Used Brewer for sale (92)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Menslage

Menslage

18,398 km

Certuss Junior TC-300 Steam Generator (2018)

Certuss

Call

Condition: used, Year of construction: 2018, Overview This automatic steam generator was manufactured in 2018 by German company Certuss. The Junior TC-300 is a gas-powered instant steam generator designed for reliable and efficient steam production. With fast startup capability and high efficiency, it is well-suited for breweries and beverage production plants. The equipment is available immediately and comes with essential accessories, including a water treatment plant and control components. Technical data Capacity: 300 kg/h Pressure: up to 10 bar Power: 218 kW Efficiency: 91% Heating: Gas-powered Startup time: max. 5 minutes Control: PLC

Kfodpfx Afoxcnnfefja

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Monoblock

FimerSRTT1-20-20-3-3 CPK

Call

Condition: used, Year of construction: 2004, Used Filling Monoblock FIMER for beer 4000 bph

The Used Filling Monoblock FIMER for beer 4000 bph constitutes a comprehensive technical solution for breweries requiring a reliable system for rinsing, isobaric filling, and capping of glass bottles. FIMER manufactured this unit in 2004, model SRTT1-20-20-3-3 CPK, combining compact design with long-term operational stability. Accordingly, this equipment meets the needs of both craft and semi-industrial beer producers.

Monoblock Configuration: Rinsing, Filling, and Capping

This machine integrates three coordinated operational modules: rinsing, isobaric filling, and capping. Specifically, the rinsing section employs 20 grippers to handle bottles securely and efficiently. In parallel, the filling system utilizes 20 isobaric valves, which maintain pressure equilibrium throughout the process—a critical requirement for carbonated beverages such as beer.

The capping module includes 3 heads, compatible with 26 mm and 29 mm cap sizes. Consequently, the system accommodates multiple closure types while ensuring precision and consistency. The capping technology derives from AROL, a reputable manufacturer known for high-performance sealing systems. As a result, the monoblock guarantees high-quality closure integrity.

Kfodpfxewcf Ace Affea

Bottle Formats and Neck Compatibility

The Used Filling Monoblock FIMER for beer 4000 bph handles various neck types, including Long Neck, APO, and Champenoise. It supports glass bottles with volumes of 33 cl and 75 cl, achieving production speeds of 4000 bottles per hour for 33 cl and 2000 bottles per hour for 75 cl, respectively. Therefore, breweries can manage different product lines within a single production flow.

Furthermore, the machine provides format flexibility without requiring significant reconfiguration time. This, in turn, enhances production efficiency and minimizes bottlenecks. In particular, this versatility proves beneficial for breweries offering multiple SKUs across various packaging standards.

Technical Specifications and Maintenance

The monoblock operates at a power consumption of 10.5 kW, which reflects its energy-efficient engineering. In addition, it incorporates all essential safety features in accordance with industrial compliance standards. CIMEC constructed the base frame, while FIMER and AROL supplied the mechanical and control components. Together, these manufacturers delivered a machine characterized by durability, accuracy, and ease of maintenance.

Certified technicians performed the most recent maintenance in April 2020. During this intervention, they replaced 20 pistons, 20 valves, and 20 valve-opening keys, and completed full regreasing of the main column. Therefore, the unit currently operates in excellent mechanical and hygienic condition. Notably, this maintenance history contributes to the monoblock’s sustained operational readiness.

Current Status and Availability

The Used Filling Monoblock FIMER for beer 4000 bph is currently in storage, available for inspection and relocation.

Listing

Oradea

Oradea

17,780 km

Vacuum pump

VerderflexDURA 35

Call

Condition: like new (used), Year of construction: 2024, operating hours: 200 h, functionality: fully functional, machine/vehicle number: 159422, Verderflex Dura 35 peristaltic pump, serial number: 159422, MFG: 2024

For demanding applications, the Verderflex Dura 35 provides:

Maximum flow rate: 5,292 L/hr

Maximum pressure: 16 bar

Maximum medium temperature: 80 ºC

Compressible solid size: 8.75 mm

Suction lift: 9.5 mWc

Certification: ATEX, FDA and EC/1935

Pump Housing made from cast iron (GG25)

Front Cover made from carbon steel with plexiglass inspection window

Rotor made from cast iron (GG25)

Drive Shaft EN24T Steel

Mounting Frame made from carbon steel

Torque Arm made from carbon steel

Bearing made from bearing steel

Flow 11/hr

Pump speed 35 PM

Installed motor power 25W

Max turndown at 5 Bar discharge pressure 101

Verderflex peristaltic pumps are the ideal low cost life cycle solution for the transfer and dosing of difficult to pump fluids such as viscous, abrasive or high solid content liquids such as slurry and sludge. Sizes range from small models such as OEM pump modules, precision and industrial style tube pumps to the world's largest hose pumps, used in the most demanding applications. These include water treatment, biotechnology, food & drink production, mineral processing and chemical manufacturing.

Features :

• Peristaltic pumps are excellent problem solving pumps and offer the following benefits:

• Abrasion Resistant

• No moving parts in the liquid stream

• Accurate Dosing

• Self Priming

• Can pump liquids containing up to 80%

• inorganic solids (fines)

• Aseptic pumping

• smooth liquid passage

• Easy and completely cleanable without disassembly

Kjdpfxowdtbcj Affjfa

• Suitable for handling shear sensitive products

• Can run dry

• Low cost of ownership

• High suction capability of up to

• 95% vacuum or a 9.5 mWc

• No seals

• Reversible rotation, empties line or blockages

• Can pump

• abrasive, very viscous or

• high density fluids

Application for abrasive fluids : Lime mixing, Kieselguhr, circulation and dosing

Application for corrosive fluids : Ferric Chloride, Copper Sulphate and similar Activators, process chemicals, Acids, including Alkalis

Application for shear sensitive fluids : Coagulants, Flocculants and bacterial remediation treatments

Application for mining industry : Dosing Process Reagents, Thickener Underflow, polymers and slurry transfer

Application for water treatment : Dosing Lime, Hypochlorite, Silicate, Polymer, Ferric Chloride, sludge transfer and filter press feeds

Application for chemical Industry : Corrosive Acids, Bases and Hydrocarbons

Application for Printing and packaging : Inks (including water based inks), Paints, Dyes and Glue

Application for Battery Filling, Chemical Cleaning, Equipment Sterilising, Seed Coating : Biocides, Hydrogen Peroxide, Sodium Hypochlorite, Caustic Soda

Application for Laboratory Systems : Biological Broths to polluted streams

Application for Agriculture : Feed Additives, Animal Vaccines and Waste Transfer

Application for Paper and Pulp : Pulp and Dyes

Food and Beverage : Breweries, Diatomaceous Earth, wineries, dairies, sugar refining, abattoirs

The pump is in excellent condition, like new.

Price Euro 4.500 Euro + VAT, negotiable, FCA: Oradea/Romania

Irrtum, Anderungen und Zwischenverkauf vorbehalten /

Subject to errors, changes and prior sale /

Ne rezervăm dreptul la greșeli, modificări și vânzare prealabila.

We speak English. /Wir sprechen Deutsch./ Beszélünk magyarul. /Nous parlons français/Vorbim romana

Listing

Germany

Germany

18,510 km

Bottle filling & capping machine w. CC

MARKL Füller f. BierflaschenBavaria Typ 40/8 VKL

Call

Condition: excellent (used), Year of construction: 2019, functionality: fully functional, For sale: (VIDEO available on request)

MARKL / BAVARIA bottling line for breweries & beverage industry, suitable for 0.5 l & 0.33 l bottles

Output: 3,000 – 15,000 bottles/h

Kfodpfx Afswqz Nnefsa

Bottle filling and capping machine for crown caps d = 26 mm with pre-evacuation system

Bottle types: 0.5 l NRW, 0.5 l long-neck, 0.5 l Warsaw, 0.33 l long-neck

Additional detailed technical data: see PDF

Machine is immediately available, removed from production only about 2 months ago.

Listing

Székesfehérvár

Székesfehérvár

18,033 km

Conductivity Measuring System

SmartecS CLD132

Call

Condition: new, Application

- Alkali/acid concentration control - phase separation in pipe systems - monitoring and control of bottle cleaning systems - product monitoring in breweries, dairies and the beverage industry - CIP system control

Measurement range

100 µS/cm - 2000 mS/cm

Kjdpfeh Ruk Iex Affofa

Process temperature

max. 140°C (max. 30 min.)

284°F (max. 30 min.)

Process pressure

max. 12 bar (90°C)

(174 psi(194°F))

Discover more used machines

Listing

DK-Thisted

DK-Thisted

17,992 km

Maselli-Misure-IB01-analyse

Maselli MisureIB01

Call

Condition: used, Maselli Misure, Analysis System IB-01 for carbometric analyse in brewery and juice production, Good condition

Kfodpfec Npzzsx Affsa

Listing

Menslage

Menslage

18,398 km

Shandong Yuesheng 10HL Brewhouse (2020)

Shandong YueshengSudhaus

Call

Condition: used, Year of construction: 2020, Overview This brewhouse was manufactured in 2020 by Chinese company Shandong Yuesheng. It is a 10 hL two-vessel system designed for small to medium-sized breweries, equipped with mash/lauter tun, wort kettle, and an additional 20 hL hot water tank. The brewhouse includes steam heating, integrated pumps, and auxiliary equipment, offering a compact and professional solution for efficient beer production. The unit is in good condition and will be available by the end of April 2026. Reason of the replacement is that they will go to a new 20hl brewhouse. Technical data Capacity: 10 hL brewhouse, up to 2 batches per day Formats: Beer, up to 20° Plato initial density Vessels: 2 (mash/lauter + kettle/whirlpool) + 1 hot water tank (20 hL) Power supply: 5.5 kW Air supply: 6 bar Construction: SUS304 stainless steel, mirror surface treatment, PU insulation (100 mm), polished welding seams (Ra ≤ 0.4 μm) Heating: Steam Features: CIP rotary ball, sparging arm, thermowell, motor with frequency conversion, grain raker, top manhole with sight glass, laser-cut false bottom, side grain door and chute, adjustable legs Scope of Delivery Brewhouse 10 hL | Shandong Yuesheng | 1000L | 2020 | 2 vessels (mash/lauter, kettle/whirlpool) Hot water tank | Shandong Yuesheng | – | 2020 | 20 hL capacity Heat exchanger | Shandong Yuesheng | – | 2020 | 10 m² surface Pumps | Shandong Yuesheng | – | 2020 | 1 hot water pump, 1 wort pump Platform with access | Shandong Yuesheng | – | 2020 | Stainless steel construction Steam generator | Shandong Yuesheng | – | 2020 | 150 kg/h

Kfjdsxb S A Dspfx Affoa

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Complete Bottling Line

Call

Condition: used, Used filling line for beer GAI up to 900 bph year 2017

The used filling line for beer GAI up to 900 bph, year 2017, delivers a highly efficient and precise technical solution for the bottling sector. Furthermore, this Filling line for beer GAI ensures high performance and adapts to various production needs, meeting the highest quality standards required by industry operators.

Main technical features of the Filling line for beer GAI

The Filling line for beer GAI operates at a speed of 900 bottles per hour (BPH), which optimizes medium productions. Moreover, the glass bottles support formats of 0.33 L, 0.50 L, and 0.70 L. This system processes beer using isobaric filling, thereby preserving the product’s organoleptic characteristics with precision.

The labeling process precedes filling, thus enhancing efficiency and order in the production line while simultaneously optimizing operational flow..

Filling monoblock

The GAI MLE441-BIER-003 filling monoblock, built in 2017, integrates several essential functions for the bottling process:

4 rinsing grippers prepare and sanitize the bottles.

4 filling valves deliver precise and rapid dosing.

1 capping head accommodates caps measuring 26.5×5.9.

The monoblock measures 3650 mm in length, 1300 mm in width, and 2200 mm in height. Additionally, it consumes 6 kW of electricity, operates at 400 Volts, and runs at a frequency of 50 Hz. Therefore, this technical profile supports flexible installation compatible with standard industry infrastructure.

Labeling machine in the Filling line for beer GAI

The Enos SIRIAM labeling machine, from 2016, applies labels to the front and rear of bottles using a linear system. Furthermore, the automatic glue level adjustment system utilizes rollers for precision.

The optical centering system, based on photoelectric technology, applies labels accurately. In addition, the electronically managed head adjustment allows for quick and reliable configuration.

The labeling machine measures 2405 mm in length, 2200 mm in width, and 1690 mm in height. It also consumes electricity at 400 Volts and operates at a frequency of 50 Hz.

Operational state and advantages

Ksdpfxsvt Np No Affjfa

The Filling line for beer GAI operates effectively and integrates seamlessly into an existing production line or constitutes a new one. Moreover, the GAI monoblock and Enos labeling machine work together to create a smooth production process, minimizing downtime and maximizing productivity.

This line serves breweries requiring a compact, reliable, and high-performing solution. Likewise, its technical configuration handles various types of bottles and products, offering great production versatility.

Conclusion

The used filling line for beer GAI up to 900 bph, year 2017, provides an excellent option for those seeking reliable and high-performing equipment. Its technical features and operational state enable immediate implementation, thereby addressing the efficiency and quality needs of the current market.

Listing

Menslage

Menslage

18,398 km

GM Gera GEL3 RV1-230 / 110 - 18 Bottle Washer (2007)

GM GeraFlaschenreinigungsmaschine

Call

Condition: used, Year of construction: 2007, Overview The bottle washer was previously used in a brewery in Germany. Due to the good and continous maintenance the machine is in very good condition. All basins and the machine body are made of stainless steel. The machine is still installed and in production. As the line speed needs to be increased, this machine is replaced, even though it is in great shape. Tech Specs: Rated Capacity: 13,000 bph (based on 1.0L mineral water bottles, format: 89 x 310 mm, weight: 600g) Total number bottle cells: 3,240 pcs Cells per basket row: 18 pcs Cell pitch: 110 mm Chain pitch: 169 mm Treatment Times total processing time: 14.95 minutes total immersion time: 7.56 minutes caustic immersion time: 6.73 minutes caustic filling time: 7.73 minutes caustic contact time: 7.89 minutes total internal spraying time: 70 seconds total external spraying time: 25 seconds Dimensions Housing (L x W x H): 8,530 x 2,300 x 2,990 mm Total dimensions (L x W x H): 8,880 x 4,200 x 3,330 mm CE certified Chemical Dosing Pumps Machine data sheet included Rotating Spray nozzles Single End Machine Label discharge rear left Label press included Finger discharge + finger infeed Bottle cells made of plastic Full machine body in SST Vapor discharge

Kedpfx Aexbr Slsffefa

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Monoblock

3MAMERICA DPS 6/6/1 EAGLE C

Call

Condition: used, Year of construction: 2003, operating hours: 10 h, Used Filling Monoblock CIMEC 6-6-1 1000 bph

Technical Features and Specifications

The Used Filling Monoblock CIMEC 6-6-1 1000 bph, model AMERICA DPS 6/6/1 EAGLE C, offers a versatile and reliable solution for isobaric bottling processes, specifically designed for beer production. Manufactured by the Italian company CIMEC in 2003, this monoblock integrates advanced features to ensure precision, quality, and operational safety.

Structure and Configuration of the Monoblock

The CIMEC 6-6-1 monoblock combines three key units into one compact structure: a rinser, an isobaric filler, and a capper. This configuration, therefore, optimizes line space and reduces processing time, ensuring a maximum output of 1000 bottles per hour (bph).

Rinser: Equipped with 6 grippers for bottle holding and a single treatment with a fixed nozzle, it efficiently cleans the bottles before the filling process. Additionally, it ensures that no contaminants remain inside the containers, contributing to product purity.

Isobaric filler: The filling section includes 6 valves with 3 buttons, allowing controlled pressurized filling, ideal for beer and other carbonated beverages. Meanwhile, the pre-evacuation and leveling system reduces oxygen presence inside the container, preserving the product’s organoleptic properties.

AROL Capper – Eagle C model: The capper handles 26 mm crown caps and operates with 1 capping head. As a result, it ensures precise capping, preventing leaks and contamination.

Advanced Technical Features

The Used Filling Monoblock CIMEC 6-6-1 1000 bph ensures high operational efficiency and precise process control. The isobaric technology, in contrast to standard gravity filling, maintains constant pressure inside the container during filling, avoiding foaming and guaranteeing accurate dosing.

Pre-evacuation system: It eliminates air from the bottle before filling, thereby minimizing oxidation.

Automatic leveling and degassing: This system ensures consistent product levels and removes excess gas, so the final seal remains airtight.

Included Formats and Spare Parts

Kfsdpfxjvy E Nle Affja

The monoblock comes with false bottles, enabling cleaning and system testing without starting production. Furthermore, it includes two formats, both with a 65 mm diameter, suitable for standard beer bottles. In addition, the machine comes with two jack cylinders, allowing fast replacements and maintenance in case of wear.

Safety Features of this Used Filling Monoblock for beer

The monoblock includes technical manuals and integrated safety systems to protect operators and comply with current regulations. Each section features safety devices that prevent malfunctions and, thus, guarantee smooth operation. Specifically, safety guards, emergency stop buttons, and pressure monitoring ensure that any risk is minimized.

Conclusion of this Used Filling Monoblock for beer

The Used Filling Monoblock CIMEC 6-6-1 1000 bph offers a reliable solution for the beer industry, designed to maximize product quality and minimize downtime. Thus, it is ideal for breweries seeking enhanced productivity and consistency. Although older in manufacturing year, its robust build and spare parts availability extend its operational life. Overall, this monoblock embodies efficiency, precision, and adaptability, making it an excellent investment..

Listing

Menslage

Menslage

18,398 km

Framax Modulblock 10/1-C + LLAC-R-SQ (VAR STEP) Atmospheric filler (2014)

Framax ModulblockAtmosphärischer Füller

Call

Condition: used, Year of construction: 2014, Overview This filling and labeling monoblock was manufactured in 2014 by the Italian company Framax. The machine was last operated in July 2025 and is still installed in the brewery but not in operation. It is immediately available for sale. Full original instruction manuals for both the filler/capper and labeler are included. Technical data Capacity: Approx. 2,000 bph (330 ml bottles, manufacturer estimate); approx. 1,670 bph (500 ml bottles, actual use) Formats possible: 250 ml – 1,000 ml Formats included: 330 ml and 500 ml long neck bottles Bottle cap type: 26 mm crown caps Execution: Filler/capper: Modulblock 10/1-C Labeler: LLAC-R-SQ (VAR STEP) Additional features: Hot foil stamper (added later) CIP dummy bottles Change parts for 330 ml format

Kfsdpfxsxalibj Affsa

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Monoblock

AlfatekMBC 7/1 LP ELVIRA

Call

Condition: used, Year of construction: 2014, Used filling monoblock ALFATEK MBC 7/1 LP ELVIRA for re-fermented beer year 2014

This filling monoblock offers a compact and efficient solution for bottling re-fermented beer in glass containers. Consequently, Alfatek manufactured this machine with a gravity filling system to ensure a stable process that meets industry standards.

Kedpfx Asv N Dcioffsfa

Technical Features of the Used filling monoblock ALFATEK ELVIRA for re-fermented beer

The ALFATEK MBC 7/1 LP ELVIRA filling monoblock for beer year 2014 includes 7 fixed filling valves, specifically designed to process beer in 0.33 L and 0.75 L glass bottles. Moreover, the gravity filling prevents organoleptic alterations, and significantly reduces the risk of foam formation during filling.

In addition, the integrated capper features 1 capping head for 29 mm crown caps, ensuring a secure and effective seal. Furthermore, this capping system works in synergy with the gravity filling process to maintain the internal pressure stability of the bottles.

Operational Specifications

Notably, the monoblock fills up to 1,000 bottles per hour, making it ideal for small to medium-sized production lines. As a result, bottles move through the system with a clockwise rotation, thereby optimizing workflow efficiency.

Along with the monoblock, the conveyors are also included in the sale. They have the following dimensions: 1.80 m in length, maximum width 52.5 cm, minimum width 25 cm.

Regarding electrical specifications, the Used filling monoblock ALFATEK ELVIRA for re-fermented beer operates at 415V and 50Hz. Therefore, it remains compatible with most industrial plants.

Safety and Structure of the Used filling monoblock ALFATEK ELVIRA for re-fermented beer

Importantly, the machine includes safety devices that protect the operator during operation. Additionally, its compact structure measures 1,190 mm in width, 1,900 mm in length, and 2,330 mm in height, allowing seamless integration into existing production lines without major modifications.

Current Condition and Availability

At present, the Used filling monoblock ALFATEK ELVIRA for re-fermented beer remains in storage. Thus, it is ready for inspection and installation in a new production facility. Given its robust structure and advanced technical features, it presents a reliable choice for breweries looking for a high-performance and tested machine.

Ultimately, this monoblock provides a valuable opportunity to improve production efficiency. Likewise, it represents a strategic investment in a well-maintained used system. Consequently, breweries can optimize their operations while reducing acquisition costs. Additionally, its compatibility with industry standards ensures smooth integration into various production setups. Therefore, this machine offers both efficiency and reliability, making it a practical choice for modern bottling facilities.

Listing

Menslage

Menslage

18,398 km

Cespedes, Anfara Sommer, Braumanufaktur Werk Brewhouse (2018)

Cespedes, AnfaraSudhaus

Call

Condition: used, Year of construction: 2018, Overview This complete brewing and packaging line was manufactured mainly in 2018 by Cespedes (Spain) and other European manufacturers such as Anfara, Sommer, and Braumanufaktur Werk. It includes brewhouse, fermentation, utilities, CIP, and filling equipment, all built in stainless steel AISI 304. With a brewhouse capacity of 1,500 L per batch and three 3,000 L fermenters, it is designed for small to medium-scale breweries. The line is in excellent condition and suitable for immediate use. Technical data Capacity: 1,500 L per batch (brewhouse), 3 × 3,000 L fermentation tanks Formats: Bottles and cans (330 ml, 440 ml, 500 ml) Brewing system: Steam-heated, fully stainless steel Filler: 6-head semi-automatic isobaric filler (bottles), modular semi-automatic filler and capper (cans, approx. 150 cph) Scope of Delivery Brewing kettle / whirlpool tank | Cespedes | - | 2018 | 1,500 L usable, double jacket, steam heating, fully insulated, stainless steel AISI 304 Mash/lauter tun | Cespedes | - | 2018 | 2. 000 L usable, motorized stirrer, insulated, stainless steel AISI 304 Hot water tank (HLT) | Cespedes | - | 2018 | 3,000 L, insulated, with heating jacket Fermentation/storage tanks (3 pieces) | Cespedes | - | 2018 | 3. 000 L usable, pressure vessel up to 3 bar, insulated, cooling jacket Control system | Cespedes | - | 2018 | Recipe management, temperature control, frequency converter Work platform with ladder | Cespedes | - | 2018 | Stainless steel, non-slip, with railing Connecting bench + piping | Cespedes | - | 2018 | Stainless steel, hygienic DIN valves, incl. Helicoidal pump Plate heat exchanger | - | UPF34/70 | - | stainless steel, for wort cooling Inline particle filter | - | - | 2018 | stainless steel AISI 304, slot width 0.2 mm Sight glass | - | - | - | stainless steel AISI 316, hygienic inline inspection window Steam generator | Anfara | AV-300 | 2018 | 300 kg/h, 5 bar, Oil burner, CE-certified CIP system | - | CDXM 70-5 | 2021 | flow rate 3.0-9.6 m³/h, 1.5 kW motor Semi-automatic bottle filler | Cespedes | ISO-6 | 2016 | 6 filling heads, isobaric, stainless steel Semi-automatic can filler + seamer | Braumanufaktur Werk | Fillmatic | 2021 | modular, formats 330-500 ml, approx. 150 cans/h Malt mill | Sommer Maschinenbau | Maltman | 2019 | up to 1,500 L batches, 2-roller mill Buffer/intermediate tank | - | - | - | 565 L

Kfjdow U Tgxspfx Affea

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Monoblock

ComacSMARTBLOCK 6-6-1

Call

Condition: used, Year of construction: 2013, Used Filling Monoblock Comac Bottle Line SMARTBLOCK 6-6-1 700 bph

The used Comac SMARTBLOCK 6-6-1 filling monoblock offers a compact and highly efficient solution for bottling beer in 0.33-liter glass bottles. This machine, manufactured in 2013, handles 700 bottles per hour, making it an ideal choice for medium-scale craft beer production. Furthermore, a detailed technical analysis of the SMARTBLOCK 6-6-1 highlights its key features and specifications, which set it apart in the industry.

Kfsdpsvgtz Asfx Affsa

Key Features of Used Filling Monoblock Comac

The Used Filling Monoblock Comac Bottle Line SMARTBLOCK combines the rinsing machine, filling machine, and capping machine into a single continuous process. As a result, it optimizes workflows, saving both time and space. Its compact structure, measuring 2580 mm x 2580 mm, proves particularly advantageous for breweries with limited floor area.

Rinsing Machine

The rinsing machine of the Used Filling Monoblock Comac Bottle Line SMARTBLOCK grips bottles securely with six clamps. Moreover, the system carries out a single rinse cycle, reducing water consumption while ensuring thorough cleaning for sensitive products like beer. In addition, the counterclockwise rotation enables a smooth and efficient sequence, ensuring consistency throughout the rinsing process.

Filling Machine

The filling machine with its isobaric system ensures precise and stable filling, even at high pressures. For this reason, it delivers excellent performance when handling carbonated products. Six traditional valves, paired with mobile nozzles, manage CO₂ effectively and prevent oxidation, thereby preserving the beer’s quality. Furthermore, the traditional isobaric valves maintain carbonation integrity during the entire process.

Capping Machine

The capping machine of the Used Filling Monoblock Comac Bottle Line SMARTBLOCK applies crown caps with a diameter of 26 mm. Notably, its single-head capper handles 700 bottles per hour without delays, sealing each bottle tightly to retain carbonation and block contamination. Consequently, the machine provides reliability while maintaining the integrity of the final product.

Operational Details and Safety

The Used Filling Monoblock Comac Bottle Line SMARTBLOCK operates in production today, demonstrating its reliability and robustness. Additionally, the machine includes all required safety certifications, protecting workers during use. The included technical manuals assist operators in performing maintenance and training efficiently. Therefore, breweries can maintain smooth operations without frequent interruptions.

Used Filling Monoblock Comac Bottle Line SMARTBLOCK: Electrical Specifications

The machine operates with a 400 V power supply, consuming 2.6 kW at 50 Hz. Similarly, its energy-efficient design minimizes power usage while delivering consistent performance. As a result, it remains a cost-effective choice for medium-scale breweries.

Listing

Menslage

Menslage

18,398 km

Speidel, Spagni, Sommer Maltmann, 500l (5hl) Brewhouse (2016)

Speidel, Spagni,Sudhaus

Call

Condition: used, Year of construction: 2016, Overview This complete 500 L brewhouse package was manufactured between 2016 and 2017 by leading European companies, including Speidel, Spagni, Skrlj, Sommer, and MTA IT. Designed as a turnkey solution for small to medium-sized breweries, it includes all key equipment for mashing, fermentation, chilling, capping, labelling, and malt processing. The system was previously operating at 600 bph and can be adapted for up to 900–1,000 bph. It is offered for sale as the brewery has ceased operations and is immediately available. Technical Details Brewhouse capacity: 500 L (Braumeister 500 L, atmospheric) Fermentation capacity: 4 × 625 L (total 2,500 L) Formats: 26 mm crown caps (adaptable to 29 mm) Labeller type: Self-adhesive, semi-automatic, for cylindrical bottles Malt mill capacity: 150 kg/h Chiller: MTA TAEevo TECH 015, 3.8 kW, refrigerant R410A Production speed: 600 bph (adaptable to 900–1,000 bph) Electrical connection (brewhouse): 230/400 V, 32 A, 50/60 Hz, IP43 Scope of Supply Speidel Braumeister 500 L brewhouse (2017) 4 × Speidel 625 L fermentation tanks (2017) Spagni Aircorona 26/29 FE pneumatic crown capper (2017) Skrlj E03 180 semi-automatic labeller (2017) Sommer Maltman 110 malt mill (2017) MTA TAEevo TECH 015 process chiller (2016) Additional equipment: crane, manual filler, air compressors, sugar mixer tank, transfer pumps

Kjdpfow Nk Ezex Affsfa

Listing

Menslage

Menslage

18,398 km

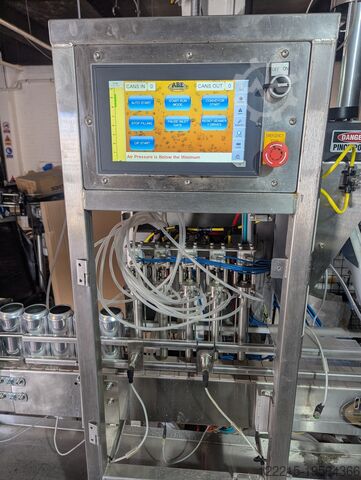

ABE / Vigo UK CraftCan35 Atmospheric filler (2017)

ABE / Vigo UKAtmosphärischer Füller

Call

Condition: used, Year of construction: 2017, Overview This CraftCan35 can filling machine was manufactured in 2017 by the British company Vigo UK (ABE). The machine has been overhauled, is currently cleaned, dismantled and safely stored and is available for immediate use. It is particularly suitable for small to medium-sized breweries that want to process 330 ml and 440 ml standard cans (202 ends). A viewing can be organized by arrangement. Technical details Output: up to approx. 35 cans per minute (depending on product) Formats: 330 ml & 440 ml standard cans (202) Filling system: 6-head filler Closure: double seam seamer for 202 ends Voltage / power supply: not specified Special features: Retrofitted rinser and dryer (Vigo UK) Pneumatics converted to metric connections Original operating instructions available Scope of delivery 1 × Can filling line | ABE | CraftCan35 | 2017 Incl. rinser and dryer (retrofitted) Optional: Stainless steel rotary table (pack-out table) and 3 m single-track conveyor belt Some acrylic protective cladding (some replacement required)

Ksdpfxjwzb Iro Affefa

Listing

Menslage

Menslage

18,398 km

Certuss Junior 300 TC Steam Generator (2017)

Certuss

Call

Condition: used, Year of construction: 2017, Overview The steam generator was built in 2017 by the German manufacturer Certuss. It is fired with gas and can deliver up to 300 kg/h. The unit was used in a German brewery. Was in operation till June 2025. Still assembled but disconnected from the gas pipe. Unit was only used once in a week during brewing, therefor the working hours are low. Technical specifications Steam production max.: 300 kg/h Powered by gas Operating Pressure: 10bar Accessories Filter Condensate recuperation

Kfsdpfxowwaxze Affsa

Listing

Menslage

Menslage

18,398 km

Tecnoimpianti W. T. MINI STAB 300 SINGLE Ion Exchange Unit (2017)

Tecnoimpianti W. T.Ionenaustausch-Einheit

Call

Condition: used, Year of construction: 2017, Overview The Tecnoimpianti MINI STAB 300 SINGLE is a compact system for the acid stabilization of must and wine using the ion exchange process. It was built in 2017 by the Italian manufacturer Tecnoimpianti Water Treatment S.r.l. and was rarely used by the original owner and is now being sold due to a change of ownership. The machine is therefore in very good condition and available immediately. It is ideal for wineries, breweries or the production of carbonated beverages. Technical details Capacity: approx. 300 l/h Area of application: Acidification / stabilization of must and wine Process: Ion exchange with strongly acidic cation exchange resin Compressed air requirement: min. 6 bar Power supply: 400 V / 3 Ph + N / 50-60 Hz Installed power: 3.2 kW Operation: Touchscreen HMI Protection class: IP65 Compressor tank: 400 L, 3 bar operating pressure Certification: EU-compliant / CE Special features Fully automated process control Precise pressure and temperature control Stainless steel construction (hygienic & durable) Plug-and-play system with touchscreen Built-in nitrogen feed Effectively reduces potassium bitartrate formation

Kfedpfx Afswm Rfkofja

Listing

Menslage

Menslage

18,398 km

Framax DEPAL, RLA, Modulblock RFCI Line for Non-Returnable Glass Bottles (2016)

FramaxAbfülllinie für Glasflaschen (Einweg)

Call

Condition: used, Year of construction: 2016, Overview This complete filling line for glass bottles is part of a brewery and used for filling beer in 330 ml glass bottles with crown caps. It consists of an automatic glass depalletizer, self-adhesive labeller, filling triblock and a carton packer. The entire equipment was installed in 2017 by Italian manufacturer Framax. All the equipment is still installed and can be viewed in person during production. Technical details Production capacity: 2,400 bph (at 0,33l) Formats recently used: 0,33l Bottle diameter: 60mm, height is adjustable 26mm crown cap Packaging: 6x4 carton box Scope of delivery Automatic depalletizer | Framax | DEPAL SS-3000 | 2017 Automatic sheet removal Photocells for depalletizer Selfadhesive labeller | Framax | RLA-H06-S3-L3-D480 | 2016 3 stations for 3 labels (front, back, neck) Date/ batch printer Isobaric filler | Framax | Modulblock RFCI-16/16/1-DPS/C | 2016 Nominal capacity: 3.000 bph 16 Rinsing positions 16 Filling positions Single head capping unit for crown caps with cap feeding unit Double air pre-evacuation with CO2 Water spray device before capping, for reducing the amount of residual oxygen Automatic carton packer | Framax | CP-0700-1T | 2017 Box erecting and inserting machine With taping machine Accessories such as conveyors, cooling, pumps

Kfsdstt Um Repfx Affea

Listing

Menslage

Menslage

18,398 km

GM Gera Arcade CDS Bottle Washer (1999)

GM GeraFlaschenreinigungsmaschine

Call

Condition: used, Year of construction: 1999, Overview The bottle washer was previously used in a brewery. Due to the complete reconditioning in 2005 and continuously maintentance, the machine is in very good condition. All basins and the machine body are made of stainless steel. The machine is already disassembled and dry stored, so that it can be easily loaded and transported. Tech Specs: Capacity: 6,700 bph Cell Pitch: 102 mm Bottles per row: 10 Dimensions + Weights: Housing: 7,200 x 1,300 x 2,850 mm / 13,500 kg Ready for operation with attachments: 7,790 x 3,450 x 2,950 mm / 20,000 kg YOM 1999 Formats: 0,33l 0,5l The Machine in Detail / Equipment Features: Heated by steam Pre Cleaning and removal of residual liquids by pulsed rinsing prior to washing CE certified Chemical Dosing Pumps Machine data sheet included High pressure pre rinsing Rotating Spray nozzles Single End Machine Label discharge rear right Finger discharge + finger feed Bottle cells made of plastic Concentration measurement NaOH supply liquid Sectional view arrangement of baths Spindles SST 24 volt control voltage Control Siemens S7 Regularly maintained Full machine body in SST Vapor Discharge Machine dismantled, ready to ship Automated machine Startup

Kfjdpfxewg E D Io Affsa

Listing

Menslage

Menslage

18,398 km

KHS Innofill DRS Isobarometric Filler (2013)

KHSDruckfüller

Call

Condition: used, Year of construction: 2013, Overview The pressure filler was built in 2013 by the German manufacturer KHS. The pressure filler is still in use at a large German brewery and can be inspected at any time. Technical data Capacity: 22,000 - 65,000 bph Number of filling stations: 168 Number of capping stations: 24 Pitch circle filler: 5040 mm Scope of delivery Valve node Vacuum unit Hygienic inlet Fill level and closure inspection Rejection and rejection belt Technical documentation Incl. program backup Extensive transporters available, which can be purchased additionally

Kedpfx Ael Sm S Deffofa

Trust Seal

Dealers certified through Machineseeker

Listing

Menslage

Menslage

18,398 km

GM Gera Arcade GEK 2.1 Bottle Washer (2024)

GM GeraFlaschenreinigungsmaschine

Call

Condition: used, Year of construction: 2024, Overview The bottle washer was previously used in a brewery. Due to the low number of operating hours, the machine is in very good condition, like new. It was replaced, as the previous owner wanted to run bottle formats, which did not fit this machine. All basins and the machine body are made of stainless steel. The machine is already disassembled and dry stored, so that it can be easily loaded and transported. The machine comes with 12months warrantee. Tech Specs: Capacity: 9,500 bph Cell Pitch: 95 mm Bottles per row: 25 Dimensions + Weights: Housing: 7,162 x 2,740 x 2,500 mm / 18,806 kg Ready for operation with attachments: 7,162 x 3,540 x 2,730 mm / 31,563 kg YOM 2024 Formats: 0,25l 0,33l 0,5l 0,75l The Machine in Detail / Equipment Features: Heated by steam Pre Cleaning and removal of residual liquids by pulsed rinsing prior to washing CE certified Chemical Dosing Pumps Machine data sheet included High pressure pre rinsing Rotating Spray nozzles Single End Machine Label discharge rear right Finger discharge + finger feed Bottle cells made of plastic Concentration measurement NaOH supply liquid Sectional view arrangement of baths Spindles SST 24 volt control voltage Control Siemens S7 Regularly maintained Full machine body in SST Vapor Discharge Machine dismantled, ready to ship Automated machine Startup

Kfedpfx Afevrfivsfja

Listing

Menslage

Menslage

18,398 km

Irudin BL-24 Rinser (2022)

IrudinRinser

Call

Condition: used, Year of construction: 2022, Overview This rinser from Irudin was manufactured in 2022 and is for sale as the original brewery was closed and merged with another production facility. The machine is designed for bottle and can formats and achieves an output of 8,000 units per hour. Technical details Output: 8,000 bottles/hour Formats: Bottles: 0.33L, 0.75L Cans: 0.33L, 0.44L Number of rinsing heads: 24 Dimensions: 2,794 x 2,004 x 1,960 mm Weight: 1,942 kg

Kfodpfsv Sdmmex Affoa

Listing

Menslage

Menslage

18,398 km

GEA Westfalia Type SB 80-106-076 Centrifuge (1994)

GEA WestfaliaZentrifuge

Call

Condition: used, Year of construction: 1994, Overview The Centrifugal Separator Type SB80-06-076 from the manufacturer GEA Westfalia was previously used at a brewery in Estonia. Due to a complete shutdown of the production plant, this unit is for sale. Till closing of the factory, the separator was used frequently. Tech Specs 4500 rpm with self cleaning drum Accessories Spare Parts Tools

Kfedsv N Hcxepfx Affja

Listing

Menslage

Menslage

18,398 km

Kosme/Krones Barifill FC Isobarometric Filler (2015)

Kosme/KronesDruckfüller

Call

Condition: used, Year of construction: 2015, Overview The Kosme / Krones Barifill is an isobaric filler that is currently in operation in a German brewery and can be seen in operation. The machine was manufactured by Kosme in 2015 and installed in 2016. It has a maximum output of 8,000 bottles per hour and the rated speed of the manufacturer is 7,000 bph. The system is designed for 26 mm crown corks and has 30 filling stations. Technical details Output: 8,000 bottles/hour (for 0.33-liter bottles) Type of closure: 26 mm crown cork Formats: 0,5 NRW 0,5 Longneck 0,5 Lochmund 0,33 ALE 0,33 SUD 0,33 Steinie Bügel Filling stations: 30 Electrical specifications: Max. Voltage: 3x400 V + N + GND 50Hz Power consumption: 13,00 kW Operating hours: 18393 (March 2025) Spare parts included: Drives Gearboxes Cardan Shaft others Serviced by Kosme/Krones each year Lifting cylinders in 2024 Valves and capper in 2025 Features: Bottle shower High pressure injection for foaming Bottle stopper Table flushing Bunker for crown caps

Kjdpfov Ic Uzjx Affsfa

We make it easier for you to find: "brewer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Brewer (92)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you