Used Turbocharger Balancing for sale (964)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Heilbronn

Heilbronn

18,588 km

SATORIUS electronic balance (art.7045)

SATORIUSAusfallwaage

Call

Condition: good (used), SATORIUS electronic balance, price: 1.150 Euro, contact: Mr. Rainer Eckerle

Rodpfx Asdblbbehzobt

Listing

Monheim am Rhein

Monheim am Rhein

18,574 km

Balancing machine

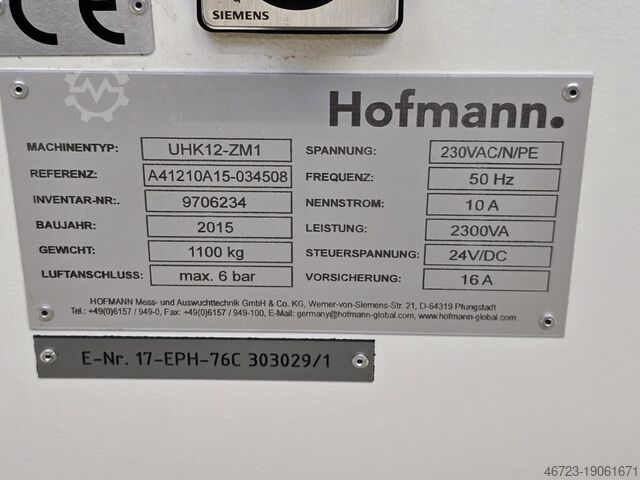

HofmannUHK 12 - ZM1

Call

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Rodswg A Sispfx Ahzsbt

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

Listing

Odesa

Odesa

17,113 km

Lightweight balancing machine

9A710 (3kg)

Call

Condition: new, workpiece weight (max.): 3 kg, rotor diameter: 400 mm, rotor length: 300 mm, High-Precision Rotor Balancing for Small Batch Production.

The 9A710 balancing machine excels at balancing various rotor designs up to 3 kg. Its exceptional accuracy and high sensitivity allow you to detect and correct even the slightest imbalances. This makes it ideal for single-piece and small-batch production, ensuring smooth operation of your rotors.

Key benefits:

• High precision: Detects minute imbalances for optimal performance.

• Wide application: Handles diverse rotor designs within the weight limit.

• Simple & reliable: User-friendly design ensures long-term operation.

• Increased productivity: Streamlines balancing processes in small-scale settings.

Originally designed for small-batch production, the 9A710's versatility makes it a valuable asset in repair shops as well.

This machine is perfect for balancing:

• Small motors & generators

• Shafts for various mechanisms

Rsdju Urwgepfx Ahzobt

• Impeller fans & pumps

• Precision machine tool components

• Rotating drive elements

! Upgrade your balancing capabilities and achieve exceptional results with the 9A710.

SPECIFICATIONS

Weight range of balanced rotors 0.03 - 3 (5) kg

Maximum rotor diameter (above the bedding) 400 mm

Distance between centres of rotor supports 4 – 300 mm

Support type Prisms

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.1 g*mm/kg

Rotor speed range 600 – 3000 rpm

Electric motor power 0.09 kW

Parameters of the supply network 220V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Odesa

Odesa

17,113 km

Horizontal Dynamic Balancing Machine

9K719

Call

Condition: new, workpiece weight (max.): 10,000 kg, rotor diameter: 2,500 mm, Horizontal soft-bearing Balancing machines 9K719 with load capacity from 100 to 10000 kg are designed for high-precision balancing of rotors of electric motors, pumps, compressors, blowers and exhausters, gearboxes, turbines of power engineering.

Self-aligning rollers ensure proper rotor alignment, simplifying setup and reducing balancing time.

Combined Drive System has a unique configuration with two axial drives and a belt drive mounted on a single bed.

Overall, this machine is highly versatile and effective in balancing various types of rotors, making it ideal for repair and production shops.

Rjdpfx Aswdgptjhzjbt

HIGHLIGHTS

• Soft-Bearing System: This system ensures linear sensitivity across the entire speed range during balancing. The result is exceptionally high balancing accuracy, achieving up to 0.04 g·mm/kg across all rotor mass ranges.

• Self-Aligning Roller Cassette automatically adjusts to the rotor along two axes, eliminating the need for precise centering. This design reduces machine setup time and, consequently, the overall time required for balancing.

• Wide Contact Area Rollers: The cylindrical rollers provide a broad contact surface, preventing scoring or deformation of the rotor's support surfaces. This is crucial when balancing heavy rotors for extended periods, minimizing the risk of damage due to prolonged contact or improper loading.

• Combined Drive System: Rotors of relatively low mass can be driven by “belt drive”, which makes the machine more versatile and allows balancing a very wide range of parts. Heavy rotors are rotated by "axial drive" using a cardan shaft.

• Rotor Jacks: Specialized loading devices can be integrated to ensure smooth and precise rotor placement onto the roller supports. This minimizes the risk of damage to the delicate roller assembly, particularly when handling heavy or sensitive rotors.

• High balancing accuracy due to automatic calibration of the balancing machine directly for each rotor by determining the influence coefficients. Its ease of use, high measurement accuracy, and integrated specialized features enable balancing professionals to achieve outstanding results in the shortest possible time.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

• No need for special foundations and vibration isolation, no need to fix the machine to the floor.

SPECIFICATIONS

Weight range of balanced rotors 100 - 10'000 kg

Maximum rotor diameter (above the bedding) 2500 mm

Distance between centres of rotor supports 400 – 5600 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 1000 rpm

Electric motor power 30 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Gebhardshain

Gebhardshain

18,555 km

SPRING BALANCE

DALEXD 6/130

Call

Condition: new, SPRING BALANCE with safety equipment in accordance with DIN 15112

Brand DALEX Type D 6/130

Tar load 115-130 kg

Cable extension 3 m

Suspension safety hook, rotatable and pivotable

Load capacity continuously adjustable via adjustment screw

Spring break protection

Weight: 44 kg

unused / as good as new / minor signs of storage

Rbsdpovr Elqsfx Ahzjt

Discover more used machines

Listing

Odesa

Odesa

17,113 km

Balancing machine modernization kit

PAK-1 Unbalance Measuring Unit

Call

Condition: new, PAK-1 Unbalance Measuring Unit is designed to modernize your balancing machine.

A balancing machine has a long mechanical life, but prolonged use leads to gradual failure of electronics and measuring instruments, causing problems with spare parts and lack of technical support.

Minimize downtime and ensure the reliability of your balancing machine by upgrading it with a new advanced measuring unit.

The PAK-1 unbalance measuring unit works in all balancing machines of most existing designs and manufacturers.

Confidence in results and ease of use: Easy to set up and work with, our devices do not require any special theoretical knowledge.

Wide range of functions for your balancing machine: The use of modern microprocessor technology and many years of experience of our developers allows us to implement functions that were previously unavailable to other manufacturers.

Your machine complies with ISO 21940: Balancing machines equipped with the PAK-1 unbalance measuring unit fully meet the precision requirements of modern standards.

HIGHLIGHTS

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

INCLUDES: 1) vibration sensor signal processing unit, 2) fanless industrial computer with touch screen, 3) new vibration and speed sensors, 4) metal protected cable set.

SEQUENCE OF WORKS for modernization of the measuring unit

- Replacement of the existing measuring system with the balancing complex PAK-1 based on an industrial computer;

- Installation of new vibration sensors and rotor speed sensor

- Replacement of all connecting cables;

- Adjustment of the measuring unit on the balancing machine;

- Training of personnel with skills to operate the machine.

VTM GROUP offers to upgrade your balancing machine.

We repair and modernise various old balancing machines of all types from all manufacturers.

It's cost effective.

An alternative to buying a new balancing machine in 95% of cases.

Urgent.

Work can be done at customer site within 1-2 days.

New components for modernization of your machine:

• Installation of new measuring system and vibration and speed sensors.

• Installation of new electrical equipment

• Manufacturing or repair of the rotation drive

• Manufacturing of new rollers

Rjdpfx Asq Ttn Dshzsbt

Every business is different. Let's discuss your task.

We can offer a solution for any balancing machine.

Please contact us to get the best offer!

👇

Listing

Malsch

Malsch

18,657 km

Balancing Machine

HOFMANNEO-Re

Call

Condition: used, workpiece weight 100 kg

workpiece length 1000 mm

diameter 500 mm

Rbedpfev Nq Swex Ahzot

centre height 280 mm

total power requirement 2,5 kW

weight of the machine ca. 1 t

dimensions of the machine ca. 1,6x 1x1,6 m

Listing

Wiesbaden

Wiesbaden

18,584 km

Grinding wheel balancing scale

HOFMANNNG 1

Call

Condition: good (used), Year of construction: 1996, Test specimen diameter: 320 mm

Test specimen width: 140 mm

Test specimen weight: 20 kg

Test mandrel length: 178 mm

Rbedpev E D Nuofx Ahzot

Test mandrel pin diameter: 15 mm

Weight: 4.7 kg

Space required: 420 x 280 x 350 mm

Auction

Auction ended

Sachsen

Sachsen

18,264 km

Horizontal balancing machine for rotors

HOFMANNUHK 26

Condition: ready for operation (used), Year of construction: 2004, functionality: fully functional, TECHNICAL DETAILS

Maximum balancing weight: 2,000 kg

Balancing body diameter without machining unit: 10 mm

Bed length: 3,000 mm

Swing diameter over machine bed: 2 mm

Rotor shaft via belt drive: 10 mm

Drive unit balancing speed (5 gears): Max. 80 / 160 / 290 / 470 / 630 rpm

Measurement method: force measuring

Electronics speed measurement range: 60 to 30,000 rpm

Center height measured in bed: 1,200 mm

Rollers: 2x 195 x 56 mm

Axle spacing: 205 mm

Adjustment travel: 3 mm vertical

MACHINE DETAILS

Drive power: 22 kW

Compressed air: 6 bar

Connected load: 25 kVA / 20 kW

Machine weight: approx. 5,500 kg

Rjdpfxew T Sqmj Ahzebt

Machine dimensions approx. (L x W x H): 3.3 x 1.5 x 2.0 m

Control cabinet dimensions: 6 x 610 x 21 mm

EQUIPMENT

- Measuring electronics PCX

- Base frame (cast steel body)

- Mounting length between bearing supports up to approx. 3,000 mm

- Adjustment with hand ratchet via rack

- Bearing supports/swing bearing blocks: 2 pieces

Listing

Bydgoszcz

Bydgoszcz

17,832 km

BALANCING MACHINE

CIMATCMT-50VSTR

Call

Year of construction: 2024, condition: as good as new (ex-display), Rim Balancing Machine:

- Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck

- Automatic brake and wheel positioning

Rjdpet Tuqbefx Ahzjbt

- Fast balancing cycle time

- Made of well-known brands heavy duty components

- Fast tool changeover time

- Servomotor as a spindle drive motor

Listing

Ankara

Ankara

16,842 km

Small occupied space balances complete p

Bodori76000W

Call

Condition: new, Year of construction: 2025, A compact design sheet fiber laser metal cutting machine with complete protection

Small occupied space balances complete protection and higher safety.

Each frame of the cutting machine bed is welded after mortise-and-tenon joint to achieve perfect mechanical property and better stability and firmness.

The pu

Convenient and fast open&close with one click; The laser cutter door is safe and reliable, by using rack-pinion transmission mode combined with self-locking cutting machine system

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Applicable Material: metal

Rodpfx Ahehwmdrjzobt

Condition: New

Laser Type: Fiber Laser

Laser Power: 1500W, 2000W, 3000W, 6000W, 12000W

Cutting Area: 3048*1524mm

Cutting Speed: 0-100m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Tychy

Tychy

17,906 km

Balancer

SCHENCKTBsonio High Speed Turbocharger Balancer

Call

Condition: excellent (used), Year of construction: 2014, workpiece weight (max.): 16 kg, input voltage: 230 V, year of last overhaul: 2025, SCHENCK TBsonio High Speed Balancing machine for turbocharger core assemblies

Rjdpfoq Nin Uox Ahzebt

Listing

Hessisch Lichtenau

Hessisch Lichtenau

18,422 km

Electrodynamic balance shaft balancing machine, vertical balancing machine; balancing machine, balan

SCHENCK RoTecEBLY

Call

Condition: used, Electrodynamic balance shaft balancing machine, vertical balancing machine, balancing machine

SCHENCK RoTec Type EBLY

Manufacturer No. 1FLY, Year of Manufacture 2000

Workpiece/Test Specimen: Balance shafts

Number of measuring planes: 2

Number of balancing planes: 2

Rjdpfowgnu Njx Ahzobt

Angle of balancing components: 145 - 215°

Test specimen weight: max. 10 kg

Indicated unbalance: 2 gmm/square

Lowest value per scale value: 8 gmm/square

Balancing spindle speed: 1200 rpm

Scale disc with test specimen holder Ø 320 mm

Test specimen diameter max. 400 mm

Vibration sensor: P01 force sensor

Angle position sensor: HBBC incremental encoder

CAB 750 microprocessor measuring device

RS232 serial interface

Workpiece weight: 2.2 kg

Workpiece length: 250 mm

Workpiece diameter: 70 mm

Power supply: 400 V, 50 Hz

Rated current: 16 A

- SCHENCK M341 balancing indicator

Space requirement: L x W x H: 2000 x 1800 x 2000 mm

Weight: 620 kg

Good condition

Listing

Odesa

Odesa

17,113 km

Crankshaft Balancing Machine

VTM Group9D715US

Call

Condition: new, 9D715US crankshaft balancing machine is adapted for balancing crankshafts of various designs, including crankshafts of V6, V8, V10 and V12 engines, with balancing weights on the connecting rod pins:

- Balancing of crankshafts of any design

- Shaft weight up to 300kg

- Shaft length up to 1400mm

- Drilling module for unbalance correction

The machine design allows balancing crankshaft separately, as well as crankshaft complete with flywheel and clutch, which guarantees minimum unbalance during engine operation.

MACHINE HIGHLIGHTS

• Hard-bearing supports - safe operation with high initial unbalance at low speeds.

• Roller cassettes with large diameter spherical rollers and provide the required accuracy for balancing heavy shafts.

• Replaceable antifriction prismatic V-blocks allow balancing of crankshafts with low mass or with special bearing journals.

• Narrow support stands of the machine allow balancing of crankshafts with complex configuration and with “narrow” bearing journals. The 9D715US machine has a cassette width of 27 mm, which is the best in its class.

• For balancing V-shaped crankshafts, the machine can be equipped with counterweights (variable weight) to simulate the weight of connecting rods.

• A vertical drilling module mounted on its own guides allows unbalance in the crankshaft counterweights to be corrected directly on the machine.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• Measuring balancing system has additional necessary functions for crankshaft balancing:

- recalculates the unbalanced mass to the drilling depth, taking into account the drill diameter and the permissible drilling depth.

- It recalculates the unbalance on several correction planes, so that unbalance can be corrected in neighboring crankshaft counterweights.

Rbsdpfswk Ittjx Ahzet

SPECIFICATIONS

Weight range of balanced rotors 3 - 300 kg

Maximum rotor diameter (above the bedding) 1100 mm

Diameter of rotor support journals 20 - 140 mm

Distance between centres of rotor journals 150 – 1350 mm

Support type Rollers / V-blocks

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 2.2 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

VTM Group balancing machines will allow you to do your job well and get positive feedback and attract more customers.

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Dortmund

Dortmund

18,510 km

Balancing mandrel

UNBEKANNT

Call

Condition: excellent (used), 1 pc. Balancing mandrel for grinding wheels with knurled nut

Smallest taper diameter 40.5 mm

Largest taper diameter 50 mm

Taper length 50 mm

Cylindrical taper R/L diameter 30 mm

Total length 250 mm

Siegfried Volz Machine Tools

Rüschebrinkstr. 151-153

D - 4143 Dortmund - Wambel

Rbodeh Ukr Hspfx Ahzjt

Listing

Dreieich

Dreieich

18,560 km

Balancing Machine

TIRAK 150 B

Call

Condition: used, Year of construction: 1998, workpiece weight 150 kg

workpiece length 2500 mm

diameter 160 - mm

balancing speed variable 100 - 3000 U/min

dia. axle journal 160 - 350 mm

voltage 400 V

Rbsdpfewcg Elsx Ahzet

total power requirement 1,5 kW

weight of the machine ca. 1,5 t

dimensions of the machine ca. 7,50 x 1,30 x 1,60 m

Control 0,60 x 0,60 x 1,85 m

Software TIRA X9000

Operating System Windows XP

Software update 2007

Serial No.: R 32/98

Max display sensivitiy: 0.5 gmm

Balancing speed 100 - 3000 RPM

Listing

Metzingen

Metzingen

18,619 km

Balancing Machine

HOFMANNEO-Re / MC 10

Call

Condition: used, Year of construction: 1982, workpiece weight 60 kg

workpiece length 700 mm

diameter 500 mm

total power requirement kW

weight of the machine ca. t

dimensions of the machine ca. m

Rbsdpfxet Hxbqj Ahzst

Listing

Kerava

Kerava

17,045 km

Balancing machine

SchenckHU 9 T

Call

Condition: used, functionality: fully functional, Used Schenck Balancing Machine HU 9 T with used CAB 690 H measuring unit.

Rsdpfx Ahew Aaugezsbt

The machine comes with original foundation drawings, documentation and manuals.

The machine can be test run in Kerava.

Technical data:

- Maximum rotor weight with roller bearings: 50 000 kg

- Maximum weight for symmetrical rotor: 56 000 kg

- Load capacity per bearing pedestal: 28 000 kg

- Load capacity per T-slot pedestal: 28 000 kg

- Minimum rotor weight: 2 500 kg (1000 kg)

- Maximum diameter over machine base: 4 000 mm

- Machine bed length: 15 000 mm

- Adjustable roller bearing diameters: 125–270 mm , 450–900 mm

- ABB electrical drive FC: 90 kW

- 4-speed gearbox: approx.120–1400 rpm

- Pneumatic locking for end drive

- Electrically operated movable pedestals

- Accuracy: Umar 0,5gmm /kg 270 rpm 1000 gmm

Listing

Odesa

Odesa

17,112 km

Turbo balancing machine

VTM GroupSBR-10

Call

Condition: new, VSR turbocharger high-speed balancing machine SBR-10

SBR-10 professional specialised equipment for high-speed balancing of assembled turbo cartridges. Equally useful for car and truck turbocharger.

The machine was designed for entry level turbocharger repair workshop, including medium re-manufacturers.

It solves a wide range of tasks that repair centres face on a daily basis.

The SBR-10 simulates the same testing and balancing conditions as the turbocharger on the vehicle, this allows the quality of the repair to be guaranteed. It also allows checking turbocharger for oil leakage.

A well-balanced turbocharger has a long service life which reduces the return rate of turbochargers and helps to build up your reputation.

HIGHLIGHTS

Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

Wide range of accessories and adapters for installing any kind of turbos

Includes adapters for installing turbochargers with lower oil inlet and reverse rotation turbines

Oil system with oil heating allows to recreate similar conditions to the real one during balancing.

The turbocharger rotation and measurement is automatic. The cycle includes acceleration to maximum speed, measurement during the cycle, and air shutdown.

Emergency shutdown is provided in case of extreme vibration increase, which prevents cartridge destruction even in case of assembly errors

Automatic cycle allows to carry out vibration measurement in a short and sufficient period of time.

Vibration measurement of the turbocharger housing - up to a value of 10G, which 2 times better than other analogs.

KEY FEATURES

• car and truck turbocharger balancing

• Any turbocharger installation

• All type turbocharger adapters

• Reverse rotation adapters

• Balancing speed up to 300 000 rpm

• Fast oil heater and temperature regulation

• 3-stage oil filtration

• Real-time unbalance measurement

• Automatic cycle turbocharger balancing

• An industrial fanless touch screen pc control system

• Access to self-editing of the data base

• Creation and printing of reports on turbocharger balancing

Rbodpfjnfvmhsx Ahzst

SPECIFICATIONS

Maximum compressor wheel diameter 120 mm

Maximum rotation speed 300 000 rpm

Pneumatic system operating pressure 0,8 – 1,0 MPa

Minimum air receiver volume 1000 L

Power supply 220V, 1Ph, 50Hz

Power input 1,5 kW

Dimensions 1120 х 780 х 1274 mm

Weight 285 kg

We manufacture fuul range turbo repair equipment.

Please contact us to get more info!

👇

Listing

Odesa

Odesa

17,113 km

Horizontal Dynamic Balancing Machine

9D717

Call

Condition: new, The 9D717 balancing machine is a versatile and reliable tool for balancing a wide range of rotors from 15 to 1500 kg.

Rodopdpn Uspfx Ahzjbt

This machine is capable of balancing different types of rotors, including inboard and outboard cantilever rotors, rotors on special mandrels and rotors in their own bearings.

The machine's design is simple yet functional, allowing it to easily balance armatures, generator rotors, impellers and fan wheels, even with large initial imbalances. In addition, the machine can balance rotors in their own bearings, saving repair time and preventing damage to the rotor trunnions.

It is suitable for determining and eliminating unbalance on rotors of electric motors, metallurgical gears, screws and printing equipment.

The 9D717 balancing machine is also capable of balancing disc-type parts such as impellers and smoke pump impellers, as well as correcting unbalance on shaft-type parts such as threshing drums and combine rotors.

Overall, this machine is highly versatile and effective in balancing various types of rotors, making it ideal for repair and production shops.

HIGHLIGHTS

• The specially designed rollers use advanced patented “Exact Barrel” grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced.

• The belt drive has a patented "Long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 15 - 1500 kg

Maximum rotor diameter (above the bedding) 1800 mm

Distance between centres of rotor supports 360 – 3000 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 7.5 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

17,113 km

Turbocharger electronic actuator tester

VTM GroupATP-1000

Call

Condition: new, ATP-1000 tester can be successfully used in companies engaged in turbocharger repair, as well as in car repair services offering a wide range of repair works to determine the cause of turbocharger malfunction. It is also suitable for companies supplying electronic actuators.

The tester checks the functionality of the actuator as a whole and its individual elements such as the position sensor and servomotor. Separate diagnostics of each element allows you to accurately determine the condition of the turbocharger actuator and detect a problem, if one exists.

The ATP-1000 is easy to use and allows you to quickly check the condition of the actuator and its components. This has made it an effective tool for monitoring the functionality of actuators.

HIGHLIGHTS

Testing of electronic actuators for turbochargers

Programming (adaptation) of SIEMENS electronic actuators

Testing of 12V DC motors up to 2A

Testing of boost solenoids used in pneumatic systems

Testing of electronic and pneumatic actuator position sensors

Works with all common types of actuators and similar in principle of operation.

Communication protocols: PWM, CAN, ADC, SENT.

KEY FEATURES

• Protection of the device by current 2A for 3 seconds

• Automatic detection of DC motor polarity inside the actuator

• Tooltip for color-coding the cable to the selected actuator type

• Display position sensor readings as a percentage

• Display of additional parameters of HELLA programmable actuators: firmware number, programmed angle value

• Portable version for testing directly on the vehicle

• USB control of actuators, when working together with the software of GEOMET-2000 turbo flowbenches.

• Regular updating of the tester firmware

СABLES

Set of diagnostic cables for actuators 12 pcs.

Set of diagnostic cables for position sensors 6 pcs.

Cable set for uncommon turbines 11 pcs.

USB cable 1 pc.

Cable AC/DC 12V, 4A power supply 1 pc.

Rsdpen E S T Ujfx Ahzsbt

!!!!

If you are looking for an electronic actuator programmer, ask me.

Trust Seal

Dealers certified through Machineseeker

Listing

Odesa

Odesa

17,113 km

Industrial Drive Shaft Balancing Machine

97VK1000

Call

Condition: new, total length: 6,000 mm, rotor diameter: 500 mm, The 97VK1000 balancing machine is a high-tech equipment designed for service and repair companies specializing in the maintenance of industrial drive shafts weighing up to 1000 kg.

It provides accurate and efficient balancing of cardan shafts, reducing repair time and ensuring high productivity of work processes.

The 97VK1000 balancing machine is the perfect combination of high technology, reliability and versatility, making it an essential tool for engineers and technicians involved in the maintenance and repair of industrial cardan shafts.

HIGHLIGHTS

1. Hard-Bearing Design: Designed with high precision and reliability in mind, the 97VK1000 balancing machine features a hard-bearing design to balance shafts with large initial imbalances.

2. Universal Design and Equipment: The 97VK1000 is equipped with universal equipment to balance shafts with flanges of various shapes and sizes. Special plates and adapters allow cardan lengths up to 6000 mm and flange diameters up to 500 mm.

3. Fast and Efficient Balancing Process: Thanks to the short unbalance measurement cycle, the 97VK1000 provides fast and accurate adjustment, which reduces repair time and increases the productivity of service and maintenance operations.

4. Safety and Ease of Operation: Screw jacks provide comfort and safety when working on the machine, the asynchronous variable frequency drive allows infinitely variable speed control without stopping the motor, providing optimal modes for balancing.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced shafts 50 - 1000 kg

Maximum tube diameter 300 mm

Redpfx Aowc T Utshzsbt

Maximum flange diameter 500 mm

Maximum drive shaft length 6000 mm

Minimum achievable residual specific unbalance 10 g*mm/kg

Rotor rotation speed 300 – 1000 rpm

Electric motor power 11 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you repair industrial drive shafts?

Then we can additionally offer an Assembly-Welding Workbench for heavy shafts.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

17,113 km

Lightweight balancing machine

9A713 (30kg)

Call

Condition: new, workpiece weight (max.): 30 kg, rotor diameter: 700 mm, The BALANCING MACHINE 9A713 is a universal horizontal-axis balancing machine designed for light rotors up to 30 kg in various configurations.

This series incorporates innovative technical solutions, ensuring that balancing is straightforward and accessible. With high performance and functionality, the 9A713 is popular in manufacturing across multiple industries.

Originally designed for small series and individual production, its versatility and productivity have also made it a favorite in various repair shops.

HIGHLIGHTS

• High balancing accuracy 0,4 gmm/kg = 0,4 µm

• Advanced Rollers: Specially designed rollers with advanced grinding technology mounted on precision bearings.

• Bearing Design Options: Hard-bearing design suitable for small rotors, with optional soft bearing support available.

• Belt Drive System: High degree of belt tensioning repeatability with a micro-tuning function for precise belt tension adjustment.

• Quick Changeovers: Easy access to support rollers for quick rotor reinstallation and rapid replacement of roller units with prism units, significantly reducing changeover time.

• Versatile Rotor Balancing: Capable of balancing rotors with small distances between bearing journals, limited only by the drive belt width.

• Variable Speed Control: Frequency inverter asynchronous electric drive with a powerful motor for infinitely variable speed control and smooth acceleration/deceleration.

• Height-Adjustable Supports: Adjustable supports to accommodate different bearing journal diameters, aiding in centering the workpiece.

• Easy Installation: Requires no special foundation and can be installed on a standard concrete floor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 0.3 - 30 kg (60 kg)

Maximum rotor diameter (above the bedding) 700 mm

Distance between centres of rotor supports 10 – 700 mm

Support type Rollers + Prisms

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 2000 rpm

Electric motor power 0.75 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Rbjdpfstu Ukaox Ahzot

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

17,113 km

Driveshaft balancing machine

VTM GroupBVI-03-88

Call

Condition: new, DRIVESHAFT BALANCING MACHINE BVI-03-88

Balancing machine for professional repair of cardan shafts up to 200 kg.

The hard-bearing machine is adapted for heavy cardan shafts of trucks and special machinery. The high sensitivity of the supports allows also high-quality balancing of cardan shafts of passenger cars.

The machine is designed for balancing cardan shafts in the facilities of cardan repair workshops. The machine can be quickly reconfigured for balancing a large amount of single cardan shafts of various designs, as well as for the production of small batches of shafts.

.

.

Rjdpon E Skwefx Ahzobt

.

TWO TIMES faster then your machine.

This balancing machine is majored to balance the shaft not only qualitatively, but also quickly.

If you can balance in 2-2.5 times faster, then this is your real competitive advantage.

.

..

...

HIGH PERFORMANCE ACCESSORIES

The machine is equipped with three main types of adapters:

1. Fast clamping universal adapters. It has two main advantages: The first is that due to the special design the driveshaft flange is clamped within 5 seconds. This advantage is due to the fact that the driveshaft flange does not need to be fixed with bolts.

THE SHAFT CAN BE CLAMPED 4 TIMES FASTER WITHOUT BOLTS.

The second advantage is the centering rings. The driveshaft is mounted in the adapters with centering rings that can be made on an ordinary lathe to fit most common driveshafts.

2. KV Flange adapters. Used for balancing shafts with cross-tooth flanges. Applies to four flange sizes: 120, 150, 180, 205 mm. Usually used on truck driveshafts.

3. Adapter with slots. Used to mount various flanges with holes. Mounting the driveshaft is the same as on universal adapters, with the help of centering rings.

KEY FEATURES

• Balancing of 2, 3 and 4-support cardan shafts

• Shaft length up to 5200mm, weight up to 200kg

• Cardan installation in 1 minute

• Standard set of adapters - Installation of 80% of cardan shafts;

• Three ways of fixing the center bearing

• Hard-bearing type machine - safe balancing of shafts with large initial unbalance

• Machine is operated by one worker

• Sliding tailstock spindle - quick changeover, comfortable operation

• Safety bracket with clamp for quick installation

• Measurement in all planes at one time

• Calibration of the machine by the operator

• Displays imbalance in real time

• Create and print reports

SPECIFICATIONS

Maximum cardan shaft weight 200 kg

Maximum flange diameter 300 mm

Maximum length of cardan shaft 5200 mm

Number of machine supports 4

Number of simultaneously measured planes 2, 3, 4

Minimum achievable residual specific imbalance, 10 g mm/kg

Rotor speed range 1000-2500 rpm

Parameters of the supply network 380V, 3 Ph, 50Hz

Power consumption, minimum, 3 kW

Dimensions (length x width x height) 6000 х 1100 х 1450 mm

Weight 1100 kg

Listing

Odesa

Odesa

17,113 km

Dynamic Balancing Machines

VTM Group9D716

Call

Condition: new, Dynamic Hard-bearing Balancing Machines of the 9D716 series have originally been designed to meet the needs of a wide range of customers.

They are undoubtedly the best solution if you need to balance a wide range of rotor types, weights and sizes. This has led to their use in a wide range of industries.

The machines have many unique technical solutions that allow you to set up and balance complex rotors in the shortest possible time without losing the accuracy of the unbalance detection.

MACHINE HIGHLIGHTS

Rbedpfxsn Hwqvs Ahzet

• The specially designed rollers use advanced patented Exact Barrel grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced and the rotor to be centred during machine set-up.

• The unique "Micro-Tuning" technology eliminates the effects of axial slippage during rotation.

• The belt drive has a patented "long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MACHINE DESIGN OPTIONS

• Axial drive that uses a cardan shaft. Capable of transmitting high torque from the electric motor to the rotor. This type of drive is used for parts with high aerodynamic resistance or special design features (e.g. augers).

• Drilling module for unbalance correction of the rotor without removing it from the machine. Convenient to use to increase the productivity of the operation.

• Extended machine bed. The base of the machine can be made for any length of rotor. In our practice we have had machines for rotors of 12 metres in length.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• World-leading functionality and accuracy.

SPECIFICATIONS

Weight range of balanced rotors 5 - 500 kg

Maximum rotor diameter (above the bedding) 1300 mm

Diameter of rotor support journals 30 - 180 mm

Distance between centres of rotor support journals 200 – 2000 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 4.0 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

We make it easier for you to find: "turbocharger balancing"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Turbocharger Balancing (964)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month