Used Edge Trimming Machine for sale (66,606)

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeVS 31.09-2

+44 20 806 810 84

Wiefelstede

Wiefelstede Milling unit for edge processing machines

PerskeDKNS 502/2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

SchwabedissenSK 75/2

Discover more used machines

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

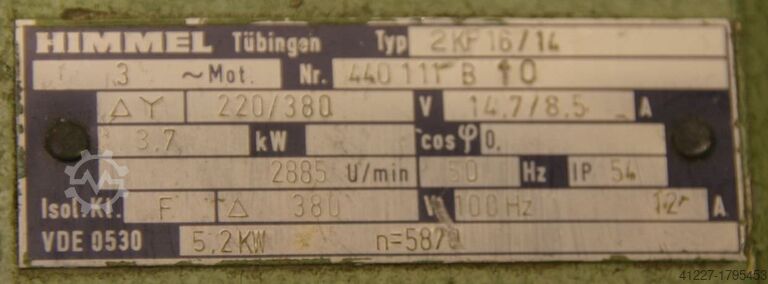

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Schwabedissen2KF16/14

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeVS 31.09-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKS80.14/4

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeDVMS903/2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Schwabedissen2KF16/19

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeDVMS2004/2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Schwabedissen2KF16/19

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKCUS72.24-2D

Wiefelstede

Wiefelstede Milling motor for edge processing machines

HomagLF-55-L-KA

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeDKNS 502/2

Wiefelstede

Wiefelstede Milling unit for edge processing machines

PerskeKNS 21.05-2

Wiefelstede

Wiefelstede Milling unit for edge processing machines

Ott StephanZBXD90L20-2 BMB 46 U 206

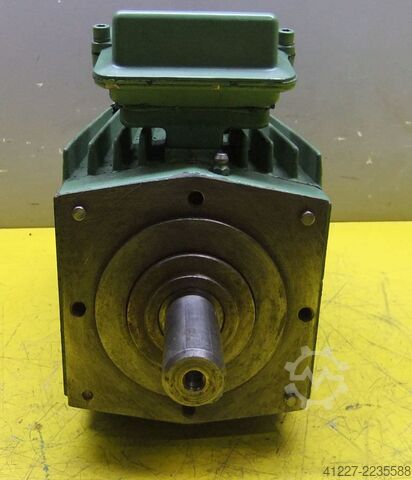

Wiefelstede

Wiefelstede Milling motor for edge processing machines

Himmel2KF16/14

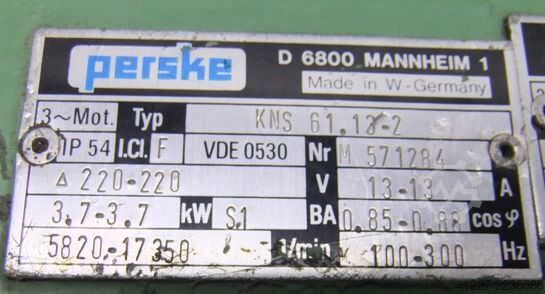

Wiefelstede

Wiefelstede Milling motor for edge processing machines

PerskeKNS 61.13-2

Germany

Germany Edge sanding machine Kündig Basiq

KündigBasiq

Wien

Wien Edge milling machine for metal

Marpol Rasant

Romania

Romania Edge Banding Machine NB860EC

NanxingNB860EC

Used Edge Trimming Machine (66,606)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84