatic table exchange system

- Fiber laser resonator with different power options

- Automatic sheet loading system

- Automatic part unloading system

- CNC-controlled filter unit

- Advanced camera-based sheet recognition and nesting system

- Additional camera and remote monitoring package

- Oil cooler or climate control system

- Additional LED illumination in cabin

- Special cutting head options

- Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (MODEL 4020)

AXES

- X Axis: 4030 mm

- Y Axis: 2030 mm

- Z Axis: 120 mm

Performance

- Acceleration: 2.5 G

- Max. axis speed: 150 m/min

- Synchronized speed: 210 m/min

- Positioning accuracy: ±0.05 mm

- Repeatability: ±0.03 mm

Table & Loading

- Max. table load capacity: 2500 kg

- Table exchange time (optional): ~30 sec

Laser Power Options

- 2 kW / 3 kW / 4 kW / 6 kW / 8 kW / 10 kW

Maximum Cutting Capacities

- Mild steel: 16 – 30 mm (depending on power)

- Stainless steel: 6 – 22 mm

- Aluminum: 6 – 20 mm

Gas Pressures

- Oxygen: 13 bar

- Nitrogen: 25 bar

- Air: 13 or 25 bar

General

- Machine weight: ~22,200 kg

- Average power consumption: 20 – 70 kW/h (depending on power)

Listing

Langenzenn

Langenzenn

18,471 km

Edgebander

HOLZ-HERSprint 1329 multi

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2128, feed rate X-axis: 18 m/min, workpiece height (max.): 65 mm, edge thickness (max.): 15 mm, warranty duration: 12 months, HOLZ-HER Edge Banding Machine SPRINT 1329 multi, year of manufacture 2025, ex works delivery

- Motorized pressure bridge adjustment

- iTronic – automatic pressure and glue quantity control

- Motorized adjustment of the infeed fence 1350 mm

- Automatic chain lubrication

- Vertical bottom nesting shoes

- Edge-Control PPC 322W control unit with 21.5" color touchscreen

- ECO-MODE energy-saving mode

- Pre-milling unit FG501 with 2 milling aggregates

- Glue application system GlueJet GJ725 for EVA and PUR in cartridge and granule form, swiveling 90 degrees

- Storage chute for 1.5 kg EVA granulate

- Motorized pressure unit D501

- End trimming unit KA501

- Milling unit FR701 Mot6 multi

Cgsdpfex Nqn Rex Abbon

- Profile milling unit FF701 with 100% repeat accuracy

- Scraping unit ZT502 Mot6 multi with motorized 6-axis adjustment

- Surface scraper FK701

- Spray unit TR501 for infeed and outfeed

- Spray unit GM501 after pressure unit for high-gloss edges

- Buffing unit SW501

- Delivery time: immediately available

Listing

Langenzenn

Langenzenn

18,471 km

Machining center

HOLZ-HERDynestic 7507 push

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 228, travel distance X-axis: 4,045 mm, travel distance Y-axis: 2,490 mm, travel distance Z-axis: 317 mm, feed rate X-axis: 70 m/min, feed rate Y-axis: 70 m/min, feed rate Z-axis: 20 m/min, workpiece length (max.): 3,100 mm, workpiece width (max.): 2,200 mm, workpiece height (max.): 120 mm, HOLZ-HER CNC Nesting Machine Dynestic 7507 push, year of manufacture 2025, brand new, delivery ex works

Campus V8 CAD/CAM software with process simulation

Campus V8 Plus CAD/CAM software with material removal simulation (Better Sim)

Campus V8 Better Nest freeform software

Handheld remote control unit

2D barcode scanner

Control panel with 21.5" touch screen

Uninterruptible power supply (UPS)

Ultrasonic measurement on controlled gantry

Milling unit 7830, power 10.3 kW

Drilling unit 7884 with 14 spindles

Vertical adapter with double feed force

Integrated saw unit in X-direction

Additional machining area at the rear with 1 stop

8-position linear pick-up tool changer

Csdex Nqdlspfx Abbsgn

Vacuum pumps 140+140+500 m³/h

ECO-VAC intelligent vacuum system

16-circuit vacuum system, software controlled

Hi-Speed USB device network server

Automatic central lubrication

Nesting milling cutter tool set in tool case

Tool kit for drilling head

Discharge table with controlled and motorized conveyor belt

Additional extraction via discharge conveyor belt

TouchLabel PRO - touchscreen and label printer mounted on stand

Extraction hood at the end of the discharge conveyor

Warranty period: 12 months

Delivery time: immediate

We make it easier for you to find: "nesting"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nesting (256)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month