Used Milling Turning for sale (15,319)

Nördlingen

Nördlingen CNC turning and milling center

DMG MoriCLX 550

Hattingen

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Lüneburg

Lüneburg CNC Turning and milling center

Nakamura-TomeNTJX

+44 20 806 810 84

Thurmaston

Thurmaston CNC turning and milling center

DOOSANPuma 5100 XLY

Schwieberdingen

Schwieberdingen CNC turning and milling center

MiyanoABX 64 SY

Discover more used machines

Germany

Germany CNC Turning- and Milling Center

MONFORTSRNC 500 AC

Alblasserdam

Alblasserdam CNC turning and milling center

Cnc lathe Hyundai WIAL200Y

Schweiz

Schweiz CNC Turning & milling center

MORI SEIKIZT 1500 YB

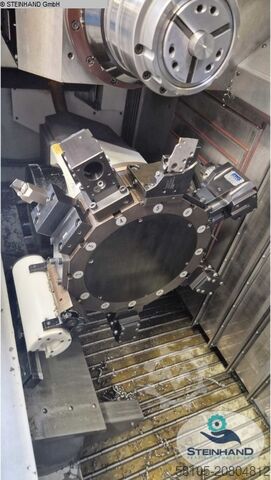

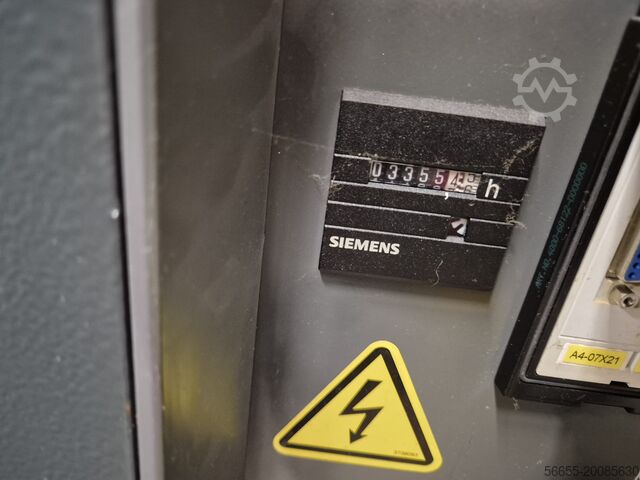

Burgoberbach

Burgoberbach CNC turning-milling center 6 AGW

GildemeisterCTX 310 Eco (nur 3.350 h)

Terrassa

Terrassa CNC turning and milling center

DOOSANPUMA 2000SY

Schwieberdingen

Schwieberdingen CNC turning and milling center

MiyanoABX51 TH2

Hlavní město Praha

Hlavní město Praha CNC turning and milling center

DoosanPuma TT 1800 SY

Basadingen-Schlattingen

Basadingen-Schlattingen Turning Milling Machine

ANAYAKHVM 3300-P

Creazzo

Creazzo CNC turning and milling center

Mori SeikiNL2000 SY

Hersham

Hersham CNC turning and milling center

MazakQuickTurn Smart 300 M

Vertou

Vertou CNC turning and milling center

GildemeisterAlpha CTX 500

Schwieberdingen

Schwieberdingen CNC turning and milling center

MiyanoABX-51 TH2

Köln

Köln CNC Turning- and Milling Center

WFLM 60 G MILLTURN

Guipúzcoa

Guipúzcoa CNC turning and milling center

GildemeisterNEF 520

Werlte

Werlte CNC turning and milling center

OkumaMultus U4000 2SW 1500

Næstved

Næstved CNC turning and milling center

EMCOHyperturn 665

Germany

Germany CNC Turning- and Milling Center

NILES-SIMMONSN30 - 3MC-2500

Sweden

Sweden CNC turning and milling center

Mori SeikiNL 2500 SY/700

Hilden

Hilden CNC Turning- and Milling Center

WFL-MILLTURNM100 MILLTURN / 6500

Hilden

Hilden CNC Turning- and Milling Center

NILES-SIMMONSN20-2 MC

Used Milling Turning (15,319)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84