Used process engineering for sale (807)

Used process engineering for sale (807)

Germany

Germany Rotor Container

ErfassungstankSieb

Germany

Germany Fine Pulverizing Mill

Alpine630 UP

Germany

Germany Stainless Steel Tanks

Rieger

+44 20 806 810 84

Forst

Forst Falling- film evaporator

Konzentrat-Verdampfer

Wymysłów

Wymysłów ALCO MONITOR mobile water cannon

Działko wodne ALCO MONITOR mobilny zestDziałko wodne ALCO MONITOR mobilny zest

Discover more used machines

Wuppertal

Wuppertal Hosokawa Mikropul ACM-10 - Classifier mill

Hosokawa MikropulACM - 10

Berndorf

Berndorf Filter system

FAUDIRMFAV 48

Germany

Germany Pressure Vessel

König & Günther

Germany

Germany Plate and Frame Filter Press

SchenkKFP 630/20 H

Misterton

Misterton Vertical multistage centrifugal pump

GrundfosPNSNA99072221

Misterton

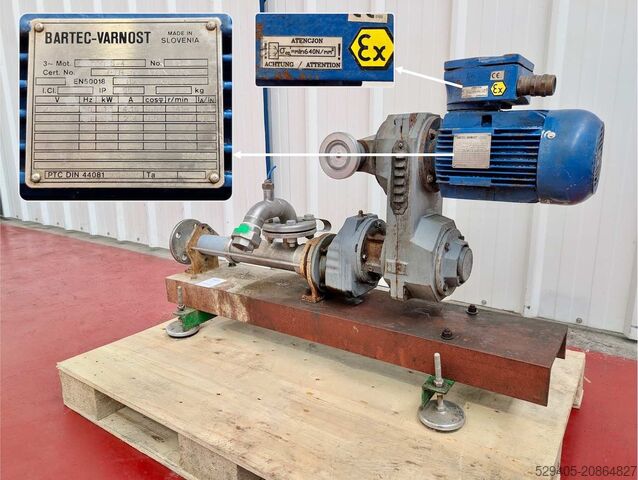

Misterton Single stage centrifugal pump

GrundfosNBE50125135

Nauen

Nauen Dissolver ATP Dispermill LD 50

Dissolver ATPDispermill LD 50

Nauen

Nauen Dissolver Pendraulik Disperlux LD 50

Dissolver PendraulikDisperlux LD 50

Janville

Janville Fine impact mill

PallmannPPSR 10-300

Janville

Janville Progressing Cavity Pump

PCM PompesMV6l5

Janville

Janville Nibbler

GerickeNBS 200/200

Janville

Janville Dust collector

WamFPXHTD12VA1498

Janville

Janville ATEX Dust collector

WamWAMFLO FNXB

Janville

Janville Cuve de stockage / process

Goavec SA-

Janville

Janville Pompe péristaltique à basse pression / Pompe à pate

PCM DelascoJZ237

Janville

Janville Low-pressure peristaltic pump

PCM Delasco2Z3

Janville

Janville 10000 L process tank

Goavec SA-

Janville

Janville Cuve de process 10000 L (B)

Goavec SA-

Janville

Janville 10000 L process tank (A)

Goavec SA-

Janville

Janville 5000 L process tank

Goavec SA-

Used process engineering (807)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84