Profile machining centerelumatec

sbz 140

Profile machining center

elumatec

sbz 140

Year of construction

2009

Condition

Used

Location

Balgoij

Show images

Show map

Machine data

- Machine type:

- Profile machining center

- Manufacturer:

- elumatec

- Model:

- sbz 140

- Year of construction:

- 2009

- Condition:

- good (used)

Price & Location

- Location:

- Torenstaat 21a, 6613 AA Balgoij, Nederland

Call

Details about the offer

- Listing ID:

- A20732117

- Update:

- 26.01.2026

Description

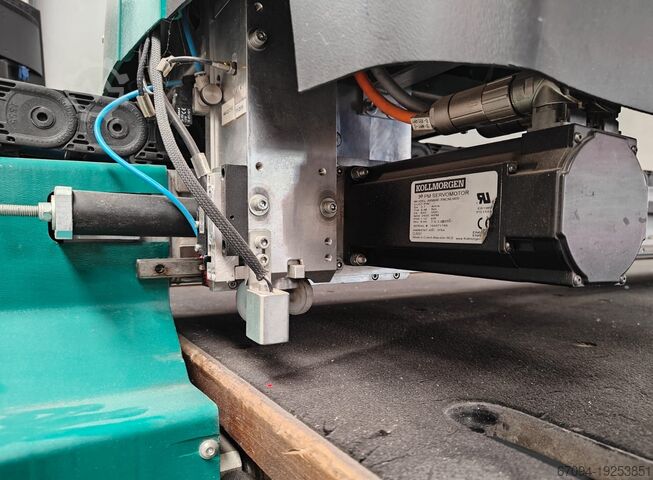

Elumatec SBZ 140 Extended Length Version: 7.6 meters

Approximate weight: 5,000 kg

Automatic tool changer

2-section clamping system

2 pneumatic stops

Safety hood

Light curtains

Automatic clamp detection

Central lubrication

Coolant spray system

Chip trolley

Conditioning unit

Max spindle speed: 24,000 rpm

Tool holder: HSK-63F, 8-position tool changer

Max milling diameter: 80 mm

Max saw blade diameter: 200 mm

Bjdpfxsx E Ahze Abbelc

Compressed air: 7 bar

The SBZ 140 is a 4-axis profile machining center (axes: X, Y, Z + A). Designed for aluminum and thin-walled steel profiles.

4-axis CNC machining center (X/Y/Z + tilt/rotation axis A)

X-axis: approx. 7,900 mm travel

Y-axis: approx. 850 mm travel

Z-axis: approx. 650 mm travel

A-axis (rotation/tilting): Freely programmable angle, –90° to +90°

Axis traverse speed: X-axis up to approx. 65 m/min, Y- and Z-axis up to approx. 60 m/min (varies with configuration)

Control: 4-axis CNC system, PC control, color display, USB & network connectivity. Software: eluCam.

Automatic material clamps; automatic positioning via index pins

Pendulum/shuttle operation (two work zones), improving production throughput time.

In addition to milling and drilling, also tapping, sawing, and profile machining—all with stationary clamped profiles.

Please note: The information on this page has been obtained and compiled to the best of our knowledge, but its accuracy cannot be guaranteed. Accordingly, it does not constitute a representation or contract and we recommend verifying all relevant details.

Financial information

VAT/margin:

VAT: The price shown is exclusive of VAT (VAT deductible for business customers).

The listing was translated automatically. Translation errors are possible.

Approximate weight: 5,000 kg

Automatic tool changer

2-section clamping system

2 pneumatic stops

Safety hood

Light curtains

Automatic clamp detection

Central lubrication

Coolant spray system

Chip trolley

Conditioning unit

Max spindle speed: 24,000 rpm

Tool holder: HSK-63F, 8-position tool changer

Max milling diameter: 80 mm

Max saw blade diameter: 200 mm

Bjdpfxsx E Ahze Abbelc

Compressed air: 7 bar

The SBZ 140 is a 4-axis profile machining center (axes: X, Y, Z + A). Designed for aluminum and thin-walled steel profiles.

4-axis CNC machining center (X/Y/Z + tilt/rotation axis A)

X-axis: approx. 7,900 mm travel

Y-axis: approx. 850 mm travel

Z-axis: approx. 650 mm travel

A-axis (rotation/tilting): Freely programmable angle, –90° to +90°

Axis traverse speed: X-axis up to approx. 65 m/min, Y- and Z-axis up to approx. 60 m/min (varies with configuration)

Control: 4-axis CNC system, PC control, color display, USB & network connectivity. Software: eluCam.

Automatic material clamps; automatic positioning via index pins

Pendulum/shuttle operation (two work zones), improving production throughput time.

In addition to milling and drilling, also tapping, sawing, and profile machining—all with stationary clamped profiles.

Please note: The information on this page has been obtained and compiled to the best of our knowledge, but its accuracy cannot be guaranteed. Accordingly, it does not constitute a representation or contract and we recommend verifying all relevant details.

Financial information

VAT/margin:

VAT: The price shown is exclusive of VAT (VAT deductible for business customers).

The listing was translated automatically. Translation errors are possible.

Seller

Note: Register for free or log in, to access all information.

Registered since: 2021

Send inquiry

Telephone & Fax

+31 24 20... show

These listings may also fit your interest.

Listing

Asse

Asse

18,711 km

4-axis machining center

ElumatecSBZ 140

ElumatecSBZ 140

Listing

Belgium

Belgium

18,713 km

Glass cutting table

INTERMACGenius 61 CT

INTERMACGenius 61 CT

Listing

Gütersloh

Gütersloh

18,438 km

2010 Elumatec SBZ 140

ElumatecSBZ 140

ElumatecSBZ 140

Listing

Dugo Selo

Dugo Selo

18,231 km

Profile machining centre

ElumatecSBZ 140

ElumatecSBZ 140

Listing

Nevers

Nevers

19,092 km

Machining center

BIESSEROVER 24S

BIESSEROVER 24S

Listing

Gütersloh

Gütersloh

18,438 km

2003 Elumatec SBZ 140

ElumatecSBZ 140

ElumatecSBZ 140

Auction

Auction ended

Brandenburg

Brandenburg

18,112 km

Rod machining center

ElumatecSBZ 140/60

ElumatecSBZ 140/60

Listing

Maasmechelen

Maasmechelen

18,639 km

Glass cutting table

Bottero353BKM-J

Bottero353BKM-J

Listing

Reiden

Reiden

18,777 km

Double miter saw

ElumatecDG 244/02

ElumatecDG 244/02

Listing

Enschede

Enschede

18,482 km

Light metal / aluminum circular saw

OzcelikMETEOR I 600

OzcelikMETEOR I 600

Your listing has been deleted successfully

An error has occurred