Used Windows Line for sale (19,577)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Częstochowa

Częstochowa

17,870 km

High-quality meltblown production line

ReifenhäuserReicofil MB 1600

Call

Condition: like new (used), High-Quality Meltblown Production Line for Nonwovens

A complete machine inspection was carried out by the manufacturer's service team on 17.12.2025.

Inspection report available.

Commissioning at the customer's site can be offered upon request.

Operating hours: 80 hours (commissioning only)

Price for a new machine: EUR 7,500,000

• Manufacturer: Reifenhäuser GmbH & Co. KG Maschinenfabrik

• Model: Reicofil MB 1600

• Year of manufacture: 2021

• Last commissioning: 2022

Podpfxsx Hx Rnj Ah Hjgg

Technical specifications:

• Working width: 1,600 mm

• Material: Polypropylene (PP), MFI 230 / 2.16 > 400 g/10 min

• Output: Up to 65 kg/h per meter width

• Product weight: 10–80 g/m²

• Production speed: 5–80 m/min

• Die head: MB 1600, 50 h/in

• Extruder: RT-1101-1-100, L/D 30

• Heating capacity, rotary beam: 65–172 kW

• Winder: contact winder with preset reel change

• Max. winding diameter: 1,250 mm

• Web width: 1,700 mm

• Winding tension: 10–100 N/m

Additional equipment and accessories:

• 3-component dosing system

• 80 mm automatic seat changer

• Ultrasonic cleaning system

• Pyrolysis unit

• Ozone extraction

• Cutting knives

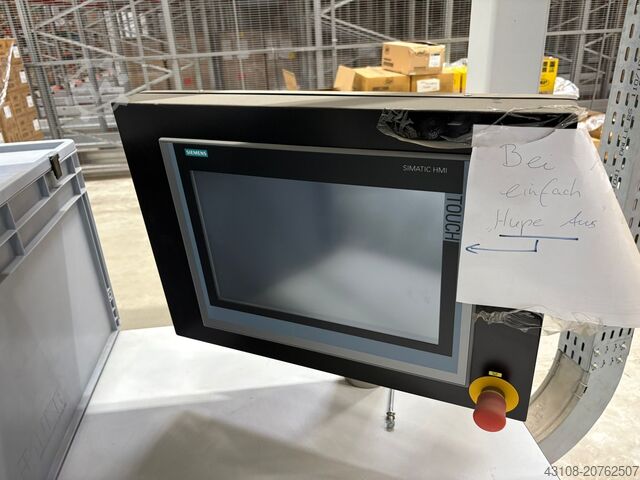

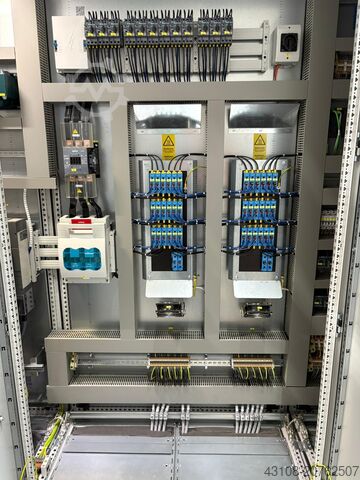

• Central control panel with touchscreen and data entry

Listing

Częstochowa

Częstochowa

17,870 km

Roll forming line

Walzenprofilieranlage

Call

Condition: excellent (used), A roll forming line with rollers for cold rolling office and storage cabinet fronts made of cold-rolled sheet metal. Roller center distance: 140 mm, Roller diameter: 45 mm, Keyway: 12 mm. The system features an electric mechanism for moving the roller sets apart by up to 1500 mm. The system is electrically operated.

Pjdjwxv H Djpfx Ah Hjgg

Listing

Germany

Germany

18,654 km

Hüttenhölscher Line

HüttenhölscherLine

Call

Condition: ready for operation (used), Year of construction: 2012, product length (max.): 2,250 mm, This Hüttenhölscher Line multi-spindle drilling machine was manufactured in 2012. It features a PC-controlled function sequence under Windows 7 with TwinCAT, a 6-station loading gantry, and a 2-axis gantry robot. The machine includes a vacuum generation by ejector and multiple conveyor lines for efficient material handling. Ideal for high precision drilling with its advanced control system. Contact us for more information about this machine.

• Control: PC-controlled function sequence under Windows 7, TwinCAT

• Part dimensions:

• Length: 300–2250 mm

• Width: 350–710 mm

• Thickness: 16–25 mm

• 2-station drilling station:

• Base frame as welded construction with machined screw-on surfaces

• 2x toothed belt conveyors V = 1.5 m/sec

• 2x pneumatic lift for toothed belt conveyors

• 2x stoppers for cabinet parts, dampened by shock absorbers

• 2x pneumatic double clamping cylinders, controlled by ball screw and servo motor, moved to side height (measuring the side height)

• 2x pneumatic cross alignment ruler (plausibility check)

• 2x vacuum clamping units in the drilling machine table

• 2x 0-line controllable

• Support:

• Support can be moved in the X direction by means of a servomotor

• 2x drilling gear (support 1):

• Support equipped with 2 units (machining from above)

• Individually movable in Y direction by servomotor

• Individually movable in Z direction by servomotor

• Drilling gear a = 32 mm, adjustable with frequency converter, drill chuck Ø 10h7 with grub screw

• Callable spindles, 8000 rpm

• Two 16-spindle drilling gears

• Groove saw (support 1):

• Sawing units for cutting special rear wall grooves

• Sawing unit with tool holder, speed control via frequency converter

• Pneumatically pilot-controlled working position

• 2x milling spindles right/left at the front edge (support 1):

• Pneumatically pilot-controlled working position

Additional equipment (automation, handling, guarding, conveyors)

• Loading/handling:

Pedpfeyctauex Ah Hsgg

• 6-station loading gantry

• 2-axis gantry robot; Y/Z axes with servo motors; travel distances: Y-axis 8500 mm, Z-axis 1500 mm

• Suction crossbeam with four-circuit vacuum supply; vacuum generation by ejector

• Double part detection

• Portal supports

• 4 stacking stations

• 1 hand rest station (automatic/manual feeding)

• 1 removal station (automatic/manual removal)

• Side feed range:

• Stack height: max. 1000 mm (60 parts) incl. protective plate

• Protective plate sizes:

• 1380 mm x 780 mm

• 1220 mm x 720 mm

• 1120 mm x 620 mm

• 2290 mm x 620 mm

• Thickness: 25 mm

• Thickness: max. 28 kg

• Floor roller conveyor / stack feed:

• 4 roller conveyor lines, 930 mm wide x 3600 mm long, AH 300 mm

• Feeding/removal: manual cross transfer carriage

• Support stations / automatic feeding:

• Transport section 950 mm wide x 4100 mm long; integrated side stop

• Manual feeding:

• Toothed belt section 900 mm wide x 2500 mm long

• Transfer shuttle:

• Toothed belt section 900 mm wide x 2500 mm long; horizontal stroke approx. 2500 mm by three-phase motor

• Return:

• Transport section 950 mm wide x 4000 mm long; pneumatic stopper

• 90° rotary unit:

• Vacuum suction cup; pneumatic stroke; rotation by three-phase motor by +/- 90°

• Discharge stations / automatic removal:

• Transport 950 mm wide x 3000 mm long; positioning of cabinet parts by encoder

• Manual removal:

• Toothed belt section 900 mm wide x 3000 mm long

• Protective system for feeding:

• 45 m protective fence with 3 access doors

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Deinze

Deinze

18,734 km

Decoiling + / or Roll forminglines

MGM + ColomboRoll forming Punch line

Call

Condition: ready for operation (used), Fabrication line for production of metal racks

14 stations: double driven

Axle Ø 80 mm

station lt;- station: 400 mm

adjustable centerdistance axles: min 100mm; max 280mm

max feedingwidth: 780 mm

max thickness: 3 mm steel

Including:

- Colombo excenter Press 100 ton for punching

Stroke: 150 mm

16.5 hp

Table: 600 x 1000 mm

Stroke/min: adjustable from 30 - 90 str/ min

- 4 column press on rails acting as flying shear

Table 400 x 400 mm

- Unloading table

Pgedoycmqmepfx Ah Hsg

Work mode: Roll forming unit

Material thickness x width: W 780 mm Max

Numbre of sections: 14 stations axle Ø80mm

PUNCHING MACHINE: Punching press

CUTTING DEVICE: Flying Shear

Conveyor: Yes

Listing

Germany

Germany

18,384 km

CNC processing centre windows & doors

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Call

Condition: used, Wooden window production line for sale on behalf of a customer.

Machines still in operation can be viewed. Sale includes machines, tools, and programming of the systems produced.

Includes angled window and arched window production.

Item 1: Weinig Powermat 500, year of manufacture 2010, window version

-----

- ??6 spindles, 5 of which are PowerLock

- 8,000 rpm

- Equipment for glazing bead removal

- Large PowerCom control system

- Includes existing Leitz planing and molding tools

- Linked to a Maweg Saturn Duo single-piece wood sander, year of manufacture 1985,

and a workpiece return conveyor system

Item 2: SCM Windor 40 R window system, year of manufacture 2006

-----

- 2 long CNC-controlled slotting spindles

- 3 long CNC-controlled profile spindles + top and bottom unit

- Rebating carriage for small sashes

- ROTATEN: Angled window attachment

- Includes Leitz window and door tools

- Includes separate OKOMA UF 3 rebating machine with tools

Item 3: HOMAG CNC machining center BMG310/42/F/K, year of manufacture 2018

-----

- Gantry machine, 5-axis Drive 5C+ with 15 kW

- Ceiling laser

- Working dimensions 4200 mm length, 1350 mm depth

- 32-position disc changer

- 8-position linear changer

- Fixed drilling head with 18 spindles V12/H6/S0/90 degrees

- 8 consoles

- 6 lifting rails

- Connection for 8 PowerClamp clamps

- Approx. 30 vacuum clamps

- 4 x PowerClamp clamps

- WoodWop

- Chip conveyor belt

- Various small solid wood clamps, used for casement windows

- Including Leitz tools for Homag with arched window production

- Including Barbaric vacuum lifter, year of manufacture 2015

Item 4: Löwer MZP 1 mini dovetail press

-----

- ??For arched window production

Item 5: S+S frame press type Bavaria 200 L, year of manufacture 2014

-----

- Working dimensions 4000 x 2600 mm

- With center pressure beam and cross pressure device

- Motorized width adjustment

- Basic equipment counter profiles

- Slanted window control

- Pendulum pressure plates + extension for pointed windows

- Intermediate insert for small-scale crimping

- Various carrier plates for counter profiles and counter profiles

Item 6: Striffler sash fitting table

-----

- With automatic screwdriver and screw feeder

- Fitting rack

- Punch for Roto fitting

Item 7: Stegherr KF counter milling machine

-----

- With existing tools

Item 8: Tools

-----

All tools belonging to the machines for the

wood+wood-aluminum systems IV 72 + 92 mm shown in the PDF

- Windows

- Lift-and-slide doors

- Round and angled windows

- Box windows

- Entrance doors in many variations

- Putty rebate variations

- ...

Sale of the tools in their current condition, scope, and with accessories as they are currently available. Note regarding window cuts, tool drawings, and tool system listings:

Pjdpfxsyclwls Ah Hogg

Engelfried GmbH does not guarantee that the tools actually present correspond to the systems listed and drawn.

(Technical specifications according to the manufacturer, without guarantee!)

-----...

Listing

Germany

Germany

18,384 km

Window production centre

Weinig, SCM, Homag, S+SPowermat 500, Windor 40 R, BMG

Call

Condition: used, Wooden window production line for sale on behalf of a customer.

Machines still in operation can be viewed. Sale includes machines, tools, and programming of the systems produced.

Includes angled window and arched window production.

Item 1: Weinig Powermat 500, year of manufacture 2010, window version

-----

- ??6 spindles, 5 of which are PowerLock

- 8,000 rpm

- Equipment for glazing bead removal

- Large PowerCom control system

- Includes existing Leitz planing and molding tools

- Linked to a Maweg Saturn Duo single-piece wood sander, year of manufacture 1985,

and a workpiece return conveyor system

Item 2: SCM Windor 40 R window system, year of manufacture 2006

-----

- 2 long CNC-controlled slotting spindles

- 3 long CNC-controlled profile spindles + top and bottom unit

- Rebating carriage for small sashes

- ROTATEN: Angled window attachment

- Includes Leitz window and door tools

- Includes separate OKOMA UF 3 rebating machine with tools

Item 3: HOMAG CNC machining center BMG310/42/F/K, year of manufacture 2018

-----

- Gantry machine, 5-axis Drive 5C+ with 15 kW

- Ceiling laser

- Working dimensions 4200 mm length, 1350 mm depth

- 32-position disc changer

- 8-position linear changer

- Fixed drilling head with 18 spindles V12/H6/S0/90 degrees

- 8 consoles

- 6 lifting rails

- Connection for 8 PowerClamp clamps

- Approx. 30 vacuum clamps

- 4 x PowerClamp clamps

- WoodWop

- Chip conveyor belt

- Various small solid wood clamps, used for casement windows

- Including Leitz tools for Homag with arched window production

- Including Barbaric vacuum lifter, year of manufacture 2015

Item 4: Löwer MZP 1 mini dovetail press

-----

- ??For arched window production

Item 5: S+S frame press type Bavaria 200 L, year of manufacture 2014

-----

- Working dimensions 4000 x 2600 mm

- With center pressure beam and cross pressure device

- Motorized width adjustment

- Basic equipment counter profiles

- Slanted window control

- Pendulum pressure plates + extension for pointed windows

- Intermediate insert for small-scale crimping

- Various carrier plates for counter profiles and counter profiles

Item 6: Striffler sash fitting table

-----

- With automatic screwdriver and screw feeder

Pgodpjyclwfefx Ah Hog

- Fitting rack

- Punch for Roto fitting

Item 7: Stegherr KF counter milling machine

-----

- With existing tools

Item 8: Tools

-----

All tools belonging to the machines for the

wood+wood-aluminum systems IV 72 + 92 mm shown in the PDF

- Windows

- Lift-and-slide doors

- Round and angled windows

- Box windows

- Entrance doors in many variations

- Putty rebate variations

- ...

Sale of the tools in their current condition, scope, and with accessories as they are currently available. Note regarding window cuts, tool drawings, and tool system listings:

Engelfried GmbH does not guarantee that the tools actually present correspond to the systems listed and drawn.

(Technical specifications according to the manufacturer, without guarantee!)

-----...

Listing

Esenkent

Esenkent

17,172 km

Coil Slitting Line 0.5 - 4 mm x 1600 mm

BOSPORASAYK-DY

Call

Condition: new, Year of construction: 2025, functionality: fully functional, blade shaft diameter: 160 mm, sheet thickness aluminum (max.): 4 mm, coil weight: 20,000 kg, sheet thickness (max.): 4 mm, sheet thickness steel (max.): 4 mm, sheet thickness copper (max.): 4 mm, sheet thickness brass (max.): 4 mm, cutting speed: 90 mm/min, product height (max.): 4 mm, working width: 1,600 mm, type of input current: three-phase, total width: 6,000 mm, total length: 28,000 mm, total height: 2,600 mm, feed roller diameter: 126 mm, operating speed: 60 mm/s, inner diameter: 508 mm, input voltage: 380 V, product width (max.): 1,600 mm, number of feed rollers: 2, number of straightening rollers: 17, power: 145 kW (197.14 HP), RAEDY IN STOCK ---> COIL SLITTING LINES

Coil Slitting Line is a machine specially manufactured for slitting master coil in to baby coils. Coil Slitting Lines consist of the following equipment and units;

Coil Car / Loading Trolley

Decoiler / Uncoiler / Coil Unwinder

Strip Transfer Unit

Straightener / Leveler

Strand Extensioner Leveler

Podpfx Aeh Dy Iyjh Hogg

Slitting Head witg Slitting Knives

Spare Slitting Head and Knives for Quick Change

Scrap Recoilers / Winders

First Strip Transfer Unit

Strip Tension Control

Separator Units and Parts

Coil Rewinder System

Coil Extraction and Easy Handling System

Exit Car

Hydraulic and Pneumatic Systems

Electronic Control Panels

Listing

Vall de Uxó

Vall de Uxó

19,605 km

Cape nailing line

CapeCP110

Call

Condition: used, Year of construction: 2000, Line composed of:

CP110-1 Nailer

tong turner

5 meter heel

turner module

Podpok Nfnbjfx Ah Hogg

marker module

corner cutter module

pallet stacker

5 meter board

Listing

Nattheim

Nattheim

18,550 km

Window production plant

WeinigUnicontrol 10

Call

Condition: used, Year of construction: 2000, Storage location: Nattheim

Pgedpfx Aevwdmweh Hog

Listing

Nattheim

Nattheim

18,550 km

Finger jointing line

Call

Condition: used, *Available from approx. end of 2025* Fully automatic finger jointing line for the following dimensions: Thickness: approx. 24 – 100 mm Width: approx. 80 – 240 mm Finger jointing length: 400 – 1,500 mm Finished length: 2.50 m – 13.50 m continuously variable Consisting of the following system components: - SMB vacuum destacking lengthwise with 2 lifting tables and 2 package roller conveyors, built in 2013 Package dimensions max. 1.20 x 1.20 x 6.00 m 4 suction pads Sicko system Separation and infeed into roller conveyor for scanner feeding, board turner, switch for too moist, too dry, switch for B-quality, marking station or automatic operation - Bidac end-face scanner for cupping detection, built in 2013 - Brookhuis moisture measurement FMI 5 Year of manufacture 2019 - Microtec scanner Goldeneye 502, year of manufacture 2012 with X-ray, 4 color cameras and new optimization software - Dimter-Opticut 350-2, year of manufacture 2003 with paddle ejector, year of manufacture 2009 and associated sorting belts and pneumatic ejector for 2 additional qualities - NKT packaging - NKT finger jointing system with turntable Spezialpack AH 1050, year of manufacture 2005 consisting of: Milling machine · Tipping station · Threading section length 5.0 m · Cyclic press length 6.00 m · Cross-cut saw - SMB stacking machine, year of manufacture 1998, 2.50 - 13.50 m length, divisible into 2 units (e.g. 2 x 5.0 m) 8 stacking arms, 8 stacking tongues, manually adjustable electro/hydraulic stop, package width: max. 1200 mm, package height: max. 600 mm, hydraulic package pusher

Storage location: Customer

Pedpfx Ahjvvi Tyj Hsgg

Listing

Düsseldorf

Düsseldorf

18,569 km

Van

MERCEDES-BENZB 250 e DCT 160kw*AMG-Line*Digital*Alcan/Leder

Call

Condition: used, mileage: 93,069 km, power: 160 kW (217.54 HP), first registration: 09/2022, fuel type: hybrid, next inspection (TÜV): 09/2027, color: black, gearing type: automatic, emission class: euro6, number of seats: 5, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), navigation system, soot filter, * AMG LINE

* AMG sports package

* AMG styling with front spoiler and side skirts

* AMG 18" alloy wheels

* 10.25" digital instrument cluster

* Seats in Alcantara / partial leather

* Front and rear parking sensors (PDC)

* Navigation system

* Automatic climate control

* 8-speed automatic transmission

* DAB radio

* Traffic sign recognition

* Lane keeping assist

* Sports leather multifunction steering wheel with paddle shifters

* Sound system

* Ambient lighting

* Cruise control

* Rain sensor

* Light sensor

* Smartphone integration package with Carplay & Android Auto

* Seat comfort package

* Multimedia system MBUX (Digital multimedia system)

* Active park assist

* Comfort suspension

* Mirror package

* Electrically adjustable, heated, and folding exterior mirrors

* Light and vision package

* Trim elements in carbon look

* Drive mode selector "AGILITY SELECT"

* EURO 6d emission standard

* 4x electric windows

* Tinted windows

* On-board computer

* Start / stop function

* Center armrest with storage compartment

* USB and AUX-IN connection

* Fog lights

* Electronic Stability Program (ESP)

* Child seat anchors "ISOFIX"

* Rear bench, split-folding with through-loading option

* 10.25" combination display

* Hybrid 160 kW (Engine 1.3 Ltr. – 118 kW)

* AC charging function with 3.7 kW charging capacity

* Charging cable SCHUKO CEE 7/7 (TYPE E/F) 8M

* High-end infotainment package

* Smartphone integrated

* Keyless Go

* Remote central locking with 2 keys

* One owner

* Fully maintained with complete service book at MB

* Last service at 73,501 km on 09.04.2025

Vehicle number: 126

Whatsapp No.:

Further vehicle offers can be found at:

ONLINE CONSULTATION / ONLINE VIEWING / ONLINE PURCHASE CONTRACT / TRADE-IN OF YOUR USED CAR OR TRUCK / DELIVERY AVAILABLE FOR AN EXTRA CHARGE

Delivery service available on request

Foreign customers have the opportunity to make a partial payment and collect the vehicle at a later date.

NET price for export possible (for vehicles with VAT deductible).

---

We are happy to handle your vehicle registration (Düsseldorf) as well as the issuance of customs/export or transit plates (5-day).

Complete export processing possible (export declaration).

---

Vehicles with TÜV used vehicle inspection possible.

Podpfsydtl Tsx Ah Hegg

---

On request, we will be happy to offer you our used car warranty 'GPG' with individual solutions tailored specifically to you and your vehicle.

---

Trade-in possible.

---

For further questions we are available by phone.

Opening hours: Monday to Thursday 09:00 – 16:30, Friday 09:00 – 16:00

---

Changes, errors, mistakes, and prior sale reserved.

Offers are non-binding.

All information provided without guarantee.

Vehicle descriptions do not constitute guaranteed characteristics.

Listing

Germany

Germany

18,384 km

FFP2 mask production line

RuhlamatMPL FFP2/016

Call

Year of construction: 2020, condition: good (used), FFP2 Mask Production Machine Production Line

Manufacturer: Ruhlamat

Model: MPL FFP2/016

Year of manufacture: 2020

Mask Production Line N95/FFP2 Masks

Installation dimensions LxWxH: 8921 x 1494 x 1985 mm

Clearance around the machine: 1500 mm all around

50 Hz / 2.6 kVa

Pressure: 6 bar

Approx. weight: 2500 kg

FFP2 masks are made of 3 to 6 layers of nonwoven fabric.

This machine can produce masks with up to 6 layers.

The system is comprised of five stations:

Station 1: Unwinder

Pgodpfx Ahjrm R Hde Hsg

Station 2: Punching nose clip and embossing roller welding

Station 3.1: Printing and welding ear loops

Station 3.2: Aligning folding edge

Station 4: Contour welding and cutting mask

Listing

Breda

Breda

18,625 km

WEBER DS 8.5 PVC Pipe Line up to 160 mm

WeberWEBER DS 8.5

Call

Condition: good (used), WEBER tube extrusion line including:

WEBER DS 8.5

Elmepla saw

Battenfeld R200/6

Pgsdpfjvryhyex Ah Heg

Battenfeld V125

Listing

Lleida

Lleida

19,551 km

Painting line

WagnerSuPER TECH HorizontalPowder Spray Booth

Call

Condition: like new (used), Year of construction: 2012, functionality: fully functional, total width: 2,600 mm, total length: 4,000 mm, Pre-heating - WAGNER Powder Spray Booth Wagner - cleaning Wanzer

S-PTG-004

Pre-Heating - before spray booth - and after Cleaning - and Gel furnace

built-in radiators, especially the dark radiators in the ovens.

Preheating:

Only metal tubular radiators 230V, 2500W, heated length = 2700 mm (drawing 18Z3-35249 a) with a quantity of 38 pieces are installed here.

Ask the drawing S-PTG-004

built-in radiators, especially the dark radiators in the ovens.

Preheating:

Only metal tubular radiators 230V, 2500W, heated length = 2700 mm (drawing 18Z3-35249 a) with a quantity of 38 pieces are installed here.

Please find attached the drawing of the radiators (tubular heaters)

There is no additional infrared radiation here.

Gel oven:

Only infrared radiators from Excelitas Nobelight (formerly Heraeus Nobelight) 400 V, 15000 W, heated length = 2,900 mm with a quantity of 12 units are installed here.

Additional heating by metal tube heaters is not used here.

Pgodpfxevy Ebhe Ah Heg

Alignment oven

Only metal tube radiators 230V, 2500W, heated length = 2700 mm (drawing 18Z3-35249 a) with a quantity of 38 pieces are installed here.

Please find attached the drawing of the radiators (tubular heaters)

There is no additional infrared radiation here.

Curing oven 1

Only metal tubular radiators 230V, 2500W, heated length = 2700 mm (drawing 18Z3-35249 a) with a quantity of 38 pieces are installed here.

Please find attached the drawing of the radiators (tubular heaters)

There is no additional infrared radiation here.

Curing oven 2

Only metal tubular radiators 230V, 2500W, heated length = 2700 mm (drawing 18Z3-35249 a) with a quantity of 38 pieces are installed here.

Please find attached the drawing of the radiators (tubular heaters)

There is no additional infrared radiation here.

Listing

Lleida

Lleida

19,551 km

Paint finishing system

WagnerHorizontal Painting line

Call

Condition: like new (used), Year of construction: 2012, functionality: fully functional, Painting line

Pgedpfxsrr Uhwe Ah Hsg

Listing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

18,619 km

FGT Graphic Machinery - Window Patching

BOTONBTM-950Q

Call

Condition: new, Year of construction: 2024, Boton BTM-950Q

- Year of manufacture: 2024

- New machine, only 30 operating hours

- Window patching machine

- Maximum blank/paper size: 950 × 780 mm

- Minimum blank/paper size: 150 × 130 mm

- Processable material thickness: Cardboard: 200–2000 g/m²; Corrugated board: 1–4 mm

- Film thickness: 0.1–0.3 mm

- Window size (max/min): 380 × 300 mm / 30 × 50 mm

- Positioning accuracy: ±0.5 mm

- Output: up to 9,000 sheets/hour

Pjdpfxeydpt Tj Ah Hogg

- Pneumatics/operating pressure: 3–6 bar

- Heated roller for rigid films

- Servo-controlled feeder

- Touch panel

- PLC control

- Modular design

- Capable of gluing corner windows

Listing

Lopik

Lopik

18,584 km

Butter Production Line

Simon FreresMD1119 C

Call

Condition: good (used), Year of construction: 1983, Continuous Butter Making Machine (CBM).

Brand : Simon Freres

Type : MD1119 C

Year : 1983

Pgjdoydnzpepfx Ah Hjg

Capacity : 2.000 kg per hour butter output

Input : ± 4,000 liters of cream 38-42% fat

With accessories:

- Water and culture dosing system

- Vacuum pump

- Controls

- Piping

1 x Butter Silo

Butter capacity: 2.000 kg

With 2x Butter Pumps: Waukesha type: 130U1

Motor: 5.5 kW

CIP return pump

Description:

Butter production line. Still located at the factory in Belgium. Operating principle of the production line:

Continuous butter making machine. A cream pump transports the cream from the buffer tanks to the CBM. The CBM is capable of converting 4.000 liters of cream into 2.000 kg of butter. It also features a recirculation system for cooling and injecting buttermilk, a vacuum section, and injection pumps for culture and brine. Furthermore, it includes a buttermilk cooler, buttermilk and CIP pumps, a collection tank, valves, piping, and all the necessary controls. After the butter is made in the CBM, it is pumped into the Egli butter silo, which includes two Waukesha outlet pumps to transport the butter to the filling machines.

Listing

Ignalina

Ignalina

17,249 km

Granulator-Pellet Mill-Pellet Line

LietuvaTSF

Call

Condition: new, Year of construction: 2025, We produce pellet-briquette line

Pjdpfxoghmpto Ah Hjgg

We are the only manufacturers in Lithuania, the only ones with our own service.

We will deliver, install, set up and train the lines.

We select a package according to your budget.

We not only produce the equipment ourselves, but we also produce pellets ourselves, you can come and see the working equipment.

Pellet production lines from 100 kg/h to 30 t/h

We produce:

Drum dryer

Belt dryer

pipe dryer

Pellet plant Mills

crushers

Conveyor

Coolers

Cyclones

Bunker

Packing machines

TSF-Justinas

Listing

Domnești

Domnești

17,481 km

Cross-cut optimization line

Paul MaschinenfabrikC11 MKL

Call

Condition: refurbished (used), C11 MKL Cross-Cut Optimization Line, offered by Wood Expert Industry, is a state-of-the-art technological solution designed specifically for industrial wood processing and operational workflow optimization in woodworking facilities. All equipment comprising the processing line is manufactured by Paul Germany and was completely overhauled in July 2025 with zero operating hours.

Paul C11 MKL Lumber Optimization Line Components

- 9.0 m / 230 mm Inclined Conveyor Belt

Ideal for the automatic and efficient handling of wood pieces towards the processing area, equipped with a guided belt and robust clamping parts for stable transport.

Pgjdpfxew Emf Ro Ah Heg

- Measuring Station with Luminescent Scanner and Photocell

Allows precise identification of the start and end of workpieces, featuring dedicated lower rollers for high-accuracy measurements.

- Pressure Roller Unit

Ensures correct alignment and pressing of pieces between 250 and 4200 mm, with manual adjustment available according to the material thickness.

- Reinforced Marking Rails, Left and Right

Automatically pre-marks cutting positions for increased efficiency and accuracy in subsequent processing.

- C11 MKL Optimizer – CNC Cross-Cut Saw Station

Includes a robust welded steel frame, 500 mm TCT blade, 5.5 kW servo-driven motor, variable speed, and an advanced feeding system with lower/upper rollers for precise piece guidance. Electric adjustment of the upper rollers allows automatic adaptation to wood thickness. The system features automatic waste extraction, extraction ports, CE safety compliance, and advanced cutting quality options (blade with 132 conical teeth).

- Waste Extraction System

Comprises an 11.5 m / 230 mm conveyor belt and ascending waste belt (3.0 m / 500 mm with collection hopper), optimizing material flow and disposal of residues.

- Length Sorting System

With pneumatic ejectors and basic sorting equipment, this facilitates automatic organization and discharge of pieces to two outfeed positions, increasing line productivity.

- Maxi8 Premium Operator Terminal and Optimization Software

17” touchscreen terminal, dust-protected, remote diagnostics, Linux-based, with dedicated optimization software (up to 60 cutting lists, 9 grading options, 400 preset lengths/list), advanced statistics, network integration capability. Includes data import/export options via USB.

- Control and Automation Equipment

Standardized electric cabinets, control panels, complete installation and wiring performed with high-quality components for intensive industrial use.

Benefits of integrating this line:

- Fully automated cross-cutting process, significantly reducing human error.

- Increased efficiency and yield through cutting list optimization and automatic length sorting.

- Adaptability to various thicknesses and sizes of workpieces.

- Advanced digital control and remote diagnostics for quick interventions.

- High reliability, reduced maintenance costs, and adherence to strict CE safety standards.

This optimization line can be customized for different types of wood processing facilities, ensuring efficient operation tailored to every client’s requirements.

Listing

Rzeszów

Rzeszów

17,704 km

Pastry line

Rondo

Call

Condition: excellent (used), Year of construction: 2005, 272 USED Rondo pastry line.

EXTERNAL DIMENSIONS (in cm):

- W: 118,

- L: 770,

- H: 189.

EQUIPMENT:

- Dough sprinkler

- Calibrator

- Cutting station

- Water sprayer

- Filling station

- Rolling roller (torpedo)

- Folding station

- Guillotine

- Various accessories.

The price is a net price.

Pedpfxsydlyvo Ah Hsgg

Our languages: ENGLISH, GERMAN, FRENCH, RUSSIAN, UKRAINIAN.

Listing

Lubin

Lubin

18,036 km

Screen changers for PVC granulation line

Call

Condition: excellent (used), functionality: fully functional, Offer: Screen Dies for PVC Granulation Lines

We offer high-quality screen dies designed for:

-production of RBS panels and other variants,

-acoustic panels,

gutter elements and other PVC profiles,

-control of granule size in the granulation process.

Available die types:

-Screen dies for Royal RNH and RCG panels – specification DKT08_07

-Dies for RNR 0 acoustic panels – specification DKT01/10

-RBS dies and other variants

-Injection moulds

-Other production dies and accessories

Features:

-Made from high-grade tool steel, resistant to abrasion and high temperature

-Precision screen holes

-Stable and repeatable line operation

-Possibility to customise die parameters and hole layouts to production requirements

Pgodpsydlt Ajfx Ah Heg

For detailed information about dies and products, please contact us.

Trust Seal

Dealers certified through Machineseeker

Listing

Velžys

Velžys

17,333 km

Laminated glass cutting line, 3700 mm

BOTTERO536 LAM/37 + 101C BLM-J

Call

Condition: excellent (used), Year of construction: 2014, functionality: fully functional, Laminated glass cutting line BOTTERO 536 LAM/37 + 101C BLM-J

With low-e deletion

Year of production: 2014

Maximum laminated glass cutting length: 3700 mm

Maximum laminated glass thickness: 8 + 4.56 PVB + 8 mm

Tilting loading table with air cushion 101C BLM-J is included

Pgedpfeydlmiex Ah Heg

Very good and clean condition

Good working order, tested

As is

Available immediately

Listing

Velžys

Velžys

17,333 km

Laminated glass cutting line, 4600 mm

BOTTERO545 VSX-46 + 100 BLC-J

Call

Condition: excellent (used), Year of construction: 2008, functionality: fully functional, Laminated glass cutting line BOTTERO 545 VSX-46 + 100 BLC-J

With low-e deletion

Year of production: 2008

Maximum laminated glass cutting length: 4600 mm

Maximum laminated glass thickness: 10 + 4.56 PVB + 10 mm

Tilting loading table with belts 101 BLC-J is included

Very good and clean condition

Pgsdpoxlqzaefx Ah Hog

Good working order, tested

As is

Available immediately

Listing

Kehra

Kehra

17,096 km

Parquet production line

Marinus not WeinigV&G 400

Call

Condition: excellent (used), Marinus Machines V&G 400 Series,

Through Feed End Matching Machine suitable for fixed or random lengths as needed

Maximum working length up to 6m,

Minimum working length: 500m/m

Podpfxeydii Is Ah Hogg

Total Power: Appr: 32kw,

Tooling included.

400v 50hZ

20 pieces per minute possible depending on length.

PLC Controls.

Complete Safety Enclosure.

Listing

Iisalmi

Iisalmi

16,758 km

Sorting line

Järme Oy23

Call

Year of construction: 2003, condition: good (used), Sorting line with 23 pockets and wood chipper

Podpfxjxuh Sbo Ah Hogg

We make it easier for you to find: "windows line"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Windows Line (19,577)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month