Used Bundle for sale (391)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

18,384 km

Bar Loader Magazine

IemcaPRA 40/33/F

Call

Year of construction: 1998, condition: ready for operation (used), An FMB bar loader including a bundle loader is available. Bar diameter range: 5mm-52mm, max. bar length: 3000mm, feed speed: 750mm/s, return speed: 750mm/s. Machine dimensions X/Y: approx. 3600mm/1100mm, weight: approx. 1300kg. Documentation available. An on-site inspection is possible.

Cgedpfx Aox Tumrobbjn

Listing

Bremen

Bremen

18,320 km

Magnetron sputter PVD system

CemeConCC 800/9 HIPIMS

Call

Year of construction: 2006, condition: used, functionality: fully functional, machine/vehicle number: 11176, We are offering this used CemeCon CC 800/9 HIPIMS Magnetron Sputtering PVD System, year of manufacture 2006.

Manufacturer: CemeCon

Model: CC 800/9

Serial number: 11176

Cgsdpsx Tt T Rofx Abbon

Year of manufacture: 2006, upgraded in 2013 and 2025

Weight: 3,000 kg

Protection rating: IP 20

Power rating: 166 kVA

Evaporators: 6

Voltage: 3x400/N/PE V

Frequency: 50/60 Hz

Cemecon CC800/9 HIPIMS

- 6 cathodes

- All cathodes DC, 2 also HIPIMS capable

- Booster anodes

- 4 gases, 1 of which is flammable

- BIAS: DC, MF-pulsed, or HIPIMS

- 3x heating

- 2 turbo pumps

- 6-position substrate holder

- Multiple targets

- Includes option for BNC terminal for Peak I, U, and P at HIPIMS cathodes + BIAS

- Extensive accessories such as loading material, spare parts, consumables

- In 07/2023, the system control was upgraded to the latest standards and a manufacturer service was performed.

A bundle option is also available including a chiller, a precision substrate cleaning system, and a lapping/polishing machine.

If you have any questions or require further information, please feel free to send us a message or call us.

Listing

Kaufungen

Kaufungen

18,422 km

Band saw

AmadaHA 250 W

Call

Condition: good (used), Year of construction: 2009, functionality: fully functional, 1 used automatic band saw

Brand Amada

Type HA 250 W

Year of manufacture: 2009

Technical specifications:

Cutting capacity:

Round: 250 mm

Square: 250 x 300 mm

Max. bundle cut: 200 x 150 mm

Saw blade dimensions: 34 x 1.1 x 3505 mm

Blade speed, continuously variable: 24 - 90 m/min

Table load: 1400 kg

Working height: 700 mm

Max. feed length per stroke: 370 mm

Saw blade motor: 3.7 kW

Hydraulics: 0.75 kW

Coolant pump: 0.18 kW

Hydraulic oil tank: 98 l

Cgedpfx Abjv T Tglobjn

Cutting fluid tank: 180 l

Approx. weight: 1500 kg

Features:

- Automatic material feed

- Coolant system

- Emergency stop button

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Hilzingen

Hilzingen

18,696 km

Wall line complete system for house construction

Call

Year of construction: 2011, condition: excellent (used), This is a complete plant for house construction. Prices are listed with each item.

Consisting of the following individual elements (see attached document as well):

Photos will follow, they are already included in the attached document.

Table 1 (Positioning and clamping of the frame structure) €34,500

- Elevating longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

Table 2 (Applying the first sheathing and fastening) €25,300

- Longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

Intermediate conveyor 3 m long €4,600

(Parking station for multifunctional bridge)

- Longitudinal conveyor with 3 hinge conveyors

Table 3 (Applying the second sheathing, fastening and turning the element onto the next table) €35,650

- Longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

- Hydraulic turning device

Table 4 (Electrical installation and insulation) €34,500

- Cross conveyor with rollers and sheathing

- Table traverse drive

- Connections for compressed air and electricity

- Hydraulic turning device

Table 5 (Applying the first sheathing and fastening the second side) €32,775

- Longitudinal conveyor with 3 hinge conveyors

- Cross conveyor with rollers

- Pneumatic cross clamping

- Connections for compressed air and electricity

Intermediate conveyor 3 m long €4,600

(Parking station for multifunctional bridge)

- Longitudinal conveyor with 3 hinge conveyors

Table 6 (Applying the second sheathing and fastening) €28,750

- Longitudinal conveyor with 3 hinge conveyors

- Pneumatic cross clamping

- Connections for compressed air and electricity

Table 7 (Erection and distribution table) €29,900

- Longitudinal conveyor with 3 hinge conveyors

- Hydraulic tilting unit

- Table traverse mechanism

- Upper guide for holding the walls vertically

Manual surface gantry with vacuum lifter on Table 2 €13,800

(Applying the first layer of sheathing)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Manual surface gantry with vacuum lifter on Table 3 €13,800

(Applying the second layer of sheathing)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Cgjdpfx Asu D Amgobbjn

Manual surface gantry with vacuum lifter on Table 5 €13,800

(Applying the first layer of sheathing on the second side)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Manual surface gantry with vacuum lifter on Table 6 €13,800

(Applying the second layer of sheathing on the second side)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Wall storage 1: 12 m long x 24 tracks €11,500

Wall storage 2: 12 m long x 20 tracks

Vacuum lifter with column slewing crane €9,200

1 cross beam 2 t Abus €20,125

1 cross beam 2 t

Listing

Dinkelsbühl

Dinkelsbühl

18,523 km

Band saw

MEBA405 DG

Call

Condition: new, Comparable to Behringer, Kaltenbach, Kasto, Jaespa, etc.

Patented miter system

Continuously adjustable cutting speed

Hydraulic feed control

Hydraulic lifting and lowering of the saw frame

Hydraulic material clamping

Cgedpfeh S Nxpsx Abbsn

Powerful frequency-controlled saw drive

Swivel range 30° right / 45° left

Cutting range in mm:

45° left round 300, flat 300 x 300

90° round 410, flat 620 x 410

45° right round 360, flat 420 x 360

30° right round 300, flat 300 x 300

Remnant piece length without bundle clamping: 60mm

Recommended options:

Micro-spray device

Laser light

Clamping pressure regulator

Powered chip brush

Manual support roller

Set-up elements

Listing

Dinkelsbühl

Dinkelsbühl

18,523 km

Band saw

MEBA335 DGA 1000

Call

Condition: new, Comparable to Behringer, Kaltenbach, Kasto, Jaespa, etc.

Automatic material feed

Double-sided mitre cuts

Compact construction

Precise material positioning by servo positioning technology

Future-oriented electric saw feed with ball screw drive:

Maximum cutting performance and quality, while minimizing wear on the saw band

Unique and patented double mitre system:

Material is always clamped at a right angle

Cutting range (mm):

90° – round 335, flat 500 x 335

45° right – round 330, flat 320 x 335

45° left – round 305, flat 305 x 335

30° right – round 180, flat 170 x 335

Minimum remnant length without bundle clamping:

Manual: 80 mm

Automatic: 300 mm

Automatic cutting pressure and feed monitoring

Frequency-controlled AC drive, 15–150 m/min

Cgjdoh S Nxdepfx Abbjn

Hydraulic full-stroke material clamping

Automatic movement of clamping jaws

Minimum speed and saw band monitoring

Electric mitre adjustment via servomotor

Visualized program input with CNC control

Material feed via servo-controlled ball screw drive

The following options are recommended:

Micro-spray device

Clamping pressure regulator

Levelling elements

Listing

Liestal

Liestal

18,780 km

DYNO-MILL Agitator Bead Mill (2007)

Willy A. Bachofen AG (WAB)KD 6

Call

Condition: good (used), functionality: fully functional, Year of construction: 2007, operating hours: 1,153 h, DYNO-MILL KD 6 Agitator Bead Mill (2007)

For sale is a DYNO-MILL KD 6 horizontal agitator bead mill, manufactured by Willy A. Bachofen AG (WAB). This machine is a premium Swiss-made unit designed for the continuous dispersion and wet-grinding of pumpable products, ranging from low to high viscosity.

This unit was manufactured in 2007 and decommissioned in fully functional, running condition with no known faults. It is distinguished by its exceptionally low usage history, having logged only 1’153 operating hours. It comes equipped with a high-wear-resistant Silicon Carbide (SiSiC) inner cylinder and hardened stainless steel discs. It is sold as a complete bundle, including a peristaltic pump, a tool kit, the original electric cabinet and yttrium-stabilized zirconium balls (used).

Highlights

• Low Usage: Only 1'153 operating hours—internal mechanics are in excellent condition.

• High-End configuration: Fitted with a ceramic Silicon Carbide (SiSiC) inner cylinder (6mm wall thickness) and hardened stainless steel discs for durability and contamination control. Sintered Silicon Carbide (SSiC) prevents product overheating significantly better than Zirconium or Steel liners.

• Ready to Run: Sold as a complete package including the Electric Cabinet and a Peristaltic Product Pump.

• Features the industry-standard WAB dynamic gap separator and pressure-balanced mechanical seal.

• Voltage: Fitted with a modern Danfoss VLT frequency converter featuring wide-range input (380-480V, 50/60Hz), making the machine immediately compatible with both European (400V) and US (480V) power grids without modification

Technical Specifications

• Manufacturer: Willy A. Bachofen AG (WAB), Switzerland

• Model: KD 6

• Grinding Chamber Volume: 6.0 Liters (Net volume ~5.7 Liters)

• Throughput: approx. 50 – 200 kg/h (dependent on product/viscosity)

• Main Drive: 11 kW Motor (440V / 60Hz rated)

• Separation System: Dynamic gap separator (Tungsten Carbide rotor/stator) with adjustable gap width (0.15–1.0 mm)

• Shaft Seal: Double mechanical seal (DGD) with integrated pressure rinsing circuit

• Cooling: Forced water cooling jacket for the grinding cylinder

• Weight: 695 kg

Scope of Delivery

• Mill: DYNO-MILL KD 6 base unit

• Grinding System: Silicon Carbide (SiSiC) Inner Cylinder & Hardened Stainless Steel Discs

• Feed Pump: Peristaltic Pump included

• Controls: Original Electric Cabinet included

• Grinding Media: Ceramic Beads, Zirconia Partially Stabilized with Yttria, four sizes, each approx. 25Kg (0.4 - 0.6 mm / 0.8 - 1.0 mm / 1.2 - 1.4 mm / 1.6 - 1.8mm)

• Documentation: Operating instructions and wiring diagrams

Cgodpfxsx Tdyzs Abbsn

Condition

• Mechanical: Excellent, running condition with no known faults at the time of decommissioning.

• Cosmetic: The machine is clean but shows minor cosmetic wear (see pictures for visual details)

• Last application: Food

Typical Applications

• Ideal for fine particle size reduction in industries such as:

• Paints, Inks, and Coatings

• Agrochemicals and Chemicals

• Life Sciences and Microbiology

• Food and cosmetics

We ship worldwide. If you are interested or have any questions, please get in touch! Can be inspected in Liestal, Switzerland.

Listing

Willroth

Willroth

18,584 km

Panel saw

MayerPS 2 Z

Call

Condition: good (used), Year of construction: 2008, functionality: fully functional, Used Panel Dividing Saw MAYER PS 2 Z

- Year of manufacture: 2008

- Processing dimensions: 4300 x 2200 mm

- Immediately available

- Rear lifting table with powered heavy-duty rollers

Codpfx Abjx Tcymsbegn

- Electronic pusher unit

- All roller conveyors and air cushion tables included

- Ideal for bundle cutting

Listing

Werberg

Werberg

18,402 km

Göbel Drent Vision

GoebelDrent Vision

Call

Condition: good (used), Year of construction: 2003, 10 colours endless with coating unit UV

max. web width 520 mm, minimum web width 200 mm

UV system IST

automatic reel splicer

Video web inspection

Print format 22'' and 25 3/6'' (10 printing units each)

Codpfjma Rq Rox Abbjgn

Cross cutter

Bundle delivery

Print > roll/sheet or roll/roll

etc.

Listing

Volkach

Volkach

18,482 km

POPP | Bandall BA 24 | 2015 | 11632

Popp MaschinenbauPOPP

Call

Condition: used, Year of construction: 2015, POPP Banding Machine

The POPP Banding Machine is a powerful and precise device for bundling and packaging printed materials, paper goods, and other products using paper or film bands. It is ideally suited for use in printing houses, the graphic industry, as well as in logistics and packaging technology. The machine impresses with its robust construction, high flexibility, and easy operation.

Special Features

- Robust, industrial design for continuous operation

- Flexible processing of various product sizes

- Stepless speed control directly on the control panel

- Product access optionally straight or transverse to the band running direction

- Lockable foot stoppers for secure positioning

Cjdpfx Abjw Evcrjbogn

- High performance: up to 600 stacks per hour

- Easy integration into existing production lines

- Suitable for various banding materials (paper, film)

- Compact design for space-saving use

Technical Specifications

- Working width: 305 mm

- Console width: 760 mm

- Working height: 740 mm (lockable)

- Product format (min.): 150 x 100 x 30 mm (L x W x stack height)

- Product format (max.): 400 x 290 x 50 mm (L x W x stack height)

- Maximum stacks/hour: 600

- Speed: 10 – 30 m/min

- Speed control: 0 – 100% on the control panel

- Machine dimensions (net): 1500 x 800 x 1700 mm (L x W x H)

- Machine weight: 500 kg

- Power supply: 400 V, 16 A, 3 phases, 50 Hz

All-Inclusive Service Package

We take care of everything: from secure packaging and transportation to customs clearance.

Sustainable and Economical

Choose a used machine and benefit twice: Save the environment and your budget. Despite possible signs of use, you receive a quality product at an attractive price.

Listing

Germany

Germany

18,384 km

Complete manufacturing line for bed slatted frames

Weinig Raimann Linde Koch Panhans GreconHydromat KR KS OPTICUT E14 E16 CNC

Call

Condition: used, Year of construction: 2000, Complete production line for the manufacture of slatted frames.

From woodworking through to final assembly and packaging.

Includes all components such as moulders, saws, profile processing, forklifts, compressors, etc.

The larger machines/plants are from around year of construction 2000.

Consisting of:

Production of solid wood rails:

- 2 x Multiblade rip saws RAIMANN KR 450 + KS 310

- Optimising cross-cut saw GRECON ILLERTISSEN OPTICUT 704R

- Four-sided planer WEINIG HYDROMAT 23

- Stacking unit

Foiling / Finishing of longitudinal rails:

- 2 x Profile wrapping machines FRIZ OPTIMA PU25-PAP

- Foil cutting machine FRIZ FSM 1500

CNC drilling and sawing units:

- KOCH CNC drilling and sawing line with turning and stacking unit

- ISE CNC drilling and sawing unit with stacking unit

- 2 x ISE CNC woodworking centres / drilling units

Cgjdpex S Sb Defx Abbon

- ISE CNC machining centre for spring slats

- 2 x Manual slat drilling machines

Single machines:

- GANNOmat CNC drilling and dowelling machine

- Pnahans table routing machine

- 2 x EiMa double mitre saws

- SCM panel saw

- Barth frame press

- 2 x FLOTT column drilling machines

- SAMCO combination sawing and milling machine

- 2 x Multi-spindle drilling machines

- 2 x Belt sanders

- Spray booth

- Various small machines

Assembly:

- Automatic assembly machine for standard slatted frames

- Capping press / line

- 14 x Pneumatic assembly tables

Logistics – operating equipment:

- 3 x LINDE forklift trucks E16 / E20

- 7 x LINDE high-lift/ electric pallet stackers

- WEYCOR wheel loader 95E SUPER

- Atlas-Copco compressor system

- WEIMA single-shaft shredder

- Kärcher ride-on sweeper

- HONDA snow blower

- Extraction system outdoor area

- Batch of mesh boxes & Euro pallets

- Various racking systems

Packaging:

- Shrink tunnel system

- Stationary pallet wrapper

- Mobile pallet wrapper

Materials:

- Remaining stock of timber / spring slats

- Remaining stock of end caps / plastic parts

- Miscellaneous remaining assembly materials

Many more PHOTOS and detailed DATA available on request.

Listing

Winterswijk

Winterswijk

18,512 km

Strapping machine

CyclopAmpg Boxer y II 1000bx1450 12mm

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, type of input current: DC, total width: 2,971 mm, total height: 2,011 mm, total length: 610 mm, overall weight: 240 kg, input voltage: 230 V, input current: 10 A, roll width: 200 mm, input frequency: 50 Hz, inner diameter: 200 mm, power: 0.74 kW (1.01 HP), space requirement height: 2,011 mm, space requirement length: 610 mm, space requirement width: 2,971 mm, We are offering this 'as new' Cyclop Ampg Boxer Y II 1000bx1450 12mm strapping machine, year of manufacture 2022.

The machine has only completed 4,009 bundles and is therefore still as good as new. It has not been in use for some time because it no longer suits our product applications.

Cjdpfxox S Iuyj Abbsgn

Manufacturer: Cyclop

Model: Ampg Boxer Y II 1000bx1450 12mm

Year of construction: 2022

Strap joint: Heat-sealed, Polypropylene

Arch size: W1400 mm x H1650 mm

Machine dimensions:

- Width: 2,971 mm

- Height: 2,011 mm

- Depth: 610 mm

Machine weight: 240 kg

Tension force:

- Up to 450 N (45.9 kgf): for CE

- Up to 784 N (80 kgf): for Non-CE

Electric power: Single phase 220, 230, 240 V – 50/60 Hz

Full load current: 10 A

SCR (Short Circuit Current Rating): 2.5

Power consumption: 0.74

Noise emission: 82.2 dB(A) measured according to EN-415-8 Annex A

Speed: 37 bundles/min

Package – Minimum size: W30 × H80 mm

Package – Maximum size: W1380 × H1620 mm

Strap – Width: 9, 12, 15.5 mm

Strap – Thickness: 0.4 mm to 0.7 mm

Strap dispenser: Strap coil ID 200 × W200 mm

If you have any questions or would like more information, please feel free to send us a message or call us.

Listing

Bitburg

Bitburg

18,682 km

Hydraulic swing frame metal band saw

METALLKRAFTBMBS 220 x 250 H-G - sofort verfügbar -

Call

Condition: new, Year of construction: 2026, For sawing e.g. stainless steel, tool steel, hollow sections and solid materials

Two-pole drive motor enables saw band speeds of 30 and 65 m/min

Monitoring of saw blade tension electromechanically via microswitch

When the saw arm is raised, the lowering cylinder locks in the upper position via the solenoid valve - additional locking at the cylinder is therefore not required

Codpfxeg U Uv Ro Abbegn

Saw arm inclined by 25°, thus longer service life of the saw band

Precise and robust band guides with adjustable HM plates

After completion of the cutting process the saw band stops automatically in the lower end position

Lowering of the saw arm by gravity or manually

With infinitely adjustable, constant saw arm lowering speed via hydraulic cylinder

Dimensions and weights

length approx. 1200 mm

width/depth approx. 650 mm

height approx. 1800 mm

Weight approx. 270 kg

Electrical data

Supply voltage 400 V

Mains frequency 50 Hz

Machine data

Saw band speed(s) 30 / 65 m/min

Speed levels 2

Saw band length 2450 mm

Saw band width 27 mm

Saw band thickness 0,9 mm

Material feed

Table height material feed 925 mm

Cutting range

0° round (tube) 220 mm

0° round (solid material) 120 mm

0° rectangular lying (hollow profile) 230 x 150 mm

0° bundle (tube) 230 x 120 mm

-45° round (tube) 160 mm

-45° round (solid material) 85 mm

-45° rectangular lying (hollow profile) 160 x 90 mm

-60° round (tube) 90 mm

-60° round (solid material) 55 mm

-60° rectangular lying (hollow profile) 90 x 90 mm

Art. No.: 3680001

S

Listing

Strassberg

Strassberg

18,652 km

KI-basierte horizontale Bandsäge

JLH sawsH-560MAX

Call

Condition: new, Year of construction: 2025, Schnittbereich rund: 560 mm

Cutting area, square (W x H): 560 x 560 mm

Smallest size that can be cut: 100 x 100 mm

Clamping range: 100 - 560 mm

Codpfx Asxu Ay Hobbsgn

Bundle cutting range (min. W x H - max. W x H): - mm

Shortest length of cut piece : 50 mm

Shortest remaining piece length in automatic mode*: 170 mm

Shortest remaining piece length in single cut: 40 mm

Length: 2300 mm

Width including chip conveyor: 5200 mm

Height: 600 mm

Weight of machine approx.: 11000 kg

Electrical connected load: 26 kW

Saw motor power: 15 kW

Hydraulic motor power: 3,75 kW

Cutting speed continuously adjustable: 20 - 80 m / min

Feed speed of the saw: 1 - 300 mm / min

Automatic material feed length, single stroke: 500 mm

Length of automatic material feed, multiple strokes: 9999 mm

Dimensions of the saw blade: 8400 x 67 x 1,6 mm

Standard configuration

Fully enclosed protection according to CE standardJLH-EHASaw MasterCE Electrical safetyLED work lightSaw blade breakage detectionSawing depth controlHMI+buttonsInverterDeviation detectorHydraulic belt tensionerVice differential pressure valvesAutomatic chip conveyor (spiral)Hydraulic belt guide tensionerVice pressure regulatorMotorised chip brushCooling fan for hydraulicsAutomatic lubrication deviceWork table with rollersHydraulic feedMovable guide arm hydraulically clampedChip container 40(L)Tool box (wire brush, levelling pads, spare paint)One-piece saw blade

Listing

Luckenwalde

Luckenwalde

18,172 km

Exhaust system

ESTANA-K 6000 B

Call

Condition: used, Year of construction: 2014, type of input current: three-phase, input voltage: 400 V, overall weight: 700 kg, volume flow: 5,150 m³/h, suction capacity: 5,150 m³/h, noise level: 89 dB, input current: 14 A, power: 7.5 kW (10.20 HP), negative pressure: 3,690 Pa, input frequency: 50 Hz, ambient temperature (min.): 5 °C, protection type (IP code): IP6K0, ambient temperature (max.): 40 °C, We are offering this used ESTA NA-K 6000 B extraction system, year of manufacture 2014.

Voltage: 400 V

Number of phases: 3

Frequency: 50 Hz

Power: 7.5 kW

Current: 14.4 A

Sound pressure level: 89 dB(A)

Pre-filter: 32 µm

Protection class: IP 6X

Maximum airflow: 5,150 m³/h

Maximum negative pressure: 3,690 Pa

Water capacity: 290 l

Weight: 700 kg

Year of manufacture: 2014

Operating temperature range: +5 to +40 °C

If you have any questions or require further information, please feel free to send us a message or call us.

This unit was used for the extraction of grinding dust/mist in connection with grinding processes (including grinding robots/grinding cells) and is ideal for reliable wet dust collection of particles.

✅ ATEX/DEKRA certification present (visible sticker)

✅ Heavy-duty industrial design, suitable for continuous operation

✅ Excellent addition/bundle for grinding cells (Krugmann/robotic systems)

Technical data (available):

Manufacturer: ESTA Apparatebau GmbH & Co. KG

Model: NA-K 6000B

Year of manufacture: 2014

Power: 7.5 kW

Cgedox Stb Espfx Abbon

Connection: 3~ 400 V / 50 Hz

Current consumption: approx. 14.4 A

Weight: approx. 700 kg

Inventory No.: 03375

Scope of delivery / Collection:

Delivery as shown in the photos. Collection from site. Dismantling/loading by purchaser or as per agreement.

Listing

Wetter (Ruhr)

Wetter (Ruhr)

18,528 km

Cut-to-length and slitting line

Bindelinie Coilverpackung Titan BöhlBinde- und Stapelanlage

Call

Condition: ready for operation (used), Year of construction: 2004, For sale is a packaging line, currently still in production and available for inspection under power. The system consists of the following main components:

Cedpox Sqlusfx Abbjgn

- Bundle loader and tipper by Eich

- Integration unit by TITAN

- Oiling station by Eich - Steidle

- Wrapping station by Böhl

- Centering table with gripper by Eich

- Stacking area feed by Eich

- Shipping preparation by STU

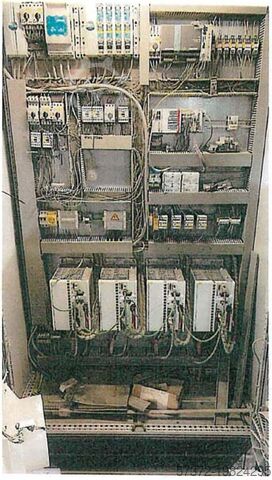

- Electrical control system by wpe GmbH

- Safety device by Hengstebeck & Eich

Technical data:

- Max. bundle diameter: 1,500 mm

- Max. bundle weight: 6,000 kg

- Max. single ring width: 600 mm

- Band thickness: 0.1 – 4.0 mm

- Stack package weight: 6,000 kg

- Stack package height: 1,400 mm including pallet

The strapping system is sold including complete documentation and software. Dismantling and transport can be organized by us.

Listing

Schweiz

Schweiz

18,782 km

CNC-controlled planing mill

Costa

Call

Condition: good (used), Year of construction: 1994, For sale is a complete, fully CNC-controlled planing mill. The planing mill can be inspected while in operation. A tour and training session prior to dismantling is available upon purchase. The mill has been in reliable operation since 1981 and has always been professionally maintained.

The mill was used exclusively for the production of wainscoting and parquet (panels).

Reason for sale:

New construction of a complete planing mill.

Equipment:

1. Stacking unit

2. Rupa vacuum lifter

- Age: approx. 1.5 years

3. Cross conveyor

4. Canali band saw

- 2 band saws

5. Longitudinal/cross conveyor including roller conveyors

6. Costa planer with 10 spindles

- Fully CNC-controlled

Spindle configuration:

1 spindle horizontal

2 lifting spindle right vertical

3 lifting spindle left vertical

4 lifting spindle horizontal

5 lifting spindle right vertical

6 lifting spindle left vertical

7 lifting spindle top horizontal

8 lifting spindle bottom horizontal

9 lifting spindle bottom horizontal

Cgjdpet Ngwrofx Abbjn

10 jointing spindle bottom horizontal

7. Roller conveyor with discharge

8. Roller conveyor to the Büttfering sanding machine

9. Cross and longitudinal conveyor

10. Büttfering sanding machine

- Working width: 1100 mm

- 3 units:

1x combo

1x single

1x brush

11. Lifting platform

Viewing and contact:

The planing mill can be viewed during operation. Schedule a viewing to get an idea of the system before dismantling.

Seize the opportunity to purchase a fully functional planing mill!

Listing

Henstedt-Ulzburg

Henstedt-Ulzburg

18,215 km

Folding machine

Heidelberg StahlfolderKH 78/6-KL

Call

Condition: good (used), Year of construction: 2007, • PFH-82 pallet feeder with TREMAT suction head and extra stacking table

• Swivel-mounted touch monitor, MCT control system

• 1st folding station 1.BUH-82 with 6 folding pockets

• Soft-PU folding rollers

• Downstream knife shafts with various tools

• Cross-folding unit BCUH-78, KL version with 2 folding knives

• Additional swiveling control panel at the cross-folding unit

• Noise protection hood

• Compressor

Connected with:

B) Automatic Bundle Delivery

Make: Palamides

Type: delta-703

Cjdpfjx R Ui Ijx Abbsgn

Format: 76 x 30 cm

Year of manufacture: 2009

Machine no.: 2307

• Working width 700 mm with triple banding

• Quick set-up mode without tools

• Automatic format detection and waste gate for consistent production without misaligned sheets in the stack

• Small format equipment for minimum 90x65 mm

• Pressing station with pre- and main press rollers with up to 3.5 t pressing force

• Package pressing

• Jogger station

• Banding of stacks in the magazine chute

• Banding with paper and plastic

• Robust and reliable electronic impulse welding system (EIS)

• Package lift output (single-operator handling for folding machine and Palamides)

• Delivery system is mobile for quick changeovers between different machines

• Various operating modes: shingle or single sheet feeding

• Quick adjustment, counter, stick bundling

Technical Data:

• Package height min.: 20 mm

• Package height max.: 150 mm

• Performance: 600 packages/h per cycle

• Speed: 15 – 200 m/min (up to 60,000 items/h)

• Infeed height: 410 – 1000 mm

• Electrical connection: 6 kW

• Compressed air: 6 bar dry air, to be supplied by the customer

Please contact us for further details.

Listing

Henstedt-Ulzburg

Henstedt-Ulzburg

18,215 km

Folding machine

Heidelberg StahlfolderKH 78/82-4-KTL-Aut

Call

Condition: good (used), Year of construction: 2009, Combination Folding Machine

• Automated combination folding machine

• MCT control with preset system

• PFH-82 pallet feeder with TREMAT suction head

• First folding station 1.BUH-82/4 with 4 motorized, individually adjustable combination folding plates

• Motorized, adjustable soft PU folding rollers

• Subsequent knife shafts with lift function

• Crossfold unit, KTL version with 2 fold knives and 1 horizontal folding plate

• Motorized adjustable functions

• FFP pneumatic window folding plate with motorized stop

• ACC-2.4 control unit

• Swiveling touch monitor for machine operation

• Soundproof hood

• Twinstacker TSH-70, 2009, bundle delivery with

• Press function and 2-level roller delivery to the left

Codpfx Aex R Uibobbogn

• Compressor

Listing

Germany

Germany

18,384 km

Stone Production Plant

OmagTronic S22 140-90

Call

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Cgsdpfx Aew R Uzijbbon

Listing

Barakfakih

Barakfakih

17,147 km

Aluminum Pvc Shutter Box and Lamella Cutting

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİSÇ 450

Call

Condition: new, Year of construction: 2026, functionality: fully functional, machine/vehicle number: SÇ 450 ALÜMİNYUM VE PVC PANJUR KUTU VE LAMEL KESİM MAKİNASI ( Ø550 mm ), • Designed for bundle cutting of roller shutter slats, setwise cutting of roller shutter boxes, cutting of side rails and set cutting of monoblock roller shutter boxes.

• Clean surface cutting thanks to high saw speed

• Roller conveyor system, right and left 3 meters each, 2 units

• Saw cutting speed is adjustable

• All roller shutter boxes up to a maximum of 350 mm can be cut

• Precise cutting thanks to the linear guide system

• Saw blade diameter Ø550 mm

OPTIONAL

Cgodpfx Aboramzfjbon

• Cooling system

• Capability to operate with digital meter

Trust Seal

Dealers certified through Machineseeker

Listing

Lübeck

Lübeck

18,172 km

Laser cutting machine

TRUMPFTruLaser Tube 5000 (T01)

Call

Condition: good (used), Year of construction: 2012, operating hours: 48,700 h, laser hours: 11,000 h, laser power: 2,700 W, sheet thickness steel (max.): 6 mm, sheet thickness aluminum (max.): 4 mm, working range: 6,500 mm, Equipment: documentation/manual, safety light barrier, Purchase options:

Option 1:

Installation, commissioning and partial overhaul and training of up to 3 operators at the buyer's premises with functional guarantee on acceptance. Surcharge, plus transportation and travel costs.

Cjdpfx Aboivaqisbogn

Option 2:

Workshop overhaul of the machine with commissioning and acceptance in accordance with the manufacturer's instructions at our factory. Installation, commissioning of the machine and training of up to 3 operators at the buyer's premises, free delivery of spare parts up to 6 months after commissioning. Surcharge, plus transportation and travel costs.

Delivery time +8 weeks.

After completion of the work, the machine can be inspected under production conditions, we look forward to your visit

Standard equipment

- Sturdy machine frame with integrated laser unit

- TruFlow 2000 high-frequency excited CO2 laser, cooling unit

- Drives: Maintenance-free three-phase servomotors

- NitroLine high-pressure cutting

- Fast processing with SprintLine

- Programmable cutting gas pressure setting

- Laser cutting head with 5'' lens

- Cutting head quick-change device

- Laser power control

- Laser logbook function

- Automatic switch-off

- Work area lighting

- Sinumerik 840D control system: Open control system based on PC, simple operation, online help, diagnostic function, maintenance logbook, technology data, teleservice, 3.5'' floppy disk drive, RJ45 network connection

- Safety: Multi-beam light barriers, fully encapsulated and ventilated beam guidance, compact dust extractor, protective cabin

- PRS 3001 ejection station with brush table

- Set of clamping jaws D 20-85mm and D 85-150mm

- 1 set of V-shaped molds and guide rollers for round pipes

- 1 set of U-shaped forming shells and guide rollers with an enveloping circle diameter of 120mm

Special equipment:

+ 2000 on Laser TruFlow 2700

+ SeamLine Tube

+ LoadMaster Tube 6.5 m with bundle trough and plastic rollers

+ Discharge station 3m with belt table

+ Focus line

+ Additional tube support

+ finished part length + 1.5m

Listing

Kruševac

Kruševac

17,847 km

Fully Automatic Optimiser Saw 9m

ProfiFeed TechnologiesA700 Fully Automatic Mitre Aluminium Saw

Call

Condition: new, Year of construction: 2026, Fully automatic cutting of large aluminium profiles with simple-to-use automation. Put down any aluminium profile, the machine will automatically detect it and cut it into jobs tasked with high-accuracy servo motor material positioning. Excel job lists WIFI input for streamlined input of large cutting lists.

Optional fully automatic inline optimiser. Automatic measuring of aluminium profile lengths using a laser sensor and on-the-fly job list optimisation against the length measured for minimised wastage in offcuts. Automatic printing of job / part number labels for each part produced (optional).

Simple, high-speed alternative to double-headed saws. Just enter (or import) the lengths and angles you need and press GO. The machine continuously produces your angled parts, accurately and at high speed.

• Fully-automatic cutting operation with bar feeding and cutting to length.

• Simple user interface for automatic operation, enter job and cut in seconds.

• Simplified part, batch, or large excel lists job cutting.

• Bundled / multi-bar cutting and counting.

• Remote WIFI excel job lists input with extensive data mapping capabilities.

• Fully adjustable saw cutting and aluminium feeding rates for maximum process productivity.

• Automatic optimiser mode with aluminium laser length measure and optimisation for minimum waste (optional).

Cgodpfsmdqwpex Abbsn

• Automatic labels printing for parts using data from the job list (manual label application, optional).

• Inline direct-to-material printing with no operator action required (optional).

• Bar codes or QR codes printing or scanning for jobs input (optional).

• Automated servo positioning of the saw mitre angle up to ±75° (optional).

Highly suitable for:

• Bulk aluminium manufacture

• Mitered aluminium structures manufacture

• Windows and doors manufacture

• Blinds, shades and furniture manufacture

• Fabricated aluminium structures manufacture

• Aluminium facades manufacture

Model: A700

Length: 9 m

Material Length: 8580 mm

Pushing capacity: 20 - 40 kg

Software: Optimiser

QUALITY AUSTRALIAN-MADE MACHINES.

Listing

Kruševac

Kruševac

17,847 km

Fully Automatic Optimiser Saw 6m

ProfiFeed TechnologiesA700 Fully Automatic Mitre Aluminium Saw

Call

Condition: new, Year of construction: 2026, Fully automatic cutting of large aluminium profiles with simple-to-use automation. Put down any aluminium profile, the machine will automatically detect it and cut it into jobs tasked with high-accuracy servo motor material positioning. Excel job lists WIFI input for streamlined input of large cutting lists.

Optional fully automatic inline optimiser. Automatic measuring of aluminium profile lengths using a laser sensor and on-the-fly job list optimisation against the length measured for minimised wastage in offcuts. Automatic printing of job / part number labels for each part produced (optional).

Simple, high-speed alternative to double-headed saws. Just enter (or import) the lengths and angles you need and press GO. The machine continuously produces your angled parts, accurately and at high speed.

• Fully-automatic cutting operation with bar feeding and cutting to length.

• Simple user interface for automatic operation, enter job and cut in seconds.

• Simplified part, batch, or large excel lists job cutting.

• Bundled / multi-bar cutting and counting.

• Remote WIFI excel job lists input with extensive data mapping capabilities.

• Fully adjustable saw cutting and aluminium feeding rates for maximum process productivity.

• Automatic optimiser mode with aluminium laser length measure and optimisation for minimum waste (optional).

• Automatic labels printing for parts using data from the job list (manual label application, optional).

• Inline direct-to-material printing with no operator action required (optional).

• Bar codes or QR codes printing or scanning for jobs input (optional).

• Automated servo positioning of the saw mitre angle up to ±75° (optional).

Highly suitable for:

• Bulk aluminium manufacture

• Mitered aluminium structures manufacture

• Windows and doors manufacture

• Blinds, shades and furniture manufacture

• Fabricated aluminium structures manufacture

• Aluminium facades manufacture

Model: A700

Length: 6 m

Material Length: 4680 mm

Pushing capacity: 20 - 40 kg

Cgedpjmdqwhjfx Abben

Software: Optimiser

QUALITY AUSTRALIAN-MADE MACHINES.

Listing

Kruševac

Kruševac

17,847 km

Fully Automatic Optimiser Saw 4.5m

ProfiFeed TechnologiesA700 Fully Automatic Mitre Aluminium Saw

Call

Condition: new, Year of construction: 2026, Fully automatic cutting of large aluminium profiles with simple-to-use automation. Put down any aluminium profile, the machine will automatically detect it and cut it into jobs tasked with high-accuracy servo motor material positioning. Excel job lists WIFI input for streamlined input of large cutting lists.

Optional fully automatic inline optimiser. Automatic measuring of aluminium profile lengths using a laser sensor and on-the-fly job list optimisation against the length measured for minimised wastage in offcuts. Automatic printing of job / part number labels for each part produced (optional).

Simple, high-speed alternative to double-headed saws. Just enter (or import) the lengths and angles you need and press GO. The machine continuously produces your angled parts, accurately and at high speed.

• Fully-automatic cutting operation with bar feeding and cutting to length.

• Simple user interface for automatic operation, enter job and cut in seconds.

• Simplified part, batch, or large excel lists job cutting.

• Bundled / multi-bar cutting and counting.

• Remote WIFI excel job lists input with extensive data mapping capabilities.

• Fully adjustable saw cutting and aluminium feeding rates for maximum process productivity.

• Automatic optimiser mode with aluminium laser length measure and optimisation for minimum waste (optional).

Cgsdpfx Abomdqrkjbon

• Automatic labels printing for parts using data from the job list (manual label application, optional).

• Inline direct-to-material printing with no operator action required (optional).

• Bar codes or QR codes printing or scanning for jobs input (optional).

• Automated servo positioning of the saw mitre angle up to ±75° (optional).

Highly suitable for:

• Bulk aluminium manufacture

• Mitered aluminium structures manufacture

• Windows and doors manufacture

• Blinds, shades and furniture manufacture

• Fabricated aluminium structures manufacture

• Aluminium facades manufacture

Model: A700

Length: 4.5 m

Material Length: 3180 mm

Pushing capacity: 20 - 40 kg

Software: Optimiser

QUALITY AUSTRALIAN-MADE MACHINES.

We make it easier for you to find: "bundle"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bundle (391)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month