Used Turning In Machining for sale (63,988)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Burgoberbach

Burgoberbach

18,497 km

3-axis CNC universal machining center

Deckel MahoDMU 60 E

Call

Condition: used, Year of construction: 1997, operating hours: 10,227 h, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 525 mm, travel distance Z-axis: 500 mm, table width: 540 mm, table length: 1,000 mm, overall weight: 4,500 kg, spindle speed (max.): 12,000 rpm, For sale is a machining centre from Deckel Maho, model DMU 60 E.

The machine is fully functional and ready for immediate use. Particularly noteworthy are the low program run hours.

Technical data:

Year of manufacture (estimated): 1997

Control: HEIDENHAIN TNC 426PB

Control ON: 8,283 h

Machine ON: 31,148 h

Program run: 10,227 h

Total power requirement: approx. 26 kVA

Travel X-axis: 600 mm

Travel Y-axis: 525 mm

Travel Z-axis: 500 mm

Clamping surface: 1,000 x 540 mm

Max. table load: 350 kg

Spindle speed range: 20 - 12,000 rpm

Tool holder: SK 40

Feed speed: 20 - 10,000 mm/min

Lhsdpfx Aew I R I Heffjr

Rapid traverse X/Y-axis: 18 m/min

Rapid traverse Z-axis: 15 m/min

Tool changer: 25 positions

Dimensions (L x W x H): approx. 2.95 x 2.1 x 2.26 m

Weight: approx. 4,500 kg

Transport and loading can be organised throughout Europe at additional cost, upon request.

All prices are subject to VAT.

Inspection possible by appointment. Contact us — our team will be happy to assist you.

Trade-in or exchange possible!

Machinery purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINERY AND MORE.

Do you require a high-quality yet affordable metalworking machine for your production? Or are you looking to sell yours?

For more information or contact options, please visit our website.

Listing

Denmark

Denmark

18,026 km

Vertical Machining Centre

HAASUMC-750

Call

Condition: ready for operation (used), Year of construction: 2014, operating hours: 60,000 h, Control Unit

Brand HAAS

Main Drive

Number of axis 3

Spindle Speed 12000 RPM

Lhedpfx Afjx Ixh Nofsr

Tool taper BT 40

This 5-axis HAAS UMC-750 was manufactured in 2014. It features a vertical machining center with a 12000 rpm spindle, BT40 tooling, and a 70-tool holder capacity. Additional highlights include coolant through spindle, a probe, toolsetter, and high-speed machining capabilities. Consider the opportunity to buy this HAAS UMC-750 vertical machining center. Contact us for more information about this machine.

Application Types

Milling

Listing

Germany

Germany

15,455 km

Machining Center - Vertical

HAASVF-2SSHE

Call

Condition: used, Year of construction: 2005, Technical details:

x-travel: 750 mm

y-travel: 406 mm

z-travel: 508 mm

weight of the machine ca.: 4 t

Ledpfsx Iwr Tsx Affshr

bore spindle turning speed range: 12.000 U/min

HAAS VF-2 is a 3-axis machining center designed for precision, high accuracy and reliability.

*

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Trittau

Trittau

15,455 km

Milling machining centers - vertical

LEADWELLVMC 25

Call

Condition: used, Year of construction: 1995, x-travel 650 mm

y-travel 410 mm

Lodex Iwg Repfx Affohr

z-travel 410 mm

Control Mitsubishi Meldas 50 M

max. turning speeds 6.000 min/-1

tool taper SK 40

In our opinion, the machine is in good used condition and can be inspected

under power by appointment.

Accessories, tools and clamping devices shown are only included in the scope

of delivery

if this is noted in the additional information.

Subject to changes and errors in the technical data and information as well

as

prior sale!

Listing

Burgoberbach

Burgoberbach

18,497 km

Universal machining center

DMGDMU 50 V 5 Achsen

Call

Condition: good (used), For sale is a CNC milling machine DMG DMU 50 V with Heidenhain 426/430 control, 5 axes. The item is in good condition.

Technical specifications:

Travel X-axis: 500 mm

Travel Y-axis: 380 mm

Travel Z-axis: 400 mm

Table: NC rotary/swivel table

Rotary/swivel axes: B-axis approx. -10° / +95°

C-axis (rotation): 360°

Max. workpiece weight: approx. 200 kg

Table surface: Ø 500 x 380 mm

Main spindle: SK 40 (ISO 40)

Lhedpoxvzy Uefx Affer

Max. spindle speed: approx. 10,000 rpm

Max. tool length: approx. 280 mm

Max. tool weight: approx. 6 kg

Transport dimensions: 2.45 x 1.76 x 2.38 m

Machine weight: approx. 3,500 kg

Total power requirement: approx. 17 kW

Transport and loading can be arranged Europe-wide for an additional charge, if required.

Prices exclude VAT.

Inspection possible by appointment. Please contact us, our team will be happy to assist you.

Trade-in or exchange possible!

Machinery Purchase / Sales

PURCHASE & SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or would you like to sell yours?

For more information or contact options, please visit our website.

Listing

Slovenia

Slovenia

18,318 km

Horizontal Turning Machine

TakamazXW-150

Call

Year of construction: 2010, condition: ready for operation (used), General Data

Machine weight 6500 kg

Control Unit

Brand FANUC

Model 21i-TA

Main Drive

Lhjdpox Iximsfx Affjr

Number of spindles 2

Spindle speed range 4000

Number of axis 4

Movement

X-Axis Movement 160 mm

Z-Axis Movement 180 mm

Turret

Number of turrets 2

Tools

Number of index 12

This 4-axis Takamaz XW-150 was manufactured in 2010, a robust horizontal turning machine ideal for precision tasks. If you are looking to get high-quality turning capabilities, consider the Takamaz XW-150 machine we have for sale. Contact us for more information.

Application Types

Turning

Listing

Trittau

Trittau

15,455 km

Milling machining centers - vertical

RÖDERSRFM 600 DS

Call

Condition: used, Year of construction: 2008, x-travel 600 mm

y-travel 450 mm

z-travel 300 mm

Lhodpfx Afex Iwg Defer

spindle tunring speed 42.000 U/min

In our opinion, the machine is in good used condition and can be inspected

under power by appointment.

Equipment:

- Extraction system, Keller

- Pallet system, Röders RC 2

Accessories, tools and clamping devices shown are only included in the scope

of delivery

if this is noted in the additional information.

Subject to changes and errors in the technical data and information as well

as

prior sale!

Listing

Burgoberbach

Burgoberbach

18,497 km

Universal machining center 3+2 axis

DMG MORIDMU 35 M TNC 530 / 625 h

Call

Condition: like new (used), Year of construction: 2009, operating hours: 625 h, functionality: fully functional, travel distance X-axis: 350 mm, travel distance Y-axis: 240 mm, travel distance Z-axis: 340 mm, total height: 2,100 mm, total length: 2,000 mm, total width: 1,700 mm, overall weight: 1,600 kg, For sale: 3+2 axis machining center by DMG, model DMU 35 M

Lodpfx Afex Aiiqefshr

This machine comes from an educational institute and was primarily used for training in control operation and setup. Note the exceptionally low spindle hours.

Technical specifications:

Year of manufacture: 2009

Spindle hours: 625

Machine no.: 18065358844

X-axis travel: 350 mm

Y-axis travel: 240 mm

Z-axis travel: 340 mm

Feed rate: Infinitely variable up to 5,000 mm/min

Rapid traverse: 5 m/min

Servomotors for X, Y & Z axes

Clamping area: Ø 400 x 280 mm

Rotary range: 360° (mechanical)

Table clamping: +105 / -150 (mechanical)

Max. table load: 100 kg

Tool changer: Manual change

Tool holder: SK 40

Tool clamping: pneumatic/mechanical

Footprint: 3,800 x 3,600 x 2,100 mm

Transport dimensions: approx. 2,000 x 1,700 x 2,100 mm

Weight: 1,600 kg

Transport and loading can be organized Europe-wide upon request and at an additional charge.

Prices are subject to VAT.

Inspection is possible by appointment. Please contact us—our team will be happy to assist you.

Trade-in or exchange possible!

Machinery buying/selling

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Do you need a high-quality yet affordable metalworking machine for your production? Or do you want to sell your equipment?

For further information or contact options, please visit our website.

Listing

Germany

Germany

18,384 km

Universal Machining Centre

DMGDMU 50 eVo

Call

Condition: ready for operation (used), Year of construction: 2004, operating hours: 15,652 h, General Data

Machine weight 6500 kg

Control Unit

Brand HEIDENHAIN

Model ITNC 530

Main Drive

Number of axis 5

Spindle Speed 18000 RPM

Tool taper SK 40

Movement

X-Axis Movement 500 mm

Z-Axis Movement 380 mm

Y-Axis Movement 480 mm

Lhedpfsx Ixiaex Affor

This 5-axis DMG DMU 50 eVo was manufactured in 2004. It features X, Y, and Z axis travel of 500/420/380 mm, rapid traverse of 50 m/min, and a spindle speed up to 18,000 rpm. Equipped with a SK40 tool holder, 32-position tool magazine, and internal coolant supply at 40 bar. Consider the opportunity to buy this DMG DMU 50 eVo universal machining centre. Contact us for more information about this machine.

Application Types

Milling

Listing

Burgoberbach

Burgoberbach

18,497 km

Machining center 5-axis CNC 92 WKZ

Deckel MahoDMU 50 eVolution 30.000 1/min Spindel

Call

Condition: good (used), Year of construction: 2004, operating hours: 39,000 h, functionality: fully functional, travel distance X-axis: 500 mm, travel distance Y-axis: 420 mm, travel distance Z-axis: 380 mm, controller model: Heidenhain Mill Plus IT, total height: 5,600 mm, total length: 9,000 mm, overall weight: 6,000 kg, For sale is a 5 axis machining center

of the Makre DMU and type 50 eVolution

Please note the GMN high frequency spindle

spindle HCS 30.000 /15 and the 92-fold tool changer

The machine is in good condition and fully functional

Technical data

Year of construction: 2004

Operating hours: approx. 39,000 h

Control system: Heidenhain MillPlus IT

Table size: approx 500 mm ⌀

Traverse paths:

X-axis: 500 mm

Y-axis: 420 mm

Z-axis: 380 mm

A-axis: 0-180°

C-axis: 360 °

Tool holder: HSK 50

Spindle speeds: max: 30,000 1/min

Frequency: 500 Hz

Power: 15 kW

Lhedpfxotyit Es Affer

Tool places: 92

NO chip conveyor

Space requirement according to drawing: 9,000*5,600 mm

Transport dimensions: 2,800*3,700*2,800 mm

Weight: 6,000 kg

On request, transport and loading can be organized throughout Europe for an additional charge.

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Fzho0bc

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For more information or to contact us, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

5-axis CNC machining center

DMU70 V IKZ 60 fach wkz wechsler

Call

Condition: used, Year of construction: 1999, operating hours: 54,418 h, functionality: fully functional, travel distance X-axis: 710 mm, travel distance Y-axis: 520 mm, travel distance Z-axis: 520 mm, rotational speed (max.): 18,000 rpm, For sale is a 5-axis CNC machining center of the DMU brand and type 70 V

The machine is fully functional and ready for immediate use

Technical data

Year of construction: 1999

Travel x: 710 mm

Travel Y: 520 mm

Travel Z: 520 mm

Control: Heidenhain TNC 426

Switch-on hours: 54,418 h

Program run: 17,396 h

Tool changer: 60 times

Tool holder: HSK 63

Spindle speed: 18,000 1/min

Included in the offer:

Chip conveyor

3D probe

Belt filter

Lhjdpfxeuu Hlms Affer

IKZ system

Hexagon tool measurement (installed)

On request, transportation and loading can be organized for an extra charge. can be organized throughout Europe.

Prices plus VAT

Viewing possible by appointment. Please contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

5-axis CNC machining center

DMG MORIDMU 60 P 60 WKZ Wechsler

Call

Condition: used, Year of construction: 1998, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 650 mm, travel distance Z-axis: 550 mm, rotational speed (max.): 12,000 rpm, overall weight: 7,500 kg, For sale: CNC 5-Axis Machining Centre, manufacturer DMG, model DMU 60 P

The machine is fully operational and ready for immediate use. In 2021, a new spindle was installed, and all required maintenance has been carried out.

History:

2019: New ball screw (KGT)

2021: New spindle

2022: Single-shift operation

2023: Occasional job orders

2024: Taken out of operation but remained connected to power

12/2025: Dismantled, cleaned, and stored

Technical Specifications:

X travel: 600 mm

y travel: 650 mm

z travel: 550 mm

Control unit: Heidenhain TNC 426

Spindle speed: max. 12,000 rpm

Spindle drive power: 15 kW

Max. torque: 130 Nm

Tool holder: SK 40

Table diameter: 630 mm

Max. table load: 500 kg

Number of tool pockets: 60 positions

Max. tool length: 350 mm

Rapid traverse (X/Y/Z): 24 m/min

Feed rate: 20 - 10,000 mm/min

Total connected load: 44 kVA

Space requirements: approx. 7.0 x 6.0 x 2.7 m

Machine weight: approx. 7.5 t

Please note: Vices or clamping fixtures are not included in this offer.

Upon request, we can organise transport and loading, at an additional cost. Europe-wide service available.

All prices are subject to VAT.

Inspection is possible by appointment. Please contact us—our team is happy to assist you.

Trade-in or exchange possible!

Machinery Purchase / Sales

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your manufacturing needs? Or are you looking to sell yours?

Ledpswbhq Hofx Affjhr

For more information or contact options, please visit our website.

Listing

Burgoberbach

Burgoberbach

18,497 km

Universal machining center

MikronVCE 600 PRO BJ 2012

Call

Condition: excellent (used), Year of construction: 2012, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 540 mm, rapid traverse X-axis: 24 m/min, rapid traverse Y-axis: 24 m/min, rapid traverse Z-axis: 20 m/min, total height: 2,720 mm, total length: 3,160 mm, total width: 2,240 mm, For sale: 3-axis CNC milling machine, Mikron VCE 600 Pro

The machine is in excellent condition and ready for immediate use.

Technical data:

Year of manufacture: 2012

Control: Heidenhain ITNC 530

Operating hours: 22,840

Spindle hours: 10,902

X-axis travel: 600 mm

Y-axis travel: 500 mm

Z-axis travel: 540 mm

Max. spindle speed: 10,000 rpm

Tool holder: SK40

Tool magazine:

Clamping surface: 700 x 500 mm

Dimensions: 3,160 x 2,240 x 2,720 mm

Weight: 4,800 kg

Included in the offer: Chip conveyor, interior extraction, through-spindle coolant system, handwheel control, coolant gun, 3D probe, Renishaw tool measurement system

Not included: Clamping devices, tool holders

Lhsdpfx Aexnprvjffsr

Transport and loading can be organised across Europe at additional cost upon request.

Prices are quoted net plus VAT.

Inspection possible by appointment. Please contact us – our team will be happy to assist you.

Trade-in or exchange possible!

Machinery Purchase / Sale

BUY / SELL PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you want to sell yours?

For further information or contact details, please visit our website.

Listing

Burgoberbach

Burgoberbach

18,497 km

Milling machine machining center

HERMLEUWF 802 M

Call

Condition: good (used), Year of construction: 1994, functionality: fully functional, feed length X-axis: 500 mm, feed length Y-axis: 430 mm, feed length Z-axis: 400 mm, spindle speed (max.): 3,550 rpm, spindle speed (min.): 17 rpm, For sale is a CNC / conventional milling machine of the Hermle brand and type UWF 802 M

Ljdjrvitlopfx Affehr

The machine is in good - very good condition and ready for immediate use

Technical data

Year of construction: 1994

Control: Heidenhein TNC 124

Clamping: Rigid angle table

Speed: 17 to 3550 rpm

Feed: Stepless

Drive power: 6 KW

Travel X 500 mm

Travel Y: 430 mm

Z travel: 400 mm

Tool holder SK40

Dimensions: L*W*H: 1800*1800*1900 mm

Weight: 1.8 t

On request, loading and transport (Europe-wide) can be organized for an additional charge.

Prices plus VAT

Viewing possible by appointment. Please contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

Machining center

DMC65 V linear Gentry HSC Spindel 18.000

Call

Condition: good (used), Year of construction: 2001, travel distance X-axis: 650 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 500 mm, For sale is a machining center with Gentry design of the DMC brand and type 65V linear

Particularly noteworthy is the high-speed spindle with 18,000 rpm

The machine is in good condition and fully functional

Technical data

Commissioning: 2001

Control: Heidenhain TNC 430 i

Table size: 850x600 mm

Tool holder: SK 40

Tool changer: 30-fold

Travel X/Y/Z: 650x500x500 mm

Max. speed: 18,000 1/min

Feed rate max: 60 m/min

Dimensions lxwxh: 2650x2700x2500 mm

Weight: 10,500 kg

Lsdpfxot I Tple Affshr

On request, for an extra charge, dismantling, loading & transport can be organized for you throughout Europe

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

BUYING / SELLING PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

Universal machining center 16,000 rpm

Deckel MahoDMU 50 eVolution 60 WKZ

Call

Condition: good (used), Year of construction: 2000, operating hours: 53,776 h, functionality: fully functional, travel distance X-axis: 500 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 380 mm, rotary table diameter: 500 mm, rotational speed (max.): 18,000 rpm, For sale is a 5-axis simultaneous milling machine from Deckel Maho, model DMU 50 eVolution.

The machine is in good condition and ready for immediate use.

Ljdjwxd Agopfx Affjhr

Technical Data:

Year of manufacture: 2000

Control: MillPlus

Power-on hours: 53,776 h

Spindle hours: 18,512 h

X-axis: 500 mm

Y-axis: 400 mm

Z-axis: 380 mm

B-axis: 0-180°

C-axis: 360°

Clamping surface: Ø 500 mm

Max. table load: 200 kg

Spindle taper: SK40

Max. speed: 18,000 rpm

Spindle power: approx. 15 kW

Tool magazine: 60 slots

Dimensions: approx. 3,400 x 2,400 x 2,500 mm

Weight: 5,500 kg

Transport and loading can be arranged Europe-wide at an additional cost upon request.

Prices are subject to VAT.

Viewing possible by appointment. Please contact us—our team is happy to assist you.

Trade-in or exchange possible!

Machinery Purchase / Sale

BUYING / SELLING OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or would you like to sell your equipment?

For further information or contact options, please visit our website.

Listing

Burgoberbach

Burgoberbach

18,497 km

3-axis vertical machining center

MikronUM 600

Call

Condition: good (used), Year of construction: 1997, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 450 mm, For sale is a machining center from Mikron, model UM 600.

The machine is in good condition and immediately ready for operation.

Technical data:

Year of manufacture: 1997

Travel X: 600 mm

Travel Y: 500 mm

Travel Z: 450 mm

Clamping surface: 900 x 530 mm

Max. table load: 300 kg

Control: Heidenhain TNC 426

Tool holder: SK 40

Max. spindle speed: 6,300 rpm

Rapid traverse X / Y / Z: 15 m/min

Lodpswx Naqjfx Affjhr

No tool changer installed; instead, a support arm for conversion of the milling head is mounted (see picture 4).

Setup dimensions (L x W x H approx.): 2.5 x 2.2 x 2.1 m

Weight approx.: 3.7 t

Accessories such as tool holders and vices are not included in the offer.

Transport and loading can be organized upon request at an additional charge, Europe-wide.

Prices plus VAT.

Inspection by appointment possible. Please contact us – our team is happy to assist you.

Trade-in or exchange possible!

Machinery purchase/sale

BUYING AND SELLING OF PRODUCTION AND METALWORKING MACHINES, ETC.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you wish to sell yours?

For further information or contact options, please visit our website.

Listing

Burgoberbach

Burgoberbach

18,497 km

4-axis machining center

AXAVario 2 Frästische CNC Fräsmaschine

Call

Condition: good (used), Year of construction: 1999, For sale is a horizontal machining center from Axa of the Vario type with 2 milling tables.

The machine is in good condition and has done little "heavy machining" (was mainly used for drilling and thread cutting).

Technical data:

Year of manufacture 1999

Control: Heidenhain TNC 410 M digital

Table dimensions 2030 mm *500 mm

Maximum table load (evenly distributed) 800 kg

Min. speed 30 1/min

Max. speed 10.000 1/min

Drill length on X-axis (mechanical feed) 1760 mm

Drill length on Y-axis (mechanical feed) 500 mm

Drill length Z-axis (mechanical feed) 620 mm

Machine dimensions:

Height: 3900 mm

Length: 2900 mm

Lsdpfx Aett Abmeffshr

Width: 3000 mm

Weight: 9 tons

SCOPE OF DELIVERY/EQUIPMENT

1 spindle version SK 40 DIN 69 871 A

1 switch cabinet (integrated in the rear of the machine)

Ball screws: Made by Deutsche Star

Central lubrication unit: Bielomatik

Hydraulic unit: Hydac

RTA 2-300

MK-3 tailstock manually operated

Electric handwheel HR 410

Scraper belt conveyor discharge side right

Measuring probe TS 630

WORKPIECE HOLDERS NOT INCLUDED IN THE OFFER

Prices plus value added tax

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

CNC turning-milling center 6 AGW

GildemeisterCTX 310 Eco (nur 3.350 h)

Call

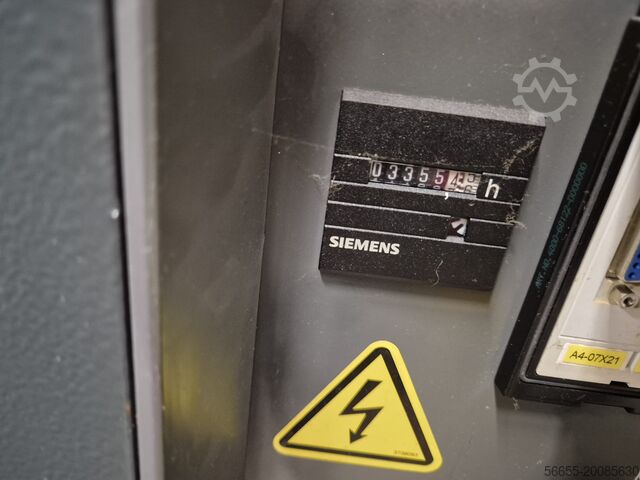

Condition: excellent (used), Year of construction: 2012, operating hours: 3,355 h, functionality: fully functional, turning length: 450 mm, turning diameter: 200 mm, spindle speed (max.): 5,000 rpm, spindle bore: 51 mm, travel distance X-axis: 160 mm, travel distance Z-axis: 450 mm, overall weight: 3,800 kg, For sale is a CNC lathe from the brand Gildemeister, model CTX 310 Eco.

The machine is in excellent condition and ready for immediate use.

Technical specifications:

Year of manufacture: 2012

Operating hours: 3,355 h (see picture)

Control: SIEMENS SINUMERIK 810D Powerline

Max. turning diameter: 200 mm

Max. swing diameter over bed: 330 mm

Max. turning length: 450 mm

X-axis travel: 160 mm

Main spindle speed: 5,000 rpm

Spindle bore: 51 mm

Turret: 12-station turret (VDI 30)

Live tooling: 6 driven tool stations

Live tool speed: approx. 4,500 rpm

Rapid traverse X/Z: 30/30 m/min

Dimensions: approx. 4200 mm x 1700 mm x 2300 mm

Machine weight: approx. 3,800 kg

Chip conveyor included in the offer.

Tool holders not included in the offer (can be offered additionally).

Transport and loading can be organized across Europe upon request, at extra cost.

Prices are exclusive of VAT.

Inspection by appointment possible. Contact us — our team is happy to assist you!

Trade-in or exchange possible!

Machinery trading

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Lhjdoxf T N Tepfx Affer

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you wish to sell yours?

For more information or contact options, please visit our website.

Listing

Burgoberbach

Burgoberbach

18,497 km

Machining center 5-axis

Deckel MahoDMU 50 M TNC 124

Call

Condition: excellent (used), Year of construction: 2002, functionality: fully functional, travel distance X-axis: 500 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 400 mm, spindle speed (min.): 50 rpm, spindle speed (max.): 4,500 rpm, For sale is a Deckel Maho machining center, type DMU 50 M with path control and manual rotation axes

The machine is in very good condition, fully functional and ready for immediate use. Particularly noteworthy is the possibility of working in an open cabin

Technical data:

Year of construction: 2002

Control: Heidenhain TNC 124

X-axis: 500 mm

Y-axis: 400 mm

Z-axis: 400 mm

Feed speed: 5,000 mm/min

Rapid traverse: 5 m/min

Tool holder: SK 40

Clamping surface: Ø 700 x 500 mm

Rotation range: 360 ° (mechanical)

Swivel range: +90/ - 15 ° (mechanical)

Max. load: 200 kg

Space requirement: 4,000 x 3,500 x 2,518 mm

Transport dimensions: approx. 2,500 x 1520 x 2,200 mm

Weight: 2,600 kg

Additional tool holders available on request

Transport and loading can be organized on request, at an extra charge. can be organized throughout Europe.

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Lodpfxou Unh Ij Affehr

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

3-axis machining center with extraction

IngersollOPS 800 HSC-42.000 1/min

Call

Condition: good (used), Year of construction: 2004, functionality: fully functional, travel distance X-axis: 800 mm, travel distance Y-axis: 700 mm, travel distance Z-axis: 500 mm, For sale is a 3-axis CNC machining center of the brand Ingersoll and type OPS 800.

Ideal for the production of graphite electrodes thanks to the built-in high-speed spindle

Lsdpfxjuu Rtho Affjhr

The machine is fully functional and ready for immediate use

Technical data

Year of construction: 2004

X-path: 800 mm

Y-path: 700 mm

Z-path: 500 mm

Control: ANDRON

Spindle speed: 42,000 min/-1

Tool changer: 36-fold

Tool holder: HSK 63

incl.

Graphite extraction:

Chip trays

Cooling system

WKZ not included

For sale is a 3-axis CNC machining center of the brand Ingersoll and type OPS 800.

Ideal for the production of graphite electrodes thanks to the built-in high-speed spindle

The machine is fully functional and ready for immediate use

Technical data

Year of construction: 2004

X-path: 800 mm

Y-path: 700 mm

Z-path: 500 mm

Control: ANDRON

Spindle speed: 42,000 min/-1

Tool changer: 36-fold

Tool holder: HSK 63

incl.

Graphite extraction:

Chip trays

Cooling system

WKZ not included

On request, transportation and loading can be organized for an extra charge. can be organized throughout Europe.

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Trust Seal

Dealers certified through Machineseeker

Listing

Burgoberbach

Burgoberbach

18,497 km

Milling Machine / Machining Center CNC

MAHOMH 300 C

Call

Condition: repair required (used), Year of construction: 1987, For sale is a small milling center of the brand Maho and type 300 C

The power supply unit is defective but can be repaired

Technical data:

YEAR OF MANUFACTURE 1987

Type: MH 300 C

CNC control Phillips 432

Table: 550x275 mm

Travel x/y/z : 300/350/220 mm

SK 40 holder

Spindle speed: 20-4000 rpm

Main drive: 3.3 kw

Rapid traverse: 3 m/min

Quill stroke: 50 mm

Dimensions: 2000 x 2000 x 2000 mm

Weight: approx. 1900 kg

Lodpfxsir U H Ee Affohr

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

München

München

18,497 km

Machining center

DMU50 V 3 Achs CNC Fräsmaschine

Call

Condition: good (used), functionality: fully functional, travel distance X-axis: 500 mm, travel distance Y-axis: 380 mm, travel distance Z-axis: 380 mm, total height: 2,380 mm, total length: 1,450 mm, total width: 17,600 mm, table width: 480 mm, table length: 800 mm, overall weight: 3,500 kg, spindle speed (min.): 20 rpm, spindle speed (max.): 8,000 rpm, A DMU brand and type 50 V milling center is for sale

A new spindle was recently installed.

The machine is in very good condition and fully operational, machining in the 100el range is possible without any problems

Technical data:

Lsdpfxordf Ebs Affjhr

Brand GRUNDIG

Model MillPlus

Spindle speed range: 20 - 8000

Number of axes: 3

X-axis travel: 500 mm

Y-axis travel: 380 mm

Z-axis travel: 380 mm

Outer length of table: 800 mm

Outer width of table: 480 mm

Spindle holder: SK40

Dimensions L*W*H: 2450*1760+2380 mm

Weight: 3500 kg

On request, loading and transport (Europe-wide) can be organized for an extra charge.

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Burgoberbach

Burgoberbach

18,497 km

Machining center only 203 spindle h

SpinnerP3-620 2fach Paletten Wechsler

Call

Condition: like new (used), Year of construction: 2011, operating hours: 1,013 h, functionality: fully functional, travel distance X-axis: 620 mm, travel distance Y-axis: 520 mm, travel distance Z-axis: 460 mm, controller manufacturer: Siemens, controller model: 840d SL ShopMill Operate, table width: 560 mm, table length: 1,100 mm, rotational speed (max.): 12,000 rpm, operating hours of spindle: 203 h, For sale is a machining center of the brand Spinner and the type P3-620

The machine has an internal 2 compartment pallet changer, which makes it possible to set up during the work process.

Particularly noteworthy are the 203 spindle hours and the very good condition of the machine

Technical data:

Year of construction: 2011

Control: Siemens 840d-SL ShopMill Operate

Spindle speed: 12,000 1/min

Spindle holder: SK 40

Table dimensions: 1,100*560 mm

Travel X 620 mm

Travel Y: 520 mm

Z travel: 460 mm

Tool changer: 32 pockets (chain)

Lhsdpfxet Sftwj Affor

Tool changer head: double arm

Pallet changer: 2-fold (180 °)

Machine lighting,

Chip conveyor in the milling area,

Chip conveyor scraper belt with coolant device

Belt filter system with IKZ 40 bar

Hydraulic oil cooling system,

Rotary feed-through in the table

On request, loading and transport (Europe-wide) can be organized for an additional charge.

Prices plus VAT

Viewing possible by appointment. Please contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Leipheim

Leipheim

18,566 km

5-axis CNC universal machining center

Deckel MahoDMC 60 T 2-fach Wechseltisch WZ 120 fach

Call

Condition: good (used), Year of construction: 2005, operating hours: 39,256 h, functionality: fully functional, travel distance X-axis: 780 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 560 mm, total height: 2,800 mm, total length: 7,000 mm, total width: 7,000 mm, rotational speed (max.): 12,000 rpm, overall weight: 12,000 kg, For sale is a machining center by Deckel Maho, model DMC 60 T.

The machine is in good condition and ready for immediate use.

Technical data:

Year of manufacture: 2005

Operating hours: 39,256

Power-on hours: 72,107

X-axis travel: 780 mm

Y-axis travel: 560 mm

Z-axis travel: 560 mm

Control: iTNC 530 Heidenhain

Spindle speed range: 20 - 12,000 rpm

Main spindle drive power: 28 / 19 kW

Max. torque: 125 Nm

Tool holder: SK 40

B-axis infinitely adjustable: 150° (-120/+30)°

Number of pallets: 2

Pallet size: 630 x 500 mm

Max. load: 400 kg

Table speed range: max. 30 rpm

Number of tool stations: 120 positions

Max. tool diameter: 80 mm

Max. tool diameter with adjacent pocket empty: 160 mm

Max. tool length: 315 mm

Max. tool weight: 8 kg

Rapid traverse ( X / Y / Z ): 50 m/min

Feed rate: 20 - 15,000 mm/min

Total power requirement: 64.2 kVA

Lodpfxjwtft Ne Affohr

Machine weight: approx. 12.0 t

Floor space required: approx. 7.0 x 7.0 x 2.8 m

Included in the offer:

Documentation, chip conveyor,

coolant system, high-pressure coolant 40 bar through spindle,

paper band filter, 2-position pallet changer, tool breakage monitoring

Accessories such as clamping devices or tool holders are NOT included in the offer.

Transport and loading can be organised throughout Europe at additional cost upon request.

Prices are subject to VAT.

Inspection is possible by appointment. Please contact us; our team will be happy to assist you.

Trade-in or exchange possible!

Machinery purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality yet affordable metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website.

We make it easier for you to find: "turning machining"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Turning In Machining (63,988)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Automatic Turning Lathe

- Cnc Turn Mill Center

- Cnc Turning And Milling Center

- Cnc Turning And Milling Machine

- Cnc Turning Center

- End Machining

- Machining Center

- Machining Centers

- Metal Working Machine

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month