Used Straw for sale (58)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Neckartailfingen

Neckartailfingen

18,617 km

Straw; Cutters

muetekMHB; MHZ

Call

Condition: new, Year of construction: 2026, Consisting of large bale breaker Type MHB and straw shredder Type MHZ

1) Bale Breaker MHB:

Special price from €22,975 net (lead time approx. 15 weeks)

Suitable for round or square bales.

Includes frequency converter (FU) – regulates the speed of the chain conveyor.

The bales are placed on the chain conveyor, and the milling advance is activated. The milling tines tear the straw from the bale and hurl it into the hopper. Ideally, the combination of bale breaker and straw shredder is recommended here.

Technical data – Bale Breaker:

Performance: 1–2 bales per hour

Up to max. 600 kg per hour (depending on screen size used in the straw mill and kW rating of the straw mill). Without straw mill, the bale breaker can process up to max. 900 kg/h straw.

Max. square bale size: 2400 x 1200 x 800 mm (L x W x H)

Milling motor: 5.5 kW, 380 Volt

Chain conveyor feed: 0.75 kW, 380 Volt

Dimensions: 3750 x 1730 x 2460 mm (L x W x H)

Weight: 400 kg

2) Straw Shredder MHZ 600 – 11/15 kW; available immediately

Special price from €6,995 net

Surcharge for even larger straw shredder (18.5 kW): + €3,940 net

Technical data, MHZ with special hopper:

Motor: 15 kW, 380 Volt electric motor

Diameter: 600 mm

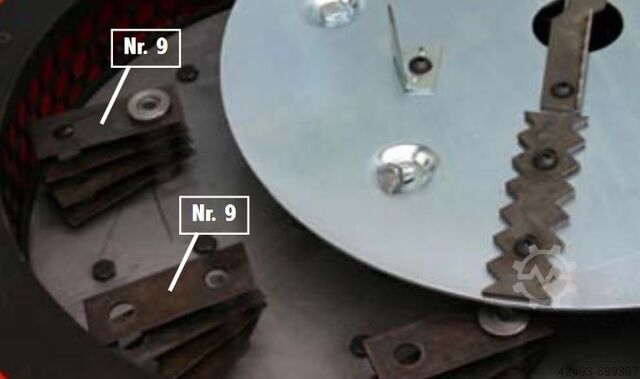

Hardened cutting knives

Screen with interchangeable inserts; selectable perforations (10, 12, 15, 22, 30, 45 mm)

With star-delta switch, phase protection, and 8 m power cable, plug-in ready

Discharge nozzle: 160 mm

Blowing distance approx. 12 m

Dimensions: approx. 1600 x 1020 x 1360 mm (L x W x H)

Weight: approx. 240 kg

---

Optional extras for a surcharge:

Feed auger: + €970 net

Cyclone (suspension by customer on site; should be no more than 10 m away):

+ €2,970 net

Simple filter: €1,750 net

---

Further options:

Industrial extraction system (demonstrator):

+ from €9,950 net

Optional rotary valve (renders material pressureless):

+ €5,750 net

Control panel: from €1,620 net

Special breaker extension 3 m (other sizes on request):

+ €9,750 net

Briquetting press MPP 180 S; little used demonstrator

70 mm briquette – up to max. 100 kg/h

from €39,700 net

Dcedpfxsb Nulhe Aa Eed

* Larger machines available on request

---

Description:

muetek bale breakers are designed for breaking up round and square bales of hay and straw. The shredder flanged to the bale breaker shreds straw from all types of cereals, hay, maize, and miscanthus. muetek machines of the MHZ / MHB series are characterized by robust construction and heavy-duty build quality.

muetek MHB series bale breakers feature a chain conveyor onto which the straw bale can be placed using a front loader. The support surface is adjustable depending on bale type.

The chain conveyor pushes the bale against the milling rotor. The feed speed is adjustable. The milling rotor is equipped with several teeth that tear open the straw bale. The separated straw is discharged.

---

The machines are generally suitable for dry input material:

- Straw

- Hay

---

Breaking up hemp bales is possible only with a special breaker (surcharge approx. €9,720 net, depending on configuration).

Straw mill is not suitable for hemp processing.

Requirements for input material:

Max. moisture content 12%

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

17,669 km

Trailer for Palox, straw

Call

Condition: like new (used), For sale: agricultural tandem platform trailer. The trailer features two platforms: the first is 200 cm long and the second is 1230 cm long, with a width of 248 cm. Additionally, the trailer is equipped with:

- LED lighting

- Both axles are steerable, manufactured by COLAERT ESSIEUX, the market leader in France

- Hydraulic brakes

- Trailer weight: 8,000 kg

- Frame made of 250 mm x 150 mm profile, with 6 mm thick chequer plate (tear plate)

Djdexpakfspfx Aa Ejcd

The entire construction is exceptionally robust.

Listing

Neckartailfingen

Neckartailfingen

18,617 km

Straw Shredding Machine

muetekMHZ 600

Call

Condition: new, Year of construction: 2025, Ideal for shredding straw, polystyrene, leaves, hay and bread.

Throughput depends heavily on the sieve and source material:

- up to a maximum of 350 kg / h for straw with a 15 mm sieve

- up to 60 kg / h for EPS with a 15 mm sieve

Motor 11 KW - 400 volts,

(9.2 kW or 15 kW also possible upon request)

Optional:

*Surcharge for the next larger machine with 18.5 kW and larger silo diameter + 1,995 € net

stable steel construction,

hardened cutting blades,

sieve with interchangeable inserts,

optional (10), 15, 22, 26, 30, 40, or 60 mm perforation

with electric drive with star-delta switch Ue protection and 8 m supply line ready to plug in,

blow-out nozzle 150 mm,

optional for plastic or Grain pipes,

Blowing width approx. 12 m,

Chassis with 2 wheels Ø 380 mm,

and a swiveling support wheel Ø 125 mm,

all wheels with solid rubber tires,

Dimensions approx. 1200 x 900 x 1270/1400 mm lxwxh

Weight approx. 240 KG,

Spare parts prices and options:

24 blades, hardened €9.90 each net

6 bolts €14.90 each net

Dcjdpfezbizsx Aa Eed

1 sieve €475 each net

Cover €290 each net

Styrofoam disc: €600 each net

Listing

Strenči

Strenči

17,170 km

Straw chopper

Call

Condition: used, Straw chopper

Dcjdpjxm S Taofx Aa Ejd

Length: 2.35 m

Width: 1.90 m

Power: 37 kW

Listing

Pichl bei Wels

Pichl bei Wels

18,329 km

Straw shredder KSTAS

voranKSTAS

Call

Condition: new, different types:

- Straw Shredder KSTAS 7,5kW

- Straw Shredder KSTAS 9kW

- Straw Shredder KSTAS 11kW

electric outlet 400V 50Hz (3 phases)

fuse 32 A

capacity 6 m³/h

dimensions:

length 1 225 mm

width 785 mm

Dcodpfx Aaob Nvtwj Eed

height 1 400 mm

weight 220 kg

material steel varnished

discharge height 550 mm

discharge connection diameter Ø 160 mm

suitable for all sorts of straw

scope of delivery screen 22 mm perforation

Discover more used machines

Listing

Pichl bei Wels

Pichl bei Wels

18,329 km

Strawshredder KSTAS power take-off drive

voranKSTAS

Call

Condition: new, - with power take-off drive 540 rpm without universal shaft

capacity 6 m³/h

dimensions:

length 1 225 mm

Dedpfjb Nvucex Aa Escd

width 785 mm

height 1 400 mm

weight 220 kg

material steel varnished

discharge height 550 mm

discharge connection diameter Ø 160 mm

suitable for all sorts of straw

scope of delivery screen 22 mm perforation

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Shredder for wood, plastic recycling

Double-Shaft Shredder For Recyclingwaste tire, wood,root,metal

Call

Condition: new, functionality: fully functional, Year of construction: 2026, Product overviews of Waste Industrial Timber Wood Pallet Double Shaft Shredder

Shredders can generally be used to shred hard-to-break plastics, rubber, large tires, large nylon materials, large pieces of fishing nets, fibers, paper, wood, electrical devices, cables, PET bottles, cardboard, wood, plastic barrels, etc. Solid objects.

The main function of the equipment is to squeeze the bulk materials and large-diameter drum metal materials that are not convenient for transportation through the shear of the shredder, and shred them into sheets that meet the requirements.

The main structure of the double-shaft shredder is a feed hopper, a knife roller, a driving device, a bearing, a hydraulic system, and an electric control box system.

Working principle: All kinds of waste materials enter the shredding chamber through the feeding hopper. The double-knife rollers do relative rotation to shred and cut the materials, and then the materials are discharged from the shredder to achieve the shredding of large pieces of materials.

Applicable materials and fields

Double shaft shredder is one of ethential equipment for waste recycling in following fields and materials:

+Bulky Waste: Sofa,Mattress,Chair, Funiture,Windows,etc

+Industrial Waste: Textiles,Leather,Rubbers, Leathers ,General industrial waste,etc

+Hazardous Solid waste: Medical waste,Paint sludge,Radioactive waste,Hazardous waste oil drum,Jumbo bag,etc

+Paper waste: Carton,Cardboard,Book,Newspaper,Document,Brochure,Packaging paper,etc

+Garden waste: Branch, Wood pallet, Trunks, Boards,etc

+Domestic waste +Biomass straw: Straw, Bamboo, Corn, Sorghum straw, Bean straw, Fruit shell, Palm shell, etc

+Scrap metal: Car Shell, Aluminum casting, Household appliances, Scrap light metal,Automobile hub,etc

+Paper mill waste: Paper mill slag, Paper mill rope, Paper mill offcut,etc

+Wood pallet, scrap furniture, waste chair, tree roots recycling, etc.

Double shaft shredder main body:

Dcsdpfjvn D I Nox Aa Eed

The main body is welded with excellent steel plate to ensure the stability of the equipment under heavy load for a long time.

Bearing:

The bearing seat is split and easy to disassemble, and the movable knife, fixed knife, bearing and other parts can be quickly removed, and it is easy to maintain and replace the knife. The sealing structure can avoid the contact of broken materials and grease, and can also protect bearings and gears when handling liquid materials.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

10,533 km

Drying system

Rotary Dryer for wood, biomass, sawdust1200X10000 rotary drum dryer

Call

Condition: new, Year of construction: 2026, power: 11 kW (14.96 HP), Rotary drum dryer for drying various kinds of materials like sand, biomass, sawdust, red mud, bentonite, coal

Diameter: 1200mm

Length: 10000mm

Power: 11-13KW

Gradient: 3%

Capacity: 1.5-3 t/h

Dcedeq Igyvjpfx Aa Ejd

Weight: 14Tons

Besides this model, we also have the other models of rotary drum dryer 1500x12000mm, 2400x20000mm, and complete drying system for various materials, welcome to contact us for more details

Our factory can design suitable solution according to your specific requirements.

Rotary drum dryers are highly efficient machines used extensively in the processing of wood chips, sawdust, and biomass. They operate by utilizing a rotating drum that heats and dries the materials as they are transported through the cylinder. The design of these dryers allows them to handle a wide range of particle sizes and moisture levels, making them suitable for various types of biomass. They can also tolerate high-temperature exhaust gases, which contributes to their efficiency and versatility in industrial applications.

Rotary Drum Dryer for Wood Chip, Sawdust, Biomass

🌳 Introduction to Rotary Drum Dryers

In the realm of biomass processing, moisture control is key. Enter the Rotary Drum Dryer, an indispensable machine designed to efficiently reduce the moisture content of wood chips, sawdust, and biomass. This essential tool enhances productivity, improves fuel quality, and is pivotal in biomass energy production. Let’s explore its functionality and benefits! 💡

💼 Key Benefits of Using a Rotary Drum Dryer

1. Energy Efficiency: Designed to optimize energy use, Rotary Drum Dryers consume less power while delivering high drying efficiency. 🌿💡

2. High Capacity: Capable of handling large volumes of biomass, these dryers are perfect for industrial applications where large-scale drying is needed. 🏭

3. Improved Product Quality: By achieving the optimal moisture content, the dryer enhances the quality of biomass for fuel, pellets, and other applications. 🔥

4. Versatility: Suitable for a wide range of materials including wood chips, sawdust, and various types of biomass, making it a versatile tool in any biomass processing plant. 🌳

# Application Fields and Materials of Rotary Drum Dryer

II. Application Fields

A. Agriculture

- Drying of grains, seeds, and forage.

- Processing of agricultural by-products like straw and husks.

B. Food Industry

- Dehydration of food products such as fruits, vegetables, and spices.

- Preservation of food quality during drying.

C. Chemical Industry

- Drying of chemical powders, granules, and crystals.

- Application in the production of fertilizers and detergents.

D. Mining and Minerals

- Drying of ores, coal, and mineral concentrates.

- Reduction of moisture content for easier handling and processing.

E. Construction Materials

- Drying of sand, cement, and other construction aggregates.

- Preparation of materials for manufacturing processes.

F. Pharmaceuticals

- Drying of pharmaceutical powders and active ingredients.

III. Materials Processed by Rotary Drum Dryer

A. Organic Materials

- Biomass, wood chips, sawdust, and animal feed.

B. Inorganic Materials

- Sand, clay, limestone, and gypsum.

C. Waste Products

- Sludge from wastewater treatment plants.

- Industrial by-products for recycling or reuse.

Listing

Sevenum

Sevenum

18,588 km

Wheel loadeWheel loader articulated load

Gunter machineGG010

Call

Condition: new, mileage: 1 km, power: 50 kW (67.98 HP), gearing type: automatic, fuel type: diesel, overall weight: 2,850 kg, lifting power: 1,000 kg/m, drive condition: 100 %, chain condition: 100 %, Year of construction: 2024, Equipment: additional headlights, cabin, GG010

The new Günter Grossmann GG010 LOADER The Günter Grossmann GG08 loader (1000 kg payload) is brand new. Günter Grossmann is a high quality machine made for a European company.

The charger is very strong and can work under all conditions. The charger is very nice. The control panel is very nice and clear. The cabin is soundproof, insulated, equipped with heating, very comfortable and beautifully glazed, allowing safe and comfortable work.

The machine has a very durable construction. The machine is equipped with a quick coupler, which makes it possible to change accessories quickly without leaving the cab.

Additional equipment: 4 in 1 bucket, crocodile grab, crocodile grab for trees, straw or silage.

Price

14,550 euros

(excl. VAT) Included as standard GG010 loader + bucket + pallet fork + quick coupler

Model 1000 kg

SPECIFICATIONS

Model: GG10

Brand: Günter Grossmann

Engine: Changchai 390

Engine: In-line setup, water-cooled four-stroke diesel engine

Engine power: 50 hp

Speed: 2200 r/min (rpm)

Steering system: Cycloid full hydraulic steering system: BZZ-80

System Pressure: 10MPa

Service brake: Hydraulic four-wheel brake with staggered shoes

Parking brake: manual

Tire: 10-16.5

Wheelbase: 2170mm

Track: 1285 mm

MEASUREMENTS

Total length (bucket at ground position): 41--mm

Ground to top of cab: 2530 mm

Total width: 1600 mm

Djdpfxeiit Ero Aa Eocd

WORKING RANGE

Bucket capacity: 0.5 m3

Bucket width: 1600 mm

Max. Height Breakout Force: 28KN

Rated load: 1000 kg

Operating weight: 2850 kg

Drive means: four-wheel drive

Min turning radius: 4600 mm

ACCESSORIES

Bucket 4 w 1: 1050 Eur

Pitchfork: 1050 Eur

Pallet fork: 650 Eur

Quick coupler: 600 Eur

Drill: 1400 Eur

Bale clamp: 950 Eur

Grass clip: 950 Eur

Lawnmower: 1450 Eur

Snowplow: 1375 Eur

Listing

Łask

Łask

17,845 km

Beverage production machine

TETRA PAK A3 COMPACT FLEX 200/250 EDGECOMPLETE LINE IN AS NEW CONDITION

Call

Condition: like new (used), Year of construction: 2010, TETRA PAK A3 COMPACT FLEX 200/250 EGDE COMPLETE LINE

INCLUDES:

1. TETRA PAK A3 COMPACT FLEX QUICK CHANGE 200/250 EDGE FILLER

V200, YOM 2010

15.120 RUNNING HOURS

CAPACITY 9.000 CARTONS PER HOUR

2. TETRA PAK ACHX 10-0400-44 HELIX CARTON ACCUMULATOR

V400, YOM 2010, 17.431 RUNNING HOURS

3. TETRA PAK STRAW APPLICATOR TS30 U-FORM

APGRATED V300, YOM 2010

4. TETRA PAK APPLICATOR CAP30 FLEX PRO23

V200, YOM 2010, 10.914 RUNNING HOURS

5. TETRA PAK FILM WRAPPER 32

V400, YOM 2010, NEVER USED, ONLY 45 HOURS!

6. TETRA PAK CARDBOARD PACKER CBP 32

V400, YOM 2010 WRAP AROUND

7. TETRA PAK LINE CONTROLLER LC30+

8. CONVEYORS SYSTEM

9. INC PRINTER VIDEOJET 1620

Dedpfeya Nf Iex Aa Ejcd

THE LINE IS IN AS NEW CONDITION. LOCATION - SWEDEN. READY FOR DISMANTLING AND SHIPPING IMMEDIATELY.

PRICE UNDER REQUEST

Listing

Hamburg

Hamburg

18,232 km

Warehouse

NordhallenR910

Call

Condition: new, Year of construction: 2025, functionality: fully functional, total width: 10,000 mm, total length: 9,000 mm, total height: 4,500 mm, Equipment: roof tent, NEW EQUIPMENT

Our various sizes—please let us know which one you require:

6m Wide

→ 6.1m x 6.1m x 3.66m → from €2,599

→ 6.1m x 9.15m x 3.66m → from €2,999

→ 6.1m x 12m x 3.66m → from €4,499

→ 6.1m x 18m x 3.66m → from €4,520

9m Wide (arch spacing 1m or 2m)

→ 9.15m x 10m x 4.5m → from €3,600

→ 9.15m x 12m x 4.5m → from €4,149

→ 9.15m x 16m x 4.5m → from €4,999

→ 9.15m x 20m x 4.5m → from €6,799

→ 9.15m x 26m x 4.5m → from €8,399

12m Wide (arch spacing 1.5m or 3m)

→ 12.2m x 12m x 6.1m → from €12,399

→ 12.2m x 21m x 6.1m → from €17,999

15m Wide (arch spacing 1.5m or 3m)

→ 15.25m x 12m x 6.1m → from €14,899

→ 15.25m x 21m x 6.1m → from €22,199

plus delivery costs

☆ FINANCING OR LEASING POSSIBLE from €69.89/month

☆ CERTIFIED PRODUCTS

☆ TRANSPARENT OFFER

☆ INCLUDES GERMAN STRUCTURAL ANALYSIS

☆ INSTALLATION AVAILABLE

☆ INSURANCE AGAINST FIRE OR STORM AVAILABLE

☑️ Genuine 750 g/m² PVC tarpaulin—more durable than standard products

☑️ Extra robust and tear-resistant thanks to fabric reinforcement

☑️ High UV resistance

☑️ 100% waterproof

☑️ Extra sturdy, galvanized tubing for maximum stability

☑️ Suitable for year-round use

☑️ German customer service and advice during purchase and assembly

☑️ Snow load: up to 130kg/m² (1m arch spacing) and 70kg/m² (2m arch spacing)

☑️ Wind load: up to wind zone 4 (1m arch spacing) and up to wind zone 2 (2m arch spacing)

☑️ Includes ground pegs and concrete anchors as well as all other small parts

☑️ Spare parts guaranteed

☑️ 5-year warranty on correctly installed PVC tarpaulin

☑️ 10-year warranty against steel frame corrosion

► Almost all models available for immediate delivery

► Colours: green or white

► Includes German structural analysis

► Doors on both gable ends

☏ Call us! We will gladly provide a non-binding quotation with best price guarantee.

THE IDEAL ALTERNATIVE TO PERMANENT BUILDINGS

Dcsdpfx Aoudwfnoa Ejd

Optimal protection from wind, sun, rain, hail, and snow!

☑️ Usually permit-free (unlike wooden, steel, or sheet metal halls)

☑️ No foundation required

☑️ High degree of stability and safety (verified by German engineering office)

☑️ Decades of use: high quality, guarantees, and spare parts supply

☑️ Robust, corrosion-free frame

☑️ Various shapes, colours, and sizes

VERSATILE APPLICATION OPTIONS

☑️ For agriculture, forestry, industry, commercial, and private use

☑️ Storage for goods, materials, or machinery

☑️ Garage / carport for trucks, motorhomes, or boats/yachts

☑️ Workshop in lightweight hall

☑️ Canopy for construction sites

☑️ Shelter or shed for livestock

☑️ Barn for straw, hay, and wood

☑️ Greenhouse for plants

! Prices incl. structural analysis

! Delivery and installation available

*Images similar

• Prices & colours may vary

• Price subject to change

• For exact pricing, please request a non-binding offer

• Available while stocks last

• Offer non-binding

Listing

Hamburg

Hamburg

18,232 km

Container roof

Covertop GmbHFT606

Call

Condition: new, functionality: fully functional, Year of construction: 2025, color: white, loading space width: 6,000 mm, loading space length: 6,000 mm, loading space height: 2,000 mm, NEW STOCK

Our different sizes:

Width x Length

→ 6m x 6m → from €1,299

→ 8m x 6m → from €2,099

→ 12m x 8m → from €3,699

→ 10m x 12m → from €4,599

→ 12m x 12m → from €10,745

plus delivery

☆ CERTIFIED PRODUCTS

☆ TRANSPARENT QUOTATION

☆ INCLUDES GERMAN STRUCTURAL ANALYSIS

☆ ASSEMBLY POSSIBLE

→ Genuine 750 g/m² PVC tarpaulin – more durable than standard market products

→ Extra strong and tear-resistant thanks to reinforced fabric

→ UV-resistant

→ 100% waterproof

→ Extra robust, galvanized tubing for maximum stability

→ Suitable for year-round use

→ German customer support and expert advice during purchase and installation

→ Snow load: 130 kg/m² (1m arch spacing) and 70 kg/m² (2m arch spacing)

→ Wind load: Wind zone 4 (1m arch spacing) and wind zone 2 (2m arch spacing)

→ Includes ground stakes, concrete anchors, and all other small parts

→ Spare parts guaranteed

→ 5-year warranty on correctly installed PVC tarpaulin

→ 10-year rust-through warranty on the steel frame

► Most models available for immediate delivery

► Colours: green or white

► Includes German structural analysis

► Doors at both gable ends

☏ Call us! We will gladly provide you with a non-binding quotation with our best price guarantee.

THE IDEAL ALTERNATIVE TO SOLID CONSTRUCTION

Optimal protection against wind, sun, rain, hail, and snow!

Usually permit-free (unlike wooden, steel, or sheet metal buildings)

No foundation required

High stability and structural safety (inspected by a German engineering office)

Decades of use: high quality, warranty, and spare parts supply

Robust, corrosion-free frame components

Various shapes, colors, and sizes available

Dodpsudwgfefx Aa Escd

MULTIPLE APPLICATIONS

→ In agriculture, forestry, industry, commerce, and private use

→ Storage space for goods, materials, or machinery

→ Garage / carport for trucks, motorhomes, or boats/yachts

→ Workshop in lightweight halls

→ Weather protection on construction sites

→ Shelter or stable for livestock

→ Barn for straw, hay, or timber

→ Greenhouse for plants

! Prices incl. structural analysis

! Delivery and assembly available

*Image similar

· Prices & colors may vary

· Subject to price changes

· For an exact price, please request a non-binding quotation

· Available while stocks last

· Non-binding offer

Listing

LEMGO

LEMGO

18,406 km

Timber transporter

MANTGS 33.520 6x6 BL Kurzholz Plattform Epsilon Kran

Call

Condition: new, power: 382 kW (519.37 HP), fuel type: diesel, tire size: 385/65-22,5, axle configuration: 6x6, wheelbase: 3,900 mm, fuel: diesel, fuel tank capacity: 390 l, brakes: retarder, color: white, driver cabin: sleeper cab, gearing type: automatic, emission class: euro6, suspension: steel-air, loading space length: 61,000 mm, Equipment: ABS, AdBlue, Bluetooth, EBS, air conditioning, central locking, crane, cruise control, differential lock, electric window regulation, electronic stability program (ESP), fog lights, navigation system, onboard computer, parking heater, power mirror, retarder, seat heater, soot filter, trailer coupling, - All-wheel drive

- Aluminum fuel tank

- Rear work lights

- Heated exterior mirrors

- Heated mirrors

- Passenger seat

- Bluetooth

- High beam

- Speed limiter

- Catalytic converter

- Automatic climate control

- Refrigerator

- LED lighting

- Air suspension

- Air-suspended seats

- Air horn

- Particulate filter

- PTO (Power Take-Off)

- Radio/multimedia system

- Reverse camera

- Sunroof

- Sleeper cab

- Seat heating

- Sun visor flap

- Lane departure warning system

- Stability control

- Parking heater

- Warming automatic system

- Toolbox

- Windshield

Internal reference number for customer inquiries: 4-093

MAN TGS 33.520 6x6 BL Shortwood Platform Body with Epsilon Crane!

Wheelbase 3,900 mm

!!! ALL-WHEEL DRIVE !!!

!! IMMEDIATELY AVAILABLE FROM STOCK !!

EURO 6E !!

* Cab TM: the comfortable one (narrow, long, medium height)

* All-wheel drive 6x6

* Suspension type: leaf/air (BL)

* 3,900 mm main wheelbase, 1,400 mm wheelbase between rear axles

* MAN D2676 LF78 diesel engine, 520 HP output, 2,600 Nm torque, Euro 6e

* MAN TipMatic 12.28 OD automatic transmission, with Retarder 35

* Eco retarder, speed-dependent, multi-stage, energy-efficient

* High-performance engine brake MAN EVBec, multi-stage

* Differential locks front, rear, center of the driven axles

* ROCKINGER trailer coupling type 500 G 6A (or 40mm on request)

* MAN EasyControl control panel, 4 functions, operable from outside with door open

* Driver comfort seat, air-suspended, with lumbar support, shoulder adjustment, and seat heating

* Multifunction leather steering wheel, height and tilt adjustable

* Lower bunk with slatted frame and adjustable head section

* Electrically operated front window sun blind (interior)

* Pull-out fridge and drawer

* MAN SmartSelect infotainment controller with touchpad and direct access

* MAN Mediasystem Navigation Professional 12.3-inch

* MAN Advanced Sound System with subwoofer

* Smartphone integration

Superstructure:

Loading length up to crane base 6,100 mm (Austria and South Tyrol special)

* Platform dimensions: length approx. 5,700 mm, width 2,540 mm

* Platform color: black

* 8x OPTIPA ALU10 stanchions with quick-change wedges, removable at any time (e.g. for transporting sawn timber, straw, hay, or silage)

* Stanchion storage vertically in front of bulkhead

* Toothed rails between stake pockets

Dcedpfx Aeylvcksa Ejd

* Lashing points in the outer frame

* Robust steel front wall

* Extendable ladder at front and rear for access to platform

* Preparation for manual strap winches (Autonordic) or alternatively air-operated (ExTe TU)

* Stainless steel toolbox under loading area

Crane:

EPSILON

FULLY HYDRAULIC TIMBER LOADING CRANE – configuration as per your choice (e.g. in stock: Epsilon TZ15 98)

* Lifting moment 104 kNm

* Slew range 425°

* Saddle seat with two mechanical levers, two mechanical foot pedals

* and more

Financing available through our financing partners.

For further questions, our sales team is happy to assist.

This is a non-binding offer. Subject to prior sale, errors, and changes.

Listing

Calden

Calden

18,424 km

Pellet mill, pellet mill, pellet plant

WALW-Solutions

Call

Condition: new, Year of construction: 2026, We offer:

Dcedpfxelt Ugto Aa Eed

Pellet machines from the WALW-Solutions brand, featuring unique quality, honest workmanship, and at a fair price.

Honest Work:

We manufacture our systems ourselves directly in Poland. Only components such as gearboxes and motors are sourced from reputable manufacturers. All other parts are designed and built in-house, allowing us to meet every requirement individually.

Fair Price:

We produce in Poland and are transparent about it. Other competitors who label their product as 'Made in Germany' typically only assemble the machines in Germany and source most components from Lithuania. We let you benefit from the lower production costs, which allows our offer prices to often be 40% below those of competitors.

These machines for pellet production are completely new to the market in this price/performance segment and are unique in Europe! WALW-Solutions machines are available exclusively through us!

From systems for processing your own wood chips from firewood operations or joineries, to professional industrial pellet production from wood chips, straw, miscanthus, etc.—as well as manufacturing hay or straw cobs—we can provide the ideal solution for your needs.

Our plants have capacities ranging from 150 kg/hour up to 5 t/hour and come equipped with all necessary components for a fully automated system. We offer tailored solutions for any input material and can integrate automation into existing systems as well.

All machines and control units are equipped with components from Siemens, ABB, Schneider Electric, or similar leading brands.

Please note: If you have a valid VAT ID, net purchases are possible!

We look forward to your inquiry! For more information or direct interest, please contact me on my mobile at:

Listing

LEMGO

LEMGO

18,406 km

Timber transporter

MANTGS 33.520 6x4 BL 3900 Kurzholz Plattform Aufbau

Call

Condition: new, mileage: 150 km, power: 382 kW (519.37 HP), first registration: 01/2026, fuel type: diesel, tire size: 385/65-22,5, axle configuration: 6x4, wheelbase: 3,900 mm, fuel: diesel, fuel tank capacity: 390 l, brakes: retarder, color: white, driver cabin: sleeper cab, gearing type: automatic, emission class: euro6, suspension: steel-air, loading space length: 61,000 mm, loading space width: 25,400 mm, Year of construction: 2026, Equipment: ABS, AdBlue, Bluetooth, EBS, air conditioning, central locking, crane, cruise control, differential lock, electric window regulation, electronic stability program (ESP), fog lights, navigation system, onboard computer, parking heater, power mirror, retarder, seat heater, soot filter, trailer coupling, - Aluminum fuel tank

- Rear working lights

- Heated exterior mirrors

- Heated mirrors

- Passenger seat

- Bluetooth

- High beam

- Speed limiter

- Catalytic converter

- Automatic climate control

- Refrigerator

- LED lighting

- Air-suspended seats

- Air horn

- Particulate filter

- PTO (Power Take-Off)

- Radio/multimedia system

- Sleeper cabin

- Seat heating

- Sun visor flap

- Lane departure warning system

- Stability control

- Auxiliary heater

- Warming automatic

- Toolbox

- Windshield

Internal reference for customer inquiries: 3-039

Dcedpfx Ajylutuea Eed

MAN TGS 33.520 6x4 BL short timber flatbed body with quick-change stakes and crane of your choice!

Wheelbase 3,900 mm

!! IMMEDIATELY AVAILABLE FROM STOCK !!

* EURO 6E!!

* Cab TM: the comfortable (narrow, long, medium-high)

* All-wheel drive 6x4

* Suspension type leaf/air (BL)

* Main wheelbase 3,900 mm, 1,400 mm axle spacing at the rear

* MAN D2676 LF78 diesel engine, 520 HP, 2,600 Nm torque, Euro 6e

* MAN TipMatic 12.28 OD automatic transmission with Retarder 35

* Retarder Eco, speed-dependent, multi-stage, energy-efficient

* High-performance engine brake MAN EVBec, multi-stage

* Differential lock on driven rear axles

* Trailer coupling at the rear cross member, RINGFEDER type 4040/G150B

* MAN EasyControl control panel, 4 functions, operable from outside when the door is open

* Driver comfort seat, air-suspended, with lumbar support, shoulder adjustment, and seat heating

* Multifunction leather steering wheel, height and tilt adjustable

* Lower bunk with slatted frame and adjustable headrest

* Front windscreen sun blind, electric, interior

* Pull-out fridge and drawer

* MAN SmartSelect infotainment control with touchpad and direct access

* MAN Media System Navigation Professional 12.3 inch

* MAN Sound System Advanced with subwoofer

* Smartphone integration

* and much more

Body:

* Loading length up to crane base 6100 mm (Austria and South Tyrol special)

* Platform itself measures approx. 5700 mm long x 2540 mm wide

* Platform color: black

* 8x OPTIPA ALU10 stakes with quick-change wedges, making the stakes removable at any time (e.g. for transporting sawn timber, straw, hay, or silage)

* Holding area for stakes upright in front of the bulkhead

* Rack rails between stake pockets

* Lashing points on the outer frame

* Sturdy steel bulkhead

* Extendable ladder front and rear for access to the platform

* Preparation for manual strap tensioners (Autonordic) or alternatively pneumatic (ExTe TU)

* Stainless steel toolbox under the loading area

Crane:

Your choice:

- Palfinger TZ15 9.8

- Palfinger Epsilon Q150Z 9.6

- TajfunLIV 150Z 9.6

- TajfunLIB 150Z 9.6 cabin crane

Financing available through our financing partners.

For further questions our sales team will be happy to assist you.

This is a non-binding offer. Subject to prior sale, errors and changes.

General information

Cab: Long distance traffic

Technical information

Number of cylinders: 6

Engine displacement: 12,419 cc

Gross vehicle weight: 33,000 kg...

Listing

Ukraine

Ukraine

18,643 km

Used aseptic line for tretra pack fino 1 L - 3600 PPH

SOCO System

Call

Condition: used, Year of construction: 2006, operating hours: 18,625 h, machine/vehicle number: LC598, Technical Specifications & Performance DataThis complete Tetra Fino Aseptic line is an integrated aseptic packaging solution engineered by Tetra Pak for liquid food applications. The core filling machine was manufactured in 2006 and is complemented by downstream packaging equipment. Designed for industrial packaging and beverage production, it provides reliable second hand performance with hygienic processing and efficient material handling.Production speed: up to 3,600 packages/hourContainer type: Carton-based aseptic packages (Tetra Fino Aseptic family)Supported volumes: 1.0L Primary product currently run: MilkMain filler year: 2006Additional module: SOCO System unit, year 2014Accessories: Trolley for packing with roll holder, ABC valve, 1 m mesh conveyorAdvanced Automation & Control SystemsThe line incorporates an industrial control panel for central operation of filling and downstream handling. The aseptic filler integrates automatic process sequences for sterilization, filling, and sealing under controlled conditions. Operator safety interlocks and machine guarding support safe operation, while standardized HMI navigation streamlines recipe selection and format changes. The architecture is designed for fast restarts and consistent uptime in high-demand environments.Production Line Integration CapabilitiesThis used bottling line is configured for inline operation, linking the aseptic filler with conveyors and a SOCO System packaging module. It supports integration with typical ancillary devices such as product dispensers, cap or straw applicators, and end-of-line packaging machinery. Format changeovers accommodate multiple carton volumes within the 0.2L to 1.0L range, enabling multi-product flexibility for milk and juice production. The conveyor layout ensures smooth product transfers and balanced accumulation between stations.Machine Condition & Maintenance HistoryThe equipment is reported in production with overall good condition. Continuous operation on milk indicates stable performance and consistent hygiene compliance. The 2006 filler and 2014 downstream module are maintained to sustain aseptic integrity and packaging quality, making this second hand industrial packaging line a strong candidate for rapid redeployment.Operational Performance & VersatilityOptimized for liquid food, the line supports aseptic packaging of products such as milk and juices in pillow-style Tetra Fino Aseptic formats. Key benefits include extended ambient shelf life without preservatives, high barrier multi-layer materials, and hermetic sealing. The layout offers reliable filling accuracy, gentle product handling, and quality consistency suitable for beverage production requiring long shelf life and stable logistics.Installation Requirements & Site PreparationThe system is designed for standard industrial facility layouts with room for filler, conveyors, and a compact end-of-line module. Typical utilities include electrical power, compressed air, and process water as required by aseptic operations. A clean, controlled environment is recommended to maintain aseptic performance, with adequate access for o...

Dcodpfjyh E Apjx Aa Ejd

Listing

Sępólno Krajeńskie

Sępólno Krajeńskie

17,842 km

Chopper Forage Harvester Shredder PC2200

AFAUPC-2200

Call

Year of construction: 2010, condition: good (used), functionality: unexamined, For sale: straw shredding line.

The line consists of:

- horizontal feeder,

- inclined feeder,

- chopper with housing,

- individual bag filter.

Line capacity: approx. 5 t/h

Dcsdpewttp Sefx Aa Eed

Length of horizontal feed table: 7.6 m

Drive motor power of horizontal feed table: 1.5 kW

Length of inclined feed table: 12.5 m

Drive motor power of inclined feed table: 1.5 kW

Shredder dimensions:

Height: 8.2 m

Length: 5.2 m

Width: 3.8 m

Power: 2 x 132 kW

Each shredder is equipped with an individual bag filter.

For more photos and details, please contact us.

Machines can be viewed in Sępólno Krajeńskie, Kuyavian-Pomeranian Voivodeship, Poland.

Listing

Sępólno Krajeńskie

Sępólno Krajeńskie

17,842 km

Tank with discharge augers

AFAU

Call

Condition: used, Year of construction: 2011, functionality: unexamined, For sale: container with extraction augers.

The container was used as a buffer in a straw pellet manufacturing facility.

Container dimensions:

Height: 7750 mm,

Width: 2150 mm,

Depth: 3140 mm,

Rail height on container: 900 mm,

Container capacity: approx. 40 m3,

Discharge window size: 1000x350 mm

Djdpfx Aswy T R Nsa Eecd

3 extraction augers, each 1.1 kW

The container has been disassembled and is ready for transport.

For more photos and details, please contact me.

Machines available for inspection in Sępólno Krajeńskie, Kuyavian-Pomeranian Voivodeship, Poland.

Listing

Sępólno Krajeńskie

Sępólno Krajeńskie

17,842 km

Pellet press

BuhlerDPAA-660

Call

Condition: used, Year of construction: 1985, functionality: fully functional, For sale: granulator from the renowned manufacturer Buhler.

Granulator model: DPAA-660

Motor power: 160 kW – option to install a more powerful motor – 200 kW.

Die diameter: 660 mm,

Die working width: 160 mm,

Granulator output on straw / sawdust: 2 – 2.5 t/h

Djdpfx Aow Uh Nzja Escd

The granulator is currently dismantled. For a committed buyer, we will assemble it using new wear parts.

Contact for more photos and details.

Machine available for inspection in Sępólnie Krajeńskie, Kuyavian-Pomeranian Voivodeship, Poland.

Listing

Elsdorf

Elsdorf

18,285 km

Weidemann wheel loader telescopic loader 5080t

Weidemann5080t

Call

Condition: like new (used), Air conditioning, heating, year of manufacture 2023, 2020 operating hours, condition: as new. Adjustable fork for straw, 3 hydraulic lines on quick coupler, tyres as new (550/45-22.5).

Dcsdjx Urdwepfx Aa Esd

Listing

Goudriaan

Goudriaan

18,595 km

Container

Stro ontijzerings container

Call

Condition: new, Year of construction: 2021, loading space volume: 8 m³, Straw de-ironizing container

• Capacity: 7.5 m3

• Lifting eyes

• Fork pockets

• Detachable grates

• Fully customizable!

Dedjykccuepfx Aa Escd

Condition: New

Year of manufacture: 2021

Trust Seal

Dealers certified through Machineseeker

Listing

Gorzów Wielkopolski

Gorzów Wielkopolski

18,013 km

Briquetting press PRODECO E60 Super

PRODECOE60 Super

Call

Condition: new, Year of construction: 2025, The E60 Super briquetting machine is a highly efficient briquetting machine, the speed of which, depending on the processed material, ranges from 40 to 100 kg/h.

The device uses a 10kM engine.

The briquetting machine is powered by 400V - 50Hz.

Dcjdpfx Ajtvmf Noa Eod

The output material has a diameter and maximum length of 60mm.

The device has a double pressure gauge, a device for measuring the oil level and a viewing window.

SIEMENS LCD control, maintenance-free operation of the machine.

Processed materials:

• sawdust,

• paper,

• straw

• etc.

Briquette diameter: 60mm

Engine power: 7.5 kW, IE2, high efficiency

Efficiency: 40/100 kg/h

Cylinder diameter: 1000mm

Pressing force: 900 kg/cm2

Maximum briquette length: 60mm

Power supply voltage: 400 V

Dimensions: 1510 x 1850 x 1170 mm

Weight: 770 kg

Number of cycles: 7/min

Number of cylinders: 3

Pump pressure gauge: electronic

Oil level and temperature sensor: in the tank

Control: PLC Siemens

Listing

Neckartailfingen

Neckartailfingen

18,617 km

Briquetting press

mütek SystemtechnikMPP 60

Call

Condition: new, Year of construction: 2026, Our best-selling briquetting press, the classic.

+ Tried and tested, simple technology for extremely low susceptibility to errors

+ 25 years of experience, further development and know-how

+ Several thousand machines in use with satisfied customers

+ Top price-performance ratio

Dcedpfogl Nlmex Aa Eod

Options for an extra charge:

* Surcharge for the level indicator that enables automatic operation + € 995 net

* Surcharge for large pre-compression chamber + 980 €

(recommended for light material like straw)

Briquette diameter: 50 mm

Front bush: 50 mm

Briquette stroke max .: 40 mm

Briquette lift opt .: 40 mm

Throughput (depending on material): 30-60 kg / h *

* depending on the bulk weight

* based on a bulk weight of 200 kg per cubic meter

.

Motor power: 5.5 kW

400 volts / 50 Hz / 3 phases

Length: 1680 mm

Width: 1100 mm

Height: 1500 mm

Weight: 680 kg

Oil volume: 110 liters

Silo diameter: 1000 mm

Silo content: approx. 0.7 square meters

Pump: 27 liters

Hydraulic pre-compressor

Option cooling pressing tongs: no

Hydraulic oil cooling option: yes

Level monitoring option: yes

CE compliant

.

Requirements for the raw material:

- The moisture content (atro) must be between a minimum of 6 and a maximum of 18%

- Maximum chip length 15 mm

- Installation temperature: temperature-controlled room at at least + 5 ° C

- The customer must insure himself against loss of hydraulic oil

- The loading must be free of metals and mineral impurities such as sand, stones, etc. This can result in damage to the pressing tools and / or increased wear

Listing

Buchen

Buchen

18,555 km

Industrial robot

DobotCR20AF

Call

Condition: new, Year of construction: 2025, DOBOT Robot CRAF Series CR20AF

The Next Generation of Force-Controlled Cobots

The DOBOT CRAF series has been developed for high-end manufacturing applications such as precision assembly, complex grinding, and medical automation, redefining intelligent force control with its proprietary algorithms and integrated high-resolution sensors.

It offers plug-and-play operation with no installation or deployment required, enabling adaptive force applications and seamless human-robot collaboration—setting a new standard for precision, safety, and user-friendliness in smart manufacturing.

CR20AF

Maximum Payload: 20 kg

Working Radius: 1,700 mm

Repeatability: ±0.05 mm

All-in-One Force Control, Plug-and-Play

Based on the CRA series, the CRAF series is equipped with a high-precision 6-axis force sensor integrated into the flange end, providing the cobot with enhanced compliant force control and precise operating functions.

Flange with Status Ring Light

Features a ring-shaped status light for real-time visibility of the robot's status. Equipped with a push-to-pull button.

Unoccupied End Interface

Does not occupy tool-side RS485 or I/O ports, ensuring compatibility with external devices (such as electric grippers or the VX500 Smart Camera).

Intelligent Force Control for Safety and Reliability

Smooth Dragging – Easy to Operate

The entire flange serves as an active resistance zone for intuitive teaching.

Dedpfx Aaeyiafus Escd

Assembly

Users can constrain the orientation for precise path programming.

Welding

Thanks to the extremely low starting force (2N), the CRAF robot can be easily guided by touching it with a straw. This enables millimetre-precise hand-guided teaching and achieves a point-to-point accuracy of 0.1 mm.

Polishing

The CRAF robot maintains constant force with automatic compensation, ensuring flawless performance in high-precision applications such as automotive sanding and polishing.

Healthcare

The robot provides real-time detection of its surroundings (e.g., detecting height differences on tables) with automatic surface scanning, enabling adaptive motion control for precise task execution based on environmental feedback.

Other Collaborative Scenarios

With the integrated force-sensitive collision detection (with sensitivity down to 1 N), the CRAF robot significantly reduces collision forces while achieving industry-leading impact resistance of 2000 N. This allows it to reliably handle frequent operational impacts and collisions caused by disturbances in real-world applications.

Application Scenarios

Welding

Loading and Unloading

Gluing

Material Handling

Listing

Menslage

Menslage

18,398 km

SIG Combiblock Meurer, Geyssel SIG Combiblock

SIG CombiblockSIG Combiblock

Call

Condition: used, Year of construction: 1999, Overview This filling line for carton packaging from 1999 consists of a SIG Combiblock filler, accumulation system, straw applicator, shrink tunnel, and carton packer. The line currently fills juices into carton packs. The machines will be in operation until the end of June and can be viewed in person at any time. One will be free in June, one in October Technical details Output: 12,000 bottles per hour Volume: 200ml Packaging: cardboard, CB7 (feeder) Format shrink tunnel: 2x5 Carton packer format: 30 pack / 60 pack Machine list Filler | SIG | Combibloc CFA 712 | 1999 | Operating hours: 112.650 h Vertical accumulation system | Meurer | CM/ VSP 1200 | 1999 Straw applicator | Geyssel Cologne | 432 | 1999 Shrink tunnel | Meurer | CM/ BK 40-T80 | 1999 Carton packer | Meurer | CMT/ TP | 1999 Shrink tunnel | Meurer | CM/ BK 40-T80 | 1999 Carton packer | Meurer | CMT/ TP | 1999

Djdpfx Aer It Stja Escd

We make it easier for you to find: "straw"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Straw (58)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you