Lead and feed screw latheMCM Italy

TC 260 x 1500

Lead and feed screw lathe

MCM Italy

TC 260 x 1500

Condition

New

Location

Mindelheim

Show images

Show map

Machine data

Price & Location

- Location:

- Biberkopfstraße 4, 87719 Mindelheim, Deutschland

Call

Details about the offer

- Listing ID:

- A3713808

- Update:

- 04.09.2025

Description

Made in Italy

Machine according to DIN 8606

Center height: 260 mm

turning diameter over bed: 520 mm

turning diameter over slide: 300 mm

center width: 1.500 mm

bed width: 400 mm

spindle bore: 82 mm

spindle nose: Camlock 8"

Spindle speeds: (24) 9 - 1600 rpm (option 11 - 2000 rpm)

motor power: 5,5 kW (option: 7,5 kW)

feed Z-axis: (93) 0,028 - 6,43 mm/rev

feed X-axis: (93) 0,012 - 2,73 mm/rev

Kdedpjdvm Euofx Ah Nog

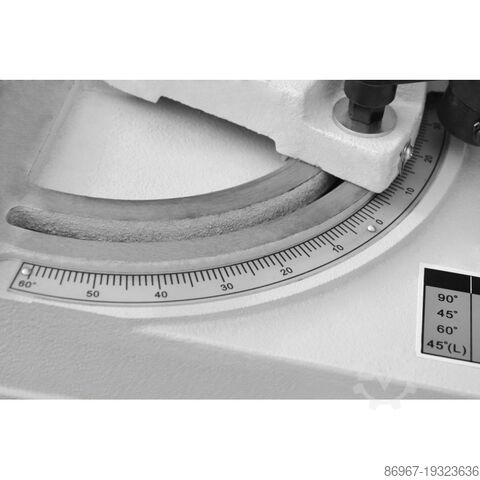

Thread, metric: (54) 0.5 - 224 mm

Thread, Witworth: (55) 72 - 1/8 TPI

Thread, modular: (54) 0.5 - 112 mm

Thread, Diametral Pitch: (54) 64 - 1/4 D.P.

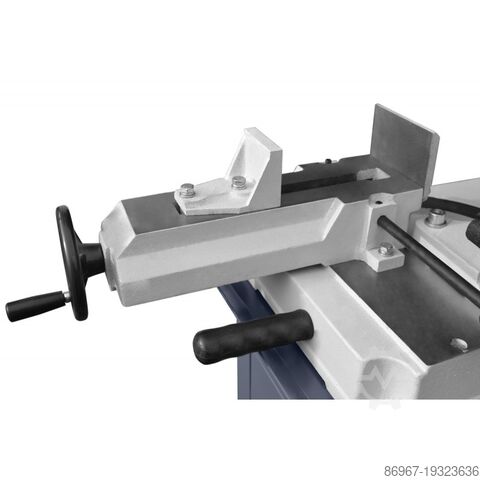

Cross slide LxW: 650 x 230 mm

cross slide stroke: 340 mm

top slide LxW: 350 x 150 mm

top slide stroke: 150 mm

Tailstock spindle diameter: 85 mm

tailstock quill stroke: 200 mm

Tailstock taper: MK 5

Weight: approx. 3,100 kg

Equipment:

- Tailstock movement pneumatically supported

- Acceptance certificate according to DIN 8605, lathe with increased accuracy

- Mechanical double clutch

- Electromagnetic brake

- Rapid traverse for X- and Z-axis

- Electrical equipment from high quality brand components e.g. Siemens/Schneider

- Lubrication of the guideways via hand pump

- Reducing sleeve

- 2 fixed center punches

- All safety devices according to CE standards: Rotary chuck guard with plexiglass disc, micro limit switch secured. Rotating chuck guard with Plexiglas disc. Rear splash guard along the entire length. Lead screw and pull screw protection by light barrier (integrated in emergency stop circuit). Emergency stop pushbutton.

- Swarf container on wheels

- Electric coolant device

- fixed steady rest

- travelling steady rest

- operating tool, acceptance protocol according to DIN, operating and maintenance manual, complete electrical installation, machine manufactured according to CE standard in the latest version

The listing was translated automatically. Translation errors are possible.

Machine according to DIN 8606

Center height: 260 mm

turning diameter over bed: 520 mm

turning diameter over slide: 300 mm

center width: 1.500 mm

bed width: 400 mm

spindle bore: 82 mm

spindle nose: Camlock 8"

Spindle speeds: (24) 9 - 1600 rpm (option 11 - 2000 rpm)

motor power: 5,5 kW (option: 7,5 kW)

feed Z-axis: (93) 0,028 - 6,43 mm/rev

feed X-axis: (93) 0,012 - 2,73 mm/rev

Kdedpjdvm Euofx Ah Nog

Thread, metric: (54) 0.5 - 224 mm

Thread, Witworth: (55) 72 - 1/8 TPI

Thread, modular: (54) 0.5 - 112 mm

Thread, Diametral Pitch: (54) 64 - 1/4 D.P.

Cross slide LxW: 650 x 230 mm

cross slide stroke: 340 mm

top slide LxW: 350 x 150 mm

top slide stroke: 150 mm

Tailstock spindle diameter: 85 mm

tailstock quill stroke: 200 mm

Tailstock taper: MK 5

Weight: approx. 3,100 kg

Equipment:

- Tailstock movement pneumatically supported

- Acceptance certificate according to DIN 8605, lathe with increased accuracy

- Mechanical double clutch

- Electromagnetic brake

- Rapid traverse for X- and Z-axis

- Electrical equipment from high quality brand components e.g. Siemens/Schneider

- Lubrication of the guideways via hand pump

- Reducing sleeve

- 2 fixed center punches

- All safety devices according to CE standards: Rotary chuck guard with plexiglass disc, micro limit switch secured. Rotating chuck guard with Plexiglas disc. Rear splash guard along the entire length. Lead screw and pull screw protection by light barrier (integrated in emergency stop circuit). Emergency stop pushbutton.

- Swarf container on wheels

- Electric coolant device

- fixed steady rest

- travelling steady rest

- operating tool, acceptance protocol according to DIN, operating and maintenance manual, complete electrical installation, machine manufactured according to CE standard in the latest version

The listing was translated automatically. Translation errors are possible.

Seller

Note: Register for free or log in, to access all information.

Registered since: 2013

Send inquiry

Telephone & Fax

+49 8261 ... show

These listings may also fit your interest.

Listing

Rohrbach

Rohrbach

18,653 km

Panel van

VolkswagenT5 Transporter 2.0 TDI PARKTRONIK EURO-5 2xSCHIEBETÜR CoC

VolkswagenT5 Transporter 2.0 TDI PARKTRONIK EURO-5 2xSCHIEBETÜR CoC

Listing

Gussago

Gussago

18,696 km

Graziano (DMG) GT300 CNC Y + Sub (like CTX300)

Graziano (DMG)GT300 CNC Y + Sub (like CTX300)

Graziano (DMG)GT300 CNC Y + Sub (like CTX300)

Listing

Siedlce

Siedlce

17,614 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Listing

Germany

Germany

18,384 km

Industrial robot

Kuka KUKAKR30L16-2 (SafeRobot)

Kuka KUKAKR30L16-2 (SafeRobot)

Listing

Isernhagen

Isernhagen

18,323 km

Lathe

KAMI/SHEMDKM 500SC X 1000 mm

KAMI/SHEMDKM 500SC X 1000 mm

Listing

Wiesbaden

Wiesbaden

18,584 km

Pipe bending attachment

WAXBN 2 / 1/2 - 2"

WAXBN 2 / 1/2 - 2"

Listing

Rennweg am Katschberg

Rennweg am Katschberg

18,395 km

Crawler excavators

CaseBM CX 145

CaseBM CX 145

Listing

Ubstadt-Weiher

Ubstadt-Weiher

18,621 km

Lead/traction spindle lathe

WEILERCommodor B - Teilüberholt

WEILERCommodor B - Teilüberholt

Listing

Schlüchtern

Schlüchtern

18,491 km

Lathe

WeilerMatador VS2

WeilerMatador VS2

Listing

Mudersbach

Mudersbach

18,541 km

Lathe

BernardoMaster 360 Pro

BernardoMaster 360 Pro

Your listing has been deleted successfully

An error has occurred