Used Filing for sale (430)

Borken

Borken Ice cube machine

NordcapSDE 100 l

Germany

Germany Gear Hobbing Machine - Vertical

Gleason-PfauterGP 130

Germany

Germany Bevel Gear Generator - Spiral

OERLIKONC28

+44 20 806 810 84

Germany

Germany Coordinate Measuring Machine

KeyenceXM-1000

Almelo

Almelo Multi-spindle drilling machine

Best DEAL Maggi technologyGT800

Discover more used machines

Cascina Faustina

Cascina Faustina Multi-level automatic bar loader

TOP AUTOMAZIONIX FILE

Germany

Germany SAFAN Darley E-Brake Premium

SAFANDarley E-Brake Premium

Majdan

Majdan Waterjet ATMS 2015-B unused 2022

ATMSolutionsWaterjet ATMS 2015-B

Vilnius

Vilnius Label printing machine

ValloyDuoblade WX I

Hattingen

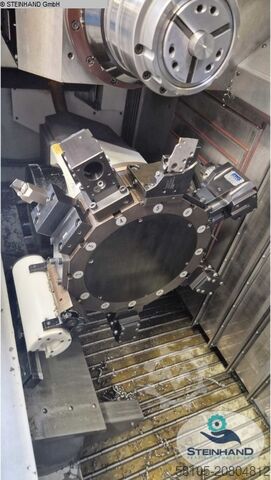

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Schijndel

Schijndel Kolbus case maker DA 260 (2011)

KolbusDA 260

Duxford

Duxford PerkinElmer Chemagic 360 – Automated Nucleic Acid

PerkinElmerChemagic™ 360

Duxford

Duxford Agilent Cary 100 UV-Vis spectrophotometer

AgilentCary 1000

Duxford

Duxford IBICO Ibimaster 300 Multifunctional Comb Binding Machine

IBICOIbimaster

Duxford

Duxford Burton Safes FFMK11 Fire Resistant 4 Drawer Fire Safe

Burton SafesFFMK11

Duxford

Duxford Phoenix FS1513K Fire Ranger Fire Proof Cabinet

PhoenixFS1513K Fire Ranger

Gdańsk

Gdańsk WatMachinery OT3015F laser cutting machine

WAT MachineryT3015F

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000x1800

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000/1800

Wiefelstede

Wiefelstede Stainless steel table

unbekanntTyp 2000/930

Wiefelstede

Wiefelstede Aluminum table

AluminiumTyp 1800/700

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000/1800

Wiefelstede

Wiefelstede Stainless steel table

unbekanntTyp 930/2000

Borken

Borken 3D printers

StratasysDimension

Borken

Borken 3D printer

StratasysDimensio elite

Used Filing (430)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84