Used Form Fill Machine for sale (66,868)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Lorquí

Lorquí

19,581 km

Automatic capping and filling machine TE

TECHMI

Call

Condition: like new (used), TECHMI Group's Rotary Food Packaging and Capping Machine is an advanced solution designed to optimise packaging processes in the food industry. It is suitable for various subdivisions within the food sector and is ideal for packaging products in liquid formats.

* Production output may vary depending on the container format and the product being sealed.

Incorporates lid feeder:

Bodex S E Spspfx Abbolc

Length: 1.35 m

Width: 0.95 m

Height: 2.02 m

Modular band width: 22.5 cm

Block height: 0.9 cm

Currently supports 2 formats:

- Format 1: 60 mm (diameter) x 130 mm (height)

- Format 2: 62 mm (diameter) x 80 mm (height)

Listing

Piera

Piera

19,459 km

Dosing filling machine

DOSITECNOMONOBLOC DZPN/DRC

Call

Condition: excellent (used), Year of construction: 2005, functionality: fully functional, Specially designed for creams. Frame constructed in AISI 304 stainless steel. Bucket conveyor suitable for different formats. Gear pumps with double tank. Dual positioning of shut-off valves. Cap table with pick-and-place system. Capper with electric motor. Safety controls for container presence, valve, and cap. Suitable for containers of 15, 25, 50, 75, 100, 275, 500, and 1000 ml. Two filling nozzles, the second one for final filling of 1000 ml containers. Maximum speed: 25 units/minute. Tooling and different formats available. Power: 7.5 kW. Serial No. 210218. CE CERTIFIED. DOCUMENTATION AVAILABLE.

Blsdpfxsx Swpyj Abbsc

Listing

Neukirchen-Vluyn

Neukirchen-Vluyn

18,558 km

Filling machine for glass and plastic

BreitnerIDR2885

Call

Condition: used, functionality: fully functional, Breitner Filling Machine / Filling Line

Blsdpfx Aex Dx Raobboc

8-head rotary filler with inductive flow measurement. Previously used for filling sauces and mustard.

Brand: Breitner Type: IDR2885

Filling range: 10ml-10L

Connected load: 4kW

Approximately 100-120 containers per minute (at 250ml)

All format parts and documentation are included with the machine.

Listing

Kaunas

Kaunas

17,402 km

Weighing & filling machine

TiulmaxTL-P-H50

Call

Condition: new, Year of construction: 2026, filling weight (max.): 60,000 g, filling weight (min.): 5,000 g, input voltage: 380 V, PUDAS-50 , semi-automatic bagging line dedicated for fast and efficient filling of open-mouth bags. Suitable for working with plastic bags of different sizes and weights. Designed for packing wood pellets, granular products, fertilizers, grains, seeds and other products.

Dosing range: 5-60kg

Capacity: up to 5tons/hour

Equiped with sealing unit

Made in Lithuania, CE sertified

Available on stock.

Bedjipmxmopfx Abbolc

Listing

Wöllstadt

Wöllstadt

18,539 km

Linear Weighing Filling Machine C

Impuls Engineering GmbHLinear Vibrations-Waage Zweikopf C

Call

Condition: new, Year of construction: 2025, functionality: fully functional, warranty duration: 12 months, Linear Scale: Gentle and Precise Filling Technology

Our linear scale is the ideal solution for simple and precise dosing and filling of products. It combines accuracy with a gentle handling process. Thanks to minimal drop heights, product damage is effectively prevented, ensuring the quality of your goods—even with delicate products.

Flexible and Efficient Operating Principle

The core of our technology is a straightforward yet highly effective operating principle: Products are conveyed via linear belts or vibrating troughs and precisely dosed into weighing containers.

Features:

- Easy operation and cleaning

- Convenient control via color touchscreen

- Memory for various weighing recipes

- Precise weighing results thanks to three-stage weighing (coarse / medium / fine), individually programmable

- Tool-free format change

- Intuitive scale design enables fast conversion and easy cleaning

- Product-friendly – the reduced drop height protects fragile and sensitive products

- Versatile – suitable for both food and non-food applications

- Accurate dosing ensures consistent product quality

- Robust and hygienic: parts made of stainless steel 304, easy to clean

- Compact design and durable construction save space and reduce maintenance

With our linear scale, you receive a reliable, precise, and hygienic solution that increases the efficiency of your production processes.

Technical Data

- Weighing range: 20 g to 2000 g

- Accuracy: up to 0.5 g, depending on product

- 4.5-liter weighing container

- Max. speed: 30 weighings/min (2-head scale)

- Material: stainless steel 304

- Connection: 220V / 50Hz / 6A

Discover more weighing systems from Impuls Packaging:

- Linear scales (1-head, 2-head, 4-head, incl. mixing systems for blending 2–4 products)

- Multihead weighers with 10 to 32 heads and mixing systems for up to 8 products (control via the system or remote control through network connection, upgradeable to live camera monitoring)

- Multipack systems with up to 36 heads and up to 8 simultaneous discharges

Blodpewymlysfx Abboc

- Systems for sticky, frozen, and meat products

- Special scales for stick-shaped products (e.g. pretzel sticks) including product alignment

- Weighing systems for large products like salads

- Fine weighing systems for accuracies up to 0.1 grams

- Auger fillers (1-stage or 2-stage weighing) and powder filling (accuracy of 0.3%–1%, including automatic recalibration in conjunction with a weighing system)

- and much more.

Discover more used machines

Listing

Rīga

Rīga

17,288 km

Salad,Kimchi, Sauerkraut filling machine

Alistar EuropeSK1200

Call

Year of construction: 2026, condition: new, functionality: fully functional, machine/vehicle number: SK1200, Semi-automatic sauerkraut, kimchi(for other products specify) filling machine. The machine is intended to fill products in Jars, Buckets, Pouches. Made of acid-resistant stainless steel materials AISI 304, 316. The product is filled with volumetric filler. Liquid filler, a transporter for product loading are optional.

The machine can be equipped with wheels for easy transportation.

Equipment can be attached with conveyor, round tables or can be put under filling nozzles manually.

Technical information

Filling range 250-1000 g (or specify)

Productivity 800-1200 jars/pouches per hour

Pneumatic pressure 0,8 MPa

Air consumption 6,0 Nm3/h

Electric connection 400V/50Hz/3phase

Service staff 1 person

Dimensions 1500x450x1350 mm

Bsdpfx Abjffwftjbslc

Weight 180 kg

Listing

Бориспіль

Бориспіль

17,073 km

Vertical filling machine

OMAGMOD. CONF. DIVA-5

Call

Condition: used, Year of construction: 2012, We offer this used OMAG MOD. CONF. DIVA-5 OMAG STICK PACKAGING MACHINE mod. DIVA/5, year of construction 2012.

Model: MOD. CONF. DIVA-5

Serial number: 2298

Year of manufacture: 2012

Accident protection guards compliant with with CE norms.

Required electric power: three phase 220/380 V, 50 60 Hz.

Required compressed air: 6 Atm.

Frame in welded steel and painted with epoxy resin paint.

Colour code: RAL 9006 (OMAG standard).

Bsdpfx Abjx Rw Hvsbolc

If you have any questions or need more information, feel free to send us a message or give us a call.

Listing

Варна

Варна

17,306 km

VEMAG FKF can filling machine

VEMAGFKF

Call

Condition: ready for operation (used), Can filling machine diameter 77 mm and 99 mm. VEMAG type FKF for filling in cans.

Note:

Bsdpjimblqefx Abbelc

The byer will another machine- same as the offered for spare parts.

Listing

Blackburn

Blackburn

18,595 km

Twin Roll forming Stud & Track Machine

Bradbury

Call

Condition: used, Year of construction: 1997, functionality: unexamined, total height: 2,500 mm, total length: 33,223 mm, total width: 2,000 mm, table width: 700 mm, input frequency: 60 Hz, input voltage: 460 V, table length: 5,000 mm, table height: 1,200 mm, control cabinet width: 600 mm, control cabinet length: 1,500 mm, control cabinet height: 2,500 mm, compressed air connection: 5.5 bar, Stud & Track Rollforming Machine With 4.5 Tonnes Decoiler & Crane 5 Tonnes Capacity - Fully Dismantled - Ready to be transported

MACHINE MANUFACTURER: BRADBURY UK

GENERAL SPECIFICATIONS STUD LINE

MATERIAL : GALVANIZED COLD ROLLED STEEL

MATERIAL STRENGTH :

85.000 PSI MAX YIELD STRENGTH

55.000 PSI MIN· YIELD STRENGTH

THICKNESS:

20 GA. TO 16 GA.-"HEAVY GAUGE"

22 GA. TO 25 GA.-"LIGHT GAUGE"

ENTRY COIL WEIGHT: 10.000 LB MAX

ENTRY STRIP WIDTH:

12" MAX C APPROX.

5" MIN C APPROX.

ENTRY COIL I .D: 20" MAX

ENTRY COIL O.D: 72" MAX

EFF. LINE SPEED : l20-150 FPM-"HEAVY GAUGE"

175-250 FPM-"LIGHT GAUGE"

ROLLFORMER SPEED: 120-250 FPM

PASS LINE HEIGHT: 51"

LINE DIRECTION : RIGHT TO LEFT

MODE OF OPERATION : PREPUNCH/POSTCUT

CUT LENGTH : 20' MAX. 5· MIN

GAUGE"

: 90 % C APPROX. ) OF PRODUCT iON < i 6'

LENGTH TOLERANCE : •/- 1/16" AT 250 FPM

MAIN POWER : ELEC : 460 VOLTS

60 HERTZ

3 PHASE

192.2 FLA

Bljdpfexya Hzsx Abbsc

: AIR : 80 PSI MIN. CLEAN 6 DRY

: HYO : 1500 PSI WORKING PRESSURE

CONTROL : 115 VOLT AC

AIR CONSUMPTION: 2 CFM MAX. AT 80 PSI

Listing

Wolkersdorf im Weinviertel

Wolkersdorf im Weinviertel

18,142 km

Form measuring machine

Taylor HobsonTR300

Call

Condition: refurbished (used), functionality: fully functional, Taylor Hobson Tallyrond 300

In good condition,

Completely overhauled by sm-instruments (with new control unit and software)

Includes side table and accessories

Blodpexpqwiefx Abbec

Delivery time: several weeks

Listing

Kreuzau

Kreuzau

18,619 km

Tube filling machine

AxomaticOptima 1000

Call

Condition: good (used), Year of construction: 1999, AXOMATIC OPTIMA 1000 Tube Filling and Sealing Machine (Plastic Tubes)

This compact machine has a capacity of up to 70 plastic tubes per minute and is used for filling and sealing tubes. With the appropriate format and pump sets, the machine can be adjusted to handle the following specifications:

Tube diameter: 10 - 60 mm

Tube length: up to 280 mm

Filling volume: 2 - 300 ml

The machine is offered with the following format parts:

Bsdpex Rqlfsfx Abbjlc

Tube holders for plastic tubes Ø 35 mm and 48 mm

Manufacturer: Optima

Year of manufacture: 1999

Required floor space: approx. 180 x 160 x 240 cm

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Machine

Tetra Pak®A3 Compact Flex 300V

Call

Condition: used, Year of construction: 2016, operating hours: 16,538 h, Used Tetra Pak A3 Compact Flex 300V Aseptic Carton Filling Machine + TSA21 straw applicator YOM 2007 – Overview

This used Tetra Pak A3 Compact Flex 300V aseptic carton filling machine is designed for high-efficiency packaging of liquid foods in the 200 ml Slim format. With a capacity up to 9,000 units per hour, it offers reliable performance for beverage production and industrial packaging operations seeking second-hand equipment with proven quality. Manufactured by Tetra Pak, a leading name in packaging machinery, this filler supports aseptic processing for sensitive products such as milk and juices, making it a strong choice for modern Usedbottlinglines and carton packaging applications.

Engineered for advanced aseptic filling performance, the A3 Compact Flex 300V combines process control, operational safety, and consistent output. The machine has been maintained to align with contemporary standards, ensuring dependable uptime, product integrity, and efficient changeovers in demanding beverage production environments.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model/Version: A3 Compact Flex 300V

Year of manufacture: 2016

Production speed: up to 9,000 units/hour

Primary format: 200 ml Slim

Filling technology: Aseptic carton filling

Recorded operating hours: 10,538 h (approx.)

TSA21 straw applicator system

Product examples: Milk, juices

Container type: Carton packages

Blodpfx Aoxvpfrsbboc

Advanced Automation & Control Systems

The system features an integrated control panel and HMI for process monitoring, recipe handling, and production diagnostics. Automated sequences support aseptic startup, steady-state operation, and controlled shutdown. The platform incorporates safety interlocks and guarding to protect operators while enabling quick access for cleaning and routine service. Tetra Pak engineering ensures coordinated control of forming, filling, and sealing steps for stable, repeatable performance.

Production Line Integration Capabilities

This filler integrates seamlessly into complete beverage production and industrial packaging lines. It is suitable for upstream UHT/ESL processing and downstream case packing, conveyors, and palletizing. The 200 ml Slim format aligns with standard secondary packaging solutions, supporting efficient logistics. The machine can operate as a core element in a second hand used bottling line configured for aseptic cartons.

Machine Condition & Maintenance History

Condition reported as perfect, with maintenance aligning the unit to modern standards for process control, performance, and operational safety. The machine is ready for operation and suitable for immediate deployment after installation and commissioning within the buyer’s plant.

Operational Performance & Versatility

Optimized for aseptic filling of dairy beverages and juices, this A3 Compact Flex 300V maintains product quality with controlled sterile conditions.

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Machine

Tetra Pak®A3/Flex Compact 150V

Call

Condition: used, Year of construction: 2008, operating hours: 34,590 h, Used Aseptic Filling Machine Tetra Pak A3/Flex 150V TBA 1000B – Overview

This second hand Tetra Pak A3/Flex 150V TBA 1000B is a proven aseptic carton filler engineered for industrial packaging and beverage production. Configured for Tetra Brik Aseptic 1000 ml (Base) packs, it delivers reliable, continuous operation for UHT milk, juices, and other shelf-stable beverages. With a nominal capacity of approximately 7,000 packs/hour, this used bottling line component combines high throughput with aseptic integrity for modern carton packaging.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model: A3/Flex 150V TBA 1000B

Year of manufacture: 2008

Filling type: Aseptic (non-isobaric carton filling)

Package format: Tetra Brik Aseptic 1000 ml (Base)

Nominal speed: ≈ 7,000 packs/hour

Working hours: ≈ 30,000 hours

Utilities

Electrical: 400 V, 50 Hz, 3-phase

Installed power: up to ≈ 50 kW (typ. 35–50 kW depending on configuration)

Compressed air: 6–8 bar, ≈ 300–500 Nl/min

Water/steam: ≈ 0.5–1.0 m³/h (for processing/sterilization utilities)

Blsdpfx Absx H Thujbsc

Dimensions & Weight

Approximate footprint (L × W × H): 7 × 3 × 4.5 m

Approximate weight: ≈ 7,000 kg (model range 6,000–8,000 kg)

Note: Technical values are indicative for this A3/Flex configuration and should be confirmed during inspection/FAT.

Advanced Automation & Control Systems

The A3/Flex platform features OEM PLC-based control with a touchscreen HMI for recipe handling, alarms, and diagnostics. Motion control synchronizes forming, filling, and sealing cycles to maintain aseptic integrity and packaging quality at high speeds. Typical capabilities include:

Recipe management for UHT milk, juices, and beverage variants

Integrated process supervision and event/alarm logs

I/O provisions for upstream/downstream line devices

Recommended verification prior to start-up: PLC functions, valve actuation, pump performance, and seal integrity

Production Line Integration Capabilities

This aseptic carton filler integrates efficiently within a used bottling line or new beverage production layout:

Upstream: packaging material feed and sterilization modules as per OEM design

Downstream: conveyors to accumulation, straw/cap applicators, case packers, palletizers

Utilities/process: interfaces for CIP/SIP connection to plant systems, sterile air, water, and steam

Controls: standard digital/analog I/O and fieldbus-ready architecture depending on configuration

Ideal for second hand industrial packaging projects requiring aseptic carton formats and stable high-speed operation.

Machine Condition & Maintenance History

Condition: used, currently in storage

Approximate machine hours: ≈ 30,000

Operational note: continuous production achievable with proper preventive maintenance

Recommended checks before commissioning: pumps, aseptic valves, PLC functionality, elastomers and seals

Routine inspection, replacement of wear parts, and validation of aseptic barriers are advised prior to restart.

Listing

Fumane (Verona)

Fumane (Verona)

18,643 km

Filling Machine

DOMINO100V

Call

Condition: used, Year of construction: 2004, operating hours: 4,047 h, Technical Specifications & Performance Data

The Tetra Pak TBA 19 100V is a proven aseptic filling machine engineered for high-reliability carton packaging in beverage production. This second-hand unit is tailored for UHT applications and supplied with a new 0.125 L Slim format kit, ensuring efficient, hygienic, and cost-effective industrial packaging. Ideal for producers seeking a used bottling line component with dependable performance, the TBA 19 integrates seamlessly into modern processing environments.

Manufacturer: Tetra Pak

Model/Version: TBA 19 100V

Filling type: Aseptic (UHT)

Year of manufacture: 2000

Working hours: 4,047

Production speed: up to 7,000 packs/hour

Primary format: 0.125 L Slim (new 2026 format kit included)

Container type: Carton (Tetra Brik Aseptic)

Application focus: UHT milk and juice

Advanced Automation & Control Systems

Designed for consistent performance in aseptic conditions, the TBA 19 100V benefits from Tetra Pak engineering for streamlined operation and reduced downtime. The machine supports integrated line controls and is compatible with standard production monitoring and printer/coder interfaces used across beverage packaging machinery. Quick-format change for the 0.125 L Slim package minimizes line interruptions and enables efficient production planning.

Production Line Integration Capabilities

The filler can operate as a standalone station or as part of a complete used bottling line. It is compatible with essential downstream equipment, enabling full industrial packaging workflows for beverage production. Optional modules can be added to expand functionality and improve throughput.

Optional equipment: TSA21 straw applicator

Material handling: Easy rider/conveyor system and conveyor line

End-of-line: Packer system

Bledpfx Abox H S Sfsbsc

Controls and coding: Line controller with Domino printer

Utilities: Paper trolley and ancillary accessories

These options support efficient integration with existing packaging machinery and enhance overall line performance.

Machine Condition & Maintenance History

The machine is offered after maintenance, with the possibility of immediate delivery in as-is condition or delivery post-maintenance within a standard lead time. With only 4,000 operating hours, this second-hand aseptic filler represents a low-wear asset for producers looking to upgrade capacity or standardize on Tetra Pak carton formats. Operational manuals and know-how transfer are available to facilitate rapid commissioning and onboarding.

Operational Performance & Versatility

Optimized for UHT applications, the TBA 19 100V provides stable aseptic filling for milk and juice products in 0.125 L Slim cartons. Its hygienic design supports consistent product quality and shelf stability expected in long-life beverage production.

Listing

Germany

Germany

18,510 km

Bottle filling & capping machine w. CC

MARKL Füller f. BierflaschenBavaria Typ 40/8 VKL

Call

Condition: excellent (used), Year of construction: 2020, functionality: fully functional, For sale: (VIDEO available upon request, further extensive technical data: see PDF) MARKL / BAVARIA bottling line for breweries & beverage industry for 0.5 l & 0.33 l bottles Performance: 3,000 - 15,000 bottles/hour Low operating hours: operated 3 days a week at 7 hours a day, rarely operated 4 days a week Maintenance carried out annually by the manufacturer Bottle filling and capping machine for crown corks, d = 26 mm, with pre-evacuation system Bottle types: 0.5 l NRW & 0.5 l Long-Neck & 0.5 l Warsaw & 0.33 l Long-Neck Machine is immediately available, was only removed from production about 5 months ago. Original purchase price was approx. €330,000

Bodpfxewqz Nns Abbolc

Listing

Europa

Europa

17,901 km

THERMO FORMING MACHINE

ILLIGRDM 37/10

Call

Condition: excellent (used), Year of construction: 1992, operating hours: 41,685 h, Technical specifications:

Rated power, kW: 11,3

Mold area, mm: 475 x 250

Max. film width, mm: 495

Min. film width, mm: 150

Max. feed length, mm: 280

Min. feed length, mm: 50

Max. drawing depth/negative, mm: 100

Number of cycles/min.-max.: 48

Consumption of air/cycle at 6 bar: 100 Nl (net-pressurized air)

Heat energy to be dissipated:

with top heating ca. 10 260 KJ/h

with top and bottom heating ca.: 17 715 KJ/h

Special equipment: Hollow floor facility available

Control cabinet: included

Bjdpfx Aboq A Um Robjlc

Listing

Bischofszell

Bischofszell

18,680 km

THERMO FORMING MACHINE

GABLERD 450

Call

Year of construction: 1988, condition: excellent (used), machine/vehicle number: 3284, (min.) material thickness: 0.65 mm

(max.) material thickness: 2 mm

Technical Data:

Width of film, max./min. 450/350 mm

Forming area max. 430 x 160 mm

Drawing depth max. negative/positive 6/20 mm (on request 22 mm negative)

Top heater max. 10,15 kW

Driving motors 3,0 kW

Total connected load at 100 % duty cycle 12,7 kW

Working air pressure 6 bar

Air consumption (dependent on product) max. 1250 I/min

Rate of water flow max. 1,0 m3/h

COMPACT AND ROBUST - giving continuous high output.

Easy and ergonomical operation (e.g. take- off height 1300 mm).

QUICKLY CHANGEOVER - from 30° to 90° foil feed giving maximum material utilisation for both square and round lids. Heater changeover problem-free.

PRECISION - The accuracy of the form table movement is guaranteed by linear guide bearings and hardened rods. The safe reliable guarantee for precision.

Bledpjhbu E Hsfx Abbec

OPTIMUM PUNCHING ACCURACY EVEN DURING MAXIMUM OUTPUT

Cam controlled function sequence guarantees absolute precision with every cycle.

Listing

Bischofszell

Bischofszell

18,680 km

THERMO FORMING MACHINE

TFTIMC 5030 (MIT WERKZEUGEN)

Call

Condition: excellent (used), Year of construction: 2000, machine/vehicle number: 403, THERMO FORMING MACHINE TFT IMC 5030 (WITH TOOLS)

Equipment / Additional information:

unwinding:

Roll recording: easy

Max roll diameter: mm 1000

Settlement: automatically

Thermoforming machine:

Maximum tool dimensions: mm 520x330

Pos. Molding height max .: 15 mm

Neg. Molding height max .: 120 mm

Sheet width: mm 150/760

Movement Step: mm 50/330

Max HIPS film thickness: 1.8 mm

Hub of the sub-table: 150 mm

Clamping force: 7500 Kg

Bsdpfjn D Ew Iex Abbelc

Inst power top heater: 18.8 Kw

Inst power under heater: 14.1 Kw

Idle clock speed: per minute 40th

power main drive motor: 2.2 Kw

Engine power. Film feed: 0.75 Kw

Air operating pressure: Kg / cm2 7

Water consumption at 12 °: 1t / 1` approx.30

Air consump. at 7 kg / cm2: 1t / cycle 125

Installed power: Kw 50

9xTool:

Article no. // Tool no. // Cavities // Description / Product:

3599 // 457 // 10 // Vending machine cup capacity/capacity/contenance=223ml

593 // 460 // 8 // Coffee-to-go / thermo mug / thermo cup

Filling capacity / Capacity / Contenance=300ml / 12 oz

509 // 452 // 6 // Ice cream cup: filled to the brim=140ml /

Filling capacity with headspace 6mm: 120 ml

591 // 459 // 10 // Thermo mug ⌀ 81/180ml

740 // - // - // Standard cup with sealing edge ⌀ 75-120ml

3589 // 458 // 12 // Coffee-to-go / thermo mug / thermo cup:

Filling capacity / Capacity / Contenance=80ml

595 // 456 // 10 // Vending cup / Gobelet pour automate:

Filling capacity / Capacity / Contenance=150ml

210 // - // - // Baking case / technical part / plate or tray

8000 // 455 // - // Granule cup 180 ml / technical part with flat sealing edge

Listing

Wekerom

Wekerom

18,542 km

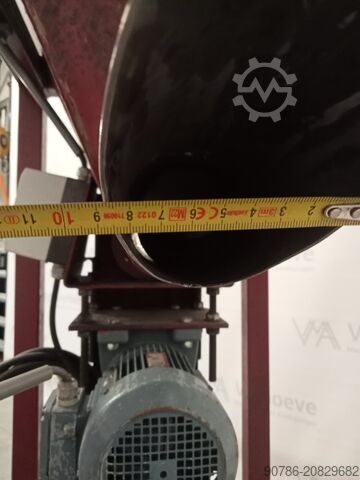

Valve bag filler, valve bag filling dosing machine

Call

Condition: used, Valve bag filler, valve filling and dosing machine

Filling pipe diameter: 88.9 mm

Motor power: 1.5 kW, 83 rpm

Bedpfx Ajx Nztwobbslc

Equipped with on/off button and emergency stop

See our other listings

VMA Wekerom

Listing

Wallern an der Trattnach

Wallern an der Trattnach

18,327 km

Can filling machine

EurostarCANFILL 6 ONE

Call

Year of construction: 2020, condition: new, Counter-pressure can filling machine Eurostar Canfill 6 One

Filling capacity: 2000 cans/h with 0.33 liter cans

1500 cans/h for 0.50 liter cans

Bodpfjq H Azlsx Abbjlc

Sleek and standard cans can be filled and sealed with the same lid (type 202).

Listing

Wallern an der Trattnach

Wallern an der Trattnach

18,327 km

Bag in Box filling machine

KreuzmayrKBF 900

Call

Condition: new, Year of construction: 2025, semiautomatic bag in box filling machine,

Bodpfoygaxex Abbjlc

with weighingframe, stainless-stell-buffer tank

mounted on chassis

filling capacity 900 l/h (with 10L bags)

Trust Seal

Dealers certified through Machineseeker

Listing

Wallern an der Trattnach

Wallern an der Trattnach

18,327 km

Gabletop filling machine

Schuy + Folmeg Maschinenbau GmbHSchuypack

Call

Condition: not inspected (used), Year of construction: 1995, gabletop filling machine for milk

1000 packs/h

0,25 L / 0,5 L / 1,0 L

Bjdpfx Ajhx D E Dsbbslc

for cartons without screwcap

Listing

Thisted

Thisted

17,992 km

Trepko 9104-2 Form–Fill–Seal Cup Packaging

TrepkoFSS 9104-2

Call

Year of construction: 2016, condition: used, Trepko 9104-2 FFS Line + Freemantle S09 (2016)

Trepko 9104-2 Form–Fill–Seal Cup Packaging Line (2016) with T. Freemantle S09 Wrapper

This complete Form–Fill–Seal (FFS) production line from 2016 is engineered for high-capacity manufacturing of thermoformed cup products. The main unit, Trepko 9104-2, forms cups from roll-fed plastic material, fills them with viscous food products, seals with PET/EVOH lids, cuts multipacks, and discharges them for further downstream handling.

Included with the line is a T. Freemantle S09 wrap-around packer from 2016 for grouping and wrapping finished multipacks.

The line is ideal for yoghurt, dairy desserts, processed cheese, margarine/spreads, pâté, and other pumpable or semi-solid food products.

Key Features

- Complete FFS system: forming, filling, sealing, cutting, and discharge

- Designed for 125 g cups (available formats: 4-pack and 8-pack)

- Fully automatic, continuous operation

- Hygienic, stainless-steel construction

- Suitable for chilled and ambient food products

- Includes T. Freemantle S09 wrapper/packer for downstream grouping

- Supplied with documentation and manuals

TREPKO 9104-2 – Technical Highlights

Cup Forming

- Thermoforming from PS/EVOH/PE roll material

- Max film width: 740 mm

- Max roll diameter: 1000 mm

- Heavy-duty forming tools for 125 g round cups

- Multi-cavity arrangement for high throughput

Filling System

- Stainless steel volumetric dosing block

- Multi-nozzle configuration for accurate filling

- Suitable for viscous food products

Bljdpsx Eldxsfx Abbsc

- CIP-compatible design

Sealing

- Lidding material: PET/EVOH, width 240 mm

- Heated sealing station for hermetic seals

- Precise lid positioning and temperature control

Cutting & Discharge

- Automatic multipack cutting

- Supports 4-cup and 8-cup retail pack formats

- Smooth discharge conveyor for integration with wrapping or case packing

T. Freemantle S09 Wrapping Unit (2016)

- For grouping and wrapping cup multipacks or blocks

- Film-fed automatic folder/wrapper

- Adjustable for various package dimensions

- Stainless-steel construction, CE marked

- Compact, reliable downstream solution

Applications

- Stirred yoghurt

- Sour cream / dairy desserts

- Processed cheese spreads

- Margarine, butter portions, vegetable fat spreads

- Dips, pâté, paste-type products

- Any pumpable or semi-viscous food requiring thermoformed cups

Technical Information

- Trepko Model: 9104-2

- Machine No.: 3859

- Year: 2016

- Voltage: 415 V / 50 Hz

- Freemantle S09 Year: 2016

- Voltage: 240 V

- Full documentation available.

Condition

The line is in very good used condition, complete with all major forming, filling, and sealing components, stainless-steel safety enclosures, and electrical cabinets. Well maintained and previously used for yoghurt production in a European dairy facility.

Listing

Vriezenveen

Vriezenveen

18,477 km

Form and cutting machine with laminating Tromp line

Tromplamineer machines Tromp

Call

Condition: excellent (used), Year of construction: 2009, total length: 3,900 mm, total width: 1,450 mm, total height: 1,500 mm, overall weight: 1,500 kg, type of input current: three-phase, input voltage: 400 V, working width: 600 mm, Equipment: type plate available, For Sale:

2x Tromp Make-up, Rolling and Cutting Unit Machines

These machines can be integrated into a laminating line, for example in a Tromp, Rademaker, or Fritsch line, etc.

Inspection on location is possible.

Specifications:

- Length x Width x Height (each): 3900 mm x 1450 mm x 1500 mm

- Conveyor belt

- Module for dough rolling (for baguettes, etc.)

Bljdpfex Eb Absx Abbjc

- The module can be lifted if no rolled products are needed

- Flour duster

- Cutting unit for smaller rolled products

- Moulder for dividing into 4 dough pieces

- Mechanically adjustable height

- Almost as new, well maintained

- Delivered complete

- Belt width: 650 mm

- Working width: 600 mm

- Output width / exit working width: 1x 800 mm and 1x 900 mm

Price per unit: €50,000

Transport upon agreement

If you have any questions or comments, please let us know.

Best regards,

Leo Holland

Listing

Raszyn

Raszyn

17,702 km

Tube filling machine

Jedliński PackagingJTB-10

Call

Condition: new, Year of construction: 2025, functionality: fully functional, total width: 913 mm, total length: 634 mm, total height: 1,700 mm, warranty duration: 12 months, compressed air connection: 6 bar, overall weight: 200 kg, power: 1.9 kW (2.58 HP), input voltage: 230 V, Semi-automatic tube filling machine.

Efficiency up to 13 tubes per minute.

Dose from 5ml to 270ml

Tube diameter from 19mm to 50mm

Tube height from 70 to 210mm

Made in Poland

Machine available to view and test at the firm's premises.

Bodpfx Abexx Uihebolc

Jedliński Packaging sp. z o.o.

ul. Wodna 3

05-090, Raszyn

Poland

We make it easier for you to find: "form fill machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Form Fill Machine (66,868)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- All Electric Injection Molding Machine

- Automatic Milling Machine

- Automatic Screen Printing Machine

- Automatic Welding Machine

- Bag Filler

- Box Wrapping Machine

- Business Form Machine

- Cup Filling And Sealing Machine

- End Finishing Machine

This may be of interest to you