Used Various for sale (5,554)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Pulheim

Pulheim

18,588 km

Semi-automatic pallet wrapper

KVK 2 MA - 2t - 1650 Teller - 2400 Höhe

Call

Year of construction: 2025, condition: new, Our KVK 2 (MA) is a semi-automatic stretch wrapper with a turntable that is even more robustly built, better equipped and can be adapted to your requirements with more options compared to our entry-level model.

The only thing that still has to be done manually with this wrapper is applying and cutting the film.

With a weight of 700 kg, this model is designed for loads of up to 2000 kg. The KVK 2 (MA) has a 1650 mm turntable and can wrap pallets up to 2400 mm high as standard. With adjustable speeds of the turntable and film carriage, as well as an electromagnetic brake that can be very finely adjusted via potentiometer, you can adapt the automated wrapping process perfectly to your product. Automatic recognition of your pallets (via photocell) is just as much a matter of course as adjustable head and foot wrapping. Programs are available for "up only" wrapping, "up & down" (cross wrapping) and "rainproof" wrapping. If required, the winder can also be controlled manually.

If the winder needs to be moved to a different location, it can be easily lifted and moved with a forklift using the integrated cut-outs.

Fedpfjx Exbksx Ag Dopr

In addition to a suitable drive-on ramp and a photocell for detecting dark packaging materials or black film, turntables in various sizes with a diameter of up to 2200 mm and higher masts for a wrapping height of up to 3200 mm are optionally available for the KVK 2 MA.

This stretch wrapper is our recommendation for professional use, with approx. 15-20 pallets per day. Especially when a fine and quick adjustment of the brake is required, as is the case with very light packing units or frequently changing pallets.

For further information, we have attached the technical data sheet as a PDF to this advertisement!

Listing

Vuren

Vuren

18,595 km

Standard-SZM

DAFXF 480 FT

Call

Condition: good (used), mileage: 867,531 km, power: 355 kW (482.67 HP), first registration: 01/2019, fuel type: diesel, tire size: 385/65R22,5, axle configuration: 4x2, wheelbase: 3,800 mm, fuel: diesel, color: blue, driver cabin: sleeper cab, gearing type: automatic, number of gears: 12, emission class: euro6, suspension: steel-air, total length: 5,960 mm, total width: 2,550 mm, total height: 4,000 mm, Year of construction: 2019, Equipment: ABS, air conditioning, central locking, cruise control, electric window regulation, parking heater, traction control, = Additional Options and Equipment =

- Digital tachograph

- Electric mirrors

- Tachograph (control device)

- Fixed fifth wheel

- Hydraulic system

- Power take-off (PTO)

- Pump

- Super Space Cab

= Remarks =

Number of axles: 2, Configuration: 4x2, Twin tyres, Payload: 11,626 kg, Curb weight: 7,874 kg, Gross vehicle weight: 19,500 kg, Total tank capacity: 845 liters, Fifth wheel height: 116 cm, Fifth wheel: Fixed, Number of locks: 1, Suspension type: Air suspension, Cab type: Super Space Cab, Cruise control, Tachograph (control device), Digital tachograph, Air conditioning, Auxiliary heater, Electric windows, Electric mirrors, Color: Blue, Heated mirrors, Lighting: Halogen lamp, Speed limiter, Lane departure warning system, Seat heating, Bluetooth, Warning lights, Engine power: 355 kW (476 Hp), Fuel: Diesel, Euro: 6, Transmission type: AS-Tronic, Transmission make: ZF, Speed limiter, Gears: 12, Power steering, ABS, ASR, Hydraulic system, Power take-off (PTO), PTO type: 1, Starter battery, Pump, Central locking, Seats: 2, Seating configuration: 1+1, Seat upholstery: Fabric, Seat adjustment: Manual

= Further Information =

Transmission

Transmission: ZF, 12 gears, automatic

Axle configuration

Brakes: Disc brakes

Axle 1: Tire size: 385/65R22.5; Steerable; Left tire tread: 5 mm; Right tire tread: 5 mm; Suspension: leaf spring

Axle 2: Tire size: 315/70R22.5; Dual tyres; Left inner tire tread: 14 mm; Left outer tire tread: 16 mm; Right inner tire tread: 13 mm; Right outer tire tread: 14 mm; Suspension: air suspension

Weights

Unladen weight: 7,874 kg

Payload: 11,626 kg

Gross vehicle weight (GVW): 19,500 kg

Functionality

Pump: Yes

Interior

Number of seats: 2

Condition

Technical condition: Good

Visual condition: Good

Damages: None

Number of keys: 2

Identification

Registration: 38-BLS-4

= Company Information =

Kleyn Trucks is one of the world’s largest independent dealers in used vehicles. Here you can choose from a constantly changing stock of 1,200 used trucks, tractors, and trailers. Our offer includes all European brands from various model years and price classes.

Why buy at Kleyn Trucks? Simple!

• Large, fast-changing inventory

• Recognizable quality

• Good prices

• Reliable business conduct

• We speak many languages

• We understand our customers

• Support with import and transport

Fpsdpfsx Ev Aljx Ag Dor

• (Export) registration plates arranged quickly

• Expert technical services

• The security of "recognizable quality"

• And more....

Please visit our website for special offers and a complete stock list:

Leasing through Kleyn Trucks is possible in most European countries!

Quickly calculate your leasing rate and send a request via our website.

Ask directly about our European warranty package.

Listing

Aurach

Aurach

18,507 km

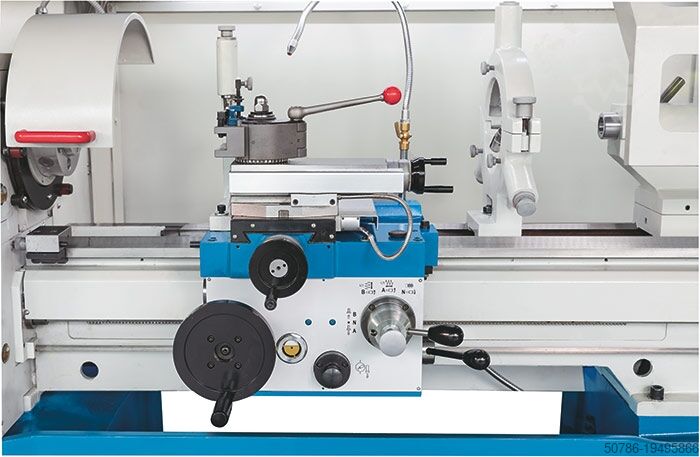

Lead/traction spindle lathe

VDF BoehringerDUE 500

Call

Condition: excellent (used), Year of construction: 2004, We are offering an exceptionally high-quality precision lathe. Within its class, this is likely the best German lathe ever built.

BOEHRINGER Precision Lathe Model DUE 500

Year of manufacture: 2004, including CE certification and central lubrication

Machine No.: T1022.2027-00

Center height: 240 mm

Swing diameter over bed: 500 mm

Swing diameter over cross slide: 285 mm

Center distance: approx. 1,200 mm

Effective turning length: approx. 1,000 mm

Bar capacity: 62 mm

Spindle nose: DIN 55027 Size 6

Spindle bore: 100 mm

Drive power: 11 kW

Maximum torque: 2,000 Nm

24 spindle speeds: 11.2 – 2,240 rpm

60 cross feeds: 0.03 – 28 mm/rev

Fpsdpfjw Rdthex Ag Djr

60 longitudinal feeds: 0.06 – 56 mm/rev

Tailstock quill stroke: 190 mm

Tailstock taper: MK 5

Machine footprint (LxW): approx. 4,000 x 1,525 mm

Weight: approx. 4,300 kg

Accessories:

- HEIDENHAIN 3-axis digital readout

- Central lubrication system

- Electrically interlocked chuck guard

- Coolant system

- Chip protection rear panel

- Röhm chuck, T 250 mm, with various jaws

- Telescopic cover for lead and feed screw, support to bed

- Machine lamp

- Multifix C + 4 quick-change tool holders

- Live center

- Operating manual

- Circuit diagram

- Rapid traverse in longitudinal and cross slides

Condition:

The machine is in very good technical and visual condition.

Backlash on cross slide approx. 0.3 mm, on compound slide approx. 0.15 mm

Spindle nose runout approx. 0.006 mm

Bed geometry: deviation approx. 0.01 mm over approx. 750 mm bed length (measured on flat guideway towards chuck using dial indicator)

The following parts have been renewed:

- Oil change

- New hoses for central lubrication

- New wipers

- Key for operating lever replaced

- Locking pin for interlock replaced

Price is net, ex stock, loaded free of charge.

Delivery by company truck can be arranged at extra cost.

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

18,569 km

Multi Folding Unit

Ricoh Multi-Folding Unit FD5020for Ricoh Pro Series

Call

Condition: used, In this offer, you are buying a used ‘Ricoh Multi Folding Unit FD5020’.

Subject of sale:

1 x Ricoh Multi Folding Unit FD5020 for various Ricoh Pro models

Ricoh Pro C7100 Series

Ricoh Pro C9100 Series

Ricoh Pro C7200 Series

Ricoh Pro 8200 Series

Ricoh pro 8300 Series

Condition:

This is a used device that may show signs of use.

(small scratches or yellowing).

The device has been functionally tested.

Packaging and shipping:

You are welcome to come and see the appliance during our office hours. Please make an appointment to do so!

Fjdpsrvhz Uefx Ag Dopr

Seaworthy packaging and worldwide shipping are available on request!

For further information, please contact us personally.

Listing

Wasbek

Wasbek

18,194 km

Conventional Vertical Milling Machine - FPK 5

KnuthFPK 5

Call

Condition: used, The FPK 5 is a top-of-the-line Conventional Vertical Milling Machine within the Toolroom Milling Machines category, offering a versatile and robust solution for various milling applications. This universal tool milling machine stands out with its vertical and horizontal spindle configuration, swiveling vertical head, and extensive clamping surfaces, making it an excellent choice for tool and mold making, repair workshops, and educational environments. Designed for flexibility, the FPK 5 excels in single-part construction and small to medium-sized batches, thanks to its easy setup and reliable operation without extensive programming. The machine features exceptional rigidity and performance, a heavy fixed-angle table with high load capacity, and a manual central lubrication system for optimal maintenance. With standard equipment that includes a coolant system, 3-axis position indicator, and easily accessible controls, the FPK 5 is engineered to enhance efficiency and precision. Experience the reliability of KNUTH engineering with this advanced milling machine; buy now to elevate your machining capabilities.

Fodpfxowut Evj Ag Dspr

Discover more used machines

Listing

Wallern an der Trattnach

Wallern an der Trattnach

18,327 km

Puree compact line

KreuzmayrKPK 1000

Call

Year of construction: 2022, condition: new, Kreuzmayr puree compact system for pitting and straining various fruits.

2 pcs. destoning-passing machines mounted on the frame

Fpjdjhx Ebyopfx Ag Djr

Mash tube heater and pasteurizer for 1000 kg/h output

Oil or gas burners can be added to the boiler as required

Listing

Pulheim

Pulheim

18,588 km

Semi-automatic pallet wrapper

KVK 2 MA - 2t - 1650 Teller - 2400 Höhe

Call

Year of construction: 2025, condition: new, Our KVK 2 (MA) is a semi-automatic stretch wrapper with a turntable that is even more robustly built, better equipped and can be adapted to your requirements with more options compared to our entry-level model.

The only thing that still has to be done manually with this wrapper is applying and cutting the film.

With a weight of 700 kg, this model is designed for loads of up to 2000 kg. The KVK 2 (MA) has a 1650 mm turntable and can wrap pallets up to 2400 mm high as standard. With adjustable speeds of the turntable and film carriage, as well as an electromagnetic brake that can be very finely adjusted via potentiometer, you can adapt the automated wrapping process perfectly to your product. Automatic recognition of your pallets (via photocell) is just as much a matter of course as adjustable head and foot wrapping. Programs are available for "up only" wrapping, "up & down" (cross wrapping) and "rainproof" wrapping. If required, the winder can also be controlled manually.

If the winder needs to be moved to a different location, it can be easily lifted and moved with a forklift using the integrated cut-outs.

In addition to a suitable drive-on ramp and a photocell for detecting dark packaging materials or black film, turntables in various sizes with a diameter of up to 2200 mm and higher masts for a wrapping height of up to 3200 mm are optionally available for the KVK 2 MA.

Fodpfxex Ew N He Ag Dopr

This stretch wrapper is our recommendation for professional use, with approx. 15-20 pallets per day. Especially when a fine and quick adjustment of the brake is required, as is the case with very light packing units or frequently changing pallets.

For further information, we have attached the technical data sheet as a PDF to this advertisement!

Listing

Bruchsal

Bruchsal

18,631 km

CNC Lathe

YCMTC-2

Call

Condition: good (used), Year of construction: 1990, functionality: fully functional, CNC Lathe YCM TC-2

Item number: 04-02-090

Manufacturer: YCM

Good overall condition

Workshop-tested machine

Delivery time: Immediately – subject to prior sale

Year of manufacture: approx. 1990

Dimensions (L x W x H): approx. 2400 x 1400 x 2100 mm

Weight: approx. 3600 kg

Control: Fanuc O-T

Technical specifications:

Swing over bed: approx. 480 mm

Swing over cross slide: approx. 310 mm

Spindle bore: approx. 52 mm

Fsdpfewfw Sujx Ag Djpr

Max. machining diameter: approx. 250 mm

Distance between centers: approx. 550 mm

Spindle speed range: approx. 110–3500 rpm

Feed rate X-axis: approx. 10 m/min

Feed rate Z-axis: approx. 15 m/min

Turret: 8 stations

Accessories:

3-jaw chuck

Various tool holders

Chip conveyor

Machine leveling feet

Documentation

Live center

Various chuck jaws

Further accessories available on request.

Price and additional technical details available upon request.

Listing

Bålsta (Stockholm)

Bålsta (Stockholm)

17,438 km

Innenlader

ScaniaP420 6X2*4, Hooklift-truck with Crane, 2008

Call

Condition: good (used), mileage: 637,245 km, power: 309 kW (420.12 HP), first registration: 10/2008, fuel type: diesel, color: white, axle configuration: 6x2, tire size: 385/65R22,5, fuel: diesel, wheelbase: 49,000 mm, brakes: engine braking, driver cabin: sleeper cab, gearing type: semi-automatic, emission class: euro5, suspension: steel-air, Year of construction: 2008, Equipment: crane, cruise control, navigation system, trailer coupling, - Aluminum fuel tank

- Rear work lights

- Brake booster

- Electric windows

- Electronic Braking System (EBS)

- Electronic Stability Program (ESP)

- Leather interior

- Leather upholstery

- Fog lights

- Beacon light

- Reversing camera

- Seat heating

- Sun visor

- Stability control

Fpedpfxox Emnxo Ag Der

- Toolbox

- Xenon lighting

- Power Take-Off (PTO)

- Central locking

1x Scania P420LB6X2*4HNA, Euro 5, Opticruise, 637,245 km, Incl. Palfinger 23 T/m, Year of manufacture 2008, air conditioning, reversing camera, electric windows and mirrors, first registration, Webasto (auxiliary heater), Suspension: steel/air, ABS, total length: 9,200 mm, total width: 2,520 mm, wheelbase: 4,900 mm, tires: 385/65/22.5 (50%) at the front and 315/80/22.5 (80%) rear, radio/CD player, aluminum fuel tank (350 liters), TÜV inspection at 627,500 km (15.08.2025), the truck is clean and fully operational!

Crane: Palfinger PK23002 (5 hydraulic extensions), incl. jib, year 2008, remote control, ... all in excellent condition!

Valid TÜV inspection until 03/2026.

Price: €42,500, Stockholm, Sweden.

For more information and photos, please contact us by phone or email. We are also available via WhatsApp and Viber.

• We speak English * Vi talar svenska * Mówimy po polsku * Hablamos español *

• We speak Ukrainian * We speak Russian * Vorbim în limba română * We speak German *

----- * Shipping costs for this truck to various destinations * -----

* Stockholm (Sweden) – Gdansk (Poland) €450.00

* Stockholm (Sweden) – Antwerp (Belgium) €1,450.00

* Gothenburg (Sweden) – Kiel (Germany) €450.00

* Gothenburg (Sweden) – Ghent (Belgium) €590.00

* Gothenburg (Sweden) – Zeebrugge (Belgium) €590.00

* Gothenburg (Sweden) – Antwerp (Belgium) €850.00

* Gothenburg (Sweden) – Naples (Italy) €4,000.00

* Gothenburg (Sweden) – Bilbao (Spain) €3,500.00

* Gothenburg (Sweden) – Barcelona (Spain) €4,000.00

* Gothenburg (Sweden) – Leixøs (Portugal) €2,500.00

* Gothenburg (Sweden) – Piraeus (Greece) €3,000.00

* Gothenburg (Sweden) – Iquique (Chile) €4,000.00

* Gothenburg (Sweden) – Jebel Ali (UAE) €4,000.00

* Gothenburg (Sweden) – Sohar (Oman) €4,000.00

* Gothenburg (Sweden) – Jeddah (Saudi Arabia) €4,000.00

----- * These rates apply exclusively to the purchase of this truck. * -----

_____

_____

Driveline

AdBlue system: Yes

Fuel tank: 350 liters

Axle configuration

Brakes: Disc brakes

Front axle: Tire size 385/65R22.5; Max. axle load: 9,000 kg; Steered; tire tread left: 50%; tire tread right: 50%; suspension: leaf spring

Rear axle 1: Tire size 315/80R22.5; Double tires; Max. axle load: 11,500 kg; inner left tire tread: 80%; outer left tire tread: 80%; inner right tire tread: 80%; outer right tire tread: 80%; suspension: air suspension

Rear axle 2:...

Listing

Germany

Germany

15,455 km

Machining Center - Vertical

HAASVF-6SS

Call

Condition: used, Year of construction: 2017, Technical details:

x-travel: 1625 mm

y-travel: 813 mm

z-travel: 762 mm

control: HAAS Automation

spindle hours: 3127 h

number of spindle speeds: max. 12.000 U/min.

max. torque on the spindle: max. 122 Nm

tool changer with: 30 + 1 Plätze

table-size: 1626 x 711 mm

max. table load: 907 kg

spindle taper MT: SK40

spindle drive: 22,4 kW

feed range: X/Y/Z: max. 21,2 m/min.

rapid traverse:: X/Y/Z: 30,5 m/min

interface: ja

control voltage: 440 V

air-pressure connection: 6,9 bar

total power requirement: 22,4 kW

Weight approx.: 10,2 t

dimension coolant device: 2,5 x 1,2 x 0,9 m

dimension machine xH: 4,8 x 3,2 x 2,9 m

High-speed machining center

Ball screws with double anchoring

all axes with high-performance servomotors, directly connected to ball screw

2-stage gearbox

Fjdpfxjva Ar Do Ag Djpr

Operation via control panel and manual control unit

Chip conveyor/screw conveyor

Cooling device

Accessories:

SK40 holder Ø finger cutter

SK40 measuring finger and various small parts

*

Listing

Wasbek

Wasbek

18,194 km

Conventional Vertical Milling Machine - Servomill® UFM 8 V

KnuthServomill® UFM 8 V

Call

Condition: used, The Servomill® UFM 8 V, a state-of-the-art Conventional Vertical Milling Machine from KNUTH, is designed to enhance efficiency and precision in various machining applications. With its horizontal spindle and swiveling vertical milling head, this robust machine boasts a wide speed range and a large clamping table that accommodates various workpieces and clamping devices. The Servomill’s advanced electronic features, including infinitely variable servomotor feed and electronic handwheels, provide users with the intuitive operation reminiscent of CNC systems without the need for programming. Ideal for repair workshops and training departments, the UFM 8 V combines conventional milling practices with significant advancements in reliability and maintenance-free operation, thanks to high-quality servo drives and preloaded ball screws. With an operational output of up to 5000 rpm and integrated features such as a coolant system and pneumatic tool clamping, this model promises both productivity and ease of use. Experience the next level of milling technology with the Servomill UFM 8 V. Request a quote today to see how this remarkable machine from the Conventional Vertical Milling Machines product group can elevate your production capabilities.

Fjdpfx Agsv Amixs Djpr

Listing

Wallern an der Trattnach

Wallern an der Trattnach

18,327 km

Labeling machine

Enos

Call

Condition: ready for operation (used), Year of construction: 1995, operating hours: 1,000 h, functionality: fully functional, Glue labeling machine

for one label

Various magazines available for different labels

hourly output approx. 2000 bottles

Bottle stars for approx. 90mm diameter installed

Fedpeq H Axiofx Ag Djpr

Listing

Kaufungen

Kaufungen

18,422 km

Tool presetter

DMG MoriUno 20/40

Call

Condition: good (used), Year of construction: 2020, 1 used tool presetting device

Manufacturer: DMG Mori / Haimer

Model: UNO 20/40

Year of manufacture: 2020

Technical details

Fedpew Skltsfx Ag Dspr

Measuring range X-axis: 200 mm

Measuring range Y-axis: 400 mm

Measuring range Z-axis: 400 mm

Overall width: 510 mm

Overall length: 1,300 mm

Overall height: 1,800 mm

Equipped with:

Microvision device package, Premium-Pro software, base cabinet, keyboard, mouse, printer, various accessories.

Listing

Bruchsal

Bruchsal

18,631 km

Multi-spindle milling machine

Fritz WernerSSF 3

Call

Condition: excellent (used), Year of construction: 1980, functionality: fully functional, Multi-spindle milling machine Fritz Werner SSF 3Article number: 07-99-001Manufacturer: Fritz WernerVery good overall conditionMachine workshop testedDelivery time: Immediate - sale subject to prior saleYear of construction: approx. 1980Dimensions (L x W x H): approx. 1900 x 1800 x 1800 mmWeight: approx. 1200 kgTravel ranges:X-axis: approx. 600 mmY-axis: approx. 200 mmZ-axis: approx. 500 mmTable clamping area: approx. 740 x 220 mmSpindle:Speed range: approx. 3000 rpmDrive power: approx. 7.5 kWFeeds & rapid movements: in all 3 axesMax. milling area (dovetail): approx. 400 mm widthSwivel range of 1st & 3rd milling spindle: approx. 50-80 degreesHeight adjustment 1st & 3rd milling spindle: approx. 80 mmHeight adjustment 2nd milling spindle: approx. 50 mmAccessories:Left/right operationMechanical vice10 pieces of various milling head attachmentsWork lightFurther accessories available upon requestPrice and further technical details available upon request.

Fpsdowl Aqvopfx Ag Dsr

Listing

Bålsta (Stockholm)

Bålsta (Stockholm)

17,438 km

Loading platform

VolvoFM 11.330 4x2, Flatbed-truck with 18t/m Crane, ...

Call

Condition: good (used), mileage: 423,567 km, power: 248 kW (337.19 HP), first registration: 06/2014, fuel type: diesel, color: gold, axle configuration: 4x2, tire size: 385/55R22,5, fuel: diesel, wheelbase: 5,600 mm, brakes: engine braking, driver cabin: day cab, gearing type: automatic, emission class: euro6, suspension: air, Year of construction: 2014, Equipment: air conditioning, crane, cruise control, parking heater, tail-lift, - Aluminum fuel tank

- Brake booster

- Electric windows

- ESP (Electronic Stability Program)

- Air conditioning

- Fog lights

- Reversing camera

- Sliding roof

- Power steering

- Sun visor

- Stability control

- Auxiliary heater

- Toolbox

- Xenon lighting

- PTO (Power Take-Off)

1x Volvo FM11, 330 HP, 4x2, Euro 6, automatic gearbox, 423,357 km, + Palfinger 18 T/m, year of manufacture 2014, air conditioning, reversing camera, electric windows and mirrors, first registration 09.06.2014, production date: 03/2014, Webasto auxiliary heater, air suspension, ABS, loading platform: 5950 mm x 2450 mm x 900 mm, overall length: 9000 mm, wheelbase: 5600 mm, tyres: 385/55/22.5 (50%) front and 315/70/22.5 (50%) rear, radio/CD player, aluminum fuel tank (315 liters), last main inspection (TÜV) carried out at 422,950 km (03.12.2025), 2 previous owners since first registration, the truck is clean and fully operational!

Crane: Palfinger PK180002-EH (5 hydraulic extensions), year 2014, remote control, operating hours: 3,292 h ... all in perfect condition! Last TÜV inspection on 05.12.2025.

Price: €63,500 Stockholm, Sweden.

For more information and photos please contact us by phone or email. We are also available via WhatsApp and Viber.

• We speak English * Vi talar svenska * Mówimy po polsku * Hablamos español *

• We speak Ukrainian * We speak Russian * Vorbim în limba română * We speak German *

----- * Shipping costs for this truck to various destinations * -----

* Stockholm (Sweden) – Gdansk (Poland) €450.00

* Stockholm (Sweden) – Antwerp (Belgium) €1,450.00

* Gothenburg (Sweden) – Kiel (Germany) €450.00

* Gothenburg (Sweden) – Ghent (Belgium) €590.00

* Gothenburg (Sweden) – Zeebrugge (Belgium) €590.00

* Gothenburg (Sweden) – Antwerp (Belgium) €850.00

* Gothenburg (Sweden) – Naples (Italy) €4,000.00

* Gothenburg (Sweden) – Bilbao (Spain) €3,500.00

* Gothenburg (Sweden) – Barcelona (Spain) €4,000.00

* Gothenburg (Sweden) – Leixøs (Portugal) €2,500.00

* Gothenburg (Sweden) – Piraeus (Greece) €3,000.00

* Gothenburg (Sweden) – Iquique (Chile) €4,000.00

* Gothenburg (Sweden) – Jebel Ali (UAE) €4,000.00

* Gothenburg (Sweden) – Sohar (Oman) €4,000.00

* Gothenburg (Sweden) – Jeddah (Saudi Arabia) €4,000.00

Fjdpfx Aex Emghog Depr

----- * These prices only apply to the purchase of this truck. * -----

_____

_____

Technical Information

Engine displacement: 10,837 cc

Driveline

AdBlue system: Yes

Axle configuration

Brakes: Disc brakes

Suspension: Air suspension

Front axle: Tire size: 385/55R22.5; Max. axle load: 8,000 kg; Steered; Tire tread left: 50%; Tire tread right: 50%

Rear axle: Tire size: 315/70R22.5; Dual wheels; Max. axle load: 13,000 kg; Tire tread left (inside): 50%; Tire tread left (outside): 50%; Tire tread right (inside): 50%; Tire tread right ...

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

18,569 km

Digital printing machine

Xerox complete finishing options fordiv. Xerox models Plockmatic

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used ‘Xerox full bleed trimming’ finishing system.

Item for sale:

1 x Xerox complete finishing system for brochure production with the following equipment:

Includes A-FN13 booklet finisher

Includes CZ module A-FN08

Includes 2-page trimming A-GW07

Includes Plockmatic Pro35

WITHOUT IDM

You will receive a complete finishing system for complete brochure production. Plug and play connection to various Xerox machines.

Xerox Versant 3100

Xerox Verdant 4100

Xerox Versant 180

Xerox Versant 280 and more...

Condition:

This offer is for a used device, which may show signs of wear

(minor scratches or yellowing).

The device has been tested for functionality.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Fpjdpfx Aoxnxy Nog Dor

Seaworthy packaging and worldwide shipping available on request!

For more information, please feel free to contact us personally.

Listing

Wasbek

Wasbek

18,194 km

Tube End Finishing Machine - PRS 76

KnuthPRS 76

Call

Condition: used, The PRS 76 is a top-tier Tube End Finishing Machine designed specifically for efficient tube and profile processing. This advanced machine features a powerful 3 kW motor that allows it to grind various materials effortlessly. With its innovative rotating design, the PRS 76 enables you to grind at any angle between 30° and 90°, accommodating diameters from Ø 20 mm to Ø 76 mm. It comes equipped with two K36 grinding belts, measuring 100 x 2000 mm, ensuring you have everything needed for optimal performance. Ideal for both tubes and profiles, the PRS 76 stands out for its ease of use and versatility. Enhance your workshop's capabilities with this robust machine. You can request a quote today to learn more about the PRS 76 and discover how it fits into your tube end finishing requirements.

Fedpfx Aeuxdb Ujg Dspr

Listing

Borken

Borken

18,513 km

Jenoptik – including button & case

Hommel TesterT1000

Call

Condition: excellent (used), Hommel

Hommel Tester T1000 Surface Roughness Measuring Instrument – Jenoptik – incl. probe & case

Item Description:

For sale is a Hommel Tester T1000 by Jenoptik / Hommel-Etamic.

The T1000 is a precise portable surface roughness tester that uses a tactile stylus to measure the surface roughness of various workpieces.

Measured values such as Ra, Rz, and Rmax are displayed immediately on the screen.

An integrated mini-printer additionally allows for direct printout of measurement protocols.

The device is suitable for use both in production environments and in laboratories.

Technical data:

Fpodpfx Aex Ebuwog Dsr

Model: Hommel Tester T1000

Manufacturer: Jenoptik / Hommel-Etamic

Measured parameters: Ra, Rz, Rmax, etc.

Measuring range: Ra approx. 0.03 – 20 µm

Display: LCD screen with direct measurement readout

Dimensions: approx. 28 × 20 × 10 cm

Power supply: Power adapter 230 V AC → Device 9–12 V DC

Weight: Device approx. 1.5 kg, in case approx. 3–4 kg

Hommel Tester T1000

External surface roughness probe

Two additional stylus probes in cases

Power supply

Original transport case

Connection cable

Important note:

“The table shown in the photos is not included in the sale.”

Condition: used

Scope of delivery: (See picture)

(Specifications may be subject to change and errors excepted!)

For any further questions, please feel free to contact us by phone.

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

18,569 km

Paper deck

Konica Minolta PF-707mpaper feeder, paper deck for bizhub

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used paper deck ‘Konica Minolta PF-707m’.

Item for sale:

1 x Konica Minolta PF-707m for various bizhub models:

C1070, C1060, C2070, C3070, C1100

Fjdox Ehagjpfx Ag Dspr

We also have other accessories and machines in stock.

Condition:

This offer is for a used device, which may show signs of wear

(minor scratches or yellowing).

The device has been tested for functionality.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Seaworthy packaging and worldwide shipping available on request!

For more information, please feel free to contact us personally.

Listing

Wasbek

Wasbek

18,194 km

Tube End Finishing Machine - RGM 2

KnuthRGM 2

Call

Condition: used, The RGM 2 is a state-of-the-art Tube End Finishing Machine designed by KNUTH, renowned for its robust and precise engineering. With a rigid design and a small footprint, this machine is perfectly suited for shops that require efficiency without sacrificing performance. The RGM 2 features an impact chuck at the front and a clamping chuck at the rear, ensuring secure handling of various tube sizes. Additionally, it includes a tube cutter and an inside tube deburrer, which provide a complete solution for finishing operations. For mobility, the machine is equipped with a mobile base. When looking for a reliable Tube End Finishing Machine, the RGM 2 stands out with its advanced features. Don't hesitate to request a quote today to enhance your tube processing capabilities with this exceptional product from the renowned KNUTH brand.

Fpodpfop Atgbjx Ag Dsr

Listing

Wasbek

Wasbek

18,194 km

Conventional Vertical Milling Machine - KB 1400

KnuthKB 1400

Call

Condition: new, The KB 1400 is a high-performance Conventional Vertical Milling Machine within the Bed-Type Milling Machines group, designed by KNUTH for exceptional cutting capabilities. This heavy universal bed milling machine features wide guides and impressive drive power, making it ideal for plant and machine construction. Its vertical milling head, which can swivel ± 45°, along with a manually adjustable quill and infinitely variable spindle speed, provides versatility and precision for diverse machining tasks. The machine's robust gearbox allows for adjustable feeds in the Y- and X-axes, ensuring rapid traverse on all axes. With a table setup area of 1,400 x 400 mm and a travel distance of 950 mm, this machine can accommodate large workpieces and various clamping devices. The KB 1400 also boasts a solid Meehanite cast-iron frame, contributing to improved stability and reduced vibration, resulting in higher accuracy and productivity. Benefit from its extensive standard equipment including a 3-axis position indicator and coolant system. Experience the precision and robust performance of the KB 1400 – request a quote today to explore how this Conventional Vertical Milling Machine can enhance your operations.

Fpedpfxewubzls Ag Dsr

Trust Seal

Dealers certified through Machineseeker

Listing

Wasbek

Wasbek

18,194 km

Conventional Horizontal Lathe - Basic 180 V

KnuthBasic 180 V

Call

Condition: new, The Basic 180 V is a robust Conventional Horizontal Lathe that stands out in the Metal Lathes group, known for its exceptional stability and performance. Designed with a heavy cast-iron bed and a significant bed width of 206 mm (8 in), this lathe offers a solid foundation for high-quality machining. Its advanced features, including an inverter that achieves up to 3,000 revolutions per minute, and a constant cutting speed function, ensure smooth operations that match the quality of a CNC lathe, even during heavier machining tasks. With a large turning diameter of 356 mm and a center width of 1,000 mm, it can accommodate various applications, making it an ideal choice for industrial requirements. The Basic 180 V includes comprehensive standard equipment such as a 3-axis position indicator and a coolant system. You can trust KNUTH for precision-engineered tools; request a quote today to explore how the Basic 180 V can enhance your machining capabilities in the Conventional Horizontal Lathes category.

Fjdouzlbujpfx Ag Dspr

Listing

Wasbek

Wasbek

18,194 km

Conventional Horizontal Lathe - Turnado 230/1000

KnuthTurnado 230/1000

Call

Condition: new, The Turnado 230/1000 is a versatile and robust Conventional Horizontal Lathe from KNUTH, designed for various machining needs within the Engine Lathes product group. This modern lathe combines a heavily ribbed machine bed and a powerful main motor with an array of standard equipment including a 3-jaw chuck and a user-friendly control panel, making it perfect for both novice and experienced operators. The rigid headstock and high-quality spindle support ensure consistent precision and performance, even under heavy loads. With features like adjustable feed stops and a micrometer longitudinal stop, it simplifies complex machining tasks. Notably, this lathe includes advanced safety features, ensuring operator safety while maintaining a clean workspace. With the Turnado 230/1000, you can confidently handle intricate projects and request a quote today to equip your workshop with this reliable engine lathe.

Fjdpfx Agjuy Ic Eo Dspr

Listing

Wasbek

Wasbek

18,194 km

Conventional Horizontal Lathe - V-Turn 410 PRO

KnuthV-Turn 410 PRO

Call

Condition: new, The V-Turn 410 PRO, a cutting-edge Conventional Horizontal Lathe from KNUTH, represents the latest in the Engine Lathes product group, designed for both efficiency and precision. This machine boasts improved ergonomics alongside enhanced safety features, making it user-friendly while maintaining top-tier performance. Equipped with a powerful 5.5 kW spindle motor and an innovative inverter, it reaches speeds of up to 3,000 revolutions per minute, allowing efficient machining of workpieces with varying diameters. Its constant cutting speed function automatically adjusts the spindle speed during face turning, achieving results comparable to CNC lathes. With a robust and rigid construction, including a heavily ribbed machine bed and pre-loaded spindle bearings, this lathe ensures exceptional stability and precision. The standard equipment includes a 3-axis position indicator, coolant system, and various tool holders, enhancing its functionality for diverse machining tasks. You can buy now to elevate your machining capabilities with the V-Turn 410 PRO, a remarkable addition to the Conventional Horizontal Lathes and Engine Lathes by KNUTH.

Fpedpfx Agsww T S Io Dor

Listing

Wasbek

Wasbek

18,194 km

Conventional Vertical Milling Machine - VHF 1.1

KnuthVHF 1.1

Call

Condition: new, The VHF 1.1 is a compact and versatile Conventional Vertical Milling Machine in the Universal Milling Machines category, designed by KNUTH. This universal milling machine boasts a robust frame made of vibration-dampening cast iron, ensuring stability during operations. Equipped with a horizontal spindle and a swiveling vertical milling head, the VHF 1.1 allows for infinitely variable spindle speed and feed on the X-axis, making it ideal for diverse applications in training departments, repair shops, and model-making workshops. Its 1.000 x 240 mm setup area and 535 mm travel on the X-axis facilitate various machining tasks, while the included coolant system and chip tray enhance functionality and cleanliness. Users benefit from the extensive standard equipment, which includes a 3-axis position indicator, drill chuck, reducing sleeves, and more. With its precise and powerful performance, the VHF 1.1 is an outstanding choice for anyone in need of a reliable milling machine. Don’t hesitate to request a quote and elevate your milling capabilities today!

Fpsdpfx Agsuyh Egs Djr

We make it easier for you to find: "various"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Various (5,554)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you