Used Copper for sale (505)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wadersloh

Wadersloh

18,459 km

NON FERROUS METAL SEPARATOR EDDY CURRENT

MetalSelectECS 500

Call

Condition: new, Year of construction: 2026, · NON FERROUS METAL SEPARATOR EDDY CURRENT

· For the separation of aluminium and copper

· Width 500 mm

Dsdpfxeyg E Nvo Ac Njun

· 14 poles concentric drum

· Durable PVC belt conveyor

· With electric cabinet, with 2 pieces of frequency inverters for speed

adjustment of conveyor and separation drum

· RAL color according to the customer´s choice

· New machine manufactured in the EU

Listing

Wadersloh

Wadersloh

18,459 km

METAL SEPARATOR

MetalSelectECS DV 500

Call

Year of construction: 2026, condition: new, ----- NEW MACHINE ---- QUALITY PRODUCT MADE IN EUROPE ----

Dsdpfx Aoyg E Npec Njun

METAL SEPARATOR EDDY CURRENT

WITH VIBRATION FEEDER AND MAGNET-DRUM

- For the separation of IRON, ALUMINIUM, COPPER etc.

- for grain sizes 3 to 300 mm

- machines with a feeding width from 500 mm to 1500 available

- 14 poles or 24 concentric drum depending on application

- durable PVC or RUBBER belt conveyor depending on application

- with electric cabinet

- with 2 x frequency inverter for speed adjustment of the conveyor and separation drum

- RAL color according to the customer´s choice

- manufactured in the EU with CE-Certificate

- new machine with 1 year warranty

DELIVERY TIME APPROX. 4 MONTHS

Listing

Fevziçakmak

Fevziçakmak

16,805 km

Cable Recycling Machine

Mizar Recycling Machinery |CMT A2 - Cable Recycling Machine

Call

Condition: new, Year of construction: 2025, Mizar Compact Series Cable Recycling Machines are designed for the efficient recycling of cables of different diameters and materials. By breaking down cables, they separate metal and plastic components, ensuring maximum material recovery.

✅ Efficient Cable & Radiator Recycling – Effectively separates metal and plastic.

✅ Turbo Mill Technology (CMT Models) – Achieves higher purity by completely separating fine copper wires.

✅ Compact Design – Ideal for facilities with limited space.

✅ Energy Efficient & Cost-Effective – Minimizes operational costs.

🔸 Recyclable Materials:

✔ Cable

Dedpfx Asv Hbdrec Noun

✔ Radiator

🔸 Technical Specifications

🔹 CMT

Power: 20 kW

Granulator Motor: 11 kW

Granulator Blade: 3+2

Length: 1300 mm

Width: 1500 mm

Height: 2140 mm

Weight: 1380 kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Günzburg

Günzburg

18,561 km

Tube bending machine

ERCOLINATB050 + A3-P60

Call

Condition: good (used), functionality: fully functional, Year of construction: 1998, Bending capacity for steel tube: 60x3 mm

Bending capacity for stainless steel: 60x2.5 mm

Bending capacity for solid material: 35 mm

Bending speed: 2 rpm

Bending capacity for hard copper & aluminium: 64x4 mm

Max. bending radius: R10–R300 mm

Total power requirement: 1.5 kW

Duedpfjyhgv Hox Ac Non

Machine weight approx.: 130 kg

Listing

Wald

Wald

18,661 km

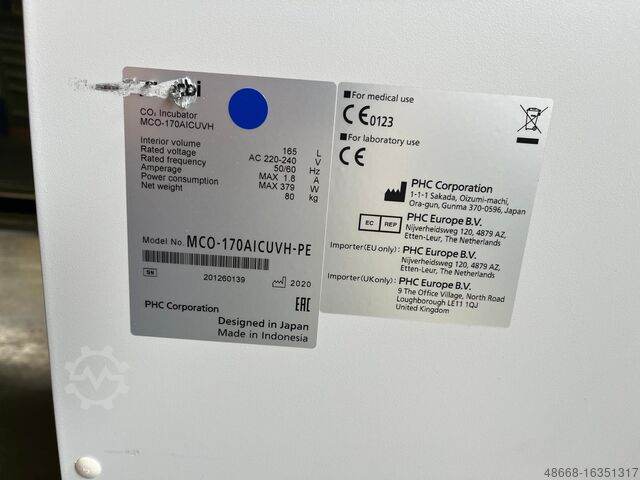

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2021, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2021

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Dodpfxjtxakxs Ac Njun

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

18,661 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

- Condensation control: this prevents unwanted condensation in the chamber and possible contamination.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Duodpfxstxaczo Ac Non

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

18,661 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

Dusdpotxarcsfx Ac Non

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Radom

Radom

17,719 km

Edge Gluer, gluing machine

Sumbel PerkeoEdge Gluer

Call

Condition: good (used), Sumbel Perkeo Edge Gluer

This machine is fully operational and ready for production.

This is the most valued brand among small laminators.

Ideal for the production of covers, decorative packaging, etc.

Made in Germany.

The machine uses cold glue.

Copper rollers.

Dedpfjyg Ebfsx Ac Neun

Smooth adjustment: glue thickness and gap width.

Set of separators.

Easy cleaning without the need for tools.

230V power supply.

Weight: 15kg.

Roller width: 60mm.

Listing

Germany

Germany

18,384 km

Cheese Maker

Kupfer

Call

Condition: ready for operation (used), An open copper cheese vat with low material removal and planetary agitator including knife harps and paddles is available. Shape: round, edge material: steel, inner diameter: 2600mm, useful volume: 7000l, outer diameter: 2850mm, height: 2950mm. Cheese mold: 2x4, mold length: 820mm, beam length: 4400mm, whey tub length: 4400mm, total length: 5000mm, width: 1500mm, depth: 900mm. An on-site inspection is possible. The copper was only gently washed.

Dedpfx Acox Db Uuo Njun

Listing

Germany

Germany

18,384 km

Induction Oven

ITGITPA 50K200+10K100

Call

Year of construction: 2006, condition: ready for operation (used), An induction system ITG for heat treatment of workpieces with vertical chain lift system is available. Process: heating/hardening, number of inductors: 2, inductor type: copper coil, cooling: water cooling, connected load: 382kVA, rated current: 552A. Documentation available. An on-site inspection is possible.

Dodpfxow Exrve Ac Neun

Listing

Germany

Germany

18,384 km

Brewhouse

Call

Year of construction: 2016, condition: ready for operation (used), A complete brewhouse including fermentation is available. Production capacity: 500l/h, space requirement X/Y: 8000mm/2000mm. 1) Brew mill, volume: 500l. 2) Mash kettle with steam or hot water, material: stainless steel, insulation: V2A. 3) Wort kettle and lauter tun with steam or hot water, material inside/outside: stainless steel/copper, without external boiler. 4) Whirlpool, material: stainless steel. 5) 2-stage plate cooler, insulation: V2A. 6) 6x cylindroconical fermentation tanks (ZKGs), volume: 1200 l, with jacket cooling. 7) Hot water generator. 8) Refrigeration system. Production capacity: 500l per 8 hours. The brewhouse is brand new and unused, but 8 years old. The brewhouse needs to be piped. Documentation available. On-site inspection is possible.

Dsdpou H H Hiefx Ac Neun

Listing

Germany

Germany

18,384 km

CNC Laser Cutting Machine

ByStronicByStar Fiber 10kW

Call

Year of construction: 2017, condition: ready for operation (used), Laser power: 10kW (10000W), working range: 3000mm/1500mm, max. material thickness: mild steel: 25mm, stainless steel: 30mm, aluminum: 30mm, copper: 12mm, brass: 15mm. Positioning speed: 120m/min, positioning accuracy: +/-0.05mm, max. workpiece weight: 1100kg. Machine dimensions X/Y/Z: approx. 9500mm/3500mm/3500mm, suction dimensions X/Y/Z: approx. 1500mm/1500mm/4000mm, machine weight: approx. 12000kg, operating hours: approx. 17000h. Documentation available. On-site inspection is possible. Expected to be available from June 2025.

Dsdpevyiqgjfx Ac Noun

Listing

Germany

Germany

18,384 km

Marking Laser Cell

Odevis Automation

Call

Year of construction: 2014, condition: ready for operation (used), A complete laser processing and marking system SIC-Marking is available. Stations: 3, table type: vacuum clamping table, processing area per station X/Y: 1000mm/1600mm, laser wavelength: 10600nm/1064nm, processes: evaporation/cleaning/structuring/surface processing, overall system dimensions X/Y/Z: approx. 25000mm/3000mm/3000mm, operating hours: approx. 2000h. Station 1: laser type: Synrad CO2 laser, number of lasers: 6, laser power: 100W, pulse frequency range: 0kHz-100kHz, power density: 250kW/cm², processed materials: polyamide/PVB/PET, processes: melting/evaporation. Station 2: laser type: IPG fiber laser, number of lasers: 6, laser power: 250W, pulse frequency range: 20kHz-500kHz, power density: 250MW/cm², processed materials: copper/aluminum/tin/lead/iron, processes: structuring/melting/evaporation. Station 3: laser type: IPG fiber laser, number of lasers: 3, laser power: 300W, pulse frequency range: 2kHz-200kHz, power density: 3MW/cm², processed materials: copper/aluminum/tin/lead/iron, processes: surface processing. The coating of the F-Theta lenses at station 2 is slightly deformed. Documentation available. An on-site inspection is possible.

Dujdpfeyfv I Hex Ac Nsn

Listing

Germany

Germany

18,384 km

Candy Kettle

Lichtenberg/Pefa83

Call

Year of construction: 1966, condition: ready for operation (used), A total of 40 copper dragee pans from the manufacturers Pefa and Lichtenberg are available. Material: copper, diameter: 950mm, motor power: 0.8kW. An on-site inspection is possible.

Djdpfsxu I Dqsx Ac Nsun

Listing

Nowe

Nowe

17,764 km

Eddy current separator ATV-180P

atervinATV 180P

Call

Year of construction: 2025, condition: new, functionality: fully functional, Eddy Current Separator ATV-180P – Available Immediately

Manufacturer: Atervin Group

Model: Eddy Current Separator ATV-180P

Condition: New

Location: Poland

Availability: In Stock – Warehouse

Delivery terms: EXW Poland

—

Description

The ATV-180P eddy current separator is designed for the efficient separation of non-ferrous metals such as aluminum, copper, and brass from non-metallic materials.

The unit features high recovery efficiency, a robust industrial-grade construction, and precise, stable operation, even in continuous mode.

—

Applications

• Recycling of steel and aluminum scrap

t• Recovery of raw materials from PET waste

• Glass and paper recycling

• Processing ASR / ELV fractions

• Incinerator slag cleaning

• Electronic waste (e-waste) recycling

—

Technical Data

Dimensions

• Length: 3,440 mm

• Width: 2,060 mm

• Height: 1,380 mm

• Effective belt width: 1,500 mm

Construction

• Powder-coated steel

• Designed for industrial environments

Operating Parameters

• Belt speed: 0–2 m/s (adjustable)

• Rotor speed:

- standard: 0–3,600 rpm

- high frequency: up to 4,000 rpm

Drive and Power

• Belt drive motor: 5.5 kW

• Rotor motor: 2.2 kW

• Total installed power: 7.7 kW

—

Operating Range

• Fraction size: 8–120 mm

• Suitable for 24/7 continuous operation

—

Integration

Compatible with:

• Belt and vibratory feeders

• Magnetic separators

• Metal detectors

• Dedusting systems

Dsdpfsyh R Ansx Ac Neun

• Existing sorting lines

—

Scope of supply

• Complete ATV-180P eddy current separator

• Device ready for installation

(transport, installation, and commissioning – priced individually)

—

Optional extras

• Vibratory tables

• Conveyors and work platforms

• Complete “turnkey” separation lines

• Material testing available at research center

Auction

Ends in

d

h

min

s

Auction ended

Niedersachsen

Niedersachsen

18,411 km

Laser cutting machine

TRUMPFTruLaser 5030 3kW Fiber

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2010, laser power: 3,000 W, sheet thickness steel (max.): 20 mm, sheet thickness stainless steel (max.): 15 mm, table length: 3,000 mm, table width: 1,500 mm, TRUMPF TruLaser 5030 3kW Fiber with LiftMaster!

TECHNICAL DETAILS

Table length: 3,000 mm

Table width: 1,500 mm

Cutting heads: 1

Sheet thickness (mild steel): 20 mm

Sheet thickness (stainless steel): 15 mm

Sheet thickness (aluminium): 15 mm

Sheet thickness (copper): 4 mm

Sheet thickness (brass): 3 mm

Laser power: 3,000 W

MACHINE DETAILS

Control: CNC

Dimensions & weight

Space requirement: 9,300 x 4,700 x 2,200 mm

Weight: 12,700 kg

Electrical connection: 40 kVA / 80 A

Dodpsygw Rlofx Ac Njun

Electrical power consumption: 23 – 33 kW

EQUIPMENT

LiftMaster

Automatic nozzle changer

Extraction system

Operating manual

Listing

Germany

Germany

18,260 km

Flanging Machine

EOCnicht bekannt

Call

Condition: used, Technical details:

Duodpou Icu Sofx Ac Non

tube diameter: siehe o mm

wall strength: siehe o mm

voltage: 230 V / 1Phase V

total power requirement: 0,55 kW

machine weight approx.: 56 kg

dimensions L x W x H: 0,45 x 0,37 x 0,35 m

HYDRAULIC LINE PRESETTING DEVICE for EO pipes

Application for crimping flared fittings on hydraulic lines.

Crimping of common raw materials such as steel (ST 35.4 NBK and-or ST 37.4 NBK and-or ST 52.4 NBK), stainless steel (1.4571/1.4541/316Ti or similar) and copper

pressure-controlled

There is a flaring tool for the size Ø 14mm on the machine.

The operating pressure is variably adjustable.

*

Listing

Bellpuig

Bellpuig

19,518 km

Inserter

HidrogarneINSERTADORA 60 DIGITAL - 6TN

Call

Condition: new, Year of construction: 2026, functionality: fully functional, total height: 1,700 mm, total width: 610 mm, total length: 780 mm, throat depth: 500 mm, pressing force: 6 t, working height: 1,033 mm, stroke length: 80 mm, Equipment: documentation/manual, Insertion and clinching equipment.

Robust, lightweight, and compact machines that provide reliability and accuracy for your operations. Fully hydraulic and precise, these units guarantee reliable insertion at any point along the punch stroke.

Equipped with a dual integrated safety system, featuring a distance sensor on the punch holder. Operated via a dual electric safety foot pedal.

Includes integrated software and a 4” touchscreen display.

Pre-loaded library with insert definitions and relevant force settings. Fully updatable and manageable.

(Available models with insertion capacities of 6 t, 10 t, or 15 t.)

FEATURES:

• Electronic adjustment of pressing time (0 to 5 sec).

• Adjustable punch return stroke.

• Controlled punch movement throughout its entire stroke.

• Precision stop system to improve insertion on soft materials such as fiberglass, PCBs, etc.

• Multi-die system allows for up to 4 different dies to be mounted, with automatic detection of the working position.

• Suitable for clinching operations on thicknesses from 1 to 6 mm.

• Compatible with all types of inserts.

• Suitable for any material: copper, aluminium, carbon steel, and stainless steel.

• Automatic feeding system (PLUS models only).

• Laser pointer (optional).

• Brush table (optional).

60 NC:

Force (t): 6

Adjustable stroke (mm): 0 – 80

Dusdpfsyhnmysx Ac Non

Throat depth (mm): 500

Working height (mm): 1033

Power (kW): 2

Dimensions (LxWxH, mm): 780x610x1700

Weight (kg): 493

Multi-die system allows up to 4 different dies to be mounted, with automatic detection of the working position.

Listing

Rheda-Wiedenbrück

Rheda-Wiedenbrück

18,445 km

Laser welding machine 4-in-1 1500W

Tec-Point GmbHLMH-1500

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Product Description

Industrial 4-in-1 Fiber Laser Welding Machine – Model LMH1500

Top performance at a fair price! Our new LMH1500 model featuring a 1500 W Raycus CE-certified laser source offers four integrated functions for professional metalworking:

✅ Key Features:

Laser welding – precise, deep, and virtually distortion-free

Laser cutting – ideal for thin sheets up to approx. 4 mm

Laser cleaning – effectively removes rust, paint, and oxidation

Weld seam cleaning – instantly cleans seams right after welding

📌 Technical Specifications:

Laser power: 1500W Raycus (CE-certified)

Wavelength: 1080 nm

Optical fiber: 10 meters

Cooling: Integrated water cooling

Operating modes: Welding, cleaning, cutting, pulse

Voltage: 3×400V / 50–60 Hz

Welding speed: up to 120 mm/s

Dusdpfew Tfbrsx Ac Njn

Dimensions (L×W×H): approx. 1000×760×450 mm

Weight: approx. 170 kg

📦 Scope of Delivery:

1× LMH1500 Fiber Laser Welding Machine

1× Handheld welding gun including nozzles

1× Automatic wire feeder

1× Laser safety goggles

1× Operating manual (German)

1× CE declaration of conformity

1× Risk assessment according to Machinery Directive

💼 Areas of Application:

Suitable for stainless steel, galvanized sheet metal, aluminum, copper, brass, and more.

Ideal for workshops, mechanical engineering, metal fabrication, body shops, or maintenance operations.

🔒 Certified & Safe:

CE certificate including risk assessment according to EU directives. Delivered with all required documentation.

📍 Manufacturer / Distributor:

TEC-POINT GmbH

Kupferstraße 10, 33378 Rheda-Wiedenbrück

🚚 Shipping & Invoice:

By freight forwarding (pallet shipping) within Germany & the EU – shipping costs on request.

🧾 Invoice with VAT shown will be issued.

✅ Buy now and have it delivered ready for immediate operation!

Listing

Rheda-Wiedenbrück

Rheda-Wiedenbrück

18,445 km

Laser welding machine Industry 4-1

Tec-Point GmbHLMH-2000

Call

Condition: new, Year of construction: 2025, functionality: fully functional, type of input current: AC, overall weight: 170 kg, type of cooling: water, input current: 16 A, laser power: 2,000 W, input frequency: 50 Hz, continuous power: 3 kW (4.08 HP), Equipment: documentation/manual, type plate available, LMH-2000 – Industrial Laser Welding Machine – 2000 W Fiber Laser – 4-in-1

Description

The LMH-2000 is a state-of-the-art 4-in-1 fiber laser welding machine of the latest generation. It combines welding, cutting, brazing, and surface treatment in a single system.

Based on the proven LMH-1500, the LMH-2000 offers even greater power and flexibility with its 2000 W laser source – ideal for thicker materials and demanding applications.

Featuring an energy-efficient fiber laser, stable cooling system, and ergonomic hand-guided operation, this machine is perfectly suited for continuous industrial 24/7 operation.

Technical Data

Model: LMH-2000 (4-in-1)

Laser Source: 2000 W (Raycus / MaxPhotonics – depending on configuration)

Laser Type: Fiber Laser

Functions: Welding, Cutting, Brazing, Surface Treatment

Operating Mode: Continuous operation possible

Cooling System: Integrated water cooling

Materials: Stainless steel, carbon steel, aluminum, copper, galvanized sheets and more

Energy Efficiency: Up to 80% savings compared to conventional methods

Operation: Ergonomic hand-guided torch, optional wire feeder

Advantages

4-in-1 functionality – highly versatile

Increased power (2000 W) for maximum welding speed and material thickness

CE compliant according to Machinery Directive 2006/42/EC and relevant EU standards

Clean weld seams with minimal post-processing required

Rugged design for industrial use

Flexible applications in metal construction, production, and maintenance

Special Notes

Immediately available from stock in Rheda-Wiedenbrück (Germany)

Demonstration/Test: Machines can be tested and demonstrated at our facility at any time – see the quality for yourself.

Initial Training: Instruction on operation and application is available by appointment.

Extras & Accessories

Wire feeding system

Shielding gas solutions

Replacement nozzles and wear parts

Extras & accessories (optional)

Dodpfx Acjxc Ebce Nsun

Replacement nozzles and wear parts: Ideal for workshops, mechanical engineering, metal fabrication, automotive bodywork, or maintenance.

🔒 Certified & Safe:

CE certificate including risk assessment in accordance with EU directives. Delivery includes all required documentation.

📍 Manufacturer / Distributor:

TEC-POINT GmbH

Kupferstraße 10, 33378 Rheda-Wiedenbrück, Germany

🚚 Shipping & Invoice:

By freight carrier (pallet shipping) within Germany & the EU – shipping costs on request.

🧾 Invoice with VAT shown will be issued.

✅ Buy now and have it delivered ready for immediate use!

Listing

Rheda-Wiedenbrück

Rheda-Wiedenbrück

18,445 km

Laser – Welding Device 4-in-1 3000W

Tec-Point GmbHLMH-3000

Call

Condition: new, Year of construction: 2025, functionality: fully functional, The LMH-3000 is a state-of-the-art, next-generation 4-in-1 fiber laser welding machine. It combines welding, cutting, brazing, and surface processing in a single system.

Building on the proven LMH-1500, the LMH-3000 offers even greater performance and flexibility with its 3,000 W laser source – ideal for working with thicker materials and demanding applications.

Thanks to its energy-efficient fiber laser, stable cooling, and ergonomic handheld operation, this machine is perfectly suited for continuous industrial 24/7 use.

Technical Data

Model: LMH-3000 (4-in-1)

Laser source: 3,000 W (Raycus / MaxPhotonics – depending on configuration)

Laser type: Fiber laser

Functions: Welding, cutting, brazing, surface processing

Operating mode: Continuous operation possible

Cooling system: Integrated water cooling

Materials: Stainless steel, carbon steel, aluminum, copper, galvanized sheet metal, and more

Energy efficiency: Up to 80% savings compared to conventional methods

Operation: Ergonomic handheld torch with optional wire feeder

Advantages

- 4-in-1 functionality – versatile applications

- Higher output (3,000 W) for maximum welding speed and material thickness

- CE-compliant in accordance with Machinery Directive 2006/42/EC and relevant EU standards

- Clean weld seams with minimal reworking

- Robust design for industrial use

- Flexible use in metal construction, production, and maintenance

Special Notes

Immediately available from stock in Rheda-Wiedenbrück (Germany)

Demonstration/Testing: Machines can be tested and demonstrated at our facility at any time – see the quality for yourself.

Initial Training: Operating and application training can be arranged by appointment.

Extras & Accessories

- Wire feeder system

- Shielding gas solutions

- Replacement nozzles and wear parts

- Extras & accessories (optional)

Replacement nozzles and wear parts—Ideal for workshops, mechanical engineering, metalworking, body shops, or maintenance departments.

🔒 Certified & Safe:

CE certificate including risk assessment in accordance with EU guidelines. Delivery includes all required documentation.

📍 Manufacturer / Supplier:

TEC-POINT GmbH

Kupferstraße 10, 33378 Rheda-Wiedenbrück, Germany

Dujdpfjxc Ec Tsx Ac Nsn

🚚 Shipping & Invoice:

Shipped by freight carrier (on pallets) within Germany and the EU – shipping costs on request.

🧾 Invoice issued with VAT shown separately.

✅ Buy now and have it delivered ready for immediate use!

Trust Seal

Dealers certified through Machineseeker

Listing

Suffolk

Suffolk

18,697 km

Jam cooking vessels

FoodmekTulip vessels

Call

Condition: good (used), Foodmek copper bottomed tulip vessels. Used previously in a jam factory. Copper bottomed. Good condition, three available.

Dodpfx Acjvvn Dds Njun

Listing

Panevėžys

Panevėžys

17,334 km

Welding set

MerkleLiteTIG 300 AC/DC

Call

Condition: like new (used), functionality: fully functional, Manufacturer: Merkle (Germany)

Model: LiteTIG 300 AC/DC

Technology: IGBT Inverter

Welding Processes: TIG AC/DC, TIG DC Pulse, MMA (Stick)

Input Power: 400 V, 3-phase, 50/60 Hz

Product Description

The Merkle LiteTIG 300 AC/DC is a compact, high-performance professional TIG welding power source, developed using advanced inverter technology to deliver excellent arc characteristics and outstanding functionality. The machine supports both AC and DC welding, making it ideal for welding aluminium as well as steel, stainless steel, and a wide range of non-ferrous metals.

Designed for professionals, the LiteTIG 300 AC/DC combines simple front-panel operation with a powerful Expert Mode, allowing experienced welders to fully customize all welding parameters for maximum precision and weld quality.

Control & User Interface

• Digital Display (Standard) – Clear monitoring of current, time, frequency, and welding parameters

• Standard & Expert Modes – Programmable modes for beginners and professionals

• Multi-Language Menu

• Control Panel Lock with PIN Code

• Rotary Control Knob – Fast and intuitive parameter adjustment

• Memory Functions – Save and recall complete welding programs (up to 28 jobs)

Advanced TIG Technology

• AC/DC TIG Welding – Suitable for aluminium, magnesium, copper, and other non-ferrous metals

• HF & Lift-Arc Ignition – Clean and reliable arc start

• High-Frequency DC Pulse up to 12 kHz – Enables extremely narrow, focused arcs for superior control and heat input reduction

• AC Frequency Control (50–200 Hz) – Adjustable arc shape and penetration

• AC Balance Control – Optimized oxide cleaning vs. penetration

• Selectable AC Waveforms – Square, soft, and sinusoidal

• Pulse Modes: Slow pulse, fast pulse, and high-frequency pulse

• Spot Welding Function – Adjustable from 0.01 to 2.5 s

_____

MMA (Stick) Welding

The LiteTIG 300 AC/DC also supports MMA welding with coated electrodes from 1.6 to 4.0 mm (electrode holder required if not included):

• Hot Start – Adjustable for reliable arc ignition

• Arc Force – Prevents electrode sticking

• Anti-Stick – Automatically cuts current if the electrode sticks

Additional Features

• Two Welding Currents (I1 / I2) – Switchable via Merkle TIG torch

• 2T / 4T Operation Modes

• Pedal Control Support

• Temperature-Controlled Cooling Fan

• Air or Water-Cooled Torch Compatibility

• Confined Space Approved (“S” Symbol)

• Optional Water Cooling Unit

Applications

• Professional TIG welding

• Industrial production and fabrication

• Maintenance and repair work

• Automotive and motorcycle repair

• Precision welding of thin materials

Dodpfxsyhdbaj Ac Noun

Technical Specifications

• Input Voltage: 400 V, 3-phase, 50/60 Hz

• Output Current Range: 5 – 300 A

• Output Voltage (TIG / MMA): 10 – 22 V / 20 – 32 V

• Duty Cycle 40 °C (10 min):

o 50% – 300 A (TIG)

o 60% – 280 A (TIG) / 270 A (MMA)

o 100% – 250 A (TIG) / 230 A (MMA)

• TIG DC Pulse Frequency: 0.2 Hz – 12 kHz

• Open-Circuit Voltage: 70 V

• AC Frequency: 50 – 200 Hz

• AC Waveforms: Square, soft, sinusoidal

• Electrode Diameter (MMA): 1.5 – 4.0 mm

• Power Factor: 0.95 cosφ

• Protection Class: IP23

• Insulation Class: H

• Torch Connection: Merkle TCG, 5-pole

• Power Connection: 50 mm²

• Cooling: Air or water

• Dimensions (L × W × H): 600 × 300 × 575 mm

• Weight: 39.2 kg

Listing

Coevorden

Coevorden

18,452 km

Laser cutting machine

IMPACT Laser3015A

Call

Condition: new, functionality: fully functional, control type: CNC control, laser power: 3,000 W, sheet thickness (max.): 20 mm, sheet thickness steel (max.): 20 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 10 mm, table length: 3,050 mm, table width: 1,530 mm, working length: 3,050 mm, working width: 1,530 mm, cutting speed: 120 mm/min, positioning accuracy: 0.02 mm, repeat accuracy: 0.02 mm, warranty duration: 12 months, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, IMPACT 3015A Fiber laser cutting machine suitable for high-precision cutting of metal plates, with high photoelectric conversion rate. It is a new energy-saving and environmentally friendly product, and one of the world’s leading technology products. It is suitable for cutting metal plates such as stainless steel, carbon steel, alloy steel, silicon steel, aluminum, copper, brass, titanium alloy, galvanized sheets, etc.

Unmatched Accessibility - Because the machine is an "open type" (without a full protective enclosure), operators have 360° access to the cutting bed. This makes loading raw sheets and unloading finished parts significantly faster and easier, especially when using a forklift or overhead crane.

Djdpfxeyhclws Ac Neun

Space Efficiency - The 3015 model is designed with a compact footprint. Without the bulk of a large safety cabin or a dual-shuttle table system, it fits comfortably into smaller workshops where floor space is at a premium, providing a high "power-to-square-foot" ratio.

Cost-Effectiveness - Open-type machines generally have a lower initial investment compared to fully enclosed or exchange-table models. They are also easier to maintain, as all mechanical components (rails, racks, and motors) are readily accessible for routine cleaning and lubrication.

Efficient and precise cutting of medium and thin plates:

• Easy access for loading and unloading the material from all 4 sides;

• Auto-focus laser head;

• Automatic edge detection;

• Nesting included for optimizing the drawings and optimize material usage;

• Easy to operate;

• CE standard.

Positioning accuracy ±0.02 mm

Repeatability accuracy ±0.02 mm

Maximum speed 120 m/min

Maximum acceleration 1.0G

Complete set of consumables included

Nesting and automatic edge detection functions included

Windows interface with internet & WIFI and assist service

Wireless remote for easy control

Movable operating panel with arm and LCD display 18.5 inch

Automatic oil lubrication system

Oxygen low pressure alarm

Exhaust smoke system with centrifugal fan

Industrial cooling/heating system of the laser head and laser source - Dual cooling system

Voltage stabilizer & regulator unit

CE mark

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Crushing unit

Construction &Delolition Waste RecyclingPE600x900 stone crusher

Call

Condition: new, Year of construction: 2026, functionality: fully functional, power: 55 kW (74.78 HP), ### Introduction to Jaw Crushers

A jaw crusher is a type of primary crusher used in mining and ore processing plants. It works by using compressive force to break down large rocks into smaller, more manageable pieces. The machine consists of a fixed jaw and a movable jaw, which together create a V-shaped cavity called the crushing chamber. The movable jaw exerts force on the rock by forcing it against the stationary plate, causing it to break.

Key Components:

- Fixed Jaw Plate: Mounted in a fixed position.

- Movable Jaw Plate: Mounted on a pitman that moves in a reciprocating motion.

- Flywheel: Provides the necessary inertia for the crushing action.

- Toggle Plates: Serve as a safety mechanism, ensuring that the jaw crusher operates efficiently and prevents damage.

### Working Principle

The working principle of a jaw crusher is based on the reciprocating movement of the movable jaw against the fixed jaw:

1. Feeding: Large rocks are fed into the top of the crusher.

2. Crushing: As the movable jaw moves back and forth, it crushes the material against the fixed jaw.

3. Output: Crushed material is discharged from the bottom of the crushing chamber.

### Applications of Jaw Crushers

Jaw crushers are versatile and can be used in a variety of industries and applications, including:

1. Mining and Mineral Processing:

- Primary crushing of mined ore (gold, copper, iron, etc.).

- Size reduction of rocks to facilitate further processing (e.g., milling).

2. Construction and Demolition:

- Crushing of concrete, bricks, and other construction materials.

- Recycling of building materials to create aggregate for new construction.

3. Aggregates Production:

- Crushing of raw materials to produce aggregates for concrete and asphalt.

- Production of road base and railway ballast.

4. Industrial Applications:

Duedpfx Aceq Nf Tvs Nsn

- Crushing materials in chemical processing plants.

- Size reduction of materials for production processes in various industries.

5. Environmental Management:

- Processing of materials for landfill cover.

- Recycling operations to reduce waste and promote sustainable practices.

### Advantages of Jaw Crushers

- High Crushing Ratio: Capable of producing a range of material sizes with a single pass.

- Durability and Reliability: Built to withstand heavy-duty use and harsh conditions.

- Simple Structure: Easy to maintain and repair, with fewer components compared to other types of crushers.

- Versatility: Suitable for various types of materials and a wide range of applications.

- Energy Efficiency: Efficiently uses energy, making it cost-effective for operations.

### Examples of Use Cases

- Mining Operations: Jaw crushers are used as primary crushers in mine sites to crush large rocks before being processed further in the milling process.

- Construction Sites: Used to break down concrete and other building materials for recycling and re-use.

- Aggregate Production: Integral in producing the base materials for construction and infrastructure projects.

- Demolition Projects: Efficiently crushes and recycles materials from demolished structures.

By understanding the introduction and applications of jaw crushers, businesses can make informed decisions about integrating this machinery into their operations for efficient and effective material processing.

We make it easier for you to find: "copper"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Copper (505)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month