Used Broach for sale (214)

Wiefelstede

Wiefelstede Horizontal slotting machine

Elliott24M SHAPER

Ensisheim

Ensisheim Vertical Slotting Machine

GSPMORT 730

Soerendonk

Soerendonk Open side planer

Yeo Sheng Machinery TSH-TUVB-1010 Spieba

+44 20 806 810 84

Stadel

Stadel Keyway nudging machine

ElmassELM-P1 / 200-A

Wasbek

Wasbek Workshop Press - 2 T

KnuthDrehdornpresse 2 T

Discover more used machines

Korschenbroich

Korschenbroich Thread rolling machine

LeistritzRT 400-CCA

Wiefelstede

Wiefelstede Horizontal slotting machine

KloppDP AP

Wymysłów

Wymysłów Pneumatic marking machine

PRO PEN P5000 GravotechPRO PEN P5000 Gravotech

Starachowice

Starachowice Slotting machine

HOV-2S

Calusco d'Adda

Calusco d'Adda Multi-spindle machine

MORI-SAY8/42 AC

Wasbek

Wasbek Workshop Press - 1 T

KnuthDrehdornpresse 1 T

Korschenbroich

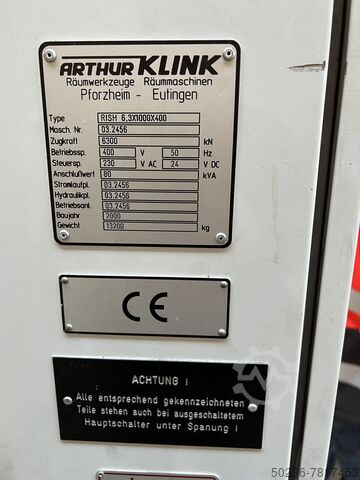

Korschenbroich CNC internal broching machine

Arthur KlinkRISH 6.3X1000X400

Siedlce

Siedlce Universal lathe 410x1000

CORMAK410x1000

Offenbach an der Queich

Offenbach an der Queich Slotting Machine - Vertical

CAMS250 2ACT

Athens - Akadimia Platonos

Athens - Akadimia Platonos Gear cutter TOS-FO 10

TOSFO-10

L'alcúdia de Crespíns

L'alcúdia de Crespíns Vertical machining center

TRAVISVT 1750

Wasbek

Wasbek Workshop Press - 3 T

KnuthDrehdornpresse 3 T

Korschenbroich

Korschenbroich Keyseating Machine

FRÖMAGKZ 32

Courbevoie

Courbevoie Groover

fromagKZM32/300

Malsch

Malsch Bevel Gear Generator - Straight

Die Kegelradfräsmaschine GLEASRevacycle Nr. 726

Germany

Germany Slotting Machine - Vertical

ROSCHER & EICHLERST III

L'alcúdia de Crespíns

L'alcúdia de Crespíns Slotting machine Urpe model M-300 G

UrpeM300 G

Wasbek

Wasbek Workshop Press - 5 T

KnuthDrehdornpresse 5 T

Gerolstein

Gerolstein Keyseating Machine

POLYMATA600

Germany

Germany Slotting Machine - Vertical

WMW MEUSELWITZSTSR400

Used Broach (214)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84