Used Wobble Riveting for sale (118)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Turkey

Turkey

17,237 km

Wobbler Feeder/ Feeding

ConstmachWobbler Feeder / Feeding for Crusher

Call

Condition: new, functionality: fully functional, Year of construction: 2025, The wobbler feeder is a feeding system that delivers superior performance, especially when handling large, sticky, and moist materials. Its structure, consisting of rotating elliptical rods, creates a vibrating motion during material flow. This motion separates fine materials from larger particles and provides consistent feeding to crushers and screens. As a result, clogging is prevented and the overall efficiency of the plant is increased.

Widely used in the mining, aggregate, and recycling industries, wobbler feeders are typically placed in front of primary crushers. This ensures that the material undergoes pre-screening in the initial stage. Its ability to operate without clogging, even with sticky and clayey materials, makes it an ideal solution for demanding conditions. Its mechanically simple design, ease of maintenance, and long-lasting performance keep operating costs to a minimum. With these features, wobbler feeders are a reliable choice for all plants requiring a continuous and balanced material flow.

Nkjdpfxjxpvh Te Ad Nst

Wobbler Feeder Technical Specifications

Body Liners: HARDOX 450 – 10 mm

Feeding Capacity: 150 - 200 t/h

Weight: 18.5 tons

Dimensions: 4,000 x 1,000 mm

Wobbler Motor: 14 x 3 kW, 1500 rpm, GAMAK brand

Gearbox: Heavy-duty type

Walking Platforms: Available

Steel Feet: Available

Why Choose CONSTMACH Wobbler Feeders?

CONSTMACH wobbler feeders stand out with their high-quality, durable materials, heavy-duty gearboxes, and ease of maintenance. Each one is designed to offer long-lasting, low-cost operation. HARDOX body liners provide maximum resistance to wear, while the adjustable design easily adapts to different material types. CONSTMACH is a trusted name in the industry for its production quality, engineering support, and after-sales service. Invest in a wobbler feeder with the CONSTMACH guarantee for the continuity and performance of your facility.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer offering a wide range of products designed to meet the needs of the construction and mining industries. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

Maastricht

Maastricht

18,649 km

Wobbler screen Kleemann

Call

Condition: ready for operation (used), Wobbler screen Kleemann

Brand: Kleemann

Screen surface: 4000 x 1800 mm

Njdpfxjw N A Rij Ad Nokt

Driving: 2 pieces gearboxmotors of each 22 kW.

Incl.: a lot of spare parts

Listing

Germany

Germany

18,384 km

Remaining Stock

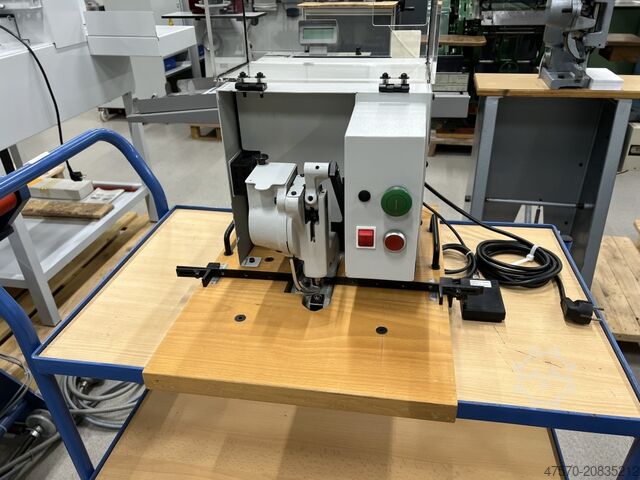

Thielicke/Schlenker & Cie/Müller/Berg & SchmidWN6/ATLAS W4/OMP67F/Mini Compact

Call

Year of construction: 2018, condition: ready for operation (used), Various metalworking machines are available as remaining stock. 1/2/3) Three wobble riveting presses Thielicke GmbH & Co. KG WN6, year of manufacture: 1998. 4) Schlenker & Cie Atlas W4 high-speed planer, year of manufacture: 1961, weight: approx. 1700kg. 5) Spot welding machine J.u.W. Müller GmbH Opladen OMP67F, year of construction: 1960. 6) Ring welding machine Ing. G. Wenninger/BAPO KH III, year of construction: 1940s, conversion: 1964. 7) Cross-cut saw Berg & Schmid Mini Compact, year of construction: 2018. 8/9/10) Three presses. Including vices and lathe accessories. On-site inspection is possible. Individual sale possible.

Njdpfsu Tuvcjx Ad Njkt

Listing

Wymysłów

Wymysłów

17,869 km

Bookbinding machine

Hang87D4P

Call

Condition: good (used), Hello,

Nksdpfx Adov I E Sce Not

-The subject of sale is.

-Hang 87D 3P double-head riveter.

-Manufacturer: Hang Germany.

-Good condition.

-The machine is used to rivet eyelets.

-Two riveting heads, with adjustable spacing.

-Cardboard thickness 0.2-4mm

-Weight 570kg

-380V power supply

-Possible transport by freight forwarder (individual valuation)

Listing

Bremen

Bremen

18,325 km

50000 liter insulated storage tank made of V2A

K0085

Call

Condition: used, tank capacity: 50,000 l, GENERAL

Design: upright

Remarks: exact dimensions may vary slightly; the riveted insulation is damaged in some areas (see images); the base of the tank is filled with concrete

External diameter: 3,100 mm

Total height: 9,000 mm

Insulation: present

Location: outdoor storage

Volume: 50,000 liters

Product-contact material: V2A 1.4301 (AISI304)

Condition: used

Nedpfx Adjyckpto Nskt

Last application: vapor condensate tank (dairy)

INSULATION

Insulation jacket: riveted

EQUIPMENT

Manhole / dome: in the cylinder

Note: slight residues

Listing

Bremen

Bremen

18,325 km

1250 litre insulated CIP tank made of V2A (stainless steel).

9845

Call

Condition: used, tank capacity: 1,250 l, GENERAL INFORMATION

Nkjdpfjyci Ibox Ad Net

Equipment: Spray head

Design: upright

Remarks: Minor differences in the design of the two tanks; dents in the insulation shell of the lower bottom; one tank also has a dent in the insulation shell in the cylindrical area (the spray head is also missing from this tank)

External diameter: 1,350 mm

Internal diameter: 1,240 mm

Total height: 1,750 mm

Insulation: present

Location: Bremen

Volume: 1,250 liters

Product-contacting material: V2A 1.4301 (AISI304)

Condition: used

Cylindrical height: 1,000 mm

Last use: CIP tanks in the pharmaceutical industry

TANK

Support type: Height-adjustable feet

Number of feet: 3 units

INSULATION

Insulation shell: riveted

Insulation shell material: stainless steel

EQUIPMENT

Manway/Dome: in top head (DN 400)

Outlet: DN50 DIN 11851

Remark: minor residues

MATERIAL SPECIFICATION

Feet material: stainless steel

Listing

Eislingen/Fils

Eislingen/Fils

18,583 km

Double Blow Header

HILGELANDCH 4 C

Call

Condition: used, Year of construction: 1966, shaft length 15 - 130 mm

wire diameter 6 - 12 mm

length of wire blank max. 170 mm

capacity/output with closed mould, adjustable 100 /min

capacity/output with open mould, adjustable 67 /min

Weight 12,5 t

dimensions of the machine (WxDxH) 2,3 x 4,0 x 1,6 m

combined double-pressure cold header press

for jaws and closed moulds

maximum wire diameter for high tensile bolts und carriage bolts 10 mm

maximum wire diameter for mild steel bolts and rivets 12 mm

Nkodpfx Adsv Sva Es Nst

wire diameter range 6 - 12 mm

minimum and maximum shaft length 15 - 130 mm

maximum length of wire blank 170 mm

capacity/output with closed mould, adjustable - 100 St/min

capacity/output with open mould - 67 St/min

power requirement 15,0 kW

mould dimensions - jaw dimensions 54 x 54 mm

Listing

Triptis

Triptis

18,329 km

Flatbed open

FlieglPlateau

Call

Condition: new, machine/vehicle number: c13a96854ea37997845c1bf36, empty load weight: 6,860 kg, maximum load weight: 28,140 kg, overall weight: 35,000 kg, axle configuration: 3 axles, tire size: 235/75 17,5, Further information

Chassis saddle forwarding

Fine-grained steel welded construction, fifth wheel plate with replaceable 2 king pins

Suspension strip for feeder ramps on the rear extension across the entire width, outer edge chamfered to prevent damage.

Frame in reinforced design for vehicle loading (up to outer frame)

Outer frame with Load-Lock profile approx. every 400 mm, for lashing strap attachment

10 pairs of lashing mushrooms embedded in the top/outside of the outer frame, 10 tons each, starting from the neck area

24 t. 2-speed support winch, single-side operation, with straight connecting plate

2 wheel chocks with holder

Aluminium side bumper

Galvanized steel underride guard

Sheet metal as splash guard riveted to the floor at the bottom, in the neck area above the axle of the SZM and above the axle unit

Half-shell mudguards

with anti-spray flaps according to EG

Container locking, 4 pairs of locking cut-outs embedded in the floor for 2 x 20 foot or 1 x 40 foot containers, 4 pairs of container locking adapters, (additional cross support required at the front and rear of the container, the container must rest evenly across the width in conjunction with the locks, cross supports are not included in the scope of delivery)

Caution! Damage to the Lohrblech floor by the cross supports possible!

Mechanical rear extension with hand crank, can be extended by approx. 1,500 mm, can be locked every 500 mm, incl. extendable underride guard with lighting, (then no access ladder at the rear)

Covered with Lohr plate in the tramline area, steel checker plate in the middle.

Attention! Ramp loading via rear only possible with rear extension in retracted position!

Storage space for access ramps integrated in rear extension, can only be used if rear extension is extended 1000 mm - then excess length

For transporting the ramps with the rear extension retracted - Storage space for ramps in FR on the right in front of the axles

1 pair of ramps 3,000 mm long, 300 mm wide, load capacity per pair 6,000 kg, (suspension bar for ramps on rear extension)

Rear sloping to approx. 500 mm

Electric cable winch, 24 volt, pulling force approx. 8165 kg, mounted centrally at the front, operation with radio remote control, cable length 35 m x approx. 10 mm, with roller rope window and removable guide rollers

Axles + suspension

Nkedpfx Ajlf Dtmed Not

Drum brake axles

Axle/chassis laser-measured Reduction in tire wear and fuel consumption

Air suspension

1st axle automatic lift axle, including forced lowering and starting aid, actuation of 3x brakes (starting aid is functional up to an axle load excess of 30% and up to a speed of max. 25 km/h)

with central lift arm

Axle lift below the recomm. Driving height, therefore no warranty for tire damage

Brake system

2-line compressed air brake system

Colored line routing for easy service.

Spring-loaded parking brake

2 swap-proof coupling heads at the front, without connecting cable

EBS, electronic braking system with EBS socket at the front, without connecting cable

Attention: The trailer may only be towed by towing vehicles that guarantee the effectiveness of the ABS!

with lifting & lowering valve

Vehicle stability system

Wheels and tires

235/75 17.5 tires of the manufacturer's choice

Steel rims in twin arrangement, factory silver

Electrical system

24 volt, multi-chamber lights, amber LED lighting at the sides

2 white LED position lights at the front

2 white/red rear lane departure lights

2 additional LED work lights at the rear, switched via reversing

Listing

Essen

Essen

18,540 km

Working platform semitrailer

KÖGELMulti Chassis. Rungen

Call

Condition: new, maximum load weight: 33,190 kg, overall weight: 42,000 kg, axle configuration: 3 axles, total width: 2,550 mm, Equipment: ABS, You can find our complete vehicle inventory, including immediately and short-term available vehicles, on our website.

Excerpt from the equipment features. Full equipment details available upon request.

Frame:

* Standard ladder-type frame in lightweight steel construction with through-bolted crossmembers

* With pre-cambered chassis frame

* Coupling plate approx. 8 mm thick, fitted with a 2-inch fifth wheel king pin according to DIN 74080 / ISO 337

Chassis:

* An increase in the total gross train weight is permitted for indivisible loads

* Axle lift mechanism on axle 1, lift control fully automatic, load-dependent

* Make of your choice, Kögel recommended

* Tri-axle assembly with disc brakes Ø approx. 430 mm, offset approx. 120 mm

* Air suspension with approx. 180 mm travel

Vehicle Tyres:

* Wheels with built-in sensors compliant with UN ECE R141

* Sixfold 385/65 R 22.5 UNIROYAL TH 506 tyres on 22.5 x 11.75 steel rims, offset approx. 120 mm (ET 120)

Chassis Attachments:

* Landing gear (make of your choice from Kögel), mechanical with compensating foot, approx. 24 t lifting capacity. Single-side operation, located on the right in the driving direction

* Spray suppression system according to Regulation (EU) No. 109/2011

* 1 pair of quarter-circle mudguards in front of the axles

* 1 pair of straight mudguards with mud flaps between the 1st and 2nd axle

* 1 pair of quarter-circle mudguards with mud flaps behind the axles

* 2 wheel chocks with brackets

* Side underrun protection according to ECE-R732

* Waterproof plastic toolboxes, dimensions (internal) approx. 545 x 400 x 400 mm. Mounted at the rear, 1 left, 1 right

* Rear right access ladder, extendable; high, rigid steel rear underrun protection according to ECE-R58

* 1 pair each of extendable warning panels for oversize loads, retroreflective red/white, with LED lighting, spiral cable, and connector. Arranged at the front and rear sections of the vehicle

Brake / Air Suspension System:

* EBS system 2S/2M with stability program (including ABS/ALB function), EBS connector ISO 7638 (without connecting lines), parking brake as spring-applied brake, external pneumatic connections, as well as external EBS diagnosis port via ISO 7638 connector

* EBS system (make of your choice from Kögel)

* Air suspension system incl. 1 lift and lower control valve, mounted on the left in the direction of travel behind the axle assembly. Driving height automatically adjusts

Nkodpfx Adex Uvlfj Not

* 2 foolproof coupling heads at the front ISO 1728

* Steel air tanks for brake system and air supply ( EN 286-2 )

Floor:

* Floor panels approx. 30 mm thick

* Floor joints sealed all-round

* Stake pockets for square tube stakes approx. 80 x 80 mm, layout according to drawing J9: 8 stake pocket rails (18 stake pockets per rail: 4 each on the outside + 10 in the centre)

Front Wall:

* Storage for up to 14 square tube stakes approx. 80 x 80 mm (length approx. 1,990 mm) on the inside front wall

* Front wall approx. 2,000 mm high, with steel volume corner posts, made from profiled steel sheeting, bolted/riveted to the frame. 2 pairs of lashing rings (permissible lashing capacity approx. 1,000 kg per ring) at the bulkhead according to EN 12640

Side Wall:

* VarioFix steel slotted outer frame

* 24 pairs of lashing rings on the outer frame (according to EN 12640), permissible tensile force approx. 5,000 kg per ring

Bumper Protection:

* 1 pair of steel buffer blocks approx. 160x85x85mm mounted on the outer rear frame plate

* Transverse zinc-plated s

Listing

Essen

Essen

18,540 km

Working platform semitrailer

KÖGEL3-Achs-Mega Chassis

Call

Condition: used, maximum load weight: 33,000 kg, overall weight: 39,000 kg, axle configuration: 3 axles, first registration: 06/2024, next inspection (TÜV): 06/2026, total width: 2,550 mm, Equipment: ABS, You can find our complete range of vehicles, including immediately and short-term available units, on our website.

Excerpt from the equipment. Full equipment details available upon request.

Frame:

* Standard ladder-type steel lightweight frame with through crossmembers

* Pre-cambered chassis frame

* Cover plate between side frame and main beams as tire protection for the drive axle wheels of the tractor unit

* Approx. 8 mm thick coupling plate with a 2-inch kingpin according to DIN 74080 / ISO 337

Chassis:

* Axle lift mechanism on axle 1

* BPW three-axle ECO Air unit with disc brakes, approx. Ø 370 mm, ET 120

* Air suspension, approx. 260 mm stroke

Vehicle Tyres:

* 6x 445/45 R 19.5, 160J tires

Chassis attachments:

* Mechanical landing gear with compensating foot, approx. 24 t lifting capacity, single-sided operation on the right in direction of travel

Nodjx Tx Efspfx Ad Nekt

* Tool-free folding side underrun protection, right and left in direction of travel

* Spare wheel carrier with winch including 1 wheel fixing kit, installed behind the axle unit

* Mounting for 16 square tube stake pockets approx. 80 x 80 x 1,990 mm, installation on both left and right sides of the longitudinal beam in direction of travel

* Waterproof plastic toolbox, internal dimensions approx. 545 x 400 x 400 mm, installed at rear left in the direction of travel

* Rear right retractable boarding ladder

Brake / Air Suspension System:

* EBS 2S/2M system with stability program (includes ABS/ALB function), EBS socket ISO 7638 (without connecting lines)

* Parking brake as spring-actuated brake, external pneumatic connections, as well as external EBS diagnostic connector via ISO 7638 socket

* WABCO EBS system

* Air suspension system including one lift and lower valve, installed on the left behind the axle unit in direction of travel. Driving position adjusts automatically

* Two foolproof coupling heads in front ISO 1728

* Brake and air reservoir tanks made of steel (EN 286-2)

Floor:

* Plywood floor panels, approx. 30 mm thick, multi-glued

* Rear floor sealed

* Pockets for square tube stakes approx. 80 x 80 mm, arrangement according to drawing J9: 8 pocket rail strips (18 stake pockets per strip: 4 outside + 10 in the center per strip)

Front wall:

* Approx. 2,000 mm high front wall with high-volume corner stanchions made of steel, profiled steel sheet, bolted/riveted to the frame, 2 pairs of lashing points (permissible lashing force approx. 1,000 kg per ring) on the bulkhead according to EN 12640. Note: When using the front wall for load securing, suitable lashing straps must be used for tensioning, especially if the vehicle is operated without side boards and tailgate/door!

* Side wall VarioFix steel perforated outer frame without stake carriers

* 24 pairs of lashing rings in the outer frame (to EN 12640), permissible tensile force approx. 5,000 kg per ring

Electrics / Electronics:

* Steel light support, positioned above the underrun protection

* KÖGEL LUXIMA Premium package consisting of: LED license plate lighting, LED marker lights and reflectors front, flashing LED side marker lamps, Superseal and bayonet light connectors

* 2 outline lights with arm, fitted to the multi-chamber tail lights

* 2 multi-chamber tail lights

* Fixed adapter box with 2x 7-pin sockets (1x ISO 1185 / 1x ISO 3731, 24 V-N / 24 V-S) and 15-pin socket ISO 12098

* Compact LED revolving beacon, orange, with mounting tube, arranged on the light support. Switch in the lamp casing

Listing

Wiefelstede

Wiefelstede

18,341 km

19 machine reamers

TITEX PLUSKonusreibahlen

Call

Condition: good (used), Machine reamers, reamer, reaming tool, locating cutter set, rivet reamer, rivet reamer

-various manufacturers: TITEX PLUS, UNISTO...

-Recordings: MK2/MK3/MK4

-Various sizes: 13-40 mm as shown in the photos

-Sale: only complete set

-Weight: 11 kg

Nkedpfxjcbyzxj Ad Njt

Listing

Wiefelstede

Wiefelstede

18,341 km

Torque assembly station

UWE TANKHI-LOK-Montage

Call

Year of construction: 2006, condition: used, Torque assembly station, torque module, assembly device, torque wrench, torque wrench, torque wrench, rivet gun, rivet gun, blind rivet gun,

Nkodpfx Adsfw Rwme Not

-Drive: torque module for Hilok assembly

-Torque: adjustable via touch screen

-Number of press-in cylinders: 1 piece

-Number of helical gears: 1 piece

-Working platform: 800 x 500 mm

-Travel: Y 400 mm, X 955 mm

-Dimensions: 1555/1470/H2110 mm

-Weight: 794 kg

Listing

Wiefelstede

Wiefelstede

18,341 km

Pneumatic staple gun

Emhart**ProSet 1600

Call

Condition: good (used), Pneumatic rivet gun, rivet nut pliers, blind rivet nut clamp, pneumatic riveting tool, blind rivet gun, blind rivet

-Compressed air rivet gun

-Application range: 2.0 to 4.0 mm

-Dimensions: 275/80/H220 mm

-Weight: 1.3 kg

Nkodpfxegzhxto Ad Not

Listing

Wiefelstede

Wiefelstede

18,341 km

Hydraulic Lockbolt Staple Gun

Hydro ControlLockboltsetzgerät

Call

Year of construction: 1999, condition: used, hydraulic lockbolt rivet gun, rivet gun, blind rivet gun

-hydraulic lockbolt rivet gun

-without: storage container

-incl.: hydraulic unit and control

-Dimensions: 1230/800/H1300 mm

-Weight: 450 kg

Nkjdpsdlw Dtjfx Ad Njt

Listing

Barcice Rososkie

Barcice Rososkie

17,698 km

Screw manufacturing machine

HilgelandCH5ALL

Call

Condition: good (used), Year of construction: 1970, Brand HILGELAND

Type CH 5 ALL

Year of build 1970

Serial number 5282

Electric connection 380V

Dimension l 5500mm

Dimension w 2200mm

Dimension h 1900mm

(screw and rivet), capacity : M6 - M14, cutting length max. 200mm, variable speed: ... up to pieces 90 p/min, diameter 16mm

Nksdsu Szucepfx Ad Njt

Listing

Hauzenberg

Hauzenberg

18,329 km

Engraving laser, engraving machine, 4th axis

LD-LaserLG50Q 60Watt Faserlaser

Call

Condition: new, Year of construction: 2025, shaft length: 1,070 mm, laser power: 60 W, type of cooling: air, Laser Engraving Machine with 60-Watt Laser Power

New demonstration unit

- 60 Watt MOPA laser (enables color laser engraving on stainless steel)

Nksdpfx Aefkgq Njd Nst

- incl. 4th axis (rotary unit)

- incl. Windows 10 Pro 64-bit PC system

- incl. 22" monitor

- fully installed and calibrated

- engraving software in German

- very easy to operate

- switch on and start immediately

- Fiber laser source with 60 watts for high-contrast and fast marking with extremely high resolution (see photos)

- Deep engraving up to 4mm possible (even in hardened steel)

- Wobble function, e.g. for cleaning metal components

- Suitable for engraving on many metals (stainless steel, brass, aluminum, etc.) and numerous plastics

- Heavy industrial quality

- Complete system / ready for immediate use

- Working area approx. 500 x 600 x 600 mm (LxWxH)

- Clamping table with threaded mounting holes in a 50mm grid

- LED workspace lighting

- 50mm port for fume extraction

- Engraving area approx. 180 x 180 mm

- Expandable up to approx. 300 x 300 mm

- Incl. foot switch for starting the engraving process

- Leasing or hire purchase possible through our finance partner

Sale to commercial customers only.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Zawiercie

Zawiercie

17,865 km

Pneumohydraulic Press 1T–50T

UNITECH

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Pneumohydraulic, Pneumatic and hydraulic Presses 0,2T–50T – Efficient, Cost-Effective, and EU-Compliant!

We offer high-quality pneumohydraulic presses with a pressure range from 0,2T to 50T, combining high efficiency, energy savings, and maximum workplace safety. Our machines fully comply with all EU regulations, including the Machinery Directive 2006/42/EC, and come with complete technical documentation and a CE Declaration of Conformity.

Key Features of Our Presses:

✅ Powerful and precise – smooth operation with advanced pneumohydraulic technology

✅ Energy-efficient – lower energy consumption compared to traditional hydraulic presses

✅ Enhanced safety – customizable safety features (light curtains, protective covers, two-hand control)

Nksdpfx Asv Snixod Not

✅ Flexible control systems – available in manual, semi-automatic, or fully automatic configurations

✅ Tailor-made solutions – we design and manufacture presses according to your specific requirements

✅ Versatile applications – ideal for stamping, punching, assembling, riveting, and bending

✅ Robust construction – built for durability and reliable operation in demanding conditions

✅ Complete documentation – each press is delivered with an operating manual, technical diagrams, and a CE declaration

Our pneumohydraulic presses are the perfect solution for European industries, offering high productivity, safety, and full compliance with EU standards.

📞 Contact us today for a customized offer tailored to your needs!

📩 Feel free to contact us via email

Listing

Germany

Germany

18,260 km

Automatic Punching Press - Double Column

WANZKESP S 63

Call

Condition: used, Year of construction: 1990, Technical details:

Pressure: 63 t

distance between columns: 200 mm

stroke: 150 mm

dayligth: 430 mm

no. of strokes: 400 Hub/min

T-slots H 12 650: 18 mm

hole in table: 420x160 b x l mm

ram surface area: 650 x 450 mm

control: Wanske Tronicpress CNC

passage of columns: 550x540 mm

tank: 200 l

stroke of ram - fixed: 100 mm

ram diameter: 40 mm

table height over floor: 1000 mm

table: 600x450 mm

table height over floor with metal base stand: 880 mm

total power requirement: 30 kW

weight of the machine ca.: 3,9 t

Hydraulic automatic punching press for precision work (high-speed press)

Nodju Icxqspfx Ad Nokt

- for punching, drawing, pressing, minting, bending, riveting, straightening, assembling

- with hydraulic gripper feed type HS 150 and 7-roller straightener (moving)

- Normal strips of approx. 0.4mm - 2.5mm thickness x approx. 160mm width, as well as narrow strips up to approx. 4mm can be processed. Feed length can be adjusted as required via the control unit.

- with ram round column guide

- with automatic central lubrication

- High-speed: up to 400 strokes min-1

- motorized adjustable fixed stop (bottom can be adjusted by hand/motorized)

- Operating modes such as continuous stroke and/or single stroke

Equipment:

- 1x hydraulic unit

- 2x control cabinets

*

Listing

Germany

Germany

18,260 km

Orbital Cold Forming Machine

KUHNE MASCHINENBAUKEPK-1

Call

Condition: used, Technical details:

shaft length: max. 30 mm

capacity: 600 ST/min

wire diameter max.: 5 mm

working dimensions: 30 mm

dimensions electric cabinet LxWxH: 1,45x0,55x2,1 m

dimensions of machine: 2,95x1,5x2,15 m

dimensions of coil: 1,15x1,15x1,15 m

Orbital Cold Forming Machine! - Not not suitable for screw production!!!!!

- mechanic cold flow press / machine is unused!!!!

- Steel core bullets

- Rivets (almost all types: flat rivets, punch rivets, precision rivets, flat head rivets, etc. -----à not for manufacturing semi-hollow rivets, because you will need 2 forming stages, model KEPK - 1 however only has 1 forming stage.

- bolts

- Pins, chain pins (short)

- Lead sheath-weighting for bullets (with straight frames front and rear)

Nksdpsu Nfrcjfx Ad Njt

- plant like new / never used!

accessories:

- coil, manual

Machine can be demonstrated under power.

Please send us your enquiry what you are going to manufacture with that machine. You can also send us a drawing in order to check it if it is possible.

*

Listing

Siedlce

Siedlce

17,614 km

Circular saw sharpener

CORMAKJMY-870

Call

Condition: new, Year of construction: 2025, The JMY-870 sharpener is an excellent tool for sharpening circular saw blades. The sharpener is equipped with a durable, diamond grinding disc. This ensures precise and effective sharpening. The solid cast iron construction guarantees stability during work, and the adjustment of the angle of inclination and the angle of the saw provide full control over sharpening. Additionally, rubber pads under the feet minimize noise, ensuring comfort of work. Standardly equipped with a 125 mm diamond grinding wheel, it is suitable for sharpening saws from 80 mm to 700 mm in size.

The most important advantages of this circular saw sharpener

The sharpener is equipped with a high-quality 125 mm diamond grinding disc, which guarantees extraordinary precision when sharpening carbide saws.

The cast iron base ensures stability during work. Thanks to this, the user can be sure that the device will not wobble or vibrate during sharpening.

The sharpener is equipped with a tilting blade support, which allows you to adjust the angle of inclination from -35° to +45°. This allows you to precisely adjust the blade setting to the specific needs of the user.

An additional function is the ability to set the saw's incisal angle in the range from +85° to -30°, which allows you to adapt the tool to different types of saws.

The saw sharpener has been designed with work comfort in mind. Thanks to the rubber pads under the feet, the device works almost silently, which has a positive effect on the comfort of use.

Application of the saw sharpener

The sharpener is designed for sharpening circular saws. The operation of the device is intuitive and simple, which means that even people who are not familiar with the technique will be able to use this tool. The JMY-870 circular saw sharpener is a professional tool that ensures high quality saw blade processing and work comfort. Thanks to the various adjustment options, it is an excellent choice for people who require a precise and effective tool for sharpening various types of saw blades.

THE SET INCLUDES A DIAMOND GRINDING WHEEL!

Technical parameters

MIN/MAX SAW DIAMETER 80mm - 700mm

HORIZONTAL SAW BLADE HOLDER TILTING -35° to +45°

GRINDING SET TILTING -20° to +20°

GRINDING DISC ROTATIONAL SPEED 2850 rpm

DISC DIMENSIONS 125 x 10 x 13 mm

MOTOR POWER 0.25 kW

SUPPLY VOLTAGE 230 V

Nkedpfxou Tti Is Ad Nst

NET WEIGHT 21 kg

DEVICE DIMENSIONS 750 x 750 x 350 mm

Listing

Siedlce

Siedlce

17,614 km

Laser welding machine 2000W

CORMAKWL2000

Call

Condition: new, Year of construction: 2025, A compact device using the FIBER technology, designed for welding many types of metals with precision far exceeding traditional welding methods.

Advanced technological solutions used in the offered welding machine allow to perform high-quality and repeatable welding welds of thin-walled materials and parts without the risk of deformation.

Advantages of a laser welding machine

Easy to use - thanks to the applied solutions and well-thought-out structure, the operator can start working after a short training

Low indirect radiation, when working, it is enough to wear protective glasses to filter strong light,

Welding much faster than with traditional methods, productivity can be increased by up to 3 to 10 times

Concentrated beam: slight structure change due to the small heat-affected area,

The repeatability of the welds, the welding seam is nice, the welds are high strength.

Very thin materials such as 0.5mm stainless steel can be welded.

Option of welding with or without wire.

Technical parameters

Maximum power 2000W

Laser wavelength 1080nm

Depth of penetration (stainless steel 1 m/min) 4.57mm

Depth of penetration (black steel 1 m/min) 3.59mm

Depth of penetration (aluminum 1 m/min) 4.0mm

Depth of penetration (brass 1 m/min) 4.0mm

Welding speed 0-120mm/s

Automatic Wire Feeder Ø 0.8 - 1.6mm

Maximum power consumption ≤6.0kW

Cooling system aqua

Working voltage 400V

Shielding gas consumption 20L/min

Dimensions 600 x 1100 x 1100mm

Weight approx. 185 kg

LATEST GENERATION WELDING HEAD

WOBBLE head;

Automatic wire feeder included;

Adjustable spot size 0-5mm;

The powerful welding head allows many types of beam guidance: -, ○, ◎, ⊙, 8, ∞;

Integrated connections for shielding gases and cooling system,

Interchangeable nozzles allow for welding at different angles,

10 m of optical fiber that connects the head to the source,

Adjustment of welding parameters directly in the head without having to go to the control panel;

Full ergonomics - thanks to the light and flexible design, the head can perform welds even in hard-to-reach places;

Easy to service - quick and easy replacement of the protective lens.

Automatic wire feeder included

The wire feeding system is synchronized with the welding machine software. The task of the feeder is to feed the filling, thanks to which the operator can focus 100% on the work of the head.

Set includes

laser welding machine with built-in cooling system

welding gun with adjustable focus and a set of accessories

Fiber laser source

automatic wire feeder

set of cables

starter kit of nozzles and protective glasses

Nksdpfxsizr Rlj Ad Net

THICKNESS OF WELDED MATERIALS

Material

WELDER POWER

1000W 1500W 2000W

Stainless steel 0.5-3.0mm 0.5-4.0mm 0.5-5.0mm

Black steel 0.5-2.5mm 0.5-3.5mm 0.5-4.5mm

Galvanized steel 0.5-2.5mm 0.5-3.0mm 0.5-4.0mm

Aluminum 0.5-1.2mm 0.5-1.8mm 0.5-4.0mm

Brass 0.5-1.2mm 0.5-1.8mm 0.5-2.5mm

Trust Seal

Dealers certified through Machineseeker

Listing

Zaandam

Zaandam

18,550 km

Perforator

Hang470 PLC

Call

Condition: excellent (used), Year of construction: 2007, operating hours: 10 h, machine/vehicle number: 103414, High-performance automatic production line for ring binders. Sheet feeder (vacuum feeder), creasing station, gripping hole punching unit (finger hole eyeletting machine), double riveting station, operator control panel (Fanuc QuickPanel View), mechanical feeding unit, single riveting station, folding station. Cover height: 120 – 400 mm; cover width: 300 – 820 mm; material thickness: min. 1 mm – max. 3.5 mm; rivet spacing: 90 – 300 mm.

Nkodpfx Ajx Apb Hed Net

Listing

Bitburg

Bitburg

18,682 km

Multiple Combination

Holzkraft SCMCU 410 Elite S 32 Tersa

Call

Condition: new, Year of construction: 2026, Maximum equipment for the professional. Multiple combination with TERSA cutterhead, miter cutting device and swiveling milling spindle.

Ø 350 mm main saw blade with 118 mm max. cutting height, which is also achieved with the scoring saw blade installed

Scoring device with separate motor and Ø 120 mm saw blade, easily and conveniently adjustable from the outside

High-precision sliding carriage made of anodized aluminum on hardened and drilled steel guide rails

Large boom (1200 x 650 mm) with roller and extendable aluminum telescopic fence up to max. 3300 mm

Sawing unit swivels from 90° to -45

Pivoting milling spindle from 90° to -45° backwards into the milling fence

Four milling speeds

Right-left rotation of the milling spindle

Quick change to thickness planer thanks to parallel opening jointer tables

2-stage feed in the thicknessing table

Sharp toothed steel infeed roller for uniform wood infeed

Three independent industrial motors

With separate saw-parallel fence and separate feeder fence

With lockable main switch

Equipment details:

Nkedpfx Adecnxa Se Not

Format fence

Immediate control

Boom

Boom with angle-adjustable telescopic lay-off stop

with graduation

Sliding carriage with ball contact system

made of anodized aluminum

guides in hardened and ground steel F550S, 15% harder than conventional steel

guides riveted and not glued

light running, low noise and reliable

10 years HOLZKRAFT warranty on wear of hardened guideways

cast iron double cradle saw unit

height adjustment via dovetail guide

extremely robust and torsionally stiff for precise cuts

close to the saw blade, mounted on both sides

height and inclination adjustable up to 45

standard scoring unit with separate scoring motor 0,55 kW

double cradle scoring unit

large-dimensioned swiveling double cradle milling unit made of cast iron

milling stop

heavy professional design

the high quality cast iron fence is supplied with fine adjustment as standard

3-fold positionable for fast readjustment of the setting

with fine adjustment via toothed rack, numerical display and aluminum fraise stop jaws

Planer

steel infeed rollers with helical teeth for a constant and uniform wood infeed

solid backstops prevent the backstroke of workpieces

4-knife torsion shaft ensures an optimal planing pattern

table lips for a quieter running

Tersa planing cutterhead

No more adjusting and screwing

Change of planing knives in seconds

Self-locking

Especially low noise

Thicknessing table

The thicknessing table is mounted on four large-dimensioned spindles, which ensure high stability under all working conditions.

Due to the special lifting device, the table position is perfectly maintained even without locking.

Rip fence

with fine adjustment and quick clamping

stable round bar guide made of ground steel

reversible aluminum ruler

no measuring gap, guide rods are overlapping

Separate dressing fence

large professional design (1800 x 150 mm)

0-45° swiveling

with quick adjustment

stable round bar guide made of ground steel

simultaneous opening

Art: No. 5500557

Listing

Radom

Radom

17,719 km

Eyeletting machine

Hang 101-50Eyeletting machine

Call

Condition: good (used), Hang 101-50 Eyeletting machine

The machine is in perfect condition and ready to use.

Technical specifications:

1 eyeletting head (Hang 271 rivet, hole diameter approx. 6mm)

Maximum capacity: 20 sheets

230V power supply

Front and side margins

Njdpex N I Rpjfx Ad Nekt

Operation: foot pedal or hand switch.

The machine punches and crimps the eyelet in a single pass.

Automatic eyelet feeding.

Listing

Germany

Germany

18,654 km

CHIRON FZ 12 KW

CHIRONFZ 12 KW

Call

Condition: ready for operation (used), Year of construction: 2012, travel distance X-axis: 550 mm, travel distance Y-axis: 320 mm, travel distance Z-axis: 360 mm, table load: 500 kg, spindle speed (max.): 12,000 rpm, tool weight: 5,000 g, number of axes: 3, This 3-axis CHIRON FZ 12 KW vertical machining center was manufactured in 2012. It features a high-speed spindle with a maximum speed of 12,000 rpm and a rapid traverse speed of up to 60 m/min on the Z-axis. The machine includes a 24-slot automatic tool changer and can handle a table load of up to 500 kg. Ideal for precision machining tasks. Contact us for more information about this machine.

Machine Benefits

Technical Machine Benefits

• Controlled axes: 6 axes

• Reach: 704 mm

• Acceleration/deceleration: 0 to 12000 min-1 in 0. 6 seconds

• Clamping surface: 820 x 440 mm²

• Drilling capacity in st 60: Ø 16 mm

Nkodpfx Asx Nr I Eod Not

• Tapping: m 16

• Milling capacity in st 60: 80 cm³/min

• Acceleration: x & y axis 0. 7 g, z axis 1. 0 g

Extra Information

Movement

Axis Movement Range and Speed:

J1: 340°/360° (option) at 350°/s

J2: 200° at 350°/s

J3: 388° at 400°/s

J4: 380° at 450°/s

J5: 240° at 450°/s

J6: 720° at 720°/s

Allowable Load Moment:

J4 & J5: 11.9 Nm

J6: 6.7 Nm

Repeatability: +/- 0.02 mm

Maximum Speed

J1: 195°/s

J2: 175°/s

J3: 180°/s

J4 & J5: 400°/s

J6: 600°/s

Allowable Load Moment

J4 & J5: 7.7 Nm

J6: 9.8 Nm

Tools

Automatic Tool Changer:

Tool Pockets: 24

Tool Change Time: approx. 0.9 s

Chip-to-Chip Time: approx. 2.4 s

The workpieces are supplied via an automated feeding system and sequentially loaded into the Chiron machining centres by two Fanuc industrial robots. Once the machining processes are complete, they are removed again. The robots then transfer the components to a transfer system, which transports them to the downstream cleaning system. The integrated washing line ensures reliable cleaning of the components in accordance with the defined cleanliness specifications. After the washing process, two synchronously operating Fanuc robots take over the cleaned parts in the rear section of the system. Depending on the process specifications, these are either palletised automatically or further processed in a downstream step, for example by riveting. The entire system operates fully automatically.

We make it easier for you to find: "wobble riveting"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Wobble Riveting (118)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you