Used Sobernheimer Engineering for sale (18,555)

Wiefelstede

Wiefelstede Starter motor for 16-cylinder diesel engine

Bosch MWMRHS 518V16

Wiefelstede

Wiefelstede Engine control

Phoenix ContactEG 45 ME2213

Wiefelstede

Wiefelstede Manifold diesel engine 16 cylinders

Bosch MWM800/210/H70 mm RHS 518V16

+44 20 806 810 84

Wiefelstede

Wiefelstede Engine valve

DungsDMK 507

Wiefelstede

Wiefelstede Petrol engine 11 hp

HondaGX340

Discover more used machines

Wiefelstede

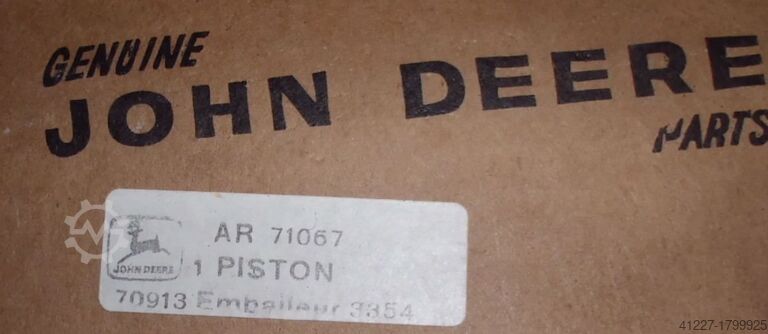

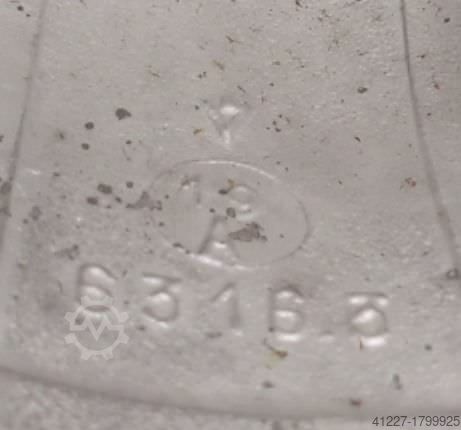

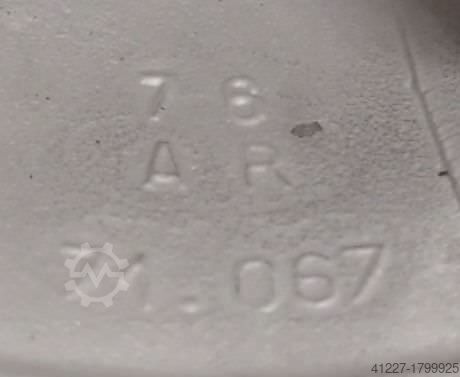

Wiefelstede Piston 2 pieces Ø 106.5 mm diesel engine

John DeereAR 71067

Wiefelstede

Wiefelstede Engine control

OttK10024-02 M-BL-10-24

Wiefelstede

Wiefelstede Engine tensioning rail

unbekannt505/55/H65 mm

Wiefelstede

Wiefelstede Pistons 4 pieces Ø 106.5 mm Diesel engine

John DeereAR 71067

Wiefelstede

Wiefelstede Transmission with gasoline engine

ALLMECHHydrantenschlüssel

Wiefelstede

Wiefelstede Engine control

FestoCMMS-AS-C4--3A G2 572986

Wiefelstede

Wiefelstede Engine mount

unbekannt400/367/H90 mm

Wiefelstede

Wiefelstede Piston 3 pieces Ø 106.5 mm diesel engine

John DeereAR 71067

Wiefelstede

Wiefelstede Mobile engine jack crane 2.3 m

Unbekannt

Wiefelstede

Wiefelstede Hydraulic pump with gasoline engine

HaweR60B

Herentals

Herentals Fire engine

Mercedes-BenzATEGO 1325 **FIRETRUCK-2000LTR TANK

Roosendaal

Roosendaal Fire engine

BerlietGBK 18 4X4 - APK oldtimer vrijstelling - 4x4 - ...

Nieuwerkerk a/d IJssel

Nieuwerkerk a/d IJssel Fire engine

MANTGM 18.320 BB CH Fire Fighter Truck (11 units)

Duisburg

Duisburg Fire engine

Mercedes-Benz2638

Duisburg

Duisburg Fire engine

MAN - Flugfeld - LöschfahrzeugPANTHER - Rosenbauer

Heiloo

Heiloo Fire engine

MERCEDES-BENZLAF 1113

Rotterdam

Rotterdam Fire engine

Mercedes-BenzAtego 1426 ZIEGLER 2000 LITER EURO 5

Rotterdam

Rotterdam Fire engine

MANLE 220C GODIVA POMP 2000 LITER TANK,MANUAL GEARBOX

Rotterdam

Rotterdam Fire engine

Mercedes-BenzAtego 1326 ziegler pump

Rotterdam

Rotterdam Fire engine

DAFLF 55.250 METZ 30 meter

Used Sobernheimer Engineering (18,555)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84