Blow Molding MachineSMI

SR 10 HP

Blow Molding Machine

SMI

SR 10 HP

Year of construction

2015

Condition

Used

Location

Fumane (Verona)

Show images

Show map

Machine data

- Machine type:

- Blow Molding Machine

- Manufacturer:

- SMI

- Model:

- SR 10 HP

- Year of construction:

- 2015

- Condition:

- used

Price & Location

- Seller location:

- Via Incisa 1, 37022 Fumane (Verona), Italy

Call

Details about the offer

- Listing ID:

- A18005851

- Reference number:

- SO112

- Update:

- 16.12.2024

Description

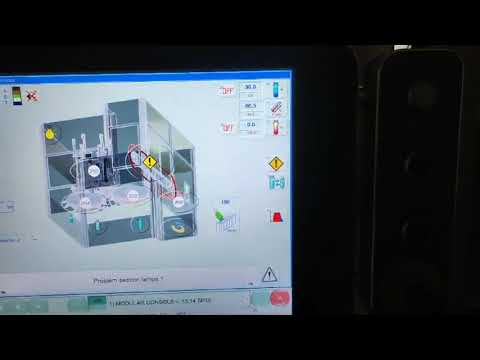

Used Blow Molding Machine SMI SR10HP year 2015

Firstly, the SMI SR10HP, produced in 2015, emerges as an advanced solution for PET container production. This analysis aims to detail its technical specifications and operational features. It significantly highlights the machine’s efficiency and productive capacity in industrial environments.

Productive Capacity and Versatility of the Blow Molding Machine SR10HP

Importantly, the machine achieves a remarkable speed of 17,000 BPH, showcasing its high capacity. It adeptly processes a variety of container sizes, including 0.20 L, 0.33 L, and 0.6 L, thereby offering considerable flexibility in production lines.

Configuration and Components

Moreover, it boasts ten cavities for simultaneous preform processing, which optimizes production time. Integrated systems, such as a loader, tipper, and unscrambler, automate preform handling. Consequently, these systems minimize manual intervention and significantly boost operational efficiency.

Technology and Innovation of the Blow Molding Machine SR10HP

Additionally, a compressor and chiller are crucial for controlling temperature and air pressure, ensuring the quality of PET containers. Furthermore, an air recovery system innovatively reduces energy consumption, highlighting a strong commitment to sustainability.

Standards and Compatibility

Equally important, the machine operates with 1881 neck type preforms, a widely accepted standard, ensuring compatibility with various bottling lines. Its rotary design facilitates high-speed production while maintaining high-quality standards, thereby ensuring reliability.

Operational Status and Safety

Fgedpfxevgt I No Afioh

Currently, the Blow Molding Machine SR10HP is in operation and meets strict safety standards, effectively protecting operators. Provided manuals support efficient maintenance and optimal machinery use, enhancing operational longevity.

Electrical Data

On the electrical front, specifications require 380V, with a consumption of 300kW and an intake of 494A. This detail underscores the machine’s commendable energy efficiency.

Conclusion

In conclusion, the 2015 SMI SR10HP machine stands out for its productive capacity, energy efficiency, and technical sophistication. With a strong focus on sustainability, it represents an ideal choice for industries seeking reliable, high-quality solutions for PET container production.

Firstly, the SMI SR10HP, produced in 2015, emerges as an advanced solution for PET container production. This analysis aims to detail its technical specifications and operational features. It significantly highlights the machine’s efficiency and productive capacity in industrial environments.

Productive Capacity and Versatility of the Blow Molding Machine SR10HP

Importantly, the machine achieves a remarkable speed of 17,000 BPH, showcasing its high capacity. It adeptly processes a variety of container sizes, including 0.20 L, 0.33 L, and 0.6 L, thereby offering considerable flexibility in production lines.

Configuration and Components

Moreover, it boasts ten cavities for simultaneous preform processing, which optimizes production time. Integrated systems, such as a loader, tipper, and unscrambler, automate preform handling. Consequently, these systems minimize manual intervention and significantly boost operational efficiency.

Technology and Innovation of the Blow Molding Machine SR10HP

Additionally, a compressor and chiller are crucial for controlling temperature and air pressure, ensuring the quality of PET containers. Furthermore, an air recovery system innovatively reduces energy consumption, highlighting a strong commitment to sustainability.

Standards and Compatibility

Equally important, the machine operates with 1881 neck type preforms, a widely accepted standard, ensuring compatibility with various bottling lines. Its rotary design facilitates high-speed production while maintaining high-quality standards, thereby ensuring reliability.

Operational Status and Safety

Fgedpfxevgt I No Afioh

Currently, the Blow Molding Machine SR10HP is in operation and meets strict safety standards, effectively protecting operators. Provided manuals support efficient maintenance and optimal machinery use, enhancing operational longevity.

Electrical Data

On the electrical front, specifications require 380V, with a consumption of 300kW and an intake of 494A. This detail underscores the machine’s commendable energy efficiency.

Conclusion

In conclusion, the 2015 SMI SR10HP machine stands out for its productive capacity, energy efficiency, and technical sophistication. With a strong focus on sustainability, it represents an ideal choice for industries seeking reliable, high-quality solutions for PET container production.

Seller

Note: Register for free or log in, to access all information.

Send inquiry

Telephone & Fax

+39 344 0... show

Your listing has been deleted successfully

An error has occurred