Used Granite Marble Slabs for sale (395)

Borken

Borken Granite measuring/control /marking plate

Vibration-isolated200x145x40cm

Leipzig

Leipzig Cnc-processing center

WINTERROUTERMAX 1325 MARBLE-STONE

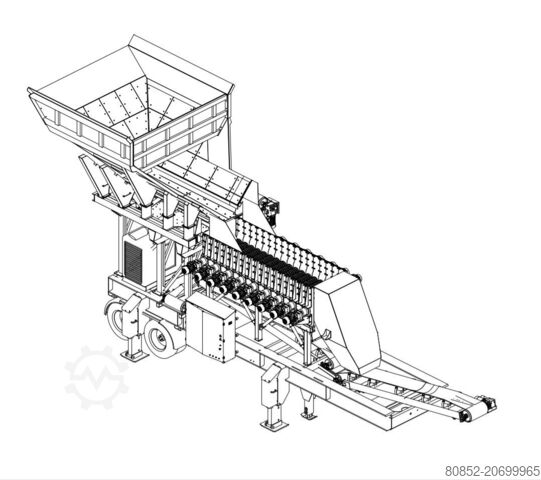

Wysoka

Wysoka Line for Concrete Blocks and Slabs

MASA

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel Granite Plate

TesaMessplatte

Ensisheim

Ensisheim Marble plate

Stiefelmayer3000 x 1500 x 350 mm

Discover more used machines

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel Granite Plate

MitutoyoMessplatte

Ensisheim

Ensisheim Marble plate

Stolle3500 x 2500 x 305 mm

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel Granite Plate

MahrMessplatte

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel Granite Plate

Ölze / HeliosMessbalken

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel Granite Plate

Johannes Fischer AschaffenburgMessplatte

Ensisheim

Ensisheim Cast iron Marbles

Marbres fonte lisse - Cast iron Marbles3910 x 2000 x 350 mm

Borken

Borken Shore A hardness tester – Year of manufacture 2023

Bareiss digi test IIDTAA II & DTE II

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crushing plant

Polygonmach350 tons per hour stationary crushing, screenin...

Bremen

Bremen Brand new 1550 liter fermenting/storage tank made of V2A stainless steel, heatable/coolable

K0183

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crusher

PolygonmachPJ110 1100x850mm primary heavy duty jaw crusher

Bremen

Bremen Brand new 8,000 liter fermenting/storage tank made of stainless steel (V2A), equipped with heating a

K0187

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crushing plant

PolygonmachTertiary impactor HSI - PTC-1

Bremen

Bremen Brand-new 6,200 liter fermenting/storage tank made of V2A (stainless steel), heatable/coolable

K0186

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crusher

PolygonmachWF wobbler feeder

Bremen

Bremen Factory-new 3000-liter fermenting/storage tank, heatable/coolable, made from stainless steel (V2A).

K0185

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crushing plant

PolygonmachPMST mobile tertiary crusher

Bremen

Bremen Brand new 2100 liter fermenting/storage tank made of V2A stainless steel, heatable/coolable.

K0184

Bremen

Bremen Factory-new 1050 liter fermenting/storage tank, heatable/coolable, made of V2A stainless steel

K0182

Bremen

Bremen Factory-new 1000-liter fermenting/storage tank made of stainless steel (V2A), equipped with heating/

K0181

Bremen

Bremen Brand new 1000 liter fermentation/storage tank made of V2A stainless steel

K0180

Used Granite Marble Slabs (395)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you