Used Spindle Router for sale (12,456)

Wiefelstede

Wiefelstede Spindle motor

Fanuc SantenbergA06B-1448-B200 GTC S 2

Wiefelstede

Wiefelstede Machine spindle grinding spindle

VoumardC 40-9 D

Wiefelstede

Wiefelstede Motor grinding spindle

FS JE SantenbergHSP 190 182.532.01 GTC S 2

+44 20 806 810 84

Wiefelstede

Wiefelstede Spindle head

WMWHub 225 mm

Wiefelstede

Wiefelstede Spreading spindle

Ehemann50 x 1266 mm

Discover more used machines

Wiefelstede

Wiefelstede Spreading spindle

Ehemann50 x 2570 mm

Wiefelstede

Wiefelstede Multi-spindle drilling head with drive

Perske18 Spindeln

Wiefelstede

Wiefelstede Machine spindle grinding spindle

DKF6.251/23 12500 U/min

Wiefelstede

Wiefelstede Wood router bit

AKE Hydro-GripT20002587

Wiefelstede

Wiefelstede Router with antennas

NetModuleNB1600

Wiefelstede

Wiefelstede Reversible wood router bits 40 pieces

Leuco997-834

Wiefelstede

Wiefelstede Multi-spindle drilling head

unbekanntØ120 5 Spindeln

Wiefelstede

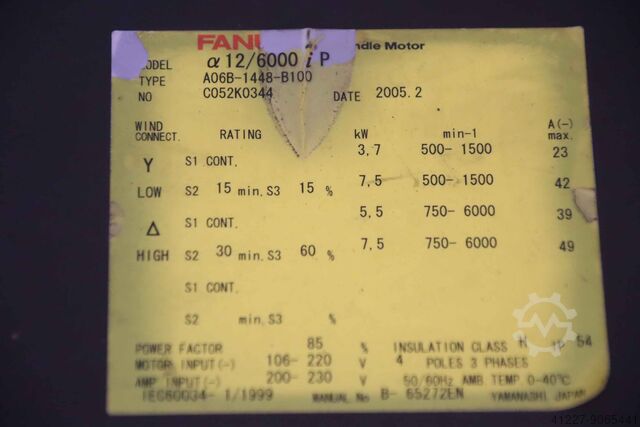

Wiefelstede Spindle motor

Fanuc SantenbergA06B-1448-B100 GTC S 2

Wiefelstede

Wiefelstede AC main spindle drive

Indramat DMTTDA1.3-100-3-API

Wiefelstede

Wiefelstede Single spindle copy milling machine

EluAS 70

Wiefelstede

Wiefelstede Wood router bit

LeitzDufix

Wiefelstede

Wiefelstede Machine spindle grinding spindle

GMNTSAV 140s x 270-6212

Wiefelstede

Wiefelstede Multi-spindle drill head

Paatz280 x 280 mm

Wiefelstede

Wiefelstede Drilling machine MK3 + two-spindle drilling head

Abarboga MaskinerGM2508

Wiefelstede

Wiefelstede Spindle drive for upper support

unbekannt450/155/H110 mm

Wiefelstede

Wiefelstede High-performance grinding spindle

Fortuna Werke6900 U/min

Wiefelstede

Wiefelstede Multi-spindle drill head

unbekanntØ120

Wiefelstede

Wiefelstede Router

Cisco1812/K9 V07

Wiefelstede

Wiefelstede Multi-spindle drill head 3 pieces

unbekannt2,3 und 4 Spindeln

Wiefelstede

Wiefelstede Router

CiscoCisco 881

Used Spindle Router (12,456)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84