Used File Paternoster for sale (648)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Weppersdorf

Weppersdorf

18,173 km

Pavoni Automazioni Vertical 2200 Open

Pavoni AutomazioniVertical 2200 Open

Call

Condition: excellent (used), Year of construction: 2015, operating hours: 2,416 h, functionality: fully functional, machine/vehicle number: 03814V2200, travel distance X-axis: 2,200 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 280 mm, rapid traverse X-axis: 7 m/min, rapid traverse Y-axis: 7 m/min, rapid traverse Z-axis: 6 m/min, feed length X-axis: 2,200 mm, feed length Y-axis: 1,200 mm, feed length Z-axis: 280 mm, feed rate X-axis: 7 m/min, feed rate Y-axis: 7 m/min, feed rate Z-axis: 6 m/min, total height: 2,400 mm, total length: 3,000 mm, total width: 1,200 mm, table width: 280 mm, table height: 1,200 mm, table length: 2,200 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 18,000 rpm, overall weight: 1,100 kg, spindle speed (min.): 1,000 rpm, spindle speed (max.): 18,000 rpm, coolant supply: 3 bar, spindle motor power: 4,500 W, number of spindles: 1, number of slots in tool magazine: 1, input voltage: 380 V, type of input current: three-phase, Equipment: rotational speed infinitely variable, NUMERICALLY CONTROLLED PANTOGRAPH WITH VERTICAL PLANE MODEL "VERTICAL 2200 OPEN"

WITH 3 INTERPOLATED AXES FOR WORKING MARBLE AND GRANITE

basic assembly:

- range: x-axis=2200 mm. y-axis=1200 mm. z-axis=300 mm;

- work surface L. 2500 x H. 1250 mm;

- heavy carpentry-made structure in processed and painted steel;

- Side openings with loops, both on the left and on the right, for processing oversized blocks with

Dcodoygxc Ajpfx Ac Noc

support rolls;

- slabs and carter support in inox steel;

- highly deep workbench made with extruded aluminium profile ;

- slab locking with n°2 clamps with mechanical blocking device;

- three-phase electro spindle hp 5 1/2 gas connection with perforated shaft and rotating joint for water

passage for internal and external tool refrigeration, and inverter for variation to maximum 18000 r.p.m .;

- openable polycarbonate protection for electro-mandrel, with safety micro;

- axes movement by means of runners and sliding blocks of balls recircle;

- dust tents for total protection of all moving parts;

- water cooling tool system with centralized drain, including pump, decanting tanks and locking electrovalve;

- electronic panel with console comprising numeric control, pc and monitor.

Windows software included

ARTCAM INSIGNA:

- carrying out of reliefed and engraved writing, using all "true Type" fonts;

- cad for carrying out drillings, cuts, engravings, millings and inlays;

- import of most common types of files as dxf and dwg to create writings, drawings and stamps, reliefed and

engraved logos, showr trays, sinks, arcs and portals;

- automatic drilling for inserting bronze letters;

- carrying out single and multiple sculptures in high and bas-relief;

automatic switch off;

3D PLAN LASER laser copyng system to import manufactured products and tree-dimansional figures (bas and

hight - relief) with interface and software for required dimensions

Listing

Łódź

Łódź

17,807 km

Steam boiler

ICI CaldaieGSX 850

Call

Condition: excellent (used), Year of construction: 2019, operating hours: 34 h, functionality: fully functional, pressure: 12 bar, operating pressure: 20 bar, temperature: 191 °C, operating temperature: 20 °C, nominal heat output: 579 kW (787.22 HP), Manufacturing Year/ Rok produkcji: 2019

Working Pressure: 12 bar

Gas Burner/ Palnik Gazowy

Dodpfx Asygvp Hjc Njcc

Performance/ Wydajność: 850 kg/h

Max. steam temprature/ Maksymalna temperatura pary: 191,7°C

Run Hours/ Ilość godzin przepracowanych: 34 R/h

Full Techincal Documentation / Pełna dokumentacja techniczna.

Documentation ready to be filed to UDT/ Dokumentacja przygotowana do zgłoszenia do UDT

Offer includes extra stainless steel set of chimneys/ Oferta uwzględnia zestaw kominów ze stali nierdzewnej

Full installation equipment & armature / Pełny osprzęt do instalacji i armatura

Listing

Emskirchen

Emskirchen

18,467 km

Automatischer Palettierer / Automatic Palletizing

KolbusPL 770

Call

Condition: used, Vollautomatisches Palettieren von losen Stapeln und festen Gebinden mit einer Geschwindigkeit von bis zu 1,800 Stapel/Std.

Fully automated palletizing of loose stacks and solid containers at a speed of up to 1,800 stacks/hr.

Automatischer Palettierer / Automatic Palletizing Kolbus PL 770

Baujahr / Year 2007 - Serial-No. 66

Djdpeydfypjfx Ac Nscc

Produktzufuhr über Staurollenbahn / product infeed via accumulating conveyor

Drehpaternoster 90° / 180° inkl. Eintaktung / rotary paternoster 90° / 180° inkl. synchronisation

Verfahranschlag zum Absetzen von besonders glatten Produkten / travel stop for dropping of very smooth products

Palettenauslage gerade / pallet delivery straight

Palettenentnahme in Laufrichtung / pallet removal in moving direction

Pallet sizes 1,360 x 1,200 or 1,000 x 800mm

Speed 30 Stacks/min

Online-Video-Inspection by WhatsApp - MS Zoom - Telegram

On Stock Emskirchen/Nürnberg - Available Immediately - Can be test

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Schijndel

Schijndel

18,596 km

Kolbus case maker DA 370 (2023)

KolbusDA 370

Call

Year of construction: 2023, condition: used, Case maker

Kolbus DA 370

Year: 2023

New generation of casemaker for faster production and shorter make-ready times.

Automatic production of book cases, files, display cards, calendar backs or game boards, at rates of up to 65 cycles/min.

Maximum production and process reliability in the manufacture of book cases. The DA 370 casemaker is a versatile machine for a wide range of applications. The machine with its non-stop case feeder is engineered to be ergonomic and extremely operator-friendly so that it can be easily operated by one person.

Configuration:

- Copilot system with touchscreen

Dedpfx Acsydc A Ie Nocc

- sectional touch panel for direct operation

- large display for showing the speed and malfunction messages

- board prestacking conveyor to automatically reload the magazines (stream cover and stack feeder)

- counter-stacker delivery with roller conveyor delivery incl. table

- cloth feeder for non-stop operation with stack magazine

- missing product check during separation of cloth and cardboard

- cloth cylinder with grippers and interchangeable plates for rubber pads (5 plates 500 mm wide and 5 plates 720 mm wide, incl. 10 rubber pads)

- cardboard centre strip magazine

- device used to prepare centre strip roll

- centre strip waste chopper

- centre strip rub-down unit (head and foot)

- rub-down unit used to bond the covering material to cardboards and spine strip without creases

- extendable gluing station for processing hot glue with glue preparation in the premelter, heated glue roller and scraper roller

- viscosity control unit for an automatic supply of water via a water container with a pump

- device for padded cases

- function used to request individual cases for monitoring purposes on the operating side

- servo-controlled drive technology based on Siemens technology

Special equipment:

- device for producing quarter-bound cases in two operating steps

- device for small format

- device for large format

- Remote Service Gateway

Technical specifications:

- Mechanical speed: up to 65 cycles/min

- Open cover size max.: 205 x 670 mm

- Joint width: 4 - 15 mm

- Spine width: 14 - 120 mm

- Turn in width open: up to 19 mm

- Cloth width: 223 - 708 mm

- Cloth height: 158 - 428 mm

- Board thickness: 1 - 4 mm

- Board width: 95 - 328 mm

- Board height: 140 - 390 mm

- Board centre strip thickness: 1 - 4 mm

- Board centre strip width: 6 - 90 mm

- Centre strip roll thickness: 0,3 - 0,6 mm

- Centre strip roll width: 6 - 90 mm

- Lining width: 195 - 670 mm

- Lining height: 130 - 390 mm

Listing

Gdańsk

Gdańsk

17,730 km

Laser cutting machine

WAT MachineryT3015F

Call

Condition: new, functionality: fully functional, Year of construction: 2025, laser power: 1,500 W, input voltage: 380 V, total length: 3,000 mm, total width: 1,500 mm, Equipment: documentation/manual, WatMachinery OT3015F is a modern fiber laser cutting machine with a 1500 × 3000 mm working area, equipped with high-quality industrial components and an automatic Raytools BS03K cutting head. The machine is designed for precise and efficient cutting of carbon steel, stainless steel, aluminum, and brass.

Available laser source powers: 1500 W / 2000 W / 3000 W (Raycus).

Key Advantages

- Heavy-duty construction – high rigidity, stability, and vibration resistance

- 4th generation aerospace-grade aluminum gantry – low weight, rapid acceleration, and high motion accuracy

- Raytools BS03K cutting head – automatic focusing, optics protection, high cutting speed

- Raycus laser source – reliability, long service life, and high energy efficiency

- Raytools XC3000S control system – intuitive operation, file editing, remote control capability

- INOVANCE servo drives – high precision, fast dynamic response, stable operation

Rebi N Auewiwtyofcen

- Precision drive system – LEITESEN racks (dual drive) + PEK Italia linear guides

- SMC pneumatic system (Japan) – reliability and longevity

- Schneider (France) electrical components – high safety standards

- S&A industrial chiller – dual-circuit cooling, alarms and machine protection

- Fume extraction system – efficient smoke removal and improved working conditions

- Complete industrial configuration – machine ready for operation immediately after installation

Technical Specifications

Model: OT3015F

Working area: 3000 × 1500 mm

Laser source: Raycus Fiber (1500–3000 W)

Wavelength: 1070–1080 nm

Interfaces: USB, RJ45

X Axis

- Max speed: 80 m/min

- Travel: 3000 mm

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Y Axis

- Max speed: 80 m/min

- Travel: 1500 mm

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Z Axis

- Travel: 100 mm

Additional Parameters

- Maximum acceleration: 0.8 G

- Power supply: 380 V / 50 Hz

- Operating mode: 24/7 continuous operation

- Machine weight: approx. 1500 kg

- Dimensions: 4500 × 2300 × 1500 mm

Applications:

✅ Kitchen equipment industry

Dedpfx Acewiwtyo Nocc

✅ Bathroom equipment industry

✅ Automotive

✅ Advertising and metalworking

Why choose us?

JET STAR INTERNATIONAL offers comprehensive solutions for laser cutting machinery, providing service, training, and spare parts availability throughout Europe. Our machines combine quality with affordability, delivering an excellent cost-to-performance ratio.

🗂️ Available to order

📞 Contact us for individual offers and delivery terms!

🌍 Support available in Polish, English, and German.

Listing

Hørning

Hørning

18,021 km

Four-sided planer

KUPERTYP SWT 23 XL - 5

Call

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, Table lenght 2000 mm.

Workingwidth: max. 230 mm / min. 18 mm.

Dcjdpfx Aexr U Azjc Nec

Workingheight: max. 150 mm / min. 8 mm

el height adjustable

Speed 7-36 m/min. 3,7 kw motor, cardan

5 pcs. Ø 40 mm. spindels: b + r + l + t + b (specifikations see file attached

Siemens touchscreen

see all technical features attached file

Listing

Hørning

Hørning

18,021 km

DEP

CMLMOD. STDA 336

Call

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, CML - DEP FLEXIBLE LINE FOR WINDOWS ELEEMNTS PRODUCTION AS PER LAYOUT LY-09-087-05 DATED 27/01/2010

01 BELT CONVEYOR 1=4500 mm

Dodpfx Aoxtacisc Nocc

02 "L" TRANSFER WITH PVC COATED ROLLERS AND BUFFER

03 DOUBLE END TENONER CML MOD. STDA 336

04 FULL SYSTEM FOR MACHINE CONTROL

SEE TECHNICAL FEATURES ATTACHED PDF-FILE

Listing

Su Zhou Shi

Su Zhou Shi

9,837 km

Semi Auto Tube Bending Machine, Bender

EQ AutomationBD38NCCOMP

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2026, operating hours: 8 h, machine/vehicle number: BD38NCCOMP, bending angle (max.): 190 °, overall weight: 900 kg, total length: 3,100 mm, total width: 950 mm, total height: 1,500 mm, power: 6 kW (8.16 HP), input voltage: 220 V, type of input current: AC, warranty duration: 12 months, Semi-Automatic Single-Head Hydraulic Pipe Bending Machine BD50NC2A

Machine Model: BD38NCCOMP

Machine Applications

Transportation Sector

For locomotives, automobiles, and bicycles: exhaust manifolds, brake lines, fuel supply conduits, steering mechanisms, air -

conditioning ducting systems, seating assemblies, balancing components, bumper structures, window frame assemblies, handlebar

components, and frame structures.

Furniture Industry

Indoor and outdoor seating and table sets, office furniture including desks and chairs, shelving units, bed frames and associated

furniture pieces.

Leisure and Recreation Industry

Fitness apparatus, infant strollers, utility carts, and amusement ride installations.

HVAC (Heating, Ventilation, and Air - Conditioning) and Appliance Industry

Water heating units, electric heating appliances, gas - fired cooktops, refrigeration units, and air - conditioning equipment.

Dcjdsya An Nspfx Ac Nec

Heavy Industrial Sphere

Piping networks for boilers, heat exchanger, power generation plants, chemical processing facilities, diesel engine manufacturing, and

shipbuilding operations.

Diverse Other Industries

Household consumer goods, rehabilitation - oriented medical devices, sanitary fixtures, the decoration and interior design sector, the construction industry, agricultural machinery and equipment, and the aviation manufacturing and maintenance industry.

Specification

The largest applicable carbon steel pipe (bending radius ≥ 2d) Φ38×2.0mm (thickness Max. 2.0)

The largest applicable stainless steel pipe (bending radius ≥ 2d) Φ38×1.5mm (thickness Max. 1.5)

Maximum core length (*) 850mm

Critical Parts and Functional Components

Maximum bending radius (*) 320mm

Maximum bend angle 190°

The number of bends that can be set for each pipe fitting (*) 25 bends

The number of pipe fitting files can be set 280 sets (extensible)

Working speed bending speed Max.90°/s

Machine tool bending angle ±0.1°

Listing

Vechta

Vechta

18,378 km

Single shaft shredder

NEUENHAUSERTARGO 3000

Call

Condition: reconditioned (used), Year of construction: 2017, functionality: fully functional, power: 405.26 kW (551.00 HP), Mobile shredder on crawler chassis.

Diesel engine: 551 HP

Folding discharge conveyor

Overbelt magnet (neodymium)

Dcjdpfx Aju R Uaxsc Noc

Radio remote control

Detailed description: see pdf-file

Listing

Alkmaar

Alkmaar

18,530 km

Paper cutting machine

IechoPK-0705 Plus

Call

Condition: new, Year of construction: 2025, functionality: fully functional, The iEcho PK-0705 Plus is a compact, fully automatic digital cutting plotter specifically designed for the graphic arts industry, packaging development, and advertising technology. It is the ideal solution for small to medium production runs where die-cutting is required without the need for expensive physical dies.

Key Features:

The PK-0705 Plus is an "all-in-one" system capable of cutting, creasing, and kiss-cutting in a single operation. Being digitally controlled, it eliminates the costs and lead times associated with conventional die-cutting tools.

Dcjdjyf D Egjpfx Ac Noc

Applications: Labels, folding cartons, personalized packaging, stickers, POP displays, and greeting cards.

Materials: Cardboard, corrugated board (E-flute), PVC sheets, sticker paper, and various plastics.

Automatic Feeding System: The plotter is equipped with a vacuum feeder that automatically processes sheet stacks, enabling productive, unattended operation.

Oscillating Tool (EOT): Unlike basic plotters, the Plus model features a vibrating knife, allowing it to precisely cut thicker or more rigid materials (up to 6 mm).

CCD Camera: A high-precision camera system automatically detects register marks on printed sheets for highly accurate contour cutting, even if the sheet is fed with a slight skew.

Vacuum Table: Securely holds the material during cutting to ensure maximum precision.

Working Area: 750 mm x 530 mm

Max. Material Thickness: Up to 5 mm (depending on the tool)

Tool Configuration: Oscillating knife, drag knife, creasing wheel

Efficiency: No setup times required for die-cutting – simply load the file and start.

Versatility: One device for a wide range of materials, from paper to thin rigid foam boards.

Space-saving: Compact design fits into nearly any print shop.

Summary: The iEcho PK-0705 Plus is a true workhorse for print shops seeking the flexibility to meet customer demands while maintaining the precision of an industrial die-cutting machine for small production runs.

Listing

Nattheim

Nattheim

18,550 km

CNC machining center

MorbidelliUniversal 3615 TV

Call

Condition: used, Year of construction: 2008, · Working area X-Y-Z: 3,660 x 1,550 x 130 mm · Travel length X-Y: 4,200 x 2,000 mm Description of the units and accessories (base) The structure of the base body is a monolithic construction made of thick-walled steel. It is stiffened by welded triangular plates across the entire machine bed, making it extremely stable. The triangular shape used for load-bearing parts, with a large base, is the secret to ensuring lasting precision and stability. The machine layout allows the user an optimal workflow despite minimal space requirements. The base body constructed in this way therefore offers the machining unit a balanced and secure base with particularly good load distribution. The mobile unit carrier in gantry design is made of a solid monoblock. It is positioned in the X direction on prismatically ground guides via recirculating ball slides. The work unit is mounted on this mobile unit carrier on prismatic, ground guides and a recirculating ball slide. Axis movement: The drive system in the Y and Z axes is provided by ground ball screws of the highest precision class. The X-axis is driven by a backlash-free, preloaded precision rack and pinion drive. This ensures balanced load distribution during the positioning process. Such characteristics are important for ensuring balanced movement even in more complex tasks. The movement of the various axes is controlled by brushless three-phase servo motors/brushless AC motors. These offer excellent positioning speeds thanks to very short ramp times. Furthermore, the measuring system is fully integrated into these motors. These properties make this type of drive completely maintenance-free. · Rapid traverse in X: 40 m/min · Rapid traverse in Y: 60 m/min · Rapid traverse in Z: 22.5 m/min Vacuum system (basic) · Vacuum pump: 100 cbm/h · Power: 2.5 kW · Max. negative pressure (connection) 0.9 bar Control / control cabinet · Office PC or industrial PC (see options) · Basic NC control: ESA-GV KVARA 6.0 · Cable remote control with the most important functions ELECTRIC/ELECTRONIC CNC CONTROL Universal is equipped with a powerful NC control. The integrated office PC gives the NC control an unparalleled level of familiarity: the software runs on Windows XP and allows quick and easy programming, which is easy to learn even for inexperienced users. The system is open and allows the connection of CD-ROM drives, audio cards, barcode readers, modems, printers, scanning systems, etc. Furthermore, the installation of all network systems, as well as all commercially available CAD programs, is possible. To reduce space, the control cabinet is located under the machine table, and the operator works at a separate terminal on casters that can be freely positioned. XILOG PROGRAMMING SYSTEM Software features: - Import of DXF files - Import of ASCII files - User interface in the operator's native language (available for languages I - GB - F - D - E) - Linear and circular interpolation in three axes, linear in space, spiral in the selected plane - Assisted programming - Calculator for direct transfer of calculated data - Graphic and syntax aids for drilling and milling operations - Parametric programming to perform the same panel machining on different P

Dsdpfx Aevvi Nzsc Nscc

Listing

Nattheim

Nattheim

18,550 km

CNC machining center

MorbidelliUniversal 3615 TV 4-Achs

Call

Condition: used, Year of construction: 2008, · Working area X-Y-Z: 3,660 x 1,550 x 130 mm · Travel length X-Y: 4,200 x 2,000 mm Description of the units and accessories (base) The structure of the base body is a monolithic construction made of thick-walled steel. It is stiffened by welded triangular plates across the entire machine bed, making it extremely stable. The triangular shape used for load-bearing parts, with a large base, is the secret to ensuring lasting precision and stability. The machine layout allows the user an optimal workflow despite minimal space requirements. The base body constructed in this way therefore offers the machining unit a balanced and secure base with particularly good load distribution. The mobile unit carrier in gantry design is made of a solid monoblock. It is positioned in the X direction on prismatically ground guides via recirculating ball slides. The work unit is mounted on this mobile unit carrier on prismatic, ground guides and a recirculating ball slide. Axis movement: The drive system in the Y and Z axes is provided by ground, high-precision recirculating ball screws. The X-axis is driven by a backlash-free, preloaded precision rack and pinion drive. This ensures balanced load distribution during the positioning process. This characteristic is important for ensuring balanced movement even in more complex tasks. The various axes are driven by brushless three-phase servo motors/brushless AC motors. These offer excellent positioning speeds thanks to very short ramp times. Furthermore, the measuring system is fully integrated into these motors. These properties make this type of drive completely maintenance-free. · Rapid traverse in X: 40 m/min · Rapid traverse in Y: 60 m/min · Rapid traverse in Z: 22.5 m/min Vacuum system (basic) · Vacuum pump: 100 cbm/h · Power: 2.5 kW · Max. negative pressure (connection) 0.9 bar Control / control cabinet · Office PC or industrial PC (see options) · Basic NC control: ESA-GV KVARA 6.0 · Cable remote control with the most important functions ELECTRIC/ELECTRONIC CNC CONTROL Universal is equipped with a powerful NC control. The integrated office PC gives the NC control an unparalleled level of familiarity: the software runs on Windows XP and allows quick and easy programming, which is easy to learn even for inexperienced users. The system is open and allows the connection of CD-ROM drives, audio cards, barcode readers, modems, printers, scanning systems, etc. Furthermore, the installation of all network systems, as well as all commercially available CAD programs, is possible. To reduce space, the control cabinet is located under the machine table, and the operator works at a separate terminal on casters, which can be freely positioned. XILOG PROGRAMMING SYSTEM Software features: - Import of DXF files - Import of ASCII files - User interface in the operator's native language (available for languages I - GB - F - D - E) - Linear and circular interpolation in three axes, linear in space, spiral in the selected plane - Assisted programming - Calculator for direct transfer of calculated data - Graphic and syntax aids for drilling and milling operations - Parametric programming to perform the same panel machining on different

Dodpfx Ajvvi Rfjc Njcc

Listing

Saerbeck

Saerbeck

18,451 km

Laser cutting machine

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Call

Condition: new, functionality: fully functional, Year of construction: 2025, operating hours: 30 h, Equipment: centralized greasing system, dust extraction, emergency stop, fume extraction, safety light barrier, Tube Laser Cutting System Ideal for Entry-Level Applications.

Simplicity meets efficiency with the Durma HD-TC COMPACT 60250 entry-level tube laser. Perfect for workshops, metal fabricators, and others looking to step into tube laser processing, this laser offers straightforward operation, reliable performance, and excellent value for money. Discover how the Durma HD-TC COMPACT 60250 can enhance your production with precise cuts and user-friendly technology, adding value to your operation.

3 kW Laser Power

Maximum Sheet Thicknesses:

- Mild Steel: 12 mm

- Stainless Steel: 6 mm

- Aluminium: 6 mm

- Copper: 3 mm

- Brass: 6 mm

Capacity:

- Maximum Tube Diameter: Ø250 mm

Dcedpferkntcsx Ac Nec

- Maximum Square Profile Dimensions: 160x160 mm

- Maximum Rectangular Profile Dimensions: 200x150 mm

- Minimum Tube Diameter: 16 mm

- Maximum Material Length: 6000 mm

- Minimum Remnant Length: 65 mm

- Unloading Length: 3000 mm

- Semi-automatic unloading unit: optional (6m)

- Maximum Material Weight: 58 kg/m

- Maximum Total Workpiece Weight: 350 kg

- Profile types that can be cut: Round, square, rectangular, elliptical

- Open profile types that can be cut: I, C, L

- Maximum open profile dimensions: 240x240 mm

Dynamics:

- X-Axis: 40 m/min

- Y-Axis: 94 m/min

- Z-Axis: 30 m/min

- A-Axis: 510 °/s

Accuracy:

- Positioning Accuracy: ±0.2 mm

- Positioning Variation: ±0.05 mm

- Tube Center Detection with Capacitive Sensor: Yes

Additional Available Configurable Options.

LASER POWER:

- Upgrade to DURMA LASER SOURCE BRILASE 4 kW ADVANCED fiber laser source (incl. chiller) + Durma cutting head

- Upgrade to DURMA LASER SOURCE BRILASE 6 kW ADVANCED fiber laser source (incl. chiller) + Durma cutting head

OPTIONS:

- Air filtration system (40 bar N₂ + 16 bar O₂ + 16 bar Air)

- Air filtration system (40 bar N₂ + 16 bar O₂ + 40 bar Air)

- CNC oscillating head (+/- 45°)

- Semi-automatic front loading system

- Unloading table (6m) with conveyor

- Unloading table (3m) with conveyor

- Additional dongle software

- Transformer 220, 440, 575V

SOFTWARE OPTIONS:

- Durma Cloud License + D-Mobile + Smart Watch

- STEP file importer

Listing

Düsseldorf

Düsseldorf

18,569 km

5-axis CNC pivoting head saw

Cms BrembanaSPRINT 36 OF

Call

Year of construction: 2022, operating hours: 1,160 h, condition: excellent (used), functionality: fully functional, Unique custom paint finish

TECHNICAL DATA

Working Area

Worktable: 4,200 × 2,000 mm

Extension table: 4,200 × 1,000 mm

Table height: 735 mm

Load capacity of worktable: 2,000 kg

Axes

5-axis CNC swivel head saw

X-axis: 4,250 mm (0–54,000 mm/min)

Y-axis: 3,200 mm (0–54,000 mm/min)

Z-axis: 600 mm (0–12,600 mm/min)

C-axis: 540° (+/-270°), max. 9,000°/min

B-axis: +8° to -90°, max. 9,000°/min

Saw Unit

Saw motor: 18.5 kW with 120 Nm torque, 4,500 rpm

Blade diameter: min. Ø 350 mm, max. Ø 625 mm

Cutting depth: max. 200 mm (90°), max. 130 mm (45°)

Flange diameter: Ø 213.3 mm

Drive shaft: Ø 50 mm H7

Water pressure: 4 bar

Drives / Guides

Brushless servo drives

Rack and pinion and Bosch Rexroth linear/slideway guides

Fully automatic central lubrication

Traversing speed (rapid traverse) up to 54 m/min

Control

CNC control OSAl OPEN M

Integrated PC with Windows 7

Control of up to 8 axes in interpolation

Interface for *.dxf files

Remote maintenance with internet connection

Electronic pressure control and automatic tool wear compensation

CAM Software

DDX “SMART SAW” (German)

Laser

Electronic red laser for saw cut positioning

Mounted on the saw blade housing

For straight cutting operations

Electrical Cabinet / Control Panel

21.5" TFT monitor

Keyboard and joysticks

CMS Active user interface

Control panel mounted on the right side of the machine

Machine Data

Connected load: approx. 25 kW at 400 V ±5 %, 50 Hz

Noise level: approx. 75 dBA

Weight: approx. 8,000 kg

Machine dimensions: approx. 8,380 × 5,270 × 3,600 mm (W × D × H)

Safety

Complete CE safety configuration

Safety doors, covers and protective grilles

Built according to EU Machinery Directive

DESCRIPTION

5-axis CNC swivel head saw CMS Brembana Sprint 36 OF – Industrial quality for natural stone & ceramics

For sale is a 5-axis CNC swivel head saw CMS Brembana Sprint 36 OF from a professional production facility.

The machine is designed for the precise processing of natural stone, engineered stone, ceramics, porcelain stoneware, and glass.

Thanks to the powerful 18.5 kW saw unit, the full-fledged 5-axis tilting head, and CNC control OSAl OPEN M, this system is ideal for miter cuts, bevel cuts, contours, multiple cuts, and complex workpieces for high-end interior finishing.

The robust welded steel construction, premium Bosch Rexroth guides, and automatic central lubrication ensure high precision, repeatability, and long service life in continuous industrial operation.

Suitable for:

– Natural stone

– Engineered stone

– Ceramics / porcelain stoneware

– Glass

Highlights:

– 5-axis CNC swivel head saw with large working area

– Worktable 4,200 × 2,000 mm plus extension table

– CNC control OSAl OPEN M with DDX “SMART SAW”

– High positioning speeds up to 54 m/min

– Industrial-grade robust construction

– Custom paint finish according to client specification

– CE-compliant safety equipment

– Inspection by arrangement possible

Condition:

Used, very well maintained, technically flawless, in operation.

Reason for sale:

Strategic realignment of the company.

Price:

€139,000 net

Djdpfxjyft S Ne Ac Nscc

Location:

North Rhine-Westphalia, Germany.

Note:

Sale as seen. Dismantling and transportation by the buyer.

Listing

Lambsborn

Lambsborn

18,678 km

Machining center

HOMAGBMG 311 Venture 316 M

Call

Condition: excellent (used), Year of construction: 2013, functionality: fully functional, machine/vehicle number: 0-201-08-2653, including tools as per list (see pdf document), equipment as per attached offers (see pdf document), machine no. 0-201-08-2653, single processing 3300 x 1550 mm, 14-position carousel tool changer, dimensions as per brochure (see pdf document), accessories as shown in the photo. VERY GOOD CONDITION. Machine has been serviced annually and checked for tolerances. Nesting software: PC85. WoodWop: HOMAG WoodWop 6.1 (.mpr and .mprx files can be used). Operating system: Windows XP. Machine is ready for demonstration – feel free to arrange a viewing appointment with us. Price ex site.

Dodpfx Aeybbhwec Nocc

Listing

Emmerich am Rhein

Emmerich am Rhein

18,543 km

Laser cutting machine

Hally Laser3015

Call

Condition: used, functionality: fully functional, Year of construction: 2020, operating hours: 6,000 h, machine/vehicle number: -, laser hours: 1,200 h, laser power: 3,000 W, laser wavelength: 1,080 nm, sheet thickness (max.): 20 mm, sheet thickness steel (max.): 20 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 5 mm, sheet thickness copper (max.): 5 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, positioning speed: 72 m/min, repeat accuracy: 0.01 mm, workpiece weight (max.): 1,000 kg, power: 3 kW (4.08 HP), input voltage: 380 V, input frequency: 50 Hz, type of input current: three-phase, overall weight: 6,500 kg, total length: 6,200 mm, working range: 3,050 mm, Equipment: cooling unit, Used Holly Laser 3015 3kW

Technical Specifications

- Maximum sheet size: 3000 x 1500 mm

- X and Y-axis positioning accuracy: ±0.05 mm/m

- Repeatable X and Y-axis positioning accuracy: ±0.01 mm

- Power: 3.0 kW

- Source brand: Raycus from 2024!

- Raytools Auto Focus cutting head

- Fuije servo motors

- The computer runs Windows and the CypCut software, which offers, among other features, design, file import and export, and work optimization.

Dcedpfx Acewcwq Sj Nsc

Installed programs have lifetime licenses.

Cutting Thickness

- Carbon steel: recommended thickness 20.0 mm

- Stainless steel: recommended thickness 8.0 mm

- Aluminum: recommended thickness 6.0 mm

- Brass: recommended thickness 5.0 mm

Listing

Aflenz Land

Aflenz Land

18,255 km

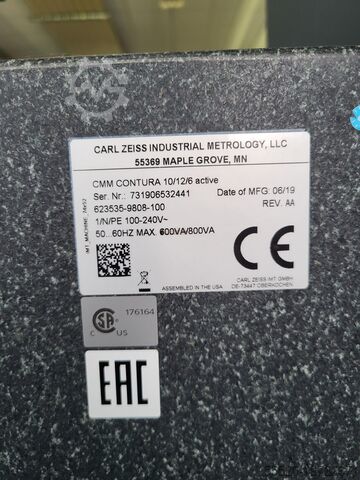

ZEISS coordinate measuring machine

ZeissCMM CONTURA 10126 active

Call

Condition: like new (used), Year of construction: 2019, operating hours: 50 h, functionality: fully functional, measuring range X-axis: 1,000 mm, measuring range Y-axis: 1,200 mm, measuring range Z-axis: 600 mm, Machine description: ZEISS CNC coordinate measuring machine (CMM) in portal design - Measuring volume X = 1000 mm, Y = 1200 mm, Z = 600 mm - Table height TH = 850 mm (standard) - Prepared for tactile active sensors - VAST navigator measuring technology (tactile active scanning) ONLY 50 OPERATING HOURS – THEREFORE AS NEW EQUIPMENT ACCORDING TO ORDER CONFIRMATION – SEE ATTACHED PDF FILE

Dsdjw H Rfdspfx Ac Njcc

Listing

Germany

Germany

18,654 km

WEMHÖNER Variopress Basic 1000S

WEMHÖNERVariopress Basic 1000S

Call

Condition: ready for operation (used), Year of construction: 2018, controller manufacturer: SIEMENS, controller model: SIVATIC HMI, This WEMHÖNER Variopress Basic 1000S was manufactured in 2018. Ideal for efficient laminating processes, this machine ensures consistent performance. Consider the opportunity to buy this WEMHÖNER Variopress Basic 1000S laminating press. Contact us for more information.

Additional equipment

• Including: 2 x paternoster magazines for film rolls

Machine Benefits

Technical Machine Benefits

• Heating plate format (mm): 2850 x 1550

Dsdpox D Hy Asfx Ac Necc

• Electric heating plate design: aluminum heating plate top

• Total pressing force (kn): 2400 / chamber pressure max (bar): 6 / operating temperature max: 180 degrees celsius / batch or workpiece size max (mm): approx. 2460 x 1180

• Thermoplastic film in rolls, width of the film: approx. 1430 mm / thickness of the film (mm): approx. pressure chamber height (mm): max. Up to 180

• Connection values: installed power (kw): approx. 46 / required air pressure (bar): approx. 8

Listing

Nördlingen

Nördlingen

18,525 km

CNC turning and milling center

DMG MoriCLX 550

Call

Condition: good (used), Year of construction: 2019, operating hours: 8,173 h, functionality: fully functional, turning length: 12,025 mm, turning diameter: 480 mm, spindle speed (min.): 3,250 rpm, travel distance X-axis: 308 mm, travel distance Y-axis: 120 mm, travel distance Z-axis: 1,240 mm, bar passage: 102 mm, overall weight: 7,200 kg, controller model: DMG MORI SLIMline Multi-Touch Control, control type: CNC control, CLX 550 V6

2-axis universal lathe

with driven tools

incl. C-axis, Y-axis, and counter spindle

Standard equipment:

1. Ergonomic DMG MORI SLIMline operating panel

2. Main spindle A2-8 with AC motor, drive power 22 / 33 kW (100/40% DC), 3,250 rpm

3. Counter spindle A2-6 with ISM 52 synchro, drive power 13 / 14 kW, torque 171.5/192 Nm (100/40% DC), 5,000 rpm

4. 12-position servo turret, VDI 40 mounting with Trifix® precision interface and 12 driven tool stations per DIN 5480

5. Y-axis ± 60 mm

6. Chip tray

7. Hollow clamping device, max. bar capacity D 80 mm

8. Electronic handwheel

Drive power (100%/40% DC) 22/33 kW

Hydraulic clamping device with bar capacity diameter 102 mm, surcharge

Differential pressure clamping for main spindle

Bar package & interface option includes:

- Workpiece unloader for parts up to D 80 x 200 mm long (D 100 x 200 mm with option C-B7000G) Max. workpiece weight 4 kg

- Interface for bar loader or bar feed unit (DMG MORI standard interface)

- Hinged belt chip conveyor instead of chip tray

- 4-color signal tower

Recommended additional option: Double cartridge filter for coolant, especially for production environments with very high chip volumes.

Automatic workpiece ejector for counter spindle with internal coolant supply for clamping device flushing. Note: Option recommended for machines with workpiece unloader option.

External flushing for counter spindle, option recommended for machines with automation

Differential pressure clamping for counter spindle

Tailstock function for counter spindle, mechatronic force control programmable in the software (force 250-600 daN), including foot switch (only for CLX 550 V6)

Dsdpfx Aeyazdpoc Nscc

Direct measuring system for X- and Y-axis (option only available for V4 and V6 versions)

Manual tool measuring device in the working area, brand Marposs

Documentation according to 'Technical Documentation Delivery List' – included in the machine price.

Software option: DXF import for converting DXF files into NC programs (SIEMENS control)

Tool monitoring system:

Easy Tool Monitor 1.0, monitors each cutting operation against a set limit. Simple learning function for determining the monitoring limit per tool and cutting operation; manual adjustment/correction possible.

Technology cycle:

Alternating speed (turning) for vibration-sensitive applications

Note: We offer flexible financing solutions for all machines as well as a professional relocation service. Dismantling, transport, and professional installation – everything from a single source. Billing based on individual terms and duration. Contact us for your personal offer.

Listing

Borken

Borken

18,513 km

Multi-camera image processing system

KeyenceXG-7501P

Call

Condition: good (used), Keyence XG-7501P multi camera image processing system control controller XG7501P

Manufacturer: Keyence

Manufacturer Number: XG-7501P

Type: multi-camera image processing system, control unit

Side cover included

Country of manufacture: Japan

Item condition: This item comes from a business liquidation of one of the largest auto parts suppliers in Germany and was stored there in paternosters, so some original packaging is missing and some items have storage marks.

Dcodpfxjib Dnco Ac Noc

Listing

Falkenberg

Falkenberg

17,853 km

ZEROLABOR ROBOT SYSTEM / Wall Production

RANDEK AB, SchwedenZEROLABOR

Call

Condition: new, Year of construction: 2023, ZEROLABOR ROBOTIC SYSTEM for Timber Frame Work

The Randek ZEROLABOR Robotic System is a fully automated robot cell that performs various working processes fully automatic. The system is flexible and can be configured to customers need. The robotic cell can be integrated into existing production lines or work as a stand alone unit. The system can handle production of walls, floors and roofs.

Automated processes:

Djdpfx Aoduub Uoc Njcc

- Sheet handling, the sheet is picked using vacuum cup system from various stacks and placed on building components according to CAD-file. The system is flexible and can handle various sizes of sheets.

- Fastening of sheets by screwing, stapling and/or nailing.

- Cut out for openings such as electrical hoses, windows etc.

- The system can handle 1, 2 or 3 layers of sheets.

- Marking of component using inkjet.

- Gluing

- Waste handling, gypsum waste and OSB waste i.e. ist placed in different places if needed, i.e. directlc in waste bin/recycle bin.

- Effective dust extraction system.

- Straightening of building component using working table

- Straightening of studs before nailing, ensuring placement of nails on stud.

Trust Seal

Dealers certified through Machineseeker

Listing

Poland

Poland

18,654 km

MACRI Provar 6-45 U-D

MACRIProvar 6-45 U-D

Call

Year of construction: 2018, condition: ready for operation (used), This 6-axis MACRI Provar 6-45 U-D was manufactured in 2018. A fully automatic CNC tube bending machine, it features minimal use with only around 20 working hours. It supports a max tube diameter of Ø45 × 4 mm and a usable tube length of 5,800 mm. Key capabilities include a max bending speed of 150°/sec and a max push speed of 1,000 mm/sec. Consider the opportunity to buy this MACRI Provar 6-45 U-D profile bending machine. Contact us for more information.

Additional equipment

• Movable slide support / Anti-wrinkle insert support / 2×1 m safety mat (aluminum) / Macri software installed on office PC (Windows 7) / Rear support-free bending system / Hydraulic cylinder for square/rectangular tube die opening / Automatic material elasticity control system / Tooling Sets

Machine Benefits

Technical Machine Benefits

• Production hours: around 20 hours, the machine was not used in the production.

• Type: fully automatic cnc tube bending machine (6-axis)

• Max. Tube diameter (round): Ø45 × 4 mm / min. Tube diameter for variable radius: Ø35 × 2 mm (rm 10d) / usable tube length: 5800 mm / max. Bending speed: 150°/sec (±0. 1°) / max. Push speed: 1000 mm/sec (±0. 1 mm)/ max. Clamp rotation speed: 450°/sec (±0. 1°) / rotation direction: clockwise / spindle movement (head travel): 6-axis (y, x, z, b1, b2, a)

• Installed power: 15 kw / voltage / frequency: 400 v / 50 hz / dimensions of machine (l×w×h): 6000 × 1200 × 1200 mm / weight (kg): 4500 kg / control cabinet dimensions: 900 × 600 × 1800 mm

Dcedjyap Upopfx Ac Nec

• Control system: industrial pc with windows 7 / display: 19" lcd tft svga touch screen / control software: graphical cartesian & cad-based interface / features: manual and semi-automatic operation, import of 3d files (e. G. , solidworks)

Listing

Borken

Borken

18,513 km

Automated Vertical Storage System 05

ModulaLift ML 50D

Call

Condition: excellent (used), Year of construction: 2010, Modula Lift ML50D Storage Lift

Modula systems are automated vertical beam storage systems based on the concept of vertical storage and space saving.

They can store any type of material safely, cleanly, and efficiently, saving up to 90% of floor space.

Modula systems are the result of over 30 years of experience from an Italian company specializing in high-tech products.

• Minimal energy consumption

• Automatic weight monitoring during beam insertion

• Dynamic beam positioning within the unit according to the stored material height

• Unit frame made of galvanized steel profiles

• Vertical drive with steel-core reinforced Eagle toothed belts

• Extractor guide system with 6 HDPE rollers per side

• Beam management with differentiated load capacity

The storage lift has been regularly serviced by the manufacturer and is in excellent condition.

The shelves are 4100 mm wide and 860 mm deep, providing a storage area of 3.53 m² per shelf.

With 56 shelves, this results in a total storage area of 197.68 m².

The load capacity per shelf is 500 kg, resulting in a total capacity of 28,000 kg for all 56 shelves.

Manufacturer: Modula

Year of manufacture: 2010

Model: Modula Lift ML 50D

Height: 6900 mm

Carrier width: 4100 mm

Carrier depth: 857 mm

Carrier height: 120 mm

Dodox E Aplepfx Ac Nocc

Net carrier payload: 500 kg

Gross total payload: 70000 kg

Device dimensions: Internal unloading (W x D) 4517 x 3165 mm

Device dimensions: External unloading (W x D) 4517 x 4058 mm

Operator interface: Console with 10.4” touchscreen technology (Copilot)

Throughput: Up to 120 carriers/hour (depending on configuration)

Height increments: 200 mm

Storage grid: 25 mm

Number of trays: 56

Product video

Product video 2

Datasheet: see Documents tab

More items - new And used items – find them in our shop!

International shipping costs on request!

Listing

Borken

Borken

18,513 km

Automated Vertical Storage System 04

ModulaLift ML 50D

Call

Condition: excellent (used), Year of construction: 2013, Modula Lift ML50D Storage Lift

Modula systems are automated vertical beam storage systems based on the concept of vertical storage and space saving.

They can store any type of material safely, cleanly, and efficiently, saving up to 90% of floor space.

Modula systems are the result of over 30 years of experience from an Italian company specializing in high-tech products.

• Minimal energy consumption

• Automatic weight monitoring during beam insertion

• Dynamic beam positioning within the unit according to the stored material height

• Unit frame made of galvanized steel profiles

• Vertical drive with steel-core reinforced Eagle toothed belts

• Extractor guide system with 6 HDPE rollers per side

• Beam management with differentiated load capacity

The storage lift has been regularly serviced by the manufacturer and is in excellent condition.

The shelves are 4100 mm wide and 860 mm deep, providing a storage area of 3.53 m² per shelf.

With 58 shelves, this results in a total storage area of 204.74 m².

The load capacity per shelf is 500 kg, resulting in a total capacity of 29,000 kg for all 58 shelves.

Manufacturer: Modula

Year of manufacture: 2013

Model: Modula Lift ML 50D

Height: 7350 mm

Dcedox Ezxlspfx Ac Nec

Carrier width: 4100 mm

Carrier depth: 857 mm

Carrier height: 120 mm

Net carrier payload: 500 kg

Gross total payload: 70000 kg

Device dimensions: Internal unloading (W x D) 4517 x 3165 mm

Device dimensions: External unloading (W x D) 4517 x 4058 mm

Operator interface: Console with 10.4” touchscreen technology (Copilot)

Throughput: Up to 120 carriers/hour (depending on configuration)

Height increments: 200 mm

Storage grid: 25 mm

Number of trays: 58

Product video

Product video 2

Datasheet: see Documents tab

Item location: 18069 Rostock

Disassembly and removal by buyer

Disassembly by our assembly team is also possible (€5,000 net)

More items – new and used – can be found in our shop!

International shipping costs on request!

Listing

Borken

Borken

18,513 km

Automated Vertical Storage System 01

ModulaLift ML50D

Call

Condition: excellent (used), Year of construction: 2021, Modula Lift ML50D Storage Lift

Modula systems are automated vertical beam storage systems based on the concept of vertical storage and space saving.

They can store any type of material safely, cleanly, and efficiently, saving up to 90% of floor space.

Modula systems are the result of over 30 years of experience from an Italian company specializing in high-tech products.

• Minimal energy consumption

• Automatic weight monitoring during beam insertion

• Dynamic beam positioning within the unit according to the stored material height

• Unit frame made of galvanized steel profiles

• Vertical drive with steel-core reinforced Eagle toothed belts

• Extractor guide system with 6 HDPE rollers per side

• Beam management with differentiated load capacity

The storage lift has been regularly serviced by the manufacturer and is in excellent condition.

The shelves are 4100 mm wide and 860 mm deep, providing a storage area of 3.53 m² per shelf.

With 60 shelves, this results in a total storage area of 211.80 m².

The load capacity per shelf is 500 kg, resulting in a total capacity of 30,000 kg for all 60 shelves.

Manufacturer: Modula

Dsdpfx Acjx Ey Avo Nocc

Year of manufacture: 2021

Model: Modula Lift ML 50D

Height: 6700 mm

Carrier width: 4100 mm

Carrier depth: 857 mm

Carrier height: 120 mm

Net carrier payload: 500 kg

Gross total payload: 80000 kg

Device dimensions: Internal unloading (W x D) 4517 x 3165 mm

Device dimensions: External unloading (W x D) 4517 x 4058 mm

Operator interface: Console with 10.4” touchscreen technology (Copilot)

Throughput: Up to 120 carriers/hour (depending on configuration)

Height increments: 200 mm

Storage grid: 25 mm

Number of trays: 60

Product video

Product video 2

Datasheet: see Documents tab

More items - new And used items – find them in our shop!

International shipping costs on request!

We make it easier for you to find: "file paternoster"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used File Paternoster (648)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month