Used Bottel Filling Machinery for sale (74,833)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Jonava

Jonava

17,370 km

Machining center

WOODLAND MACHINERYSX1325A-4

Call

Condition: new, Type SX1325A-4

Useful working area axis X-Y-Z 2850-2100-150 mm

Shaft, air cooled, 6kw+4.5kw x 3 18000 rpm.

Engine Hybrid servo

Control system LNC system

Repeat positioning accuracy 0.03mm

Work table vacuum plate

Vacuum pump 11kw

Cpjderxtwdopfx Aa Eow

Maximum speed 50000 mm/min

Maximum working speed 25000mm/min

Resolution ±0.05 mm

System resolution ±0.001 mm

Code G

Inverter 7.5 kw

Voltage 380V/50HZ

Transport dimensions 3200x2100x1800mm

Weight 2100 kg

The price is 23100 Eur

Listing

Jonava

Jonava

17,370 km

Machining center

WOODLAND MACHINERYSX1325A-12

Call

Condition: new, Type SX1325A-12

Useful working area axis X-Y-Z 2850-2100-150 mm

Shaft, air cooled, 9.0kw 24000 rpm.

Servo motor

Control system LNC

Cpsdpfx Aaerxtvkj Esw

Drive gear

High precision automatic positioning cylinder

Work table vacuum plate

Vacuum pump 7.5 kw

Maximum speed 60 m/min

Maximum working speed 15-20m/min

Flexible towing cable (with screen)

Air components BLCH

Voltage 380V/50HZ

Transport dimensions 3200x2100x1800mm

Weight 3100 kg

The price is 24500 Eur

Listing

Przemyśl

Przemyśl

17,660 km

Beverage production machine

ELOPAK SHIKOKU ASEPTIC FILLING LINES-PS80HA

Call

Condition: excellent (used), ELOPAK SHIKOKU ASEPTIC FILLING LINE

Model S-PS80HA

YOM 2008

Cjdpfx Aexdbwioa Ejpw

Working hours - 9,000 hours.

Line capacity for 3 streams - 8100 pcs./h, for two 7100 pcs./h for one 6000 pcs./h

Carton format: 500ml, 750ml, 1000ml

The line includes:

- Elopak filler S-PS80HA for Pure Pak classic packaging material

- 3 units of PURE-PACK PLA-S30 cap applicators for Pure-Twist 2U cap

- WA-Flex-30 packer

- Conveyor system.

- Conveyor lubrication station.

- Spare parts a total of 4,000 dollars.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Weert

Weert

18,619 km

Cable stripper Cable stripping machine

Jeffra Machinery & SupportKM1

Call

Year of construction: 2025, condition: new, This robust professional cable stripping machine, type KM1, cuts electrical cables from 1 to 70 mm in diameter.

The blades are hardened so when stripping reinforced ground cable they are not immediately blunted.

There are 15 different cable entries.

The cable is cut from 2 sides so the copper core comes out easily.

You can also use it to strip rubber and flat cables.

Technical data:

Mains voltage: 230 v ~ 50 hz

Power: 3000 watts with dual pulley drive.

Cpjdpfx Aaop I I U Do Esw

Dimensions: 60 cm long, x 75 cm wide and 90 cm high

Machine speed: 35 m/min

Output: Depending on the cable 400 and 1200 kg/day

Weight: 185 kg.

Listing

Fevziçakmak

Fevziçakmak

16,805 km

Cable Recycling Plant

Mizar Recycling Machinery |PRP S1 Cable Process Line-Up to 400kg/h

Call

Year of construction: 2025, condition: new, ⚡ Processing Capacity

✔️ Up to 400 kg/h

Perfect for medium to high-volume operations.

🔁 Applicable Materials

✔️ All types of electrical cables

✔️ Mixed and contaminated cables

✔️ Complex, multi-layered cable structures

Cjdjwnm Spjpfx Aa Espw

🔍 Included Machines & Functions

Machine Functionality

Shredder Primary size reduction for bulky cables

Overbelt Magnetic Separator Ferrous metal removal with high-power magnets

Granulator Fine and uniform size reduction

Zigzag Separator Light/heavy fraction separation

Densimetric Separator Density-based material classification

Air Cyclone Separation of dust and light particles

Turbo Mill Ultra-fine grinding for tough materials

🔄 Key Advantages

🧩 Modular Design: Each machine operates independently

📈 Scalability: Easily expandable and reconfigurable

🧪 High Purity Output: Precise and clean material separation

🌱 Sustainability: Energy-efficient and environmentally friendly

🔧 Easy Maintenance: User-friendly design and accessible parts

🎯 Designed For

Recycling companies seeking maximum efficiency

Businesses aiming for high purity and low loss rates

Operators needing flexibility and growth options

Listing

Soltvadkert

Soltvadkert

17,978 km

Foil processing machine

Lung Meng MachineryTAF-400

Call

Condition: excellent (used), Year of construction: 2006, Used high-performance roll garbage bag manufacturing machine for sale.

Includes: Roll lifter, longitudinal welder, folding unit, bottom welder, and labelling unit.

The machine is in perfect operational condition and can be viewed in production.

For sale with factory support and spare parts due to underutilization.

Technical Specifications:

- Welding width: 700 mm

- Maximum bag length: 2000 mm

- Minimum bag length: 380 mm

- Film speed: 120 m/min

- Drive: Servo

- Number of tracks: 2

Cpedpfx Aaoykz Ebe Eow

Additional Specifications:

- Heavy-duty, automatic 2-track roll garbage bag manufacturing machine

- Film thickness:

- LD/LLDPE: 0.012–0.060 mm (single layer)

- HDPE: 0.008–0.015 mm (single layer)

- Bag width: 300–700 mm

- Line speed: 100–165 m/min (depending on material, thickness, and film quality)

- Finished roll size: roll width 200–300 mm; roll diameter up to 130 mm

Single-line labelling unit:

- Label width: 70–200 mm (1 line)

- Label length: 180–350 mm

- Label roll diameter: max. 250 mm

Year of manufacture: April 2006

Components:

1. TAI-1300C Lifting unwinder

2. SSB-1300A Slitting knife and longitudinal welding unit

3. TA-800C1 Bag making & welding machine

4. TAF-400-2N-M 2-lane folding machine

5. TAD-700 Four-axis spindle winder

Other information:

- Warranty: No warranty

- Current status: In production

- Availability: Immediate

- Power requirement: 20 kW

- Price: EUR 50,000

Listing

Székesfehérvár

Székesfehérvár

18,033 km

5 axis vertikal machining center

Yeong Chin Machinery Industries Co. Ltd. (YCM)FX380A

Call

Condition: good (used), Year of construction: 2018, functionality: fully functional, Controller FANUC MXP-200FC

Table size D380 mm

Table load max 200 kg

X travel 700 mm

Y travel 520 mm

Z travel 480 mm

A axis +30/-120 degree

C axis 0-360 degree

Spindle speed 12000 rpm

Tool holder type BBT40

Rapid speed 36/36/24 m/min

Feedrate 1 - 100000 mm/min

Max tool diameter and length D78 x 280 mm

Max tool weight 6 kgs

Spindle power 22,5 kW

ATC magazin 30-fold

Power required 46 kVA

Accessories, features

- CTS

Codpor I Az Tjfx Aa Eepw

- integrated 4/5 axis

- Coolant unit

- Chip conveyor

- Mist collector

- external hydraulic

- manuals

The machine is still under power and can be inspected in function. Ready to buy.

Listing

Iszkaszentgyörgy

Iszkaszentgyörgy

18,046 km

Cnc EDM Spark machine

NEUAR Precision Machinery Co. LtdCNC-C50E2

Call

Condition: like new (used), Year of construction: 2020, operating hours: 2,000 h, functionality: fully functional, machine/vehicle number: HU50610, Controller 15" touch screen with Windows Operation System Interface

Table size 630 x 360 mm

Dimension of tank LxWxH = 940 x 550 x 350 mm

X travel 400 mm

Y travel 300 mm

Z travel 300 mm

Distance between the table and chuck 100 ~ 400 mm

Max weight of electrode 11/50 kgs

Max weight of wpc on table 500 kgs

Max Output power 50A

Best surface quality of work 0,08 Ra

Input power 10 kVA

Dielectric capacity 300 litre

Dimensions of the machine LxWxH = 1320 x 1380 x 2150 mm

Weight 1450 kgs

Accessories, features

Codpfxowktkkj Aa Ejpw

- No. of filters 3 pcs.

- C axis (max loading 11 kg)

- Dielectrictank

- Machine mouths

- Manuals

- Handtools

Listing

Fevziçakmak

Fevziçakmak

16,805 km

Cable Recycling Machine

Mizar Recycling Machinery |CMT A2 - Cable Recycling Machine

Call

Condition: new, Year of construction: 2025, Mizar Compact Series Cable Recycling Machines are designed for the efficient recycling of cables of different diameters and materials. By breaking down cables, they separate metal and plastic components, ensuring maximum material recovery.

✅ Efficient Cable & Radiator Recycling – Effectively separates metal and plastic.

✅ Turbo Mill Technology (CMT Models) – Achieves higher purity by completely separating fine copper wires.

✅ Compact Design – Ideal for facilities with limited space.

Codpfx Aaev Hbdrs Eopw

✅ Energy Efficient & Cost-Effective – Minimizes operational costs.

🔸 Recyclable Materials:

✔ Cable

✔ Radiator

🔸 Technical Specifications

🔹 CMT

Power: 20 kW

Granulator Motor: 11 kW

Granulator Blade: 3+2

Length: 1300 mm

Width: 1500 mm

Height: 2140 mm

Weight: 1380 kg

Listing

Fevziçakmak

Fevziçakmak

16,805 km

Cable Stripping Machine

Mizar Recycling Machinery |CBR A3 - Cable Stripper Machine

Call

Condition: new, Year of construction: 2025, total width: 780 mm, total length: 1,240 mm, total height: 1,330 mm, overall weight: 480 kg, The CBR A3 Cable Stripping Machine is specially designed to strip the outer insulation material from cables of all sizes, making it easy to remove the conductive material inside.

This series offers superior performance on;

steel-armored cables (SWA),

double steel-armored cables,

steel tapes,

PVC-coated cables,

lead-coated cables,

thick rubber-coated cables,

nylon-coated cables,

low-grade cables,

TT cables, and more.

Specially processed blades with unique designs allow cables of any length to be cut and stripped for a long time without dulling the blades. All electrical and electronic components in the CBR A3 Series are Siemens brand. Our products are manufactured and certified in accordance with CE and EAC standards.

Cpodpfxeff H Ime Aa Esw

Technical Specification

POWER 5.5 KW

CABLE DIMENSIONS 1-120 mm

CUTTING SPEED 25 meter/min

LENGTH 1240 mm

WIDTH 780 mm

HEIGHT 1330 mm

WEIGHT 480 kg

Listing

Fevziçakmak

Fevziçakmak

16,805 km

Cable Recycling Plant

Mizar Recycling Machinery |PRP M1 Cable Process Line-Up to 800kg/h

Call

Year of construction: 2025, condition: new, ⚡ Processing Capacity

✔️ Up to 800 kg/h

Perfect for medium to high-volume operations.

🔁 Applicable Materials

✔️ All types of electrical cables

✔️ Mixed and contaminated cables

✔️ Complex, multi-layered cable structures

🔍 Included Machines & Functions

Machine Functionality

Shredder Primary size reduction for bulky cables

Overbelt Magnetic Separator Ferrous metal removal with high-power magnets

Granulator Fine and uniform size reduction

Zigzag Separator Light/heavy fraction separation

Densimetric Separator Density-based material classification

Cpsdpfx Aewnnmbea Eow

Air Cyclone Separation of dust and light particles

Turbo Mill Ultra-fine grinding for tough materials

🔄 Key Advantages

🧩 Modular Design: Each machine operates independently

📈 Scalability: Easily expandable and reconfigurable

🧪 High Purity Output: Precise and clean material separation

🌱 Sustainability: Energy-efficient and environmentally friendly

🔧 Easy Maintenance: User-friendly design and accessible parts

🎯 Designed For

Recycling companies seeking maximum efficiency

Businesses aiming for high purity and low loss rates

Operators needing flexibility and growth options

Clickout

Göteborg

Göteborg

17,806 km

Cold Chamber Die Casting Line (Unused)

LK MachineryImpress Plus DCC 3500

Condition: like new (used), Year of construction: 2022, functionality: fully functional, total height: 3,100 mm, total width: 3,100 mm, stroke length: 950 mm, column diameter: 130 mm, mold height (min.): 900 mm, clamping force: 35,000 kN, pressure: 400 bar, Installed and commissioned with dry, test run only.

- Two‑platen machine

- Max locking force: 35,000kN

- Injection force: Approx. 390–420kN (varies by plunger size)

- Plunger diameter: Ø130mm

- Plunger stroke: 950mm

- Shot weight (Al): 6.5–8.5kg, depending on plunger

- Projected area at 400 bar: 8,750–9,000cm² (calculated from 35,000kN clamping force)

- Platen size (H × W): 3100× 3100mm

- Distance between tie bars (H × W): 1950×1950mm

- Die height (min / max): 900/1350mm

- Die opening stroke: 1200mm

Støtek melting system with

- Støtek SMG 3.0_7.0 two chamber gas fired melting shaft furnace with ingot charging elevator, furnace melting capacity approx. 1.5t/h

- Støtek DTI 6020 holding furnace with Fuco-Heg MBS 2000 molten metal treatment/rinsing station

- Støtek AMET 1700 dosing furnace

Cpsdpfxoygxr Re Aa Eow

LK Impress Plus DCC 3500 die casting machine with

- Siemens PLC S7-1500 controls

- ABB IRB 6650S die release agent spray robot

- Wollin OSA 15-2-C die release agent supply system and spray head

- AED 181-080 die lubrication dilution system

- Fondarex Highvac Premium 2C 200 die casting vacuum system with air tank and vacuum pumps

- 5x IECI PFN 330 2-Z oil temperature control units

- 5x IECI PF-ZH 1802-Z water temperature control units

- KMA Ultravent UV 20000EE fume extraction and filter system

- ABB IRB 7600 robot for die casting machine unload, trim press load/unload and cooling station load

- LK WB-100 1,000kN trim press with trim conveyor

- ABB robot for cooling station unload, laser marking and outfeed

- Keyence MD-X 1500C 3 axis laser marking system

- Outfeed conveyor with cooling tunnel

A quantity of spare parts is available with the line.

Listing

Gargždai

Gargždai

17,502 km

Rotational Juice Filter

ProFruit MachineryRotational Juice Filter

Call

Year of construction: 2026, condition: new, Machine works well with various fruit, berry and vegetable juice and pulp. During the work process, the juice enters the machine through the spinning filtration sieve. This way excess pulp and sediments stay in the sieve and filtered juice enters the juice collection tank. The sieve spins continuously so juice can flow without interruptions.

Output: 1000 L/h.

Conical form of the filter facilitates the work process so the pulp is collected and removed easily.

The washing of the filter is rarely needed because of convenient conical filter form. That is why washing can be done once per day.

Rotational juice filter has an integrated juice collection tank which collects the juice.

Juice collection tank has an automatic pump and liquid level control. When the tank is full, the pump automatically turns on and transfers the juice for further processing.

Machine is made entirely from stainless steel.

Rotational juice filter is mounted on wheels.

Cpjdpfxoizbawo Aa Ejw

Machine is especially simple to use and easy to maintain.

This filter is often used after our DESTONE destoning & pulping machine to remove the pulp from the berries or other fruits and achieve uniform quality juice or puree.

Listing

Gargždai

Gargždai

17,502 km

Juice filtration

Profruit MachineryDouble juice filters

Call

Year of construction: 2026, condition: new, Mechanical double juice filters are made of stainless steel. The set includes two parallel stainless steel filters that can work separately one from each other. The double juice filters filtrate the juice and eliminate various thick particles in it. This provides particularly clean juice. The valves of the filters can also be shut off separately during the washing process or for other purposes.

Cedpfx Ajhu Aafoa Ejpw

Available mesh: 60 µm, 200 µm, 300 µm, 400 µm, 500 µm.

Connection D25.

Capacity: 2000 L/h.

Stainless steel ensures longevity as well as quality of the product.

Stainless steel filters are easy to clean after using.

Listing

Peskojai

Peskojai

17,508 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2026, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Cjdpfst Rft Uex Aa Eepw

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

17,508 km

Automatic Bag in Box Filler

ProFruit MachineryMAXIFLOW

Call

Year of construction: 2026, condition: new, Machine provides fully automatic filling process for webbed Bag in Box bags. After inserting the first bag, machine removes the cap, fills the liquid and caps the bag. Then it releases the filled bag and takes another one for filling. This way the filling process is continuous and operator only needs to take the filled bag out of machine.

To fill separate Bag in Box or Pouch bags, insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag.

Capacity: ~2000 l/h

Cpsdoq Nl A Ropfx Aa Eow

-Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

-Easy-to-use mechanism does all the work automatically. In addition to that, bags can be supplied to machine manually (separate bags or pouches) or automatically (bags in web).

-Suitable for both hot and cold filling.

-Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

-Machine fills packages with tap closure. It is also possible to fill packages with different closures on request.

-Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

-Machine is made from stainless steel materials (AISI 304).

-Touch-screen control panel and multi-language menu grant easier work.

-The error of repeatability of volumes is only ± 0,3 %.

-Additional filling table is possible, which slides beneath the main table for filling bags of bigger volume (from 20 to 30 L).

-The filler is easy to clean after work with external and CIP cleaning.

-Working surface of the table consists of conveyor rollers which are exceptionally easy to clean.

-All parts have IP 65 water protection.

Listing

Gargždai

Gargždai

17,502 km

Belt press for juice

Profruit machineryPOWERPRESS 800

Call

Year of construction: 2026, condition: new, Belt presses POWERPRESS 800 are designed for pressing fruit, berry and vegetable mass. Fruit mass is placed on the belt which presses it against cylinders.The obtained juice flows in the collection trays under the belt presses. Pressing is continuous.

Capacity: 800 kg/h

The most evolutionary feature of our belt press POWERPRESS line is integrated pump and juice collection tank into the press itself. That means that you save money and do not need an additional juice collection tank and pump which otherwise would use much space and money.

There is a filtration sieve integrated into the juice collection tank. Because of that the machine filtrates the juice even during the pressing stage providing cleaner and more pure product.

Entirely made of stainless steel.

Has adjustable feet.

The belt presses function automatically. When the tank of the mass is full, all other machines which come before belt press turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

Includes High pressure washer.

Has an integrated pump.

Belt tension is adjustable.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

The cleaning of the belt is automatic with high pressure cleaner, scraper and brush.

Cpjdpfx Aaehu Ab Ds Ejw

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Listing

Gargždai

Gargždai

17,502 km

Diesel Pasteurizer

ProFruit MachineryHEAT 500

Call

Year of construction: 2026, condition: new, Diesel/gas pasteurizer 500 heats up the liquid before the filling process. The liquid comes into the tubular spiral which is surrounded by hot water. The heat from the water heats up the liquid and eliminates the bacteria.

One of our highest machinery achievements is our energy-saving solution integrated into our pasteurizers. It saves the heating energy up to 15-20 % and results in incredibly low heating costs. Calculations show that it costs up to 2 Euro Cents to pasteurize 1 liter of liquid.

Capacity per hour – 400-600 L of 80 ºC (176 °F) heated juice.

- The pasteurizer is suitable to heat various liquids, including viscous liquids: juice, puree, wine, broth, milk and other.

- The maximum heating temperature of diesel pasteurizer is 90 ºC (194 °F).

- Our pasteurizers are equipped with highest quality German diesel and gas burners GIERSCH.

- The heating power is 53 kW.

Cjdpfsflrk Isx Aa Eopw

- Pasteurizers’ heating chambers are covered with special heat-insulating paint which preserves high temperature for a longer time and increases heating capacity.

- Diesel/gas pasteurizer has a digital thermostat which provides an automatic water temperature control.

- Automatic regulation of juice temperature ensures an easy way to change the filling temperature on digital display.

- The pasteurizer is fast and easy to clean. It can be washed by CIP cleaning together with our Bag in Box fillers.

- Machine can use diesel or gas on client’s request.

- The boiler has an integrated spiral. This provides saving of space and also prevention of heat loss when pumping the water into external heat exchanger. As a result, this technology saves the heating energy up to 15-20%.

- Diesel/gas pasteurizer has pivoting wheels.

- Diesel/gas pasteurizers work in perfect synergy with our Bag in Box fillers. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

17,502 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2026, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Capacity – 250 pcs. of 3 L bags/h

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

Cpedpsflriusfx Aa Ejw

Listing

Gargždai

Gargždai

17,502 km

Screw conveyor

ProFruit MachineryScrew conveyor

Call

Year of construction: 2026, condition: new, The leftover fruit, berry or vegetable mash enters the loading hopper of the screw conveyor. The screw inside the machine is continuously turning and this way transports the mash from the loading hopper to the exit outlet at the top of the machine. The mash exits the machine.

Screw conveyor is made of stainless steel.

Cpodpfx Asizbffja Eow

Machine has a closed tunnel.

Conveniently transports leftover pressed mash from press.

Listing

Gargždai

Gargždai

17,502 km

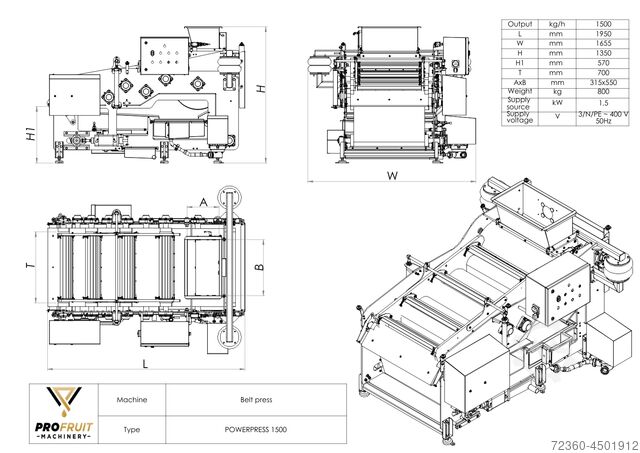

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Csdpeflpp Eefx Aa Eopw

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Trust Seal

Dealers certified through Machineseeker

Listing

Gargždai

Gargždai

17,502 km

Bath pasteurizer for bottles

ProFruit MachineryBath pasteurizer for bottles

Call

Year of construction: 2026, condition: new, Bath pasteurizer option is the perfect solution for post fill pasteurization of your bottled or canned products. 97 units of standard 0.75 L bottles easily fits in 4 baskets.

Our bath pasteurizers can be produced in two options:

1. Autonomous bath pasteurizer with electric heating elements and integrated control panel.

2. Bath pasteurizer as an option together with HEAT or ECOHEAT pasteurizers. Then water heating is done with our pasteurizer and the same control panel is used for controlling both devices.

Features:

Mounted on pivoting wheels.

Codpfx Aerif Smea Eopw

Insulated heating bath to save the energy and temperature.

Can be used for glass bottles, jars, cans, any other heat resistant package.

Works with different products, like juices, jams, marmalades, puree, sauces, etc.

Automatic temperature and time control.

Water overflow protection.

Fast and easy loading and unloading of bottle trays.

Entirely made of stainless steel.

The bottles, cans, or jars are loaded into the trays and then trays are loaded into the bath. The desired pasteurization temperature and holding time settings can be set simply using the integrated control panel or on the HEAT or ECOHEAT pasteurizers.

At a start of process, bottles or jars are placed into the bath, then water is filled into the bath until it reaches bottle neck. Then pasteurizer is connected, temperature (max 90 C⁰) and time is set. Then it starts to heat up the water inside the bath. When set temperature is reached, timer turns on and pasteurization is started. In the meantime, in the new set of trays filled bottles can be loaded for a faster exchange process.

When timer ends, water out of the bath pasteurizer is released and bottles are unloaded.

As the temperature is only measured in the bath, it is important to monitor the core temperature of your product to ensure that adequate pasteurization has been achieved.

Listing

Peskojai

Peskojai

17,508 km

Belt press

ProFruit MachineryPOWERPRESS 3000

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 3000 kg/h.

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

-The juice yield of apples using our belt press 3000 is ~75 %.

Csdpfjq Nl Aqsx Aa Espw

-There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

-The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

-The belt press 3000 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

-Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

-After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

-Belt tension is adjustable.

-Machine is made entirely of stainless steel and has adjustable feet for more convenient use.

-Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

17,508 km

The Mobile Juice Production Line

ProFruit MachineryMobile Line

Call

Condition: new, Year of construction: 2026, The Mobile Fruit Processing Line is designed to conveniently accommodate all the machines necessary for juice production and a smooth work process. It contains:

-Fruit and vegetable washer elevator mill MAXIMILL 3000

-Belt press POWERPRESS 1500

-Transporter for leftover mash

-Stainless steel tanks

-Diesel pasteurizer

-Semi-automatic Bag in Box filler

-Juice filters

-Sink with a stainless steel table

Capacity: 1500 kg/h.

Other available capacities: 400 kg/h, 800 kg/h, 1200 kg/h.

Features:

-The mobile juice line conveniently contains all the machines required for fruit processing & juice production.

-Requires only 1 person to operate the whole line.

Cpodpfx Aaoq Nl Afe Eow

-Mobility is the biggest advantage which eliminates costs for premises and provides the ability to change location.

-The juice yield from apples is ~75 % .

-All machines are interconnected and controlled automatically.

-The mobile juice production unit includes a Bag in Box filler which fills the juice into both Bag in Box and Stand up Pouch packages.

-The mobile juice line can be customized on client’s request.

-The line is easy to operate and maintain.

-The mobile fruit processing line is installed in a specially made trailer which can be easily opened for work and shut when needed.

-The biggest advantage of our Mobile Fruit Processing Line is the ability to produce juice anywhere you like. This way the client avoids additional expenses for premises and gets the ability to change work location.

Mobility is the key aspect here which provides the client with more possibilities, such as developing a juice pressing service business at various apple farms or different towns.

Listing

Gargždai

Gargždai

17,502 km

Bin tipper

ProFruit MachineryUNLOADER 800

Call

Year of construction: 2026, condition: new, It is a first processing step during which machine transfers fruit, vegetable or berries to the next stages of processing: washing, sorting or crushing. Bin tipper lifts the box and pours out the products into sorting conveyor, AQUA or MAXIMILL.

Bin tipper is entirely made of stainless steel.

Machine has a hydraulic drive.

Controls of the machine are very simple: just put the box in and move the control handle to lift it up.

Suitable for boxes with different dimensions. Max size: 120x120x85.

Loading power – 800 kg.

Cjdsichbbopfx Aa Espw

We make it easier for you to find: "bottel filling machinery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bottel Filling Machinery (74,833)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month