Used Axes for sale (3,414)

Remscheid

Remscheid Component

FanucA20B-3300-0120/02A 2/4 Axes Servo Card - ! -

Remscheid

Remscheid Component

OkumaDC Power Supply 6 Axes PCB mit E4809-436-002-A

Kreuztal

Kreuztal Laser welding system 4 kW / 6 axes

AMADALaserschweißanlage FLW-4000

+44 20 806 810 84

Roreto

Roreto C.N.C. WORKING CENTER with 3 axes X-Y-Z

BIESSESkipper 130

Roreto

Roreto CNC WORKING CENTER 3 axes (X-Y-Z)

WEEKE (HOMAG Group)BHX 500

Discover more used machines

Roreto

Roreto C.N.C. WORKING CENTER - 4 axes BIMA CUT

IMABIMA Cut 120 (160) / 420

Roreto

Roreto C.N.C. WORKING CENTER 3 axes. Vertical

BREMA (BIESSE Group)Vektor PI 25-13 (1R10 - 2MI+1MI)

Roreto

Roreto CNC WORKING CENTER 3 axes (X-Y-Z)

MORBIDELLI (SCM Group)UNIFLEX HP

Marl

Marl Fanuc Servo Unit

FanucA06B-6105-H002 6-AXES SERVO

Remscheid

Remscheid Component

SiemensSINAMICS 6SL3111-4VE22-0HA1 Combi Power Module 4 Axes generalüberholt mit 12 Monaten Gewährleistung! -

Iserlohn

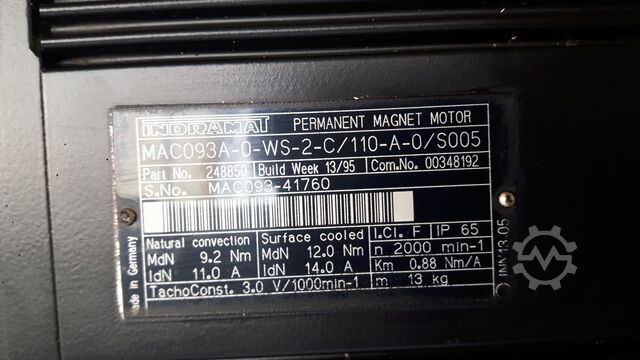

Iserlohn Axes motors INDRAMAT CNC lathe

INDRAMATMAC093A-0-WS-2-C/110-A-0/S005

Deinze

Deinze Bed milling machine with moving column & CNC

ParpasML120-1 -8 axes X: 12 000- Y: 3500- Z: 1250 mm CNC

Egenhofen

Egenhofen Circular sawing machines

RojekPF 400 NC 3 axes

Sorocaba

Sorocaba Gear Shapping Machine

LorenzLS 404 - New Siemens - 4 axes

Trenčianske Stankovce

Trenčianske Stankovce Stäubli RX160 (2009) 6 axes robot quick sale

StäubliRX160

Deinze

Deinze Universal Milling machines & CNC

FanucRobot + 3 Breton machining centers 5 axes

Montbrison

Montbrison CNC vertical lathe - 3 axes

Hyundai WIALV 800 RM

Deinze

Deinze Bed milling machine with moving column & CNC

Giddings & Lewis6 axes X: 24 000 - Y: 2133 - Z: 4572 mm CNC

Halberstadt

Halberstadt CNC turning and milling center – 5 axes – simultaneous

IGREKFR 1000 T

Halberstadt

Halberstadt CNC portal milling machine - 5 axes - simultaneous

IGREKFR 3500 XL

Halberstadt

Halberstadt CNC machining center – vertical – 3 axes

IGREKVMC 1160

Germany

Germany CNC Universal 5-Axes Milling Machine

Deckel MahoDMU 100 monoBLOCK/DMU 60 monoBLOCK

Halberstadt

Halberstadt CNC portal milling machine - 5 axes - simultaneous

IGREK3500 XXL

Biebrich

Biebrich Machining center / 5 axes

PrimaconPFM 24 NGD

Bayreuth

Bayreuth CNC milling machine, 3 axes

OptimumTyp F 105

Used Axes (3,414)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84